3D MC3 Wizard v1.1 or how I assembled my first 3D printer

It so happened that free time coincided with a great desire to do something with their own hands from scratch. Some acquaintance with the Arduino controllers, process automation and the completion of repairs in the house suggested the creation of a robot vacuum cleaner. It could have ended by buying some finished product, but I wanted to do everything myself from the very beginning. Moreover, I even wanted to design and manufacture all the parts for him.

3D printers, for the majority, are a hobby or a toy, and only for a small percentage of people is a tool in achieving the ultimate goal. In my case, such a printer will become a tool for implementing a very specific task: to make all the mechanics, fasteners and case of the end device. Well, so that it was not boring - it was decided to assemble the printer almost from scratch, that is, from the KIT kit. The choice fell on the new printer of the company "Master Kit" 3D MC3 Master v1.1 . Reaching the manufacturer, I got my hands on a blue small suitcase and went home to complete the first step towards the goal.

So, to get the details you need to assemble a 3d printer with your own hands. On the forums, many times everything is documented, but there is no step-by-step description of the assembly sequence, because of which the process can take several days and weeks. The finished set is pleased that there is a step-by-step instruction with photos and a simple description of this process. But we will begin in order. All printer is located in a compact, but powerful plastic small suitcase. It has a pair of latches, but is also fastened with a tie to prevent accidental opening during transport. Trifle, but nice.

')

An autopsy revealed that everything was neatly laid out in boxes and signed.

We spread everything on the table and consider it carefully.

Hex keys for complete screws are included in the kit, but pliers and a Phillips screwdriver are also needed (for tightening just one screw).

Even during the receipt of the kit, I asked the engineers how much time it would take for me to assemble the printer? The answer to me was “before 12 o'clock” - and this is only an assembly, and not the beginning of printing. But the whole process is mono divided into two big stages:

1. The physical connection of all parts and mechanics

2. Wire pulling and electronics connection

It must be said that even with the instruction and the seeming simplicity of the process, both stages take approximately equal time, especially considering that when connecting you should be extremely careful and not confuse the polarity, otherwise you can easily burn the controller.

The whole process from opening the suitcase to connecting to a computer took me about 5.5-6 hours of time, which is a good result, given the fact that I first assembled a 3D printer. It is worth paying tribute to the accompanying documentation: there are many photos, plastic parts are numbered, and the bags with the kit are signed.

So, we begin fast assembly.

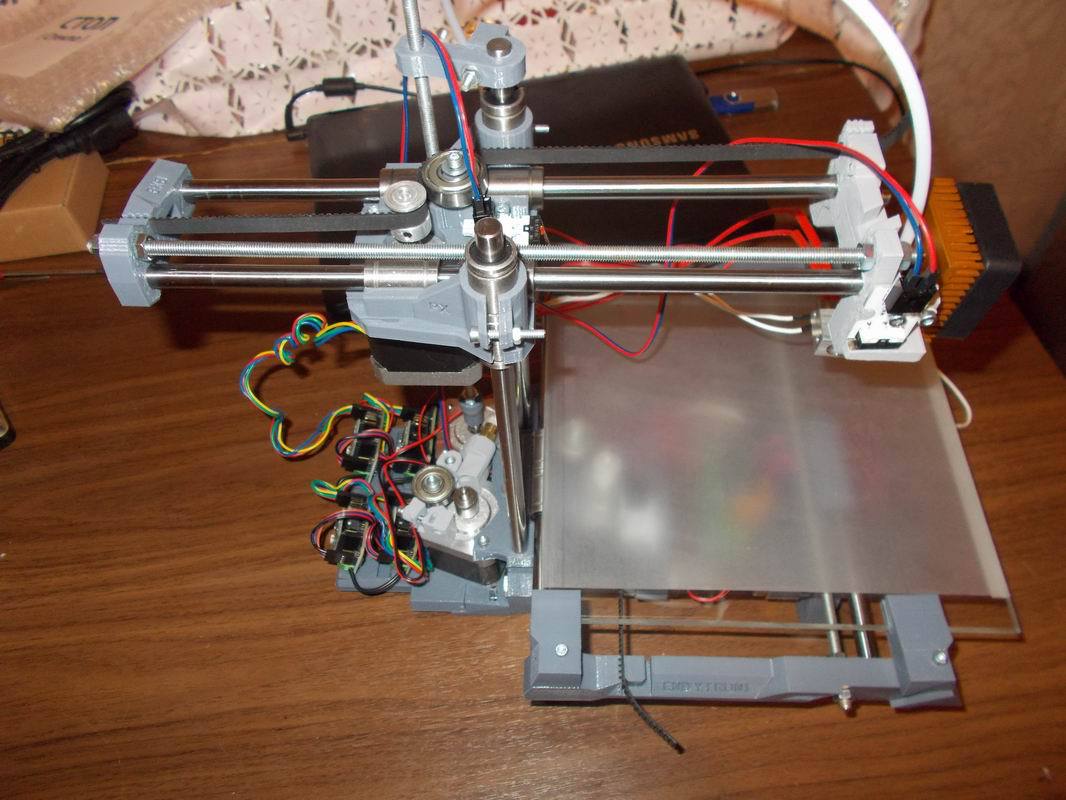

As a result of more than 5-hour labor, I managed to get such a printer.

