As we thought out the designer for children's robotics. #one

Hi, Habr! Some time ago I could not stand the silence about what I do at work. Well and rolled, and wrote about it article on Geektimes: “As we thought out the designer for children's robotics. Part 0. Acrylic .

The result of that article was two things:

Are you familiar with the topic of child robotics? Have you already tried to wind the Arduino to the metal constructor with a blue electrical tape? In this case, you are interested in tackle.

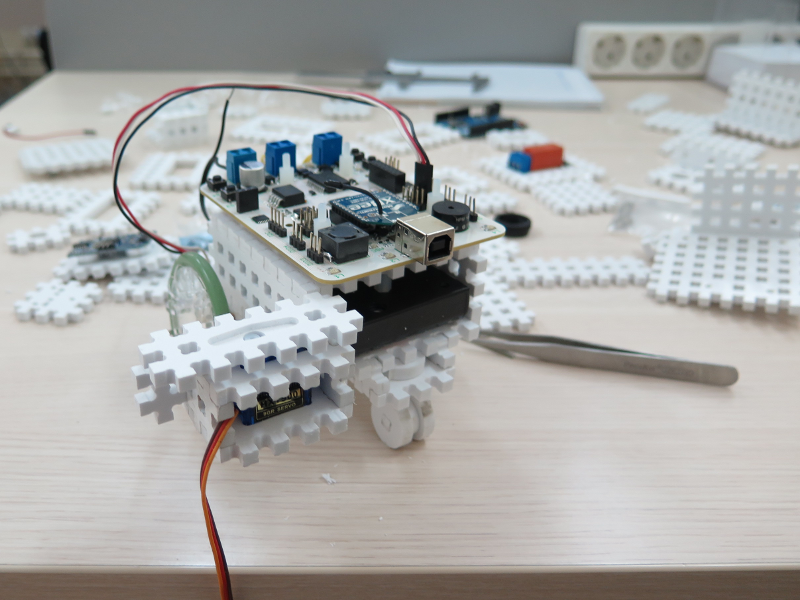

I was still looking for suitable material for the designer. Worked out options with penokarton. At this time, the same evangelist of children's robotics with a world name, Alexey, introduced me to the head of the children's circle, Alexander Zhigulev. Alexander is the happy owner of the milling machine. He also made such a wonderful robot out of PVC foam scraps on it:

')

This design is very good:

Of course, we lacked something:

These are the tasks that had to be solved.

The material seems clear, but what about the mode of production? I did not understand these things at all, so I climbed onto specialized forums. It turned out that PVC foam should never be cut with a laser. With laser cutting, it ceases to be harmless and releases HCl. And this thing kills both the laser cutter and the machine operator. Therefore, only milling.

We wanted to preserve some compatibility of our parts with a metal constructor. For this, the connecting holes had to be located at a distance of 1 cm from each other. Therefore, the material should be 5 mm thick. This was the initial design data.

Sketched the first version of the possible designer for milling:

With this drawing it was already possible to ring up the advertising workshops, and cause them to be perplexed. Technologically better when the diameter of the cutter is large enough, ideally 4-5 mm. In this case, the wear of the cutter is minimal. For me, it was more interesting to have a mill of smaller diameter, so that the square holes would be more square, and the contact area between the parts inserted into each other would be maximum.

After a heap of various consultations, this was born:

It was the second month of my inventive activity.

Three problems loomed on the horizon:

Fablab MISI helped me with the first problem. They, among other things abundance of machines, there is also a large milling machine. The second problem was quickly solved by the purchase of material, but I considered this option last. I was still not sure that PVC foam is what you need. Therefore, it was decided to get this material. I just called the advertising workshops and begged for trimming. Somewhere I was sent right away, somewhere they offered to buy small scrap at the price of a finished sheet. One day I went to such a workshop with my feet. In the production workshop I was met by an unshaven hungover uncle. He without much talk gave me a huge scrap. When I left, he recommended that I hide the scrap under my coat so that no one could see. He felt like a Soviet man.

Right from this workshop I rushed to Fablab to solve problem number 3.

I do not know what it was. Miracle probably. Surely a milling machine from Fablab Dima golden hands. Even more surprising was the fact that the "got" piece of foamed PVC turned out to be of excellent quality. And yet, by a miracle, the parts were correctly oriented on the sheet. And everything turned out perfectly from the first time.

It was both healthy and bad at the same time.

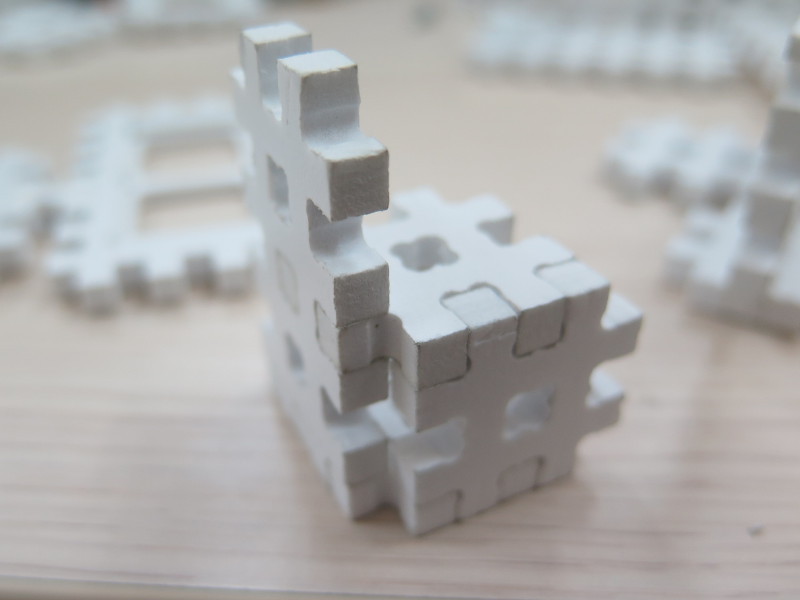

Great, because we immediately realized what the coolest thing we have turned out. The material was very light and durable. Because of its porous structure, it is very convenient to join the joint to the joint. Details at the same time firmly hold each other. It is easy to screw the screw into it. And if you make a hole, then it is easy to screw the screw into this hole and it will hold tight. With all this magnificence, the material was also harmless.

