4th generation SCADA system: AggreGate SCADA / HMI

In this article, we continue the story about products developed on the basis of the AggreGate IoT platform. In 2010, two years after the appearance of the AggreGate Network Manager product, we launched the AggreGate SCADA / HMI project - the SCADA-system of the 4th generation.

What is the 4th generation SCADA?

An English-language Wikipedia article tells us about this:

- The first generation SCADA is a monolithic system developed before the widespread spread of the Internet. Now such systems are no longer used.

- Second generation SCADA is a system designed to work in the local network of the enterprise. They already assumed the use of an IP network for communication between the controller, the data collection server, the control server and the operator workstation.

- The third generation SCADA architecture has the ability to control and coordinate geographically distributed process control systems, including a large number of individual production sites and remote monitoring sites. Until recently, the crowning evolution of SCADA, the 3rd generation systems include the ability to run HMI interfaces in mobile device browsers, the ability to remotely edit a project directly on the combat server and test innovations without having to stop the server and copy project files.

- Finally, fourth-generation SCADA must be adapted for the Internet of Things. This implies an even greater degree of decentralization and unification, that is, the ability to quickly move the execution points of algorithms between SCADA servers and controllers, which, in fact, should be unified and have the same execution environment. Another necessary feature is the ability to work through cellular and satellite networks without the use of VPN, that is, the ability of controllers that do not have static IP addresses to connect to the SCADA servers running "in the cloud".

')

Of course, all SCADA vendors develop their products, which are gradually passing from generation to generation. At the same time, the development of old systems is often severely hampered by the need to maintain compatibility with past developments, which are usually difficult to fit into the concept of a changed world of industrial automation.

Built on the IoT platform, AggreGate SCADA / HMI inherited all the functions typical of SCADA 4th generation systems:

- The system built on the Java platform works perfectly under Linux, which allows you to run the SCADA kernel on embedded systems. Many of our OEM partners supply a pre-deployed system on Raspberry Pi, BeagleBone Black and similar low-cost microcomputers. At the same time, in most cases it is possible to access the SCADA core not only to IP communications and serial ports, but also to other controller peripherals — discrete and analog inputs, etc.

- The same system is deployed on conventional servers to provide centralized data collection and work with mnemonic circuits of technical processes. Based on a single architecture, regular servers establish peer-to-peer relationships for communicating with micro-servers (PLCs) within the AggreGate distributed architecture.

- The system is fully compatible with all ranges of programmable controllers and Tibbo modules.

- Mnemonic schemes can be run on ordinary PCs, in touch panels running Windows or Linux, or opened in a web browser.

- There is no concept of “development environment” and “execution environment” in the system - development is carried out via remote connection directly on the future combat server, taking into account the role-based access rights differentiation system. In this case, there are many ways to clone the entire project or its parts. The capabilities of the platform for creating reference projects and legacy products will be described in a separate article.

- The AggreGate platform is oriented to work with M2M / IoT devices, the server is perfectly able to work with controllers that connect to it independently. In our terminology, such controllers are called agents .

Still, the question may remain: why did we decide to make another SCAD? The world market in this area is saturated, and in Russia there are well-established manufacturers.

