Green power for base stations and just up to 2 KW - three years of experience with wind turbines, solar generation + geo-probe

Installation of the wind generator

Wind generator, container with batteries, geo probe and base station in Samara

About 3 years ago we began an experiment to provide base stations with energy from on-site sources. After six months, it became clear that the geo-probe for base stations is a very useful thing in the middle lane, the solar panels of the Zelenograd plant show themselves remarkably, but the main problem is not in obtaining energy, but in its transformations and accumulation.

')

I'll tell you about broken windmills and what we understood in three years, and a unique geo-probe for cooling a rack with communication equipment.

Experiment

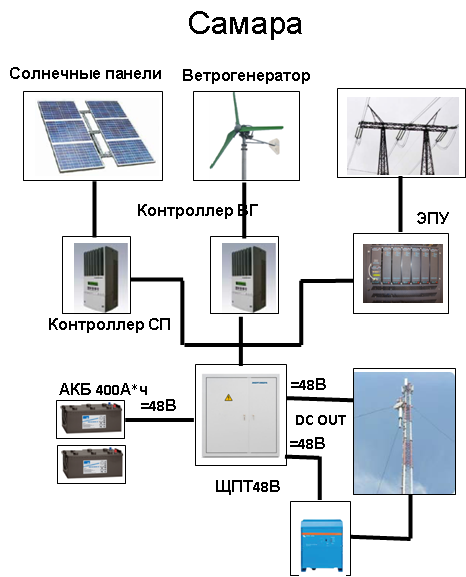

Test base stations are located in Samara and Murmansk. In Samara, the base station operates from alternative energy and is insured by the usual industrial input from the “city”. In the event of a power cut from our installation, the base station switches to the city network and continues to work. The second object on the coast of the Barents Sea was immediately made autonomous, the city network was not there. In the event of a power failure, a DGU was installed with a daily supply of fuel and a controller allowing it to be started remotely.

In Samara, we also drilled 25 meters down and set a geo probe, which allows us to obtain a good temperature difference with the surface.

According to the results of three years, we can say that everything works quite stable, but it took many, many rakes, experience and improvements to reach this stability. I will immediately say about the payback - in Samara, the system goes into plus five years in comparison with the work of the DSU, in Murmansk much faster - in 3 years.

Equipment

Let me remind you, we put sensors on objects and collected data, plus we used statistics. The results obtained were a little different, followed by practice, but uncritically. It turned out that: in Samara, the average daily consumption of 19.2 kWh, average annual wind speed of 5.2 m / s, the arrival of solar radiation 4.5 kWh per square meter per day. In Murmanka, the average daily consumption is 26.4 kWh, the average annual wind speed is 6.5 m / s, the arrival of solar radiation is 3 kWh per square meter per day.

In Samara, we installed a 4 kW wind turbine and 6 solar panels of 200 watts each. The base station was on a hill, the winds in the region are on average quite good. The first problem was with the Israeli wind turbine, which, apparently, was designed for a special Israeli wind. In general, he was very smart and functional, but did not give out the stated characteristics. But the Dutch windmill was simple and reliable as a Kalashnikov assault rifle (and with a roughly comparable amount of automation, a “weather vane” with a passive wind orientation system), but it produced exactly what was promised. All the time, until one of the blades literally recently threw a nearly hurricane atypical for the region. The same windmills are used in Africa, and there they have proven themselves well even in the conditions of the mass of abrasives in the air.

In Samara, horizontal-axis wind turbine, rated wind speed - 12 m / s, rated power - 4 kW, rotor diameter - 4.2 m, operating range up to 55 m / s, efficiency 43%, average daily output up to 12.5 kW * h

Plain, we are on the dais

In Murmansk, there is also a horizontal axial wind turbine, rated 12 m / s, nominal 4 kW, rotor diameter more - 5 m, working speed range up to 60 m / s, efficiency 45%, average daily output of 38.6 kW * h.

Sea coast in Murmansk, installation site

In Murmansk, the wind, in Samara - the sun. The windmill begins to give sufficient current only when the wind is strong. There is almost a cubic dependence on wind speed, so it’s really good only on cloudy days when there is no sun, and what the wind is. But without this in any way - on such days you would not otherwise charge.

The base station itself consumes about 500 watts, on average, the same takes the cooling system. Below, at a depth of approximately between 30 and 50 meters, it is warm and charming: there, regardless of the season, the temperature is kept from +4 to +8. If you dig a kilometer, you can meet quite hot places, but such geozond makes for data centers in Iceland, for example. We have a reverse system - we lower the water down, wait until it becomes about +10, then raise up to cool the equipment. Instead of 500 watts per conditioner, we got 15 watts per pump. Cooling capacity - 2600 W, power consumption - 35 W (with additional systems), well 25 meters.

Water from geosunda

In Murmanka with a geo-probe, it is impossible to stick in - the ground is rocky, and such a solution will not be included in the series. Even in Samara, we have two drills stuck until everything was done. In Murmansk, such a good wind on the coast, which bent the mast of one of the test wind generators at the very beginning of the project.