Bad, because I never met with pitfalls.

"Yes, with this thing, we will throw **** out of school!" - this is just one of the many thoughtlessly enthusiastic exclamations that sounded in the technical department of Amperka that evening.

This was the first reaction of our guys to sample the details of the future designer. The details were few, they were not enough to satisfy the curiosity of all comers. We inserted motors and electronics into these parts, tried to quickly manage to collect at least something from a pair of parts, while the other did not select them: “Let me! Give me that! ” They bent, bit, broke - they carried out full test tests.

That day my searches of forms and material for our designer finally ended.

Initially, we planned to make a simple platform for the robot with variations. And in the end it turned out a full-fledged designer, from which you can build the whole universe! From that day on, I always carry a handful of parts in my backpack. Showing them to different people, I found a high addiction to the designer. A person temporarily falls out of conversation, collecting all sorts of things. Watching is very nice.

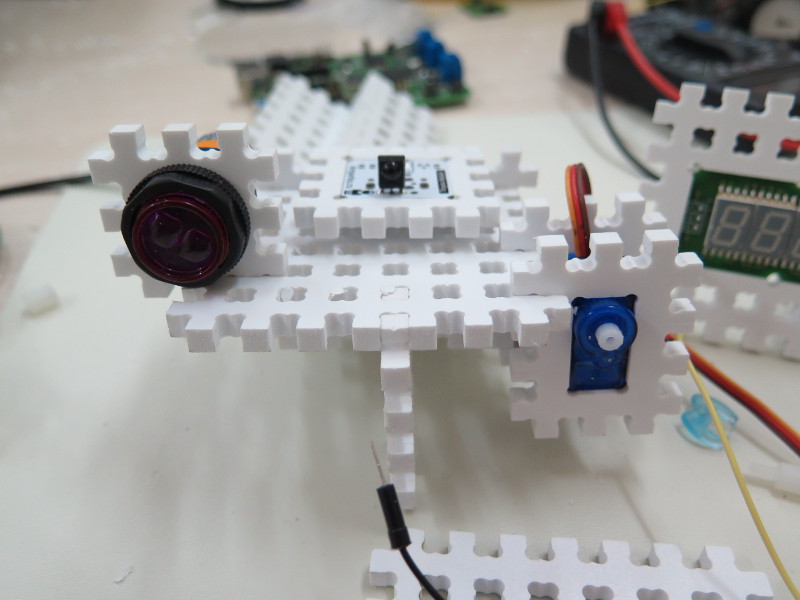

Electronic modules are simply inserted into the grooves prepared for them, and they independently hold there.

Or fastened with screws, without any nuts.

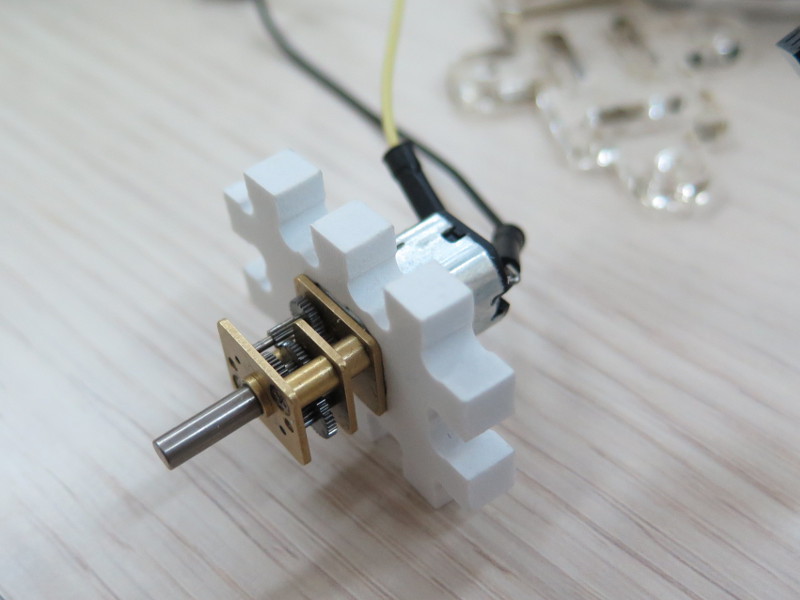

And the motor can simply be inserted into the hole prepared for it, and it will not go anywhere.

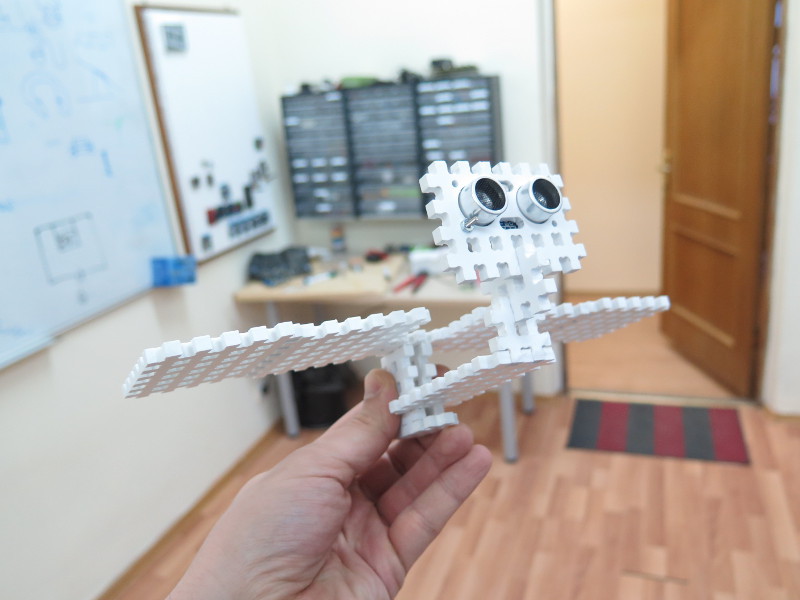

And you can easily make an owl!

Hooray, material and form found!