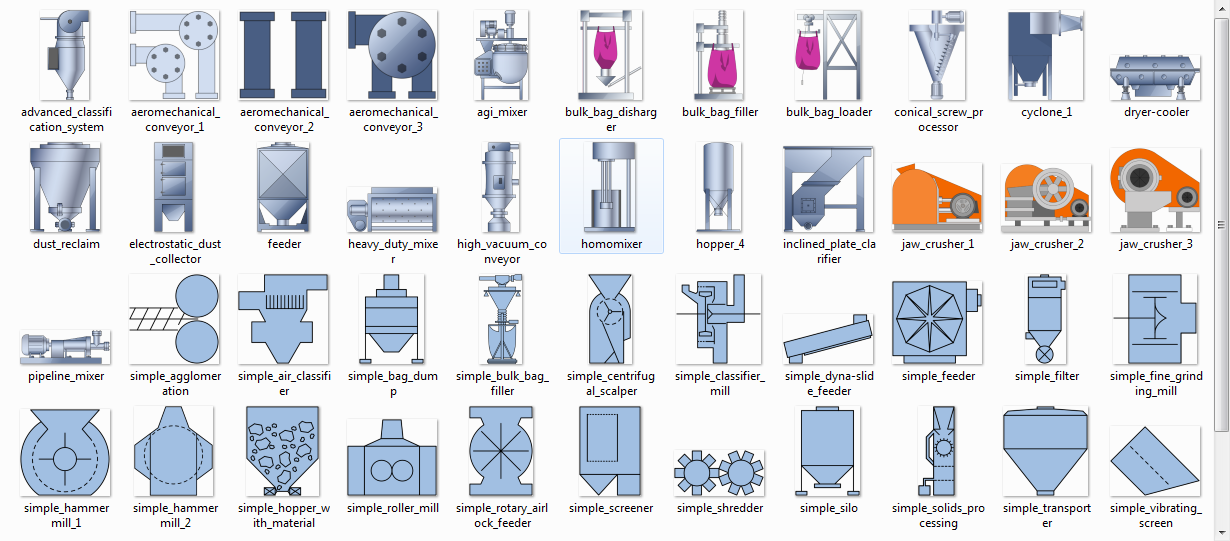

The fact is that AggreGate SCADA / HMI in the form of a "superstructure" above the AggreGate platform is, from a technical point of view, just a set of drivers for data collection and characteristic for ACS TP vector images. All the functionality necessary for SCADA is part of the AggreGate platform itself — it is the editor of mnemonic diagrams (widgets), the report editor, the mechanisms for managing events and alarms, the system for modeling its own tags, the technology of the failover cluster, and the SDK with the driver development kit (DDK). ), and so on.

Therefore, our investments in the creation of SCADA systems were small compared to the creation of such a system from scratch - for implementing projects to automate production processes and buildings, we developed drivers for standard protocols of the ACS TP world (Modbus, OPC, OPC UA, BACnet, DNP3 , etc.) and drew several thousand dynamic vector images.

In addition to the functions standard for SCADA systems, the AggreGate platform gives our product many unusual opportunities for this market, for example:

- Storage of statistics to the ring database (RRD) and NoSQL class database (BigData)

- Unlimited horizontal and vertical scaling of the system using AggreGate distributed architecture

- Ability to collect data and manage both IT management and monitoring protocols (SNMP, FTP, JMX, SSH, WMI ...) and universal protocols (SQL, SOAP, CORBA, LDAP ...)

These features allow you to use the system in a variety of projects that are not classic for the application of SCADA solutions. In particular, AggreGate SCADA / HMI is used for telemetry of the transport fleet of manufacturing companies, replacement of MES systems, cell tower monitoring and monitoring of the data center engineering infrastructure (as part of AggreGate Data Center Supervisor product).

In terms of architecture and the concept of building the project, AggreGate SCADA / HMI is similar to most other products. The development cycle of a typical project includes:

- Deploy a server or multiple servers in a failover configuration

- Connecting the storage, which can be a regular relational DBMS, or integrated into the Apache Cassandra DBMS system, which provides the preservation of tens of thousands of tags per second

- Connecting controllers and other data sources (such as external databases), setting up tag polling periods

- Setting up automated tag processing algorithms on the server — these can be models that define additional calculated tags, alarms that deliver e-mail and SMS alerts, schedules for performing various tasks, and so on.

