Lock for the designer

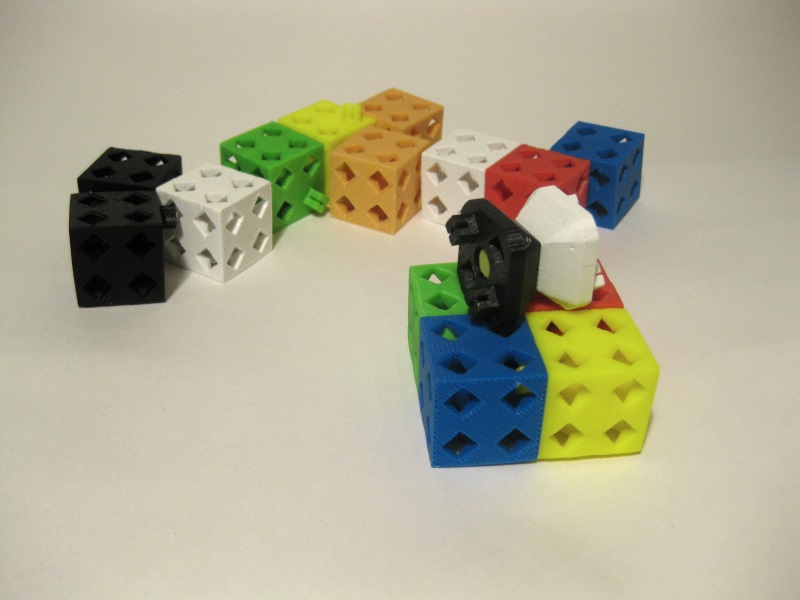

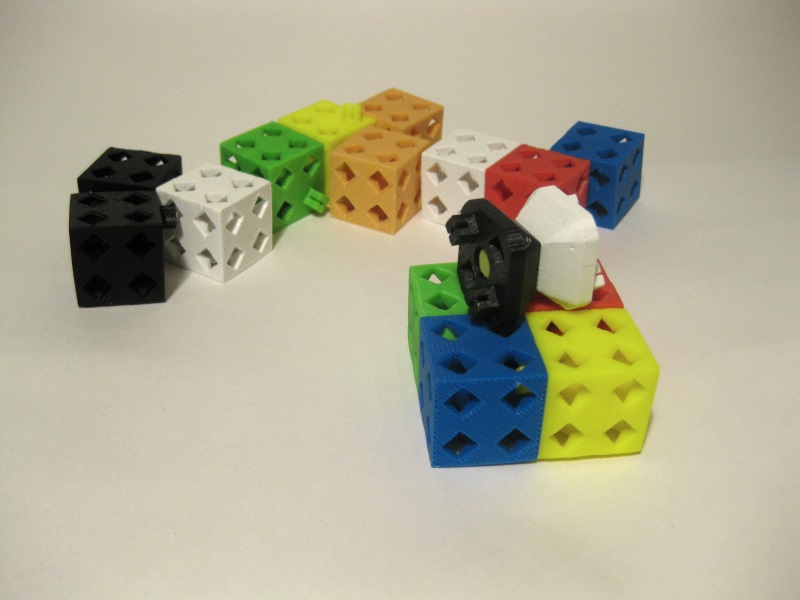

Experimenting with cubes and getting feedback from those who printed and built something from our cubes (ours are cubes that are printed without support on a regular 3D printer), a problem was found that depends on both the structure of the structure and the properties plastic.

The problem was that the lock, this protrusion, which is printed on top and used to connect the cubes together, sometimes broke after 20-30 awkward movements. Especially if you separate the cubes are not strictly along the axis of the lock.

')

The decision came after going through the options and understanding that there are already many castles with broken petals.

We also found out that with different settings of the printer, the bottom layer of the lock is always slightly wider and additionally squeezes the elements of the lock when connected, and such a load caused the lock petal to break. They also experimented with petals: the most reliable with such dimensions turned out to be double, but the slot was ideally removed below the face to ensure the deformation of the castle's petals along the entire length of contact between the cubes.

The solution is very simple: make a cube and a lock with separate parts.

An assembly diagram and a cross-section of the resulting joint is shown below.

The diagram shows that the slot is located below the surface of the face of the cube and will ensure the deformation of the castle's petals.

You can download the files of the cube without a lock, the lock itself and the “crutch” for the lock in the cube on our website .

This flexible solution has several advantages.

The first is that everyone, having printed a regular cube, can pick up any type of lock. But the main thing is that you can collect cubes with the necessary number and location of locks.

Second: we can begin to develop modules for various electrical, radio, or mechanical devices for which you will need to use more locks.

Important! When printing the LOCK elements, the following conditions must be met:

- the lock is printed vertically;

- the crutch (clamp) is printed horizontally.

When printing a cube, its orientation can be any, it is completely symmetrical.

The problem was that the lock, this protrusion, which is printed on top and used to connect the cubes together, sometimes broke after 20-30 awkward movements. Especially if you separate the cubes are not strictly along the axis of the lock.

')

The decision came after going through the options and understanding that there are already many castles with broken petals.

We also found out that with different settings of the printer, the bottom layer of the lock is always slightly wider and additionally squeezes the elements of the lock when connected, and such a load caused the lock petal to break. They also experimented with petals: the most reliable with such dimensions turned out to be double, but the slot was ideally removed below the face to ensure the deformation of the castle's petals along the entire length of contact between the cubes.

The solution is very simple: make a cube and a lock with separate parts.

An assembly diagram and a cross-section of the resulting joint is shown below.

The diagram shows that the slot is located below the surface of the face of the cube and will ensure the deformation of the castle's petals.

You can download the files of the cube without a lock, the lock itself and the “crutch” for the lock in the cube on our website .

This flexible solution has several advantages.

The first is that everyone, having printed a regular cube, can pick up any type of lock. But the main thing is that you can collect cubes with the necessary number and location of locks.

Second: we can begin to develop modules for various electrical, radio, or mechanical devices for which you will need to use more locks.

Important! When printing the LOCK elements, the following conditions must be met:

- the lock is printed vertically;

- the crutch (clamp) is printed horizontally.

When printing a cube, its orientation can be any, it is completely symmetrical.

Source: https://habr.com/ru/post/258009/

All Articles