Now they need to make a robot.

In addition, we were invited to Peter to the round table of the Minister of Education, who gathered all those involved in child robotics for something there. The details on the assembly of a full-fledged robot were not enough, and I wanted to boast in front of the minister to our designer.

Yes, and for the future development of a large number of parts was necessary. Not in the CAD-ah robots draw? You need to play them yourself!

In general, we needed a lot of details. And quickly - the round table stung sharply deadlines.

In the shortest possible time, a full set of all kinds of details that would come to mind would be drawn. A workshop was found in which they agreed to fulfill our order. Well, they allowed me to participate in the process so that I would learn many new things. The window during which the order could be executed is Friday night. On Tuesday, the director leaves for a round table. On the assembly of the robot remains Monday.

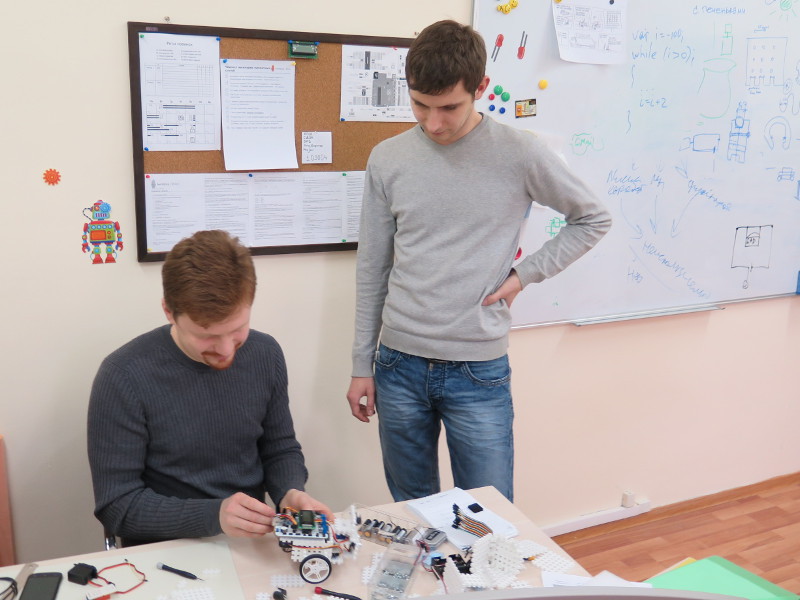

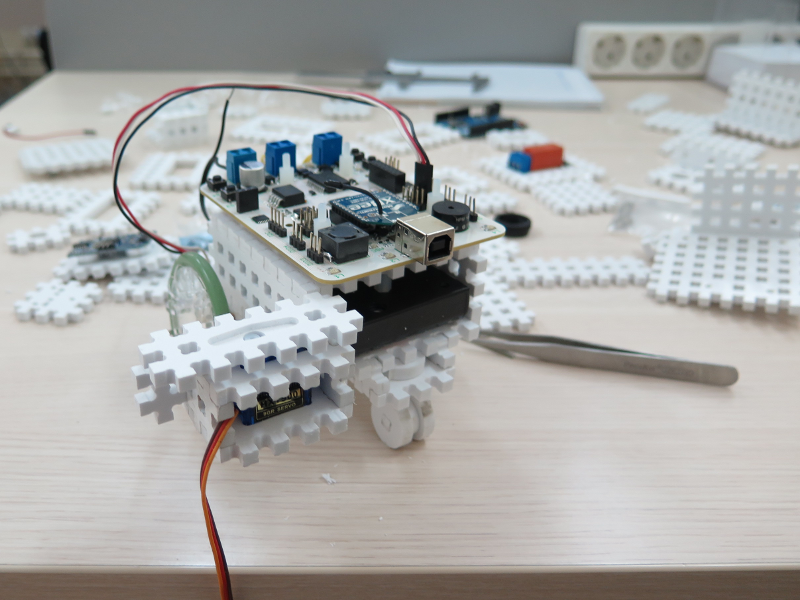

Long or short, and on Monday a large set of parts was in Amperk. And General Mikhail gathered his first full-fledged robot in half an hour.

And drove him to the round table. According to his story, everything was in vain. The participants were with beautiful presentations and slides. And we were with a robot.

Mikhail's speech was one of the shortest. Something like this: “Here is a constructor with an Arduino. For kids. Schoolchildren can collect robots, physics experiments, and an owl. And if a schoolboy collects robots then robots drive. You can build cranes ... ".