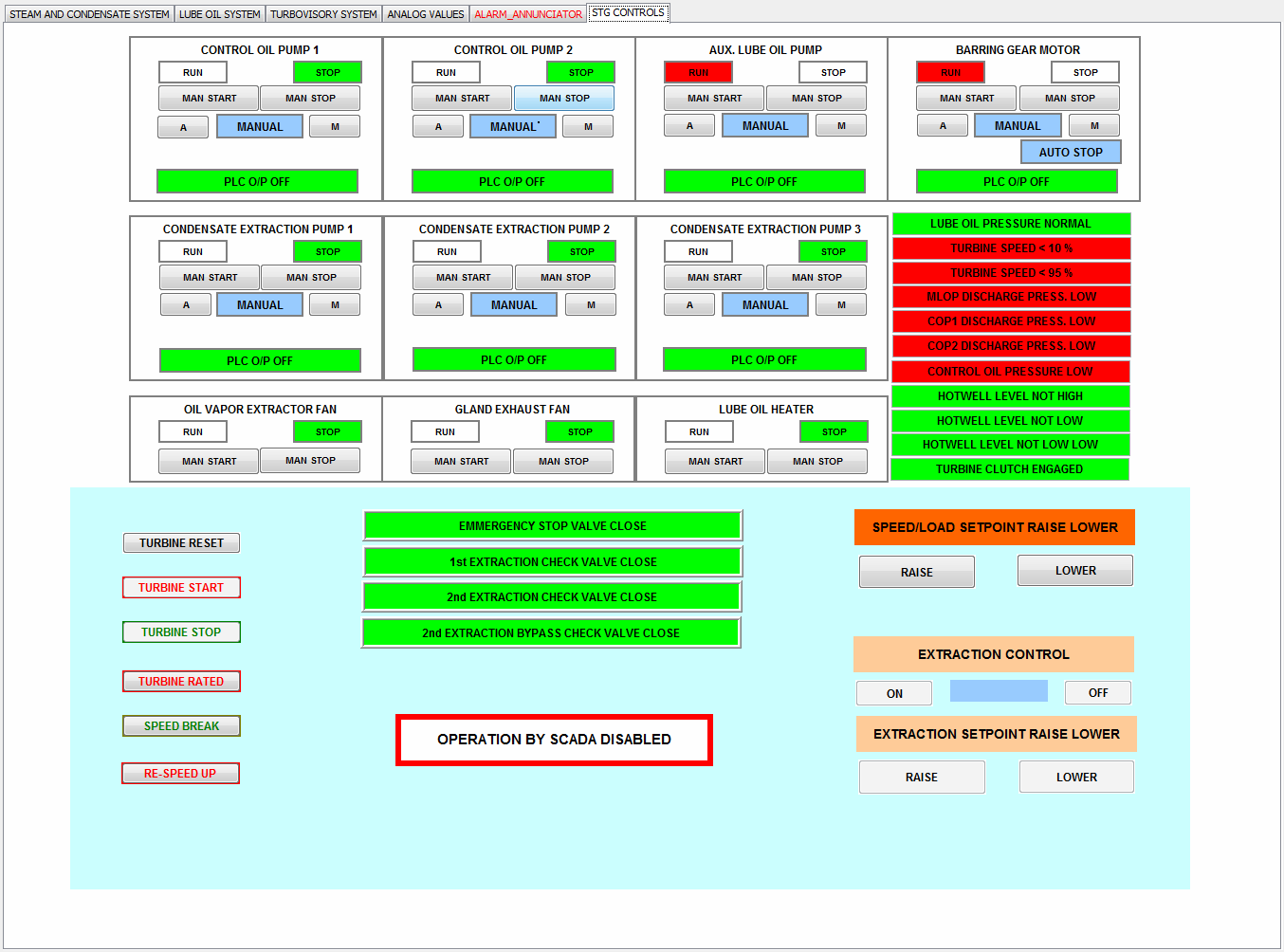

- Development of mnemonic diagrams and dashboards with navigation between them

- Setting user roles, access rights for them, and, if necessary, external authentication via LDAP / AD

The Linux-based AggreGate server has the ability to collect data from OPC servers running under Windows. This process is carried out through the IP network using the DCOM protocol, there is no longer any need to install a SCADA server and an OPC server on one computer.

