Self resettable fuses. Myths and Reality

In the comments to my last article on how to protect against incorrect polarity of the power supply, I was repeatedly reproached for not mentioning a protection method using a self-resetting fuse. To correct this injustice, at first I just wanted to add an additional protection scheme to the article and a short explanation to it. However, I decided that the topic of self-restoring fuses deserves a separate publication. The fact is that their well-established name does not reflect the essence of things too much, and they often begin to dig into datasheets and understand the principle of operation when using such “elementary” components as a fuse, after the first batch of motherboards began to fail. Well, if not serial. So, under the cut you are waiting for an attempt to figure out what kind of animal this PolySwitch is , the original name, by the way, better reflects the essence of the device , and understand what it is eaten with , how and in what cases it makes sense to use it.

PolySwitch is a PPTC (Polymeric Positive Temperature Coefficient) device that has a positive temperature coefficient of resistance. In truth, it has much more in common with a posistor, or a bimetallic thermal cutoff, than with a fusible one, with which it is usually associated, not least due to the efforts of marketers.

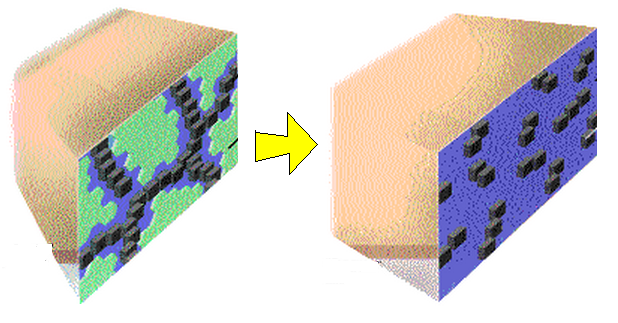

The whole trick is in the material from which our fuse is made - it is a matrix of non-conductive polymer mixed with technical carbon. In a cold state, the polymer is crystallized, and the space between the crystals is filled with carbon particles, forming many conductive chains.

')

If too much current starts to flow through the fuse, it starts to heat up, and at some point in time the polymer goes into an amorphous state, increasing in size. Because of this increase, carbon chains begin to break, which causes an increase in resistance, and the fuse heats up even faster. In the end, the resistance of the fuse increases so that it begins to noticeably limit the flow of current, thus protecting the external circuit. After the device cools down, the crystallization process takes place and the fuse again becomes an excellent conductor.

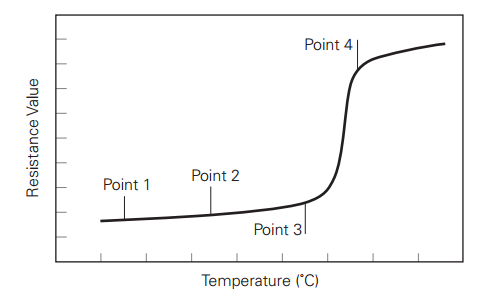

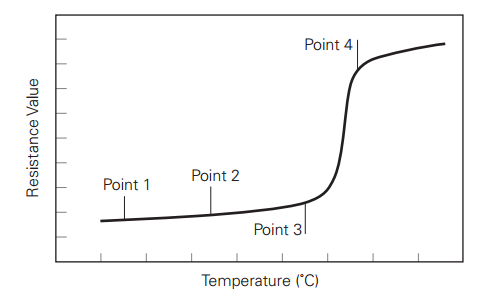

What the temperature dependence of resistance looks like is shown in the following figure.

Several characteristic points of the instrument operation are noted on the curve. Our fuse is an excellent conductor while the temperature is in the operating range of Point1 <T <Point2 (normal operating conditions). After it reaches a certain boundary value, the resistance begins to increase rapidly and in the range Point3-Point4 changes according to a law close to exponential.

It's time to move from theory to practice. Let's put together a simple protection scheme for our valuable device, so simple that, if depicted by GOST, it would just look indecent.

What will happen if an inadmissible current in excess of the tripping current occurs in the circuit? The resistance of the material from which the device is made will begin to increase. This will lead to an increase in the voltage drop across it, and hence the power dissipation equal to U * I. As a result, the temperature rises, this again leads to ... In general, an avalanche-like process of heating the device begins with a simultaneous increase in resistance. As a result, the conductivity of the device drops by orders of magnitude and this leads to the desired decrease in current in the circuit.