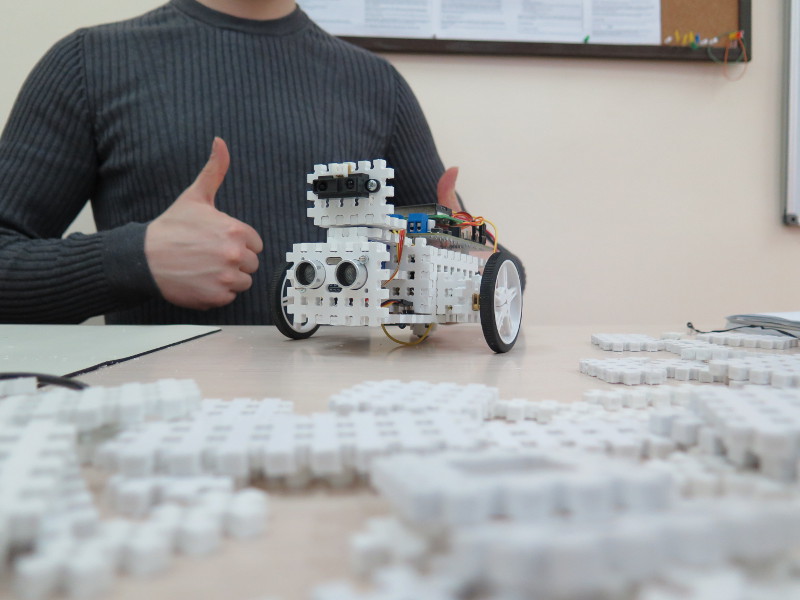

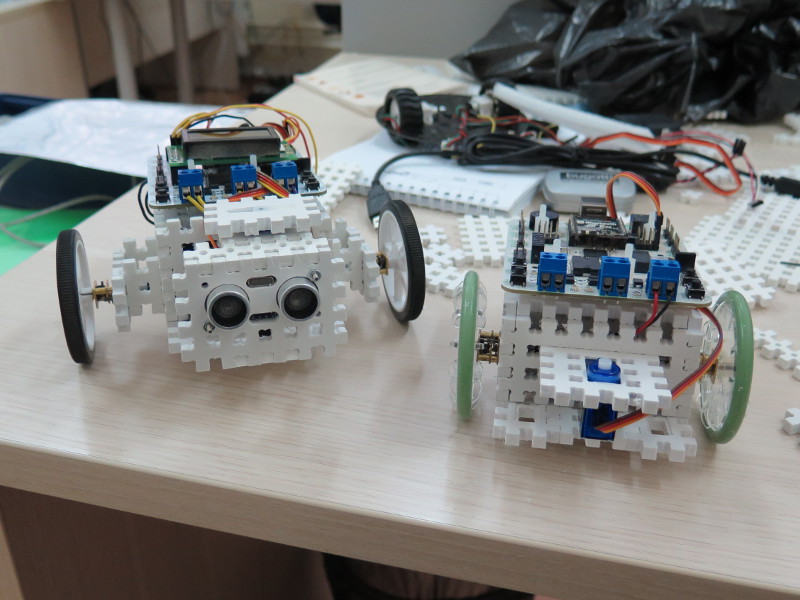

Now we are actively developing our designer. We play it every day, collect robots. We finish the missing parts. We are trying to come up with a functional and cute robot for the start, which children would be interested to play with. Yes, and so that the side effect of the game was learning programming.

The apparent simplicity of assembling parts is somewhat deceptive. When assembling something serious, one has to strain the spatial imagination quite strongly. In a few iterations, we got this handsome:

He has a sufficient set of sensors that would perform a very wide range of tasks.

Soon this designer will see the light. There is still a lot of work to bring gloss and create the necessary infrastructure - after all, he will have to compete with the giants. I'd like to believe that its attractiveness, openness and availability for self-production will bring him due popularity.

I hope this is not my last article on Habré. I am pleased to tell you about the designer yet. Moreover, in the course of the game some more interesting applications were born for him.

PS And the name for the designer never came up. Offer in the comments, please. We will be very happy with new ideas.

UPD. As we thought out the designer for children's robotics. # 2

The result of that article was two things:

- got a hat for arbitrariness;

- The topic was interesting and found its reader. Therefore, we decided to resurrect Amperka's blog so that I could continue the story officially.

Are you familiar with the topic of child robotics? Have you already tried to wind the Arduino to the metal constructor with a blue electrical tape? In this case, you are interested in tackle.

In the previous series

It all started with the fact that we conceived a designer to invent, to create wheeled robots for children. With the condition: all constructive available for repetition by any leader of the circle of robotics, wherever he is. Making acrylic robots is the first thing that comes to mind with such introductory. But in acrylic we are disappointed. The material is not suitable for creating such a robot designer, which we wanted to receive. You can call various reasons why this is so. For me personally, the reason is this: acrylic designer is not sexy. If you are interested in the details, they are in the last article on the GT .

PVC foam

I was still looking for suitable material for the designer. Worked out options with penokarton. At this time, the same evangelist of children's robotics with a world name, Alexey, introduced me to the head of the children's circle, Alexander Zhigulev. Alexander is the happy owner of the milling machine. He also made such a wonderful robot out of PVC foam scraps on it:

')

Great-grandfather of our designer

This design is very good:

- details are connected in a simple and understandable way - they are simply inserted into each other;

- there is compatibility with the Soviet metal constructor: holes in the deck for screw M4 in the corners of a square with a side of 1 cm;

- parts can be made in any workshop for the production of outdoor advertising. This means that the manufacture of such parts is available to any leader of the robotics circle.

Of course, we lacked something:

- after fabrication on the mill, the robot must be “filed”. You cannot get a right angle on the milling machine, so the grooves for inserting the parts into each other are brought to working condition with a knife;

- no versatility;

- There are no special items for common electronics.

These are the tasks that had to be solved.

Cooking parts

The material seems clear, but what about the mode of production? I did not understand these things at all, so I climbed onto specialized forums. It turned out that PVC foam should never be cut with a laser. With laser cutting, it ceases to be harmless and releases HCl. And this thing kills both the laser cutter and the machine operator. Therefore, only milling.

We wanted to preserve some compatibility of our parts with a metal constructor. For this, the connecting holes had to be located at a distance of 1 cm from each other. Therefore, the material should be 5 mm thick. This was the initial design data.

Sketched the first version of the possible designer for milling:

Difficult, incomprehensible, terrible, premature first version of foam PVC components

With this drawing it was already possible to ring up the advertising workshops, and cause them to be perplexed. Technologically better when the diameter of the cutter is large enough, ideally 4-5 mm. In this case, the wear of the cutter is minimal. For me, it was more interesting to have a mill of smaller diameter, so that the square holes would be more square, and the contact area between the parts inserted into each other would be maximum.

After a heap of various consultations, this was born:

Nya, not nya?

We make parts

It was the second month of my inventive activity.

Three problems loomed on the horizon:

- Where to make Circuits?

- Where to get the material?

- “Vasya, where is the robot?”

Fablab MISI helped me with the first problem. They, among other things abundance of machines, there is also a large milling machine. The second problem was quickly solved by the purchase of material, but I considered this option last. I was still not sure that PVC foam is what you need. Therefore, it was decided to get this material. I just called the advertising workshops and begged for trimming. Somewhere I was sent right away, somewhere they offered to buy small scrap at the price of a finished sheet. One day I went to such a workshop with my feet. In the production workshop I was met by an unshaven hungover uncle. He without much talk gave me a huge scrap. When I left, he recommended that I hide the scrap under my coat so that no one could see. He felt like a Soviet man.

Right from this workshop I rushed to Fablab to solve problem number 3.

