How does a boiler house in Middle Akhtuba differ from a power center of a data center?

Coal boiler room (for example, 4000 rubles per Gcal)

Normal boiler room (example, approximately 1500 rubles per Gcal)

In March 2014, a competition for a new boiler house began in Srednyaya Akhtuba. Our engineering team was suddenly called there, although our main profile has always been equipment for data centers. We applied all our skills gained during the years of building data centers and won the competition. On August 25, a municipal contract was signed.

')

In general, we have been building trigeneration energy centers in recent years. These are such objects on gas, from which electricity, heat and cold are given to the nearest data center or some important infrastructure facility. And now I will tell you about the difference between the urban-type settlement of 50 thousand inhabitants and the data center.

Let's start with the fact that the servers, even very powerful ones, do not steal water. Even when the data center falls, the main thing is not shown on TV along with Shoigu. And the water in the pipes throughout the city does not stop and does not freeze, breaking the nodes.

Formulation of the problem

On the site there are old-old boilers of the 79th year, which, it seems, have long gone out of the estimated useful life and live only thanks to the word of honor, prayers and the Soviet strength reserve. Local engineers worked wonders, but with each repair it was necessary to solder new and new blocks, pipes ducked, and the quality and efficiency fell. Last year, there were already problems with heat, and no one needs new accidents in the cold, everyone understands that going through the winter on old equipment is something from the science fiction field.

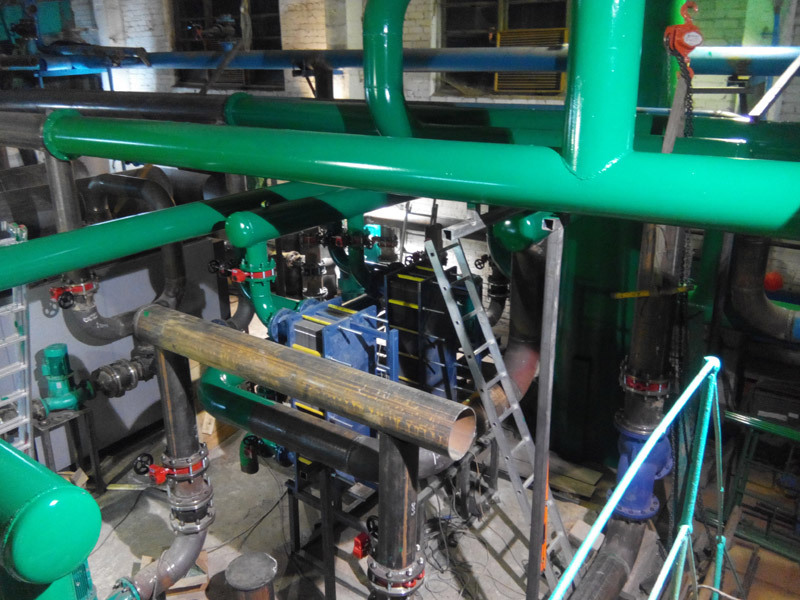

The local business executives are very good: everything is clean, properly colored. And usually you come to the object - scary, horror movie.

But running a little ahead, I will say that a serious accident in the winter did happen, and, according to the experience of the neighboring regions, if there were no backup system, they would have shot the entire administration. Well, at first the minister would be shown on TV, and then heads would fly.

Last year there were about 40 emergency shutdowns. Naturally, the head of the facility was tugged very badly: the administration was disturbed around the clock, because they understood that if anything - it was not the engineer who was to blame.

Naturally, a year ago and five years ago it was clear that a new boiler house should be built, and immediately with a reserve. Only here is the problem: there is no money in the budget immediately for a new object. They tried to look for those who can build an energy center with energy service (when a team builds and operates, but does not transfer it to the property of the administration, but sells heat to the city). Naturally, this long payback scheme was not very necessary for suppliers - this is usually done when there is already a large consumer nearby, such as the same data center or shopping center.

While there was an assessment of the energy centers, the engineers came to us. Here, perhaps, the most interesting. We have a work plan for data centers, when we first build, then we get paid. The administration was well aware that when the object was already there, the money was easier to find. Though under the leasing scheme, even under the repurchase. We would not go to the energy service - how to exploit data centers, we know, and the payback period there is stable for 8 years, so they are often owned. And here the payback in 2-3 years, so installments make sense. To make it clear, all the boiler houses are subsidized, each year they cost 15–20 million rubles, they don’t have enough money for gas, repairs and maintenance.

For them, such a system turned out to be the most convenient, because the guys in the region had already encountered a couple of times and the opposite situation, when the money for the object is given, and the contractor disappears a month later. This is Russia.

According to approximately this scheme, they build houses - and they have been working like this for a long time. So we got to the competition.