AggreGate SCADA / HMI does not have the concepts of “project”, “development environment” and “execution environment”. According to her concept, a single “primary” server is used at the production facility. During the initial implementation phase, system engineers can connect to the server locally or remotely to develop displays, create PLC accounts, set up data storage, etc. After the initial configuration step is completed, the same server will be used during commissioning and in normal operation. although transferring the system to another server is possible and easy.

The unified environment allows you to make changes to the "combat" system without interrupting its work. For this you need:

- Make temporary copies of one or more system components (for example, mnemonic diagrams or alarms)

- Make changes to the copy and test them.

- Replace the original component with a successfully modified copy.

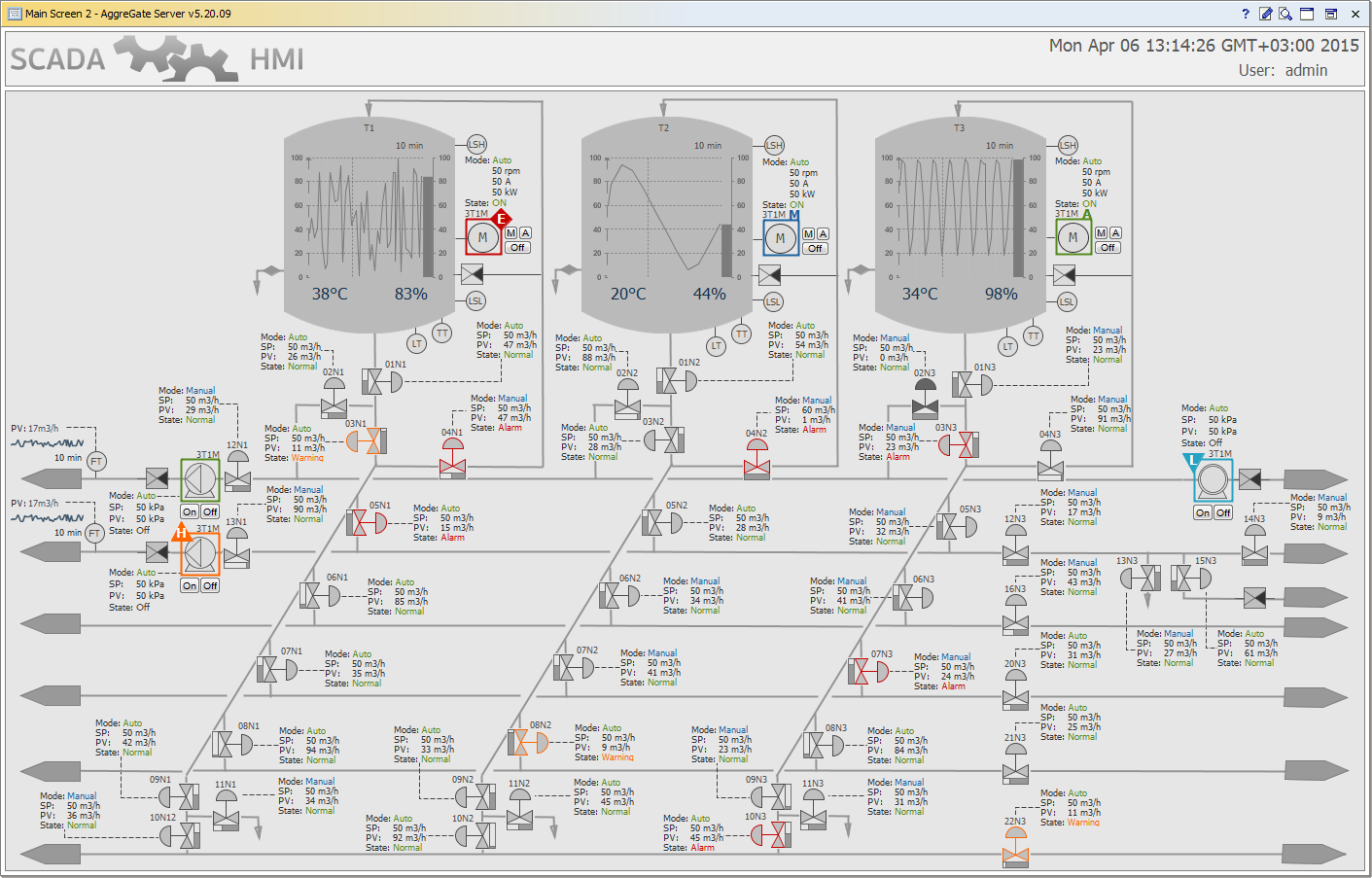

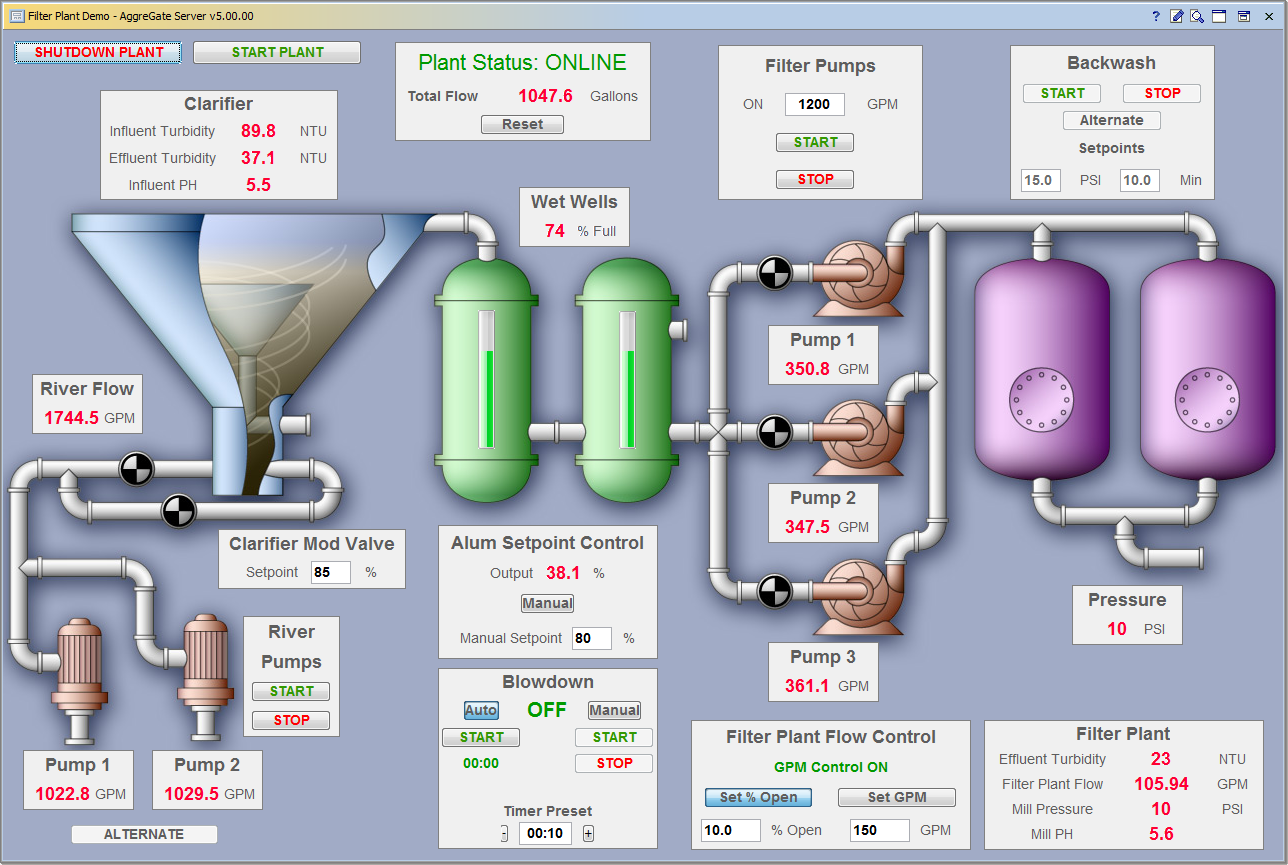

One of the most important components of any SCADA system is the mnemonic editor. The widget editor inherited from the AggreGate platform (GUI Builder) allows you to quickly draw and “animate” any mimics and human-machine interfaces containing both simple components (buttons, captions, text fields, lists, etc.) and complex (tables , multi-layered panels, tabbed panels, charts, geographic maps, dynamic SVG images, video windows, and others).