Large milling machine decides

I do not know what it was. Miracle probably. Surely a milling machine from Fablab Dima golden hands. Even more surprising was the fact that the "got" piece of foamed PVC turned out to be of excellent quality. And yet, by a miracle, the parts were correctly oriented on the sheet. And everything turned out perfectly from the first time.

It was both healthy and bad at the same time.

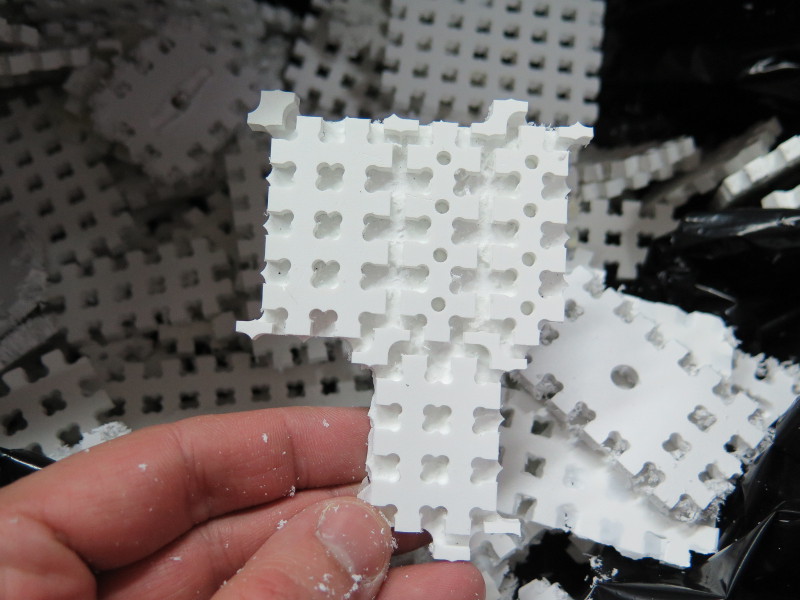

Great, because we immediately realized what the coolest thing we have turned out. The material was very light and durable. Because of its porous structure, it is very convenient to join the joint to the joint. Details at the same time firmly hold each other. It is easy to screw the screw into it. And if you make a hole, then it is easy to screw the screw into this hole and it will hold tight. With all this magnificence, the material was also harmless.

Bad, because I never met with pitfalls.

What happened?

"Yes, with this thing, we will throw **** out of school!" - this is just one of the many thoughtlessly enthusiastic exclamations that sounded in the technical department of Amperka that evening.

This was the first reaction of our guys to sample the details of the future designer. The details were few, they were not enough to satisfy the curiosity of all comers. We inserted motors and electronics into these parts, tried to quickly manage to collect at least something from a pair of parts, while the other did not select them: “Let me! Give me that! ” They bent, bit, broke - they carried out full test tests.

That day my searches of forms and material for our designer finally ended.

Initially, we planned to make a simple platform for the robot with variations. And in the end it turned out a full-fledged designer, from which you can build the whole universe! From that day on, I always carry a handful of parts in my backpack. Showing them to different people, I found a high addiction to the designer. A person temporarily falls out of conversation, collecting all sorts of things. Watching is very nice.

Simple and clear way to connect parts

Electronic modules are simply inserted into the grooves prepared for them, and they independently hold there.

What else would such a stick?

Or fastened with screws, without any nuts.

Need a thread? Cut

And the motor can simply be inserted into the hole prepared for it, and it will not go anywhere.

Close your eyes and poke it to any place of the robot. Everything - you attached the motor

And you can easily make an owl!

I do not know why, but the ability to make an owl is very important

We need more details!

Hooray, material and form found!

Now they need to make a robot.

In addition, we were invited to Peter to the round table of the Minister of Education, who gathered all those involved in child robotics for something there. The details on the assembly of a full-fledged robot were not enough, and I wanted to boast in front of the minister to our designer.

Yes, and for the future development of a large number of parts was necessary. Not in the CAD-ah robots draw? You need to play them yourself!

In general, we needed a lot of details. And quickly - the round table stung sharply deadlines.

It is impossible to conjure on Friday

In the shortest possible time, a full set of all kinds of details that would come to mind would be drawn. A workshop was found in which they agreed to fulfill our order. Well, they allowed me to participate in the process so that I would learn many new things. The window during which the order could be executed is Friday night. On Tuesday, the director leaves for a round table. On the assembly of the robot remains Monday.

Notes on milling and walking on a rake

At 5:52 in the morning, I am sitting in the car of the first metro, I am writing these lines, waiting for the train to depart. It has been 11 hours since I left the Amperca office for production to produce the first large set of parts for our designer. It's like coming back from a good party. But the night was so-so.

In the previous series, the technologist left for jazz, instructing me to deal with my drawing to the foreman.

Arrived for production at 7 pm Friday. I was introduced to a great guy Roman, a foreman, and his ward milling machine.

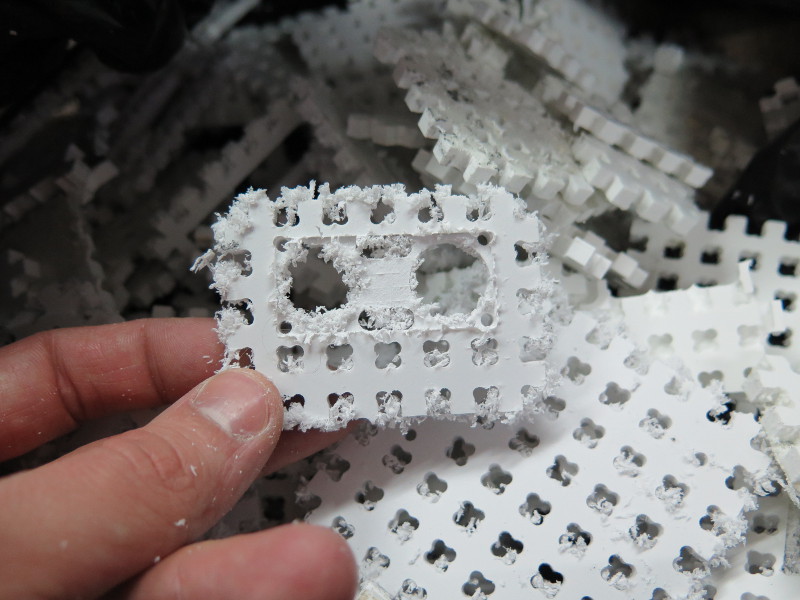

Trouble started a little earlier. I could not try to draw the requirements for the drawing, my drawing did not fit because there was a distance of 3.1 mm between the parts, 0.1 mm larger than the diameter of the cutter. And it was necessary to 7-8 mm. When a part is cut along the contour, the last not cut piece is thinned so much that it cannot hold the part. Therefore, the detail is shifted and spoiled mill. This I later learned.