After the device cools down, its resistance is restored. After a while, unlike a fuse with a fusible link, our Perfect Fuse is ready for work again!

Is it perfect? Let's get armed with our modest knowledge of the physics of the device, let's try to figure it out.

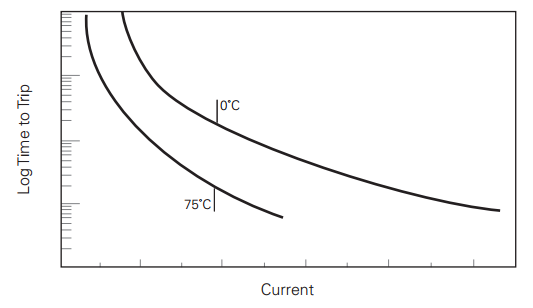

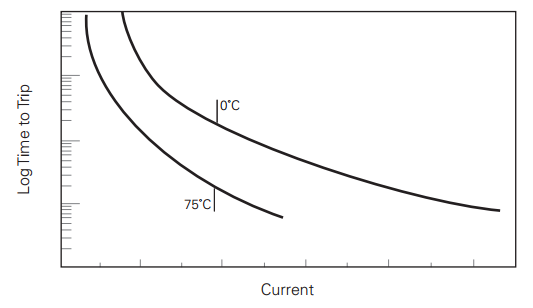

Perhaps the main problem is time. Time in general is such a substance that is very difficult to win, although many really wanted to ... But let's not talk about politics - closer to our polymers. As you probably already guessed, I lead to the fact that a change in the crystal structure of a substance is a much longer process than the rearrangement of holes with electrons, for example, in a tunnel diode. In addition, in order to heat the device to the desired temperature, it takes some time. As a result, when the current through the fuse suddenly exceeds the threshold value, its limitation does not occur at all instantly. At currents close to the threshold, this process can take several seconds, at currents close to the maximum permissible for the device, a fraction of a second. As a result, during the response time of such protection, a complex electronic device will fail, perhaps more than a dozen times. In confirmation, I give a typical graph of the response time (vertical) versus the current that triggered it (horizontal) for a hypothetical PTVC device.

Note that the graph shows for comparison two dependences taken at different ambient temperatures. I hope you still remember that the root cause of the restructuring of the crystal structure is the temperature of the material, and not the current flowing through it. This means that, other things being equal, in order to heat the device to a state of metamorphosis from a lower temperature, it is necessary to expend more energy than from a higher one, which means that this process in the first case takes more time. As a consequence, we obtain the dependence of such important device parameters as the maximum guaranteed current of normal operation and the guaranteed response current from the ambient temperature.

Before you bring the schedule appropriate to mention the main technical characteristics of this class of devices.

At the bottom of the graph is the working area of the device. What happens in the middle part depends, apparently, on the relative position of the stars in the sky, well, having been at the top of the chart, the device will go on a trip (trip), which will cause the metamorphosis of its crystalline structure and, as a result, the protection to trigger. Below is a table with data from real devices. The difference in current response depending on the temperature is impressive!

Thus, in devices designed for operation in a wide temperature range, PPTC should be used with caution. If you think that the problems of our candidate for the title of Ideal Fuse are over, then you are mistaken. He has another weakness inherent in people. After a stressful condition caused by excessive overheating, it needs to return to normal. However, the physics of the hot body is very similar to the physics of the soft. Like a man after a stroke, our fuse will never be the same again! For the sake of persuasiveness, I’ll give you a regular schedule of the rehabilitation process after the stress caused by the excess of the current flowing, which the British, well-versed, called Trip Event.and how they are not afraid of our RosPotrebnadzor?

From the graph it is clear that the recovery process can last for days, but never full. With each case of protection operation, the normal resistance of our device becomes higher and higher. After several dozen cycles, the device generally loses the ability to perform the functions assigned to it properly. Therefore you should not use them in cases when overloads are possible with high frequency.

Perhaps this would be worth it and finish, and finally begin to discuss the areas of application and circuit design solutions, but it is worth discussing some more nuances, for which we look at the main characteristics of the widespread episodes of our hero of the day.