Despite its external similarity with editors typical for other systems, the AggreGate editor has one important feature. In addition to the classic absolute positioning of visual components, any panel can use a grid layout of components similar to a table in HTML. Moreover, in the case of a complex form with a multitude of nested panels (regular, multi-layered, with bookmarks, split-panels), each panel can independently use the absolute as well as the grid layout.

Grid positioning allows you to design mimics, data entry forms and toolbars that beautifully and organically adapt to any screen resolution. In the case of absolute positioning, proportional scaling of all components with increasing their height is used for adaptation, which leads to unacceptable results for almost all forms and dialogs.

Mnemonic diagrams are animated using so-called bindings that allow you to copy data between the properties of server objects and the properties of visual components in response to server events and mnemonic events. The expression language AggreGate helps to apply any operations for processing numbers, strings, dates and times, tables, etc. on the fly.

Any data that is processed by AggreGate can be used to generate reports. The expression editor and the embedded language of SQL-like queries will help to extract the necessary indicators, and the system will create the optimal template for their visual presentation. After that, you can customize it at your discretion using the report editor.

For important parameters, you can configure alarms that will be triggered when critical states of an object are detected or when certain chains of events are received. The system allows you to deliver alerts about alarms almost by any means (for example, pop-up windows, sound alerts, emails, SMS messages). Actions that are automatically triggered by an alarm can work both independently and under the control of an operator. The alarm module also supports the rest of the typical functions for the process control system - beat detection, hysteresis, prioritization, handshaking, escalation, etc.

AggreGate SCADA / HMI helps to automate the production process, display all necessary information to the call center, organize visualization, save working information to the database and create reporting documents - all that is required of SCADA. The system also allows you to quickly analyze information about the efficiency of the process and make important decisions on its optimization, that is, it partially covers the areas of competence of the software of the Manufacturing Execution System Class (MES).

In large enterprises, as a rule, several different SCADA installations are working at the same time. Each of them performs its function in a workshop under the control of a separate group of operators. The systems are logically interconnected by a specific production chain, therefore both their mutual integration and the automated transfer of performance and output indicators to the MES / ERP levels is required. In the AggreGate ecosystem, this is accomplished by sharing parts of a single data model between servers using a distributed architecture .

Often there are situations when on the same site or within the same project it is necessary to use not only SCADA, but also the IT infrastructure management system, building automation, access control and physical security management, AMR, and others in different combinations and different configurations. The use of other solutions based on AggreGate will allow implementing these functions within one installation, often even combining some modules on one server. Where does this occur in practice? For example, in data centers where it is necessary to monitor the active network equipment of the core, climate sensors, UPS, diesel generator sets, air conditioners, water cooling systems, personnel access, staff time. Another example: cell towers requiring monitoring of the parameters of radio relay equipment of the transport network and sector antennas, climate sensors, air conditioners, UPS, security sensors, and so on. In large warehouses, monitoring of personnel access, loader movement, ventilation and lighting systems is required. Practically all large objects can benefit from the combination of various control and monitoring systems.

In the following articles on SCADA we will tell you more about the unusual features of our system, how to solve various problems of the automated process control system, and interesting projects in which we participated.

Special Offer for Habrazhiteli

After the success of a similar special offer on IT monitoring, we offer the AggreGate SCADA / HMI Standard free perpetual license for 5 devices or data sources, without limiting the number of tags, to all who refer to Habr. To obtain a license, you need to send us the activation key of the “combat” server. The offer is valid until 05.05.2015. There are no conditions for obtaining a license, we hope to receive feedback.

Source: https://habr.com/ru/post/254551/

All Articles