We wanted to make all the details as quickly as possible - an hour or two, because this is Friday night! I think many people on Habré already have a rule not to conjure on Friday, now I decided to introduce this for myself.

Our designer is a huge number of curved lines on a small section of material, which is not usual for advertisers.

The computer showed that the first part of the set, containing most of the details, will be cut 1 hour and 40 minutes.

How is the milling part. First, a sample is made if it is on the part. Then the holes are cut. And the most recent stage is milling the parts along the contour, after which the finished part is obtained. If we immediately cut a large number of parts, then everything happens exactly the same, but for all parts at the same time. The set of parts was very large, I was counted 1300 meters of the cutter's passage on the site of 60 * 70 cm.

A slight digression: sheet material, such as foamed PVC or plywood, is pressed to the base with a vacuum when milling. The material lies on a special substrate through which air is sucked. The thin pressure presses the sheet and the results of the milling to the base of the machine - the “sacrificial table”.

The clock was already around 11 pm, when the machine finished with all the holes and proceeded to the passage of parts along the contour. Here the trouble happened. Due to the too narrow gap between the parts, they began to deviate under the pressure of the cutter and deteriorate. Having received a couple of defective parts, the machine operator came up with a great way to avoid damage to subsequent parts - glue the sheet to the base on a double-sided tape. This is not a trivial operation, because the detail cannot be shifted, otherwise all the work will go down the drain. At first, things went more vigorously, but only at first. It got to the smallest details - connecting crosses. And fresh ready-made crosses began to suck into the vacuum cleaner built into the machine. Yes, a vacuum cleaner is integrated into the milling machine, sucking dust and chips. Because of him, the details could stick to this vacuum cleaner and rise along with the cutter. This also led to damage to parts. By that time, the double-sided tape had already ended, and heavy artillery was put into operation. A huge sticky film, rather like glue, now fastened a PVC sheet to the substrate over the entire area of the sheet. All this was applied to the sheet from the bottom side, so as not to move the sheet. This is an acrobatic exercise. The price of a mistake - you have to start all over again. I do not remember how long it was, but the mill was started up again, and everything seemed to go well.

Milling is an art. Each material requires its own approach. Certain spindle speeds, and material feed rates, and the type of cutter itself. And these three parameters can vary very widely. For example, for foamed PVC, two or three passes of 3 mm cutters are required. Spindle speed should be low. The feed rate of the material (that is, the speed of movement of the cutter on the sheet) must be some definite. I do not remember which one.

Our miller did everything at 50,000 rpm. It's a lot. And for some reason I called it 5,000. We only discovered it later. He also spoke little Russian. And he did not understand very much.

The workshop master Roman worked there recently, and did not yet know this machine and its software. Understood together. But he knew his business perfectly, despite his youth. Therefore, he commanded the machine with the help of a poorly speaking Russian CNC operator.

Let's go back to the milling. Details began to turn out. Everything was going well, the machine had already cut through the first round of the perimeter of the parts and began to cut the second. Started with holes, of course.

When the mill pierces the material, it rests on a soft substrate. This is the very substrate of the machine through which the machine “sucks the vacuum” and presses the part to the frame. And between the substrate and the part now was a very sticky film resembling glue. We after all glued a sheet to a bed.

Quickly enough, this glue wound on the mill, and began to push through the holes of the parts. The holes of the parts must be of a certain shape. That is why they keep the designer together - because of the form. And here a thick skein of a mixture of glue and sawdust crashes into this beautiful shape. Marriage began to appear.

At this point, it became clear that the drawing needs to be redone and start over.

Qcad-ovsky DXF does not open everywhere. Dwg too.

While Roman and I hurriedly tried to remake the drawing, increasing the distances between the parts, the poorly spoken in Russian CNC operator milled the details of the marrying. Sometimes he took out the cutter, and, burning, removed the glue from it. Then marriage declined. Or gibitation. Bracheny details. I didn’t take the parts 8 mm apart (the expanding universe) from my hand. Because the cursor of my laser mouse did not want to work on the surface that I had at hand. Sometimes I tried to drive a mouse over my trouser leg, even if it was a chance to get into the right line of the drawing.

I spat on the redraw. Yes, and Roman spat.

Around midnight. We start over.

With the help of a poorly understanding Russian operator of the CNC, Roman and I commanded a graphic editor on the CNC control computer, hastily reworking the drawing right at the machine. Along the way, adding jumpers that were supposed to protect the part from lifting and bending.

It was decided to replace the substrate of the machine with another one that does not contain glue.

A small digression: when the cutter pierces the material and sticks into the substrate, it has nothing left to do but cut the substrate. The backing is quite thick and fuzzy artificial mat. The substrate is consumables. During her service, she maintains various projects on her nap. A huge pile of milled lines. Thick, thin, deep and not very. The rug keeps on itself history of an advertising workshop. Somewhat reminiscent of the desert with sand dunes. The cutter presses the part to the substrate, and if there is a cavity on the substrate, the material bends under the cutter. Especially flexible PVC foam! The distance that the milling cutter falls is set before milling once. They try to make this distance small so as not to injure the mat too much. But if the material sags, then you have to immerse the cutter deeper into the mat. Therefore, trying to find a compromise - just enough to cut through the part.

Our rug was very old.

So we started again. Went the next 1 hour and 40 minutes.

The first cutter pass passed without surprises. Began the second pass.

The material began to cut through.

We romance, making sure that the material is cut, went to smoke.