When choosing an element that you will use in the project, pay attention to the maximum allowable operating current. If the probability of its exceeding is high, then it is worth turning to an alternative type of protection, or limit it with the help of another device. Well, like a wire resistor.

Another very important parameter is the maximum operating voltage. It is clear that when the device is in normal mode, the voltage on its contacts is very small, but after switching to protection mode, it may increase dramatically. In the recent past, this parameter was very small and was limited to dozens of volts, which made it impossible to use such fuses in high-voltage circuits, for example, to protect network power supplies.

Recently, the situation has improved and a series has appeared, designed for relatively high voltage, but note that they have very small operating currents.

Judging by the variety of devices PolySwitch offers on the market, you can use them in the devices you are developing, and in some cases even need to, but you should be very careful when choosing a particular device and how to use it.

By the way, with regard to circuit design, direct replacement of fuses on the PolySwitch works well only in the simplest cases.

For example: to be embedded in battery compartments, or to protect equipment (electric motors, activators, mounting blocks) and electrical wiring in automotive applications. Those. devices that do not fail instantly when overloaded. Especially for this there is a wide class of performance of these devices in the form of jumpers with axial leads and even drives for batteries.

In most cases, PolySwitch should be combined with faster security devices. This approach allows you to compensate for many of their shortcomings, and as a result, they are successfully used to protect computer peripherals. In telecommunications, to protect PBX, crosses, network equipment from current surges caused by line voltage and lightning. And also when working with transformers, alarms, loudspeakers, test equipment, satellite television and in many other cases.

Here is a simple example of protecting the USB port.

As an integrated approach, we consider a hypothetical scheme of the complexly-solving task of building an ultra-protected LED driver with 220V AC power.

In the first stage, a self-resetting fuse is used in conjunction with a wire resistor and a varistor. The varistor protects against sudden voltage surges, and the resistor limits the current flowing in the circuit. Without this resistor at the moment of switching on the pulsed power supply to the network, an unacceptably large current pulse may flow through the fuse, due to the charging of the input capacitors. The second stage of protection protects against incorrect polarity switching, or erroneous connection of a power source with too high a voltage. At the same time, at the time of an emergency, the inrush current is assumed by a protective TVS diode, and the PolySwitch limits the power flowing through it, preventing thermal breakdown. By the way, this bundle is so prompting during the development of circuit technology and is so widespread that it has generated a separate class of devices - PolyZen. A very successful hybrid of grassland and quivering doe.

Well, and at the output our self-resetting fuse serves to prevent short circuits, as well as in case of exit from the operating mode of the LEDs, or their driver as a result of overheating, or malfunction.

The scheme also contains elements of static protection, but this is not the topic of this article ...

In parting, let's briefly summarize:

ru.wikipedia.org

www.platan.ru

www.te.com

www.led-e.ru

www.terraelectronica.ru

as well as pieces of knowledge from my head, drawn during the implementation of various projects on the development of radio-electronic devices , training at MIET and habits instilled from the school bench, look for physical meaning throughout.

Physics of a warm body.

PolySwitch is a PPTC (Polymeric Positive Temperature Coefficient) device that has a positive temperature coefficient of resistance. In truth, it has much more in common with a posistor, or a bimetallic thermal cutoff, than with a fusible one, with which it is usually associated, not least due to the efforts of marketers.

The whole trick is in the material from which our fuse is made - it is a matrix of non-conductive polymer mixed with technical carbon. In a cold state, the polymer is crystallized, and the space between the crystals is filled with carbon particles, forming many conductive chains.

')

If too much current starts to flow through the fuse, it starts to heat up, and at some point in time the polymer goes into an amorphous state, increasing in size. Because of this increase, carbon chains begin to break, which causes an increase in resistance, and the fuse heats up even faster. In the end, the resistance of the fuse increases so that it begins to noticeably limit the flow of current, thus protecting the external circuit. After the device cools down, the crystallization process takes place and the fuse again becomes an excellent conductor.

What the temperature dependence of resistance looks like is shown in the following figure.

Several characteristic points of the instrument operation are noted on the curve. Our fuse is an excellent conductor while the temperature is in the operating range of Point1 <T <Point2 (normal operating conditions). After it reaches a certain boundary value, the resistance begins to increase rapidly and in the range Point3-Point4 changes according to a law close to exponential.

The perfect spherical horse in a vacuum.