Task execution

When the power module is transported to the data center, as a rule, there is nothing else in place, the maximum is some kind of all-weather container for 3-5 racks or a server one in the nearest office, which is necessary for operation before full deployment. If the equipment for some reason is delayed, it is generally very sad, of course, but not in the way that is directly critical. Of course, if we are talking about, for example, anything collected under an order from Europe, dropping it on unloading thanks to the transport company is a 4-month disaster.

In our case, the problem is that the old equipment no longer pulls, and the new one is not there yet. And winter is near. There were problems with the iron: it is not unique and not made to order, and as long as all the traditional approvals, checks and payment delays went, the vendor removed the reservation and sold the complex to someone else. We had to wait for the next production, which meant a delay of 2 months for the project. That is, we rapidly flew in the winter.

Installation

They began to pray for the weather - so that there would be no cold weather when the old equipment could not cope. As a result, when the new complex arrived, we began to mount it. On December 29, it was possible to put it into test operation (the heat went no further than the boilers themselves, the old equipment was still connected to the main circuit), and on the 30th a great surprise awaited us: an accident occurred, and the old boilers finally failed.

Installation

It was necessary to urgently switch the contours. It’s quite simple on paper, but in fact you need to drain the water, wait for the pipes to cool down, cut them in and put the water back on. And everything is so that residents do not freeze during this time. And even if you brake, the sections of the pipeline with cooled water in the city will begin to freeze, tear the pipes, become blocked ... In general, this would be a complete polar fox. When something falls in the data center, we can at least count on a backup system. Here it was not corny.

A day later, everything was safely done without freezing - the heat supply was restored to all. In total, 16 MW were needed - 8 changed, 8 on old boilers, we will change again.

After commissioning

Again, after we “saved” the circuit, it was necessary to introduce already new equipment into continuous operation. In data centers, a support team is usually formed during construction (these are people who actively help with work and know every detail). In our case, for staff, the commissioning of new equipment was a shock: the New Year, and no one knows how to operate. They used to live on the valves, and regulate everything by physical force. And then - the cost of under 30 million, touch scary. Just afraid to approach the equipment. As a result, we found a local guru from a neighboring city, operating a similar installation. He arrives if something is abnormal.

Exploitation

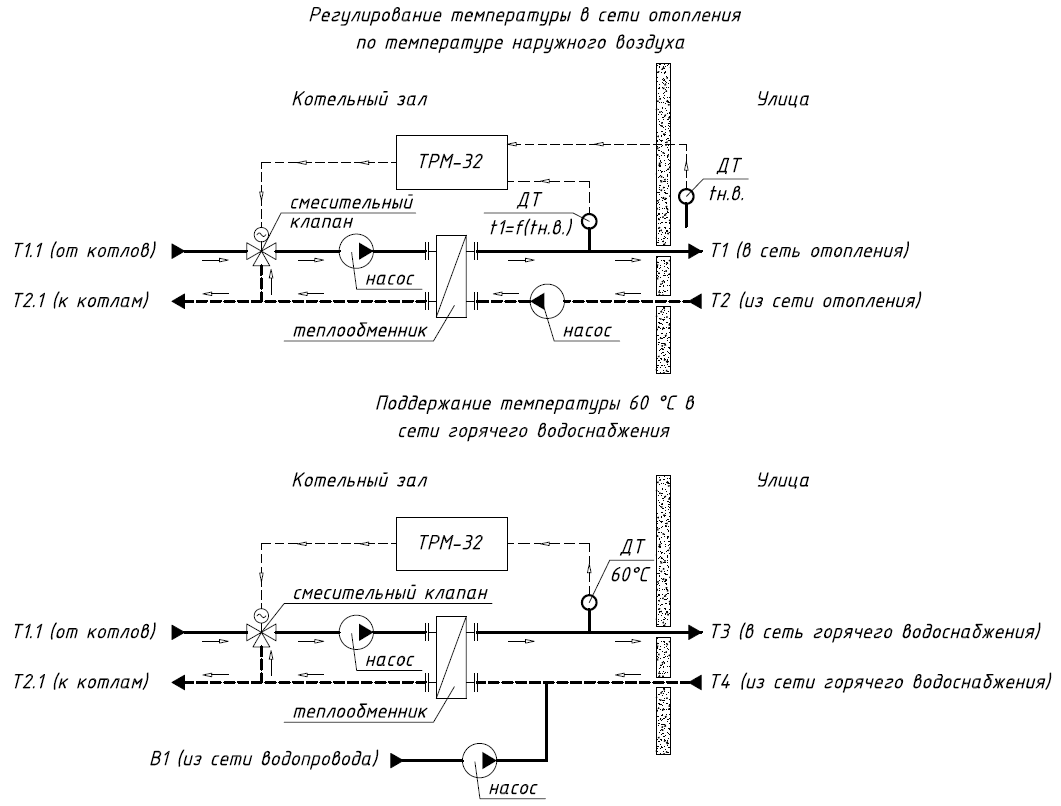

In general, the equipment works quite stably - it is only necessary to withdraw it to the mode, then it itself. There, the main task is to provide the desired temperature in the circuit depending on the weather. That is, when it is cold outside, you need to heat the water more strongly to compensate, and when it is relatively warm - less. We have a weather sensor on the street, from which information is sent to the controller that allows us to make weather-dependent automation. This is a quality regulation for the heating circuit of houses.