Immediately it is worth noting that the kit comes with ordinary glass, but to improve the adhesion of plastic, I applied a matte self-adhesive film Lomond to it. All the wires initially hang in the air and before launching them better to remove. The package includes ties that will help to collect all the wires in neat harnesses. Before the final tightening of the screeds, it is necessary to transfer all moving elements to the extreme position several times in order to ensure free running and the absence of hooks. If some shafts or bearings do not immediately fall into place, then chamfers can be made with an ordinary stationery knife, since the parts are printed from plastic.

It should look like this (the cat is not included in the package):

What are the differences of this 3D MC3 Printer Master v1.1 from MC3 Stealth .

What are the pros and cons of self-assembled 3D printer I learned from my experience?

Pros:

Minuses:

3D printers, for the majority, are a hobby or a toy, and only for a small percentage of people is a tool in achieving the ultimate goal. In my case, such a printer will become a tool for implementing a very specific task: to make all the mechanics, fasteners and case of the end device. Well, so that it was not boring - it was decided to assemble the printer almost from scratch, that is, from the KIT kit. The choice fell on the new printer of the company "Master Kit" 3D MC3 Master v1.1 . Reaching the manufacturer, I got my hands on a blue small suitcase and went home to complete the first step towards the goal.

So, to get the details you need to assemble a 3d printer with your own hands. On the forums, many times everything is documented, but there is no step-by-step description of the assembly sequence, because of which the process can take several days and weeks. The finished set is pleased that there is a step-by-step instruction with photos and a simple description of this process. But we will begin in order. All printer is located in a compact, but powerful plastic small suitcase. It has a pair of latches, but is also fastened with a tie to prevent accidental opening during transport. Trifle, but nice.

')

An autopsy revealed that everything was neatly laid out in boxes and signed.

We spread everything on the table and consider it carefully.

Hex keys for complete screws are included in the kit, but pliers and a Phillips screwdriver are also needed (for tightening just one screw).

Even during the receipt of the kit, I asked the engineers how much time it would take for me to assemble the printer? The answer to me was “before 12 o'clock” - and this is only an assembly, and not the beginning of printing. But the whole process is mono divided into two big stages:

1. The physical connection of all parts and mechanics

2. Wire pulling and electronics connection

It must be said that even with the instruction and the seeming simplicity of the process, both stages take approximately equal time, especially considering that when connecting you should be extremely careful and not confuse the polarity, otherwise you can easily burn the controller.

The whole process from opening the suitcase to connecting to a computer took me about 5.5-6 hours of time, which is a good result, given the fact that I first assembled a 3D printer. It is worth paying tribute to the accompanying documentation: there are many photos, plastic parts are numbered, and the bags with the kit are signed.

So, we begin fast assembly.

As a result of more than 5-hour labor, I managed to get such a printer.

Immediately it is worth noting that the kit comes with ordinary glass, but to improve the adhesion of plastic, I applied a matte self-adhesive film Lomond to it. All the wires initially hang in the air and before launching them better to remove. The package includes ties that will help to collect all the wires in neat harnesses. Before the final tightening of the screeds, it is necessary to transfer all moving elements to the extreme position several times in order to ensure free running and the absence of hooks. If some shafts or bearings do not immediately fall into place, then chamfers can be made with an ordinary stationery knife, since the parts are printed from plastic.

It should look like this (the cat is not included in the package):

What are the differences of this 3D MC3 Printer Master v1.1 from MC3 Stealth .

- Complete failure to spring up the table and springs in the bar feed system

- The sensor limit switch on the Z axis is now moved to the extruder, so it is easier to align the printer along this axis.

- Before each printing, the printer makes alignment along the axes, while doing this along the Z axis at three different points, thereby building a clear picture of the plane for itself. This solves the problem of non-compliance of the horizontal table when installing or installing the printer itself.

What are the pros and cons of self-assembled 3D printer I learned from my experience?

Pros:

- Self-assembly is significantly cheaper than a finished device.

- Good instruction - the key to quality and fast assembly. This set of instructions is very detailed.

- Ready kit saves time on the purchase of components and the calculation of the required parts

- No need to take a soldering iron in hand. If you have the skill of using a screwdriver, that's enough

- If you have children, then the whole day will fly quickly and fascinatingly.

Minuses:

- The assembly kit requires the simplest understanding of mechanics.

- To build a 3d printer should prepare a large table and release at least 1 full day

- Electrician debugging will also take time, unlike in the finished device.

Source: https://habr.com/ru/post/255827/

All Articles