It's time to move from theory to practice. Let's put together a simple protection scheme for our valuable device, so simple that, if depicted by GOST, it would just look indecent.

What will happen if an inadmissible current in excess of the tripping current occurs in the circuit? The resistance of the material from which the device is made will begin to increase. This will lead to an increase in the voltage drop across it, and hence the power dissipation equal to U * I. As a result, the temperature rises, this again leads to ... In general, an avalanche-like process of heating the device begins with a simultaneous increase in resistance. As a result, the conductivity of the device drops by orders of magnitude and this leads to the desired decrease in current in the circuit.

After the device cools down, its resistance is restored. After a while, unlike a fuse with a fusible link, our Perfect Fuse is ready for work again!

Is it perfect? Let's get armed with our modest knowledge of the physics of the device, let's try to figure it out.

It was smooth on paper, but they forgot about the ravines.

Perhaps the main problem is time. Time in general is such a substance that is very difficult to win, although many really wanted to ... But let's not talk about politics - closer to our polymers. As you probably already guessed, I lead to the fact that a change in the crystal structure of a substance is a much longer process than the rearrangement of holes with electrons, for example, in a tunnel diode. In addition, in order to heat the device to the desired temperature, it takes some time. As a result, when the current through the fuse suddenly exceeds the threshold value, its limitation does not occur at all instantly. At currents close to the threshold, this process can take several seconds, at currents close to the maximum permissible for the device, a fraction of a second. As a result, during the response time of such protection, a complex electronic device will fail, perhaps more than a dozen times. In confirmation, I give a typical graph of the response time (vertical) versus the current that triggered it (horizontal) for a hypothetical PTVC device.

Note that the graph shows for comparison two dependences taken at different ambient temperatures. I hope you still remember that the root cause of the restructuring of the crystal structure is the temperature of the material, and not the current flowing through it. This means that, other things being equal, in order to heat the device to a state of metamorphosis from a lower temperature, it is necessary to expend more energy than from a higher one, which means that this process in the first case takes more time. As a consequence, we obtain the dependence of such important device parameters as the maximum guaranteed current of normal operation and the guaranteed response current from the ambient temperature.

Before you bring the schedule appropriate to mention the main technical characteristics of this class of devices.

- The maximum operating voltage Vmax is the maximum allowable voltage that the device can withstand without breaking at rated current.

- The maximum allowed current Imax is the maximum current that the device can withstand without destruction.

- The rated operating current Ihold is the maximum current that the device can conduct without tripping, i.e. without opening the load circuit.

- The minimum response current of Itrip is the minimum current through the device, leading to a transition from a conductive state to a non-conductive state, i.e. to trigger.

- The initial resistance Rmin, Rmax is the resistance of the device before the first response (when received from the manufacturer).

At the bottom of the graph is the working area of the device. What happens in the middle part depends, apparently, on the relative position of the stars in the sky, well, having been at the top of the chart, the device will go on a trip (trip), which will cause the metamorphosis of its crystalline structure and, as a result, the protection to trigger. Below is a table with data from real devices. The difference in current response depending on the temperature is impressive!

Thus, in devices designed for operation in a wide temperature range, PPTC should be used with caution. If you think that the problems of our candidate for the title of Ideal Fuse are over, then you are mistaken. He has another weakness inherent in people. After a stressful condition caused by excessive overheating, it needs to return to normal. However, the physics of the hot body is very similar to the physics of the soft. Like a man after a stroke, our fuse will never be the same again! For the sake of persuasiveness, I’ll give you a regular schedule of the rehabilitation process after the stress caused by the excess of the current flowing, which the British, well-versed, called Trip Event.

From the graph it is clear that the recovery process can last for days, but never full. With each case of protection operation, the normal resistance of our device becomes higher and higher. After several dozen cycles, the device generally loses the ability to perform the functions assigned to it properly. Therefore you should not use them in cases when overloads are possible with high frequency.

Perhaps this would be worth it and finish, and finally begin to discuss the areas of application and circuit design solutions, but it is worth discussing some more nuances, for which we look at the main characteristics of the widespread episodes of our hero of the day.

When choosing an element that you will use in the project, pay attention to the maximum allowable operating current. If the probability of its exceeding is high, then it is worth turning to an alternative type of protection, or limit it with the help of another device. Well, like a wire resistor.