In addition to heating, there is still a hot water supply (about 100 cubic meters per day are dismantled). There it is important to maintain 60 degrees regardless of the situation, this is standard. The problem is different: you need to automatically maintain pressure in the outer loop and in the inner one. Accordingly, the controller monitors the pressure sensors (before, of course, everything was in the hands). If necessary, the pump is turned on, the valve is fed.

Plus, the water passes chemical treatment in the preparatory installation - all in automatic mode. There is a main filter, backup when one ends, automatically switches to the second, and the first one gets up to regeneration. Permanent presence of staff is not required.

By the way, because of the new sites, 8 people will be fired, so they are not very fond of us on the spot. In fact, of course, most likely, there will be work - the administration has long had problems with external heating networks.

The population without hot water in the homes of trite steals boiling water from the heating system (about half a million rubles a year). They simply crash into the heating circuit and start pumping themselves home - here there is an uncalculated pressure drop (as a result of temperature), and just the water leaving the heating circuit, and the formation of air bubbles, and the freezing pipes due to foreign inserts. Problems above the roof.

Engineers told, in some places nearby they tried to add a blue dye to the heating circuit, - it does not flow from the taps, and only the baths of those who steal would be painted. Some other Kulibins added fuel oil to the circuit. All these experiences are useless. First, our people are trying to drain the stolen water more, they say, the blue will soon end. Already day merge, it remains a bit. Then another day trying to wash the bath. Losses of water are colossal. Another city solved the problem simply: the people from the old stock who stole most of all got apartments in new houses first. Therefore, in the Middle Akhtuba work there.

Knots

To control the boilers and auxiliary equipment in the project, the control panels of the boiler house manufactured by Rospromgaz Plant LLC were used. Each boiler is controlled independently of other boilers.

Automation of hot water boilers is made on the basis of the ELLPREX 4000 remote control unit supplied with the boiler. It provides automatic start and stop of the boilers in accordance with the selected operation algorithm, automatic control of burner power, protection of the boiler at high / low water pressure and excess water temperature.

FBR K450 / M TL burners are installed on the boilers with automatic equipment providing protection in case of power failure, extinguishing the burner torch, decreasing the air pressure in front of the burners, reducing the vacuum and increasing the pressure in the furnace. Plus alarm and closure of the solenoid valve in emergency situations.

Alarms are displayed on the SAKZ-MK-3 boiler room control unit, located in the boiler room, and the dispatcher console installed in the control room.

Automation of auxiliary general-boiler equipment includes: regulation of the temperature of the network water at the outlet from the boiler room (depending on the outdoor temperature) by the TPM-32 “OWEN” controller; regulation of the temperature of hot water at the outlet of the boiler room by the controller TRM-32 "OVEN"; automatic maintenance of mains water pressure; automatic emergency switching of pumps (from main to standby) and automatic rotation of pumps by controller SAU-MP-15 “OWEN”; smooth start-up of pumps is performed by a Danfoss MCD 201 device. Plus, there is protection of pumps from dry running.

Signaling gas pollution with carbon monoxide (CO) and methane (CH4) is carried out from the sensors of the company "CIT - PLUS", Saratov. If the level of gas content in methane and carbon monoxide gas is exceeded, the inlet gas is switched off using a shut-off valve and a signal is transmitted to the controller's controller.

It is possible to transmit discrete signals about equipment failure to the control and dispatching system to the wired controller's dispatcher.

Now

From 6 coppers 4 heating, 2 GVS. Those who have hot water - they are new, in 2006, are relatively good. We dismantled the two oldest emergency boilers, replaced them with our own blocks.

That's how we from the “Only Data Centers” team became the “Engineering Solutions Everywhere” team. Now we offer similar options in other regions - there are reviews in St. Petersburg, Krasnodar. Not energy service, but in fact installments of up to one and a half years. As a rule, it is interesting to large plants or administrations. The first object - this is in the Middle Akhtuba - we built with our own money. We paid the first half in January.

Yes, and unlike data centers, such boiler houses have another great advantage for me personally and, perhaps, for you: as a rule, you can talk about them.

Links

- Power centers with trigeneration for data centers

- Experience of building trigeneration centers in Russia and FAQ

If you have questions that cannot be asked in the comments, my mail is DMarkin@croc.ru.

Source: https://habr.com/ru/post/255337/

All Articles