Returning after a while from the smoking room, we found the CNC operator, who removed almost all the details from the machine. Highly. A lot of places were not cut through. The hilly rug has done its job. It was possible to correct the situation by going through the parts for the third time, with a lower Z, but this could only be done before the parts were removed from the machine.

So, we found the details removed from the machine.

Sometimes the thickness of the uncut parts reached a millimeter. It was impossible to cut it with a stationery knife without damaging the geometry of the part.

Most of the details were rejected for this reason. It was decided to add them to the next part, where we made small constructive.

After cutting parts, jumpers against lifting parts are cut off with a clerical knife.

A badly speaking Russian, the CNC operator decided to be resourceful, and appointed automatic jumper setting against lifting.

The machine did everything as she was told - randomly placed jumpers. Even where exact geometry is needed, and not just at the tips.

Found it later.

Marriage.

We start again.

It seems finished off the structural details. The queue for the interface.

In the morning we remembered for a long time why we decided to change the mill? Then he stopped at the thought that because of the glue.

Put another cutter. Another cutter for some reason behaved differently. Due to the high speed of the cutter, its temperature quickly increases. The shavings are heated from it, and begin to melt. The chips began to burn into details, remaining on the part forever.

The interface set was ready when we found something was wrong. The finished part could not be cleaned of chips adhered to it.

Marriage. We start this part again.

Oh, there were a lot of them! And the black bloom from the rug on the details due to the vacuum cleaner turned off. And inadvertently shifted sheet. And just the details with the wrong order of clipping. For example, if you first remove the internal large hole, and then make a contour, the part will be inward and milled with a cone.

Interface details contain a sample - this is when removed in an even layer, say 1.5 mm in depth. This is so that you can insert some kind of board into the groove. For example a line sensor. The groove turned out from the second attempt.

Sometimes the machine itself had to be rebooted. The floating Z coordinate after that, plus the rug hills. The result - a sample of a millimeter shorter than necessary.

In short, I arrived home on the first subway train. I sit drinking beer, I write)

At 5:52 in the morning, I am sitting in the car of the first metro, I am writing these lines, waiting for the train to depart. It has been 11 hours since I left the Amperca office for production to produce the first large set of parts for our designer. It's like coming back from a good party. But the night was so-so.

In the previous series, the technologist left for jazz, instructing me to deal with my drawing to the foreman.

Arrived for production at 7 pm Friday. I was introduced to a great guy Roman, a foreman, and his ward milling machine.

Trouble started a little earlier. I could not try to draw the requirements for the drawing, my drawing did not fit because there was a distance of 3.1 mm between the parts, 0.1 mm larger than the diameter of the cutter. And it was necessary to 7-8 mm. When a part is cut along the contour, the last not cut piece is thinned so much that it cannot hold the part. Therefore, the detail is shifted and spoiled mill. This I later learned.

We wanted to make all the details as quickly as possible - an hour or two, because this is Friday night! I think many people on Habré already have a rule not to conjure on Friday, now I decided to introduce this for myself.

Our designer is a huge number of curved lines on a small section of material, which is not usual for advertisers.

The computer showed that the first part of the set, containing most of the details, will be cut 1 hour and 40 minutes.

Rake. Hidden threat

How is the milling part. First, a sample is made if it is on the part. Then the holes are cut. And the most recent stage is milling the parts along the contour, after which the finished part is obtained. If we immediately cut a large number of parts, then everything happens exactly the same, but for all parts at the same time. The set of parts was very large, I was counted 1300 meters of the cutter's passage on the site of 60 * 70 cm.

A slight digression: sheet material, such as foamed PVC or plywood, is pressed to the base with a vacuum when milling. The material lies on a special substrate through which air is sucked. The thin pressure presses the sheet and the results of the milling to the base of the machine - the “sacrificial table”.

The clock was already around 11 pm, when the machine finished with all the holes and proceeded to the passage of parts along the contour. Here the trouble happened. Due to the too narrow gap between the parts, they began to deviate under the pressure of the cutter and deteriorate. Having received a couple of defective parts, the machine operator came up with a great way to avoid damage to subsequent parts - glue the sheet to the base on a double-sided tape. This is not a trivial operation, because the detail cannot be shifted, otherwise all the work will go down the drain. At first, things went more vigorously, but only at first. It got to the smallest details - connecting crosses. And fresh ready-made crosses began to suck into the vacuum cleaner built into the machine. Yes, a vacuum cleaner is integrated into the milling machine, sucking dust and chips. Because of him, the details could stick to this vacuum cleaner and rise along with the cutter. This also led to damage to parts. By that time, the double-sided tape had already ended, and heavy artillery was put into operation. A huge sticky film, rather like glue, now fastened a PVC sheet to the substrate over the entire area of the sheet. All this was applied to the sheet from the bottom side, so as not to move the sheet. This is an acrobatic exercise. The price of a mistake - you have to start all over again. I do not remember how long it was, but the mill was started up again, and everything seemed to go well.

Rake 2. Glue Attack

Milling is an art. Each material requires its own approach. Certain spindle speeds, and material feed rates, and the type of cutter itself. And these three parameters can vary very widely. For example, for foamed PVC, two or three passes of 3 mm cutters are required. Spindle speed should be low. The feed rate of the material (that is, the speed of movement of the cutter on the sheet) must be some definite. I do not remember which one.

Our miller did everything at 50,000 rpm. It's a lot. And for some reason I called it 5,000. We only discovered it later. He also spoke little Russian. And he did not understand very much.

The workshop master Roman worked there recently, and did not yet know this machine and its software. Understood together. But he knew his business perfectly, despite his youth. Therefore, he commanded the machine with the help of a poorly speaking Russian CNC operator.

Let's go back to the milling. Details began to turn out. Everything was going well, the machine had already cut through the first round of the perimeter of the parts and began to cut the second. Started with holes, of course.

When the mill pierces the material, it rests on a soft substrate. This is the very substrate of the machine through which the machine “sucks the vacuum” and presses the part to the frame. And between the substrate and the part now was a very sticky film resembling glue. We after all glued a sheet to a bed.