But a lot of good support for the mast generator

Here is the mount

System optimization

First, the base station equipment consumes 48 V. In the first stage, we crashed before entering the base station container. It turned out like this: we give out direct current, we need to convert it to 220 for a standard BS input interface (designed for the city network), and then get 48 again to power the equipment. Still, it was necessary to climb into the typical configuration of the base station - we saved about 9% on these redundant conversions. True, 220V on the BS is still needed - it is monitoring equipment and other auxiliary things, but they consume little. In order to work this way, you need to install the equipment in one container (thermobox) from the base station itself - initially, on that base station, our container was separate.

Secondly, it was necessary to dump excess energy in certain circumstances. We assembled small heaters outside the container in order to warm the ambient air in the event that there is no need to recharge the battery.

Murmansk, delivery of equipment, visible container BS

Thirdly, it turned out that one more PETN is needed inside the container. The fact is that once the temperature inside has dropped to +5. The telecom rack is good, but the batteries (our and UPS BS) are not very good. But this is better than heating up to +35, when batteries age on the eyes, and with each new degree, the service life is right. So, it is more efficient to spend energy on heating a thermobox than to lose capacity due to the cold.

Automation panel, solar panel controller and inverter

Fourth, we put the first solar panels at the rate of "how much will fit on the container." Now the serial projects will include not 6, but 12 pieces - they are not very expensive, but the profit is very, very good from such a doubling. By the way, the batteries themselves from Zelenograd showed themselves perfectly - no complaints to them from the first day, the output current is stable and has not been falling for 3 years.

Experienced installation

Fifthly, the work with the charge controller turned out to be very important. A more complex algorithm for calculating the optimal charge current and the optimal use of energy from a windmill and batteries in different modes made it possible to clearly find the optimal point along the charge response curve. We constantly corrected it on the basis of the data collected, and now we have very good heuristics, which is applicable in any region except the extreme north (but there it is a matter of a month or two to get the necessary data).

Branch box for parallel ballast loading

Fifth, our bottleneck is the battery. It is the most expensive, in particular, because it requires regular replacement every few years. The first salt battery of increased capacity with molten salt inside was ideal, but fantastically expensive. The series will include the usual lead elements. And here there is another important point - on the BS and so there are batteries, these are UPS units, which are enough for several hours of the station broadcasting. Our 800-ampere-hour battery, available on the BS array, is 500 ampere-hours. At one of the BSs, the operator suggested combining our batteries and them in order to get an array of larger capacity. So usually with different types of batteries do not (this reduces the life), but the operator, and it was important for us to obtain experimental data from increasing the capacity. Connected. We will introduce such batteries into the series so that the battery bank is common. After the rectifiers are our controllers - they make a selection of power to our batteries and batteries BS. It also gave optimization in the event that all the same because of bad weather it was necessary to start DGU.

Operator's shield

Sixth, we immediately made a good monitoring. He demanded minor improvements, which was important - to put a new control contactor DGU to put the diesel in manual mode, start and stop. Initially, it was often necessary to change the thresholds for starting a diesel engine at low battery voltage, then, again, gained the necessary experience. As a result, the sensors are on all sources and consumers, we see how much comes from solar panels, what is the output from the wind generator, the voltage on all parts of the circuit, the consumption. There are weather sensors (temperature-wind), two cameras for external and internal surveillance (it is convenient to look at the rack through the camera).

The same operator's shield

Seventh, in Murmansk, instead of a geosonde, there was a free cooling system. With it arose complexity. The problem is that the hot air valve was in the container wall on the opposite side of the cold fence. So, with strong winds, this valve (looking like a curtain) simply arched and opened in the opposite direction. Foreigners had no such experience. And our domestic manufacturer has already promised another tricky valve that will not behave this way, now we are mounting it.

Wind generator controller

Now the battery replacement is on the way, let's try another option.

Series

Total for the series we see this scheme:

- Wind power complex with a mast, for some regions it is a Dutch-made wind turbine with a passive orientation;

- Solar energy complex on 12 panels;

- Geothermal cooling system, if the ground allows;

- Natural cooling system;

- Power distribution and management;

- Energy storage system 800 ampere-hours minimum;

- container block;

- Video surveillance system;

- Monitoring system;

- SCADA dispatching system.

Routine work:

- Twice a year, a visual inspection, removal of dust and checking the tension of the stretch of the mast.

- Once a year, lowering the mast of the wind generator, drawing the threaded connections, spinning the cable of the wind generator, checking the batteries.

BS in Murmanka, lifting the mast of a wind generator

results

Our solutions really liked the network operations. The fact is that the number of trips has decreased 10-12 times. Previously, we went to refuel the DGU as on duty. On average, 90–95% of the time in our diet, 5–10% of diesel can be obtained at almost any BS. Accordingly, maintenance of a diesel engine is also done less often - it has a TTO for engine hours. By the way, the operators especially liked the fact that when the power lines dropped next to, “our” BS did not leave the network.

The last year of tests after optimization, the results. Samara: reduction of BS consumption by 30%, autonomy ratio - 81%, use of alternative sources - 60%. Murmansk: reduction in BS consumption by 15%, autonomy ratio - 100% (lucky with the weather, it could be about 97%), utilization rate from alternative sources - 100%.

I will answer theoretical questions in the comments, and practical for specifically your object - in the mail PVashkevitch@croc.ru.

Source: https://habr.com/ru/post/254043/

All Articles