Self assembly or purchase of ready equipment for design. 3d printer. Part 1

Hi, Habr!

I recently published a post about the constructor Hwatohod. Now we are preparing for the training of people of different ages in design and electronics, in our coworking center. To do this, you also need to pick up equipment.

')

According to the task set by the management, the construction equipment must meet the following requirements:

- cost no more than 30 thousand rubles

- open architecture (software and hardware)

- easy maintenance and availability of parts

- operational safety

- the possibility of manufacturing on it complex products

- quick payback

I previously had over 1.5 years experience in the field of 3D printing. Therefore, the choice was made in favor of a 3D printer.

For the design and electronics classes, a DIY kit (Do It Yorself), an MC5 3D printer by MasterCit, was created, which was created on the basis of one of the Russian manufacturers of 3D printers:

The set for assembly, is created tosell it to collect and train. It will be used to create self-parts (RepRap concept), ancillary equipment and electronics training.

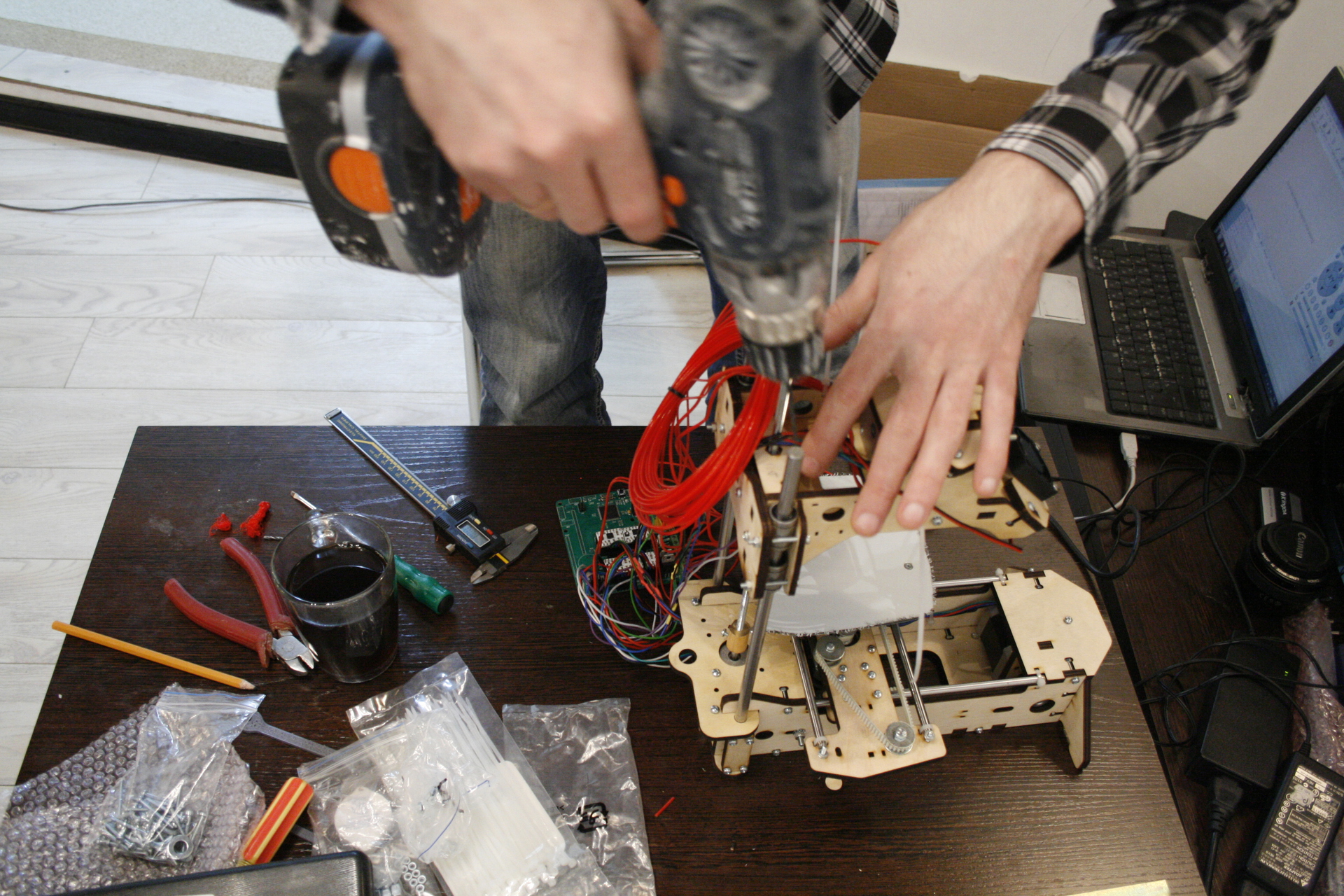

The amount of coffee consumed can be calculated in the time-lapse assembly process, which took only 12 hours:

The whole process is quite trivial, if the weight of the screwdriver in your hand does not scare you. There is quite clear, Russian-language instructions . Before starting the assembly process, it is better to mark parts made of plywood with a pencil for easy perception:

I recommend to wear linear bearings immediately on the axle to avoid misalignment, loss of balls and nerves:

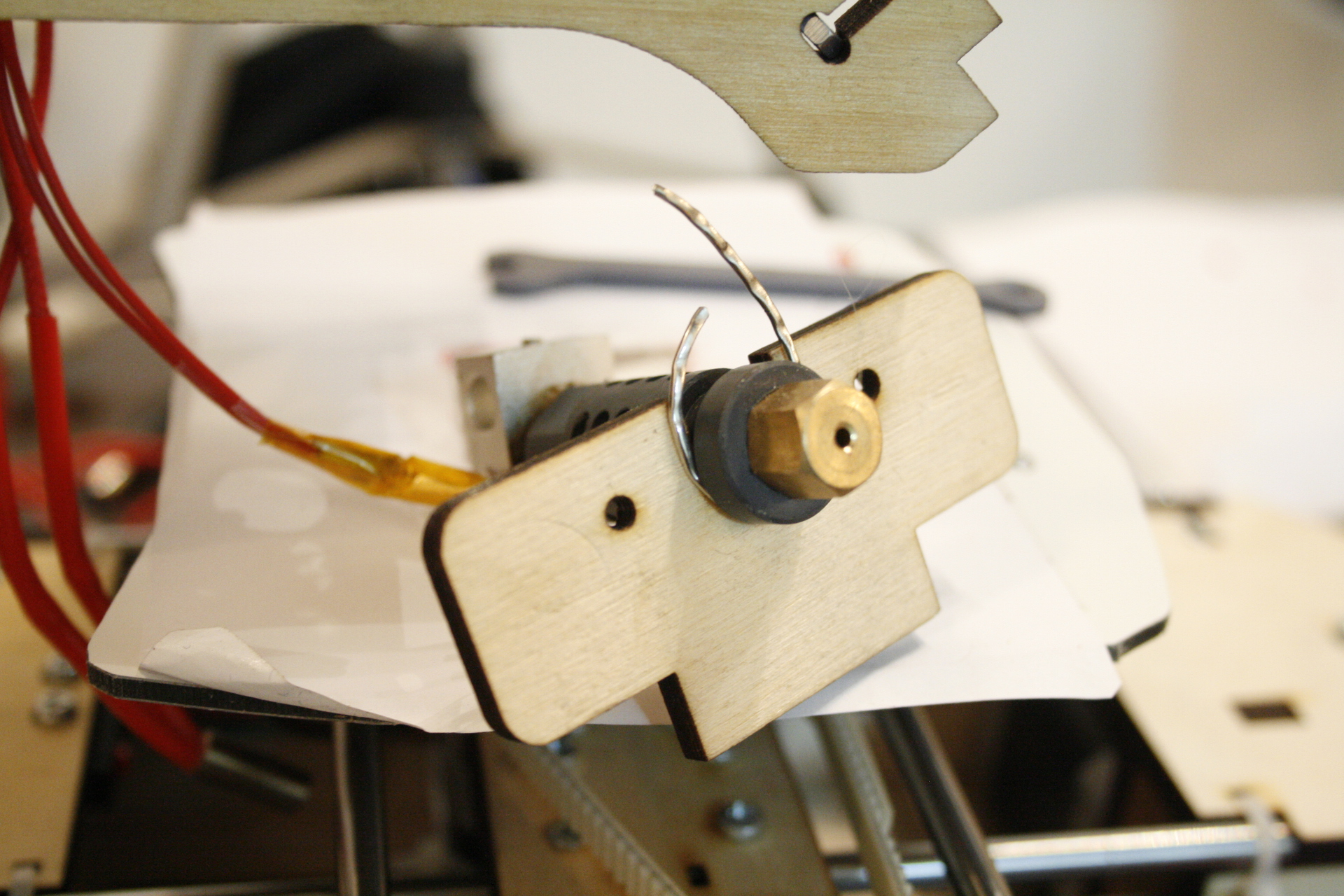

When assembling the printhead assembly in attaching the J-Head extruder to the body, there was a controversial point. The instructions need to put the washer M8, tried different options, but the head J-Head still dangling:

J-Head printhead:

A temporary solution was found using a ring from a laser pointer, which was planted instead of the specified washer:

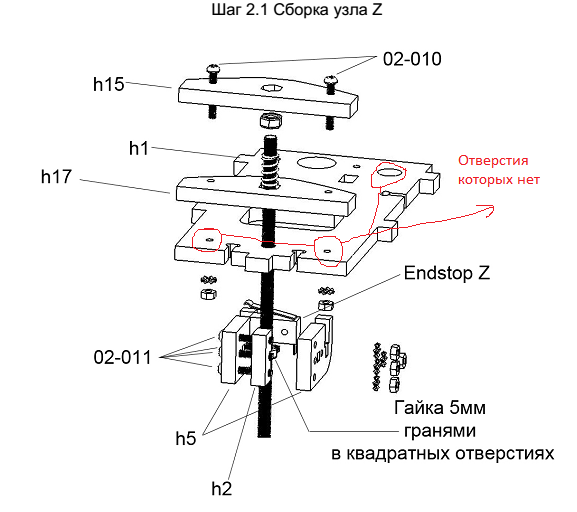

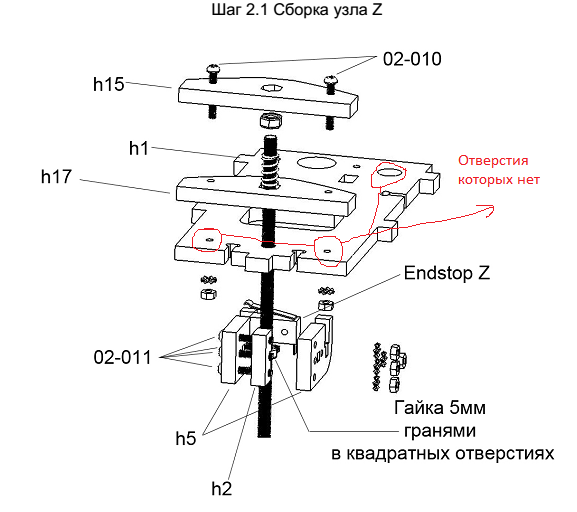

Also, I did not manage to find the indicated holes in the details for fixing the nut on the stud of the vertical Z axis and for the wires from the print head:

But the process does not stop. With the help of alaser drill and drills 3 mm and 8 mm, the missing 3 holes are easily made:

It remains to tighten the belts on theabdomen XY axes and you can connect the electronics.