Another very important parameter is the maximum operating voltage. It is clear that when the device is in normal mode, the voltage on its contacts is very small, but after switching to protection mode, it may increase dramatically. In the recent past, this parameter was very small and was limited to dozens of volts, which made it impossible to use such fuses in high-voltage circuits, for example, to protect network power supplies.

Recently, the situation has improved and a series has appeared, designed for relatively high voltage, but note that they have very small operating currents.

Cross the grass and the quivering doe.

Judging by the variety of devices PolySwitch offers on the market, you can use them in the devices you are developing, and in some cases even need to, but you should be very careful when choosing a particular device and how to use it.

By the way, with regard to circuit design, direct replacement of fuses on the PolySwitch works well only in the simplest cases.

For example: to be embedded in battery compartments, or to protect equipment (electric motors, activators, mounting blocks) and electrical wiring in automotive applications. Those. devices that do not fail instantly when overloaded. Especially for this there is a wide class of performance of these devices in the form of jumpers with axial leads and even drives for batteries.

In most cases, PolySwitch should be combined with faster security devices. This approach allows you to compensate for many of their shortcomings, and as a result, they are successfully used to protect computer peripherals. In telecommunications, to protect PBX, crosses, network equipment from current surges caused by line voltage and lightning. And also when working with transformers, alarms, loudspeakers, test equipment, satellite television and in many other cases.

Here is a simple example of protecting the USB port.

As an integrated approach, we consider a hypothetical scheme of the complexly-solving task of building an ultra-protected LED driver with 220V AC power.

In the first stage, a self-resetting fuse is used in conjunction with a wire resistor and a varistor. The varistor protects against sudden voltage surges, and the resistor limits the current flowing in the circuit. Without this resistor at the moment of switching on the pulsed power supply to the network, an unacceptably large current pulse may flow through the fuse, due to the charging of the input capacitors. The second stage of protection protects against incorrect polarity switching, or erroneous connection of a power source with too high a voltage. At the same time, at the time of an emergency, the inrush current is assumed by a protective TVS diode, and the PolySwitch limits the power flowing through it, preventing thermal breakdown. By the way, this bundle is so prompting during the development of circuit technology and is so widespread that it has generated a separate class of devices - PolyZen. A very successful hybrid of grassland and quivering doe.

Well, and at the output our self-resetting fuse serves to prevent short circuits, as well as in case of exit from the operating mode of the LEDs, or their driver as a result of overheating, or malfunction.

The scheme also contains elements of static protection, but this is not the topic of this article ...

Forewarned is forearmed.

In parting, let's briefly summarize:

- Polyswitch is not a fuse.

- When applying Polyswitch, it is necessary to ensure that the current that passes through it even in the case of an emergency does not exceed the permissible one. It is necessary to use current limiters. In some cases, such elements as connecting wires (car wiring) or internal resistance of batteries / accumulators can serve as a limiter. In such cases, the simplest scheme of inclusion in the chain break is possible.

- Polyswitch is a very inertial device, it is not suitable for the protection of circuits sensitive to short current surges. In these cases, it must be used in conjunction with other elements of protection - zener diodes, suppressors, varistors, arresters, etc., which does not relieve you from the need to take measures that limit the maximum current in the circuit.

- Applying Polyswitch should be monitored so that the voltage on it does not exceed the permissible. High voltage may appear after the device triggers when its resistance increases.

- It should be remembered that the number of actuations of the device is limited. After each operation, its characteristics deteriorate. It is not suitable for protecting circuits in which overloading is commonplace.

- And finally, do not forget that the current of operation of this device essentially depends on the ambient temperature. The higher it is, the smaller it is. If your device is designed to operate in an extended temperature range or periodically operates in an area of elevated temperatures (a powerful power supply or low-frequency amplifier), this can lead to a false positive.

PS

Especially to once again not to offend the feelings of the user kacang I want to note that when preparing the article materials from the following sources were used:ru.wikipedia.org

www.platan.ru

www.te.com

www.led-e.ru

www.terraelectronica.ru

as well as pieces of knowledge from my head, drawn during the implementation of various projects on the development of radio-electronic devices , training at MIET and habits instilled from the school bench, look for physical meaning throughout.

Source: https://habr.com/ru/post/254339/

All Articles