Quickly enough, this glue wound on the mill, and began to push through the holes of the parts. The holes of the parts must be of a certain shape. That is why they keep the designer together - because of the form. And here a thick skein of a mixture of glue and sawdust crashes into this beautiful shape. Marriage began to appear.

At this point, it became clear that the drawing needs to be redone and start over.

Qcad-ovsky DXF does not open everywhere. Dwg too.

While Roman and I hurriedly tried to remake the drawing, increasing the distances between the parts, the poorly spoken in Russian CNC operator milled the details of the marrying. Sometimes he took out the cutter, and, burning, removed the glue from it. Then marriage declined. Or gibitation. Bracheny details. I didn’t take the parts 8 mm apart (the expanding universe) from my hand. Because the cursor of my laser mouse did not want to work on the surface that I had at hand. Sometimes I tried to drive a mouse over my trouser leg, even if it was a chance to get into the right line of the drawing.

I spat on the redraw. Yes, and Roman spat.

Around midnight. We start over.

With the help of a poorly understanding Russian operator of the CNC, Roman and I commanded a graphic editor on the CNC control computer, hastily reworking the drawing right at the machine. Along the way, adding jumpers that were supposed to protect the part from lifting and bending.

Rake 3. Revenge rug

It was decided to replace the substrate of the machine with another one that does not contain glue.

A small digression: when the cutter pierces the material and sticks into the substrate, it has nothing left to do but cut the substrate. The backing is quite thick and fuzzy artificial mat. The substrate is consumables. During her service, she maintains various projects on her nap. A huge pile of milled lines. Thick, thin, deep and not very. The rug keeps on itself history of an advertising workshop. Somewhat reminiscent of the desert with sand dunes. The cutter presses the part to the substrate, and if there is a cavity on the substrate, the material bends under the cutter. Especially flexible PVC foam! The distance that the milling cutter falls is set before milling once. They try to make this distance small so as not to injure the mat too much. But if the material sags, then you have to immerse the cutter deeper into the mat. Therefore, trying to find a compromise - just enough to cut through the part.

Our rug was very old.

So we started again. Went the next 1 hour and 40 minutes.

The first cutter pass passed without surprises. Began the second pass.

The material began to cut through.

We romance, making sure that the material is cut, went to smoke.

Returning after a while from the smoking room, we found the CNC operator, who removed almost all the details from the machine. Highly. A lot of places were not cut through. The hilly rug has done its job. It was possible to correct the situation by going through the parts for the third time, with a lower Z, but this could only be done before the parts were removed from the machine.

So, we found the details removed from the machine.

Sometimes the thickness of the uncut parts reached a millimeter. It was impossible to cut it with a stationery knife without damaging the geometry of the part.

Most of the details were rejected for this reason. It was decided to add them to the next part, where we made small constructive.

Rake 4. New rake

After cutting parts, jumpers against lifting parts are cut off with a clerical knife.

A badly speaking Russian, the CNC operator decided to be resourceful, and appointed automatic jumper setting against lifting.

The machine did everything as she was told - randomly placed jumpers. Even where exact geometry is needed, and not just at the tips.

Found it later.

Marriage.

We start again.

Rake 5. Milling cutter strikes back

It seems finished off the structural details. The queue for the interface.

In the morning we remembered for a long time why we decided to change the mill? Then he stopped at the thought that because of the glue.

Put another cutter. Another cutter for some reason behaved differently. Due to the high speed of the cutter, its temperature quickly increases. The shavings are heated from it, and begin to melt. The chips began to burn into details, remaining on the part forever.

The interface set was ready when we found something was wrong. The finished part could not be cleaned of chips adhered to it.

Marriage. We start this part again.

Rake 6. Return rake

Oh, there were a lot of them! And the black bloom from the rug on the details due to the vacuum cleaner turned off. And inadvertently shifted sheet. And just the details with the wrong order of clipping. For example, if you first remove the internal large hole, and then make a contour, the part will be inward and milled with a cone.

Interface details contain a sample - this is when removed in an even layer, say 1.5 mm in depth. This is so that you can insert some kind of board into the groove. For example a line sensor. The groove turned out from the second attempt.

Sometimes the machine itself had to be rebooted. The floating Z coordinate after that, plus the rug hills. The result - a sample of a millimeter shorter than necessary.

Bag of marriage

In short, I arrived home on the first subway train. I sit drinking beer, I write)

Long or short, and on Monday a large set of parts was in Amperk. And General Mikhail gathered his first full-fledged robot in half an hour.

Build the first robot

Here he is handsome

And drove him to the round table. According to his story, everything was in vain. The participants were with beautiful presentations and slides. And we were with a robot.

Mikhail's speech was one of the shortest. Something like this: “Here is a constructor with an Arduino. For kids. Schoolchildren can collect robots, physics experiments, and an owl. And if a schoolboy collects robots then robots drive. You can build cranes ... ".

What's next?

Now we are actively developing our designer. We play it every day, collect robots. We finish the missing parts. We are trying to come up with a functional and cute robot for the start, which children would be interested to play with. Yes, and so that the side effect of the game was learning programming.

First robots lumpy

The apparent simplicity of assembling parts is somewhat deceptive. When assembling something serious, one has to strain the spatial imagination quite strongly. In a few iterations, we got this handsome:

Fotostolik quietly left. Lost scotch to stick to the floor. You can twist and consider better

He has a sufficient set of sensors that would perform a very wide range of tasks.

Soon this designer will see the light. There is still a lot of work to bring gloss and create the necessary infrastructure - after all, he will have to compete with the giants. I'd like to believe that its attractiveness, openness and availability for self-production will bring him due popularity.

I hope this is not my last article on Habré. I am pleased to tell you about the designer yet. Moreover, in the course of the game some more interesting applications were born for him.

PS And the name for the designer never came up. Offer in the comments, please. We will be very happy with new ideas.

Thanks

Thanks to Alexey Perepelkin for the idea and active participation in the project.

Thanks to Fablab Misa for what they are.

Thanks to Fablab Misa for what they are.

UPD. As we thought out the designer for children's robotics. # 2

Source: https://habr.com/ru/post/256831/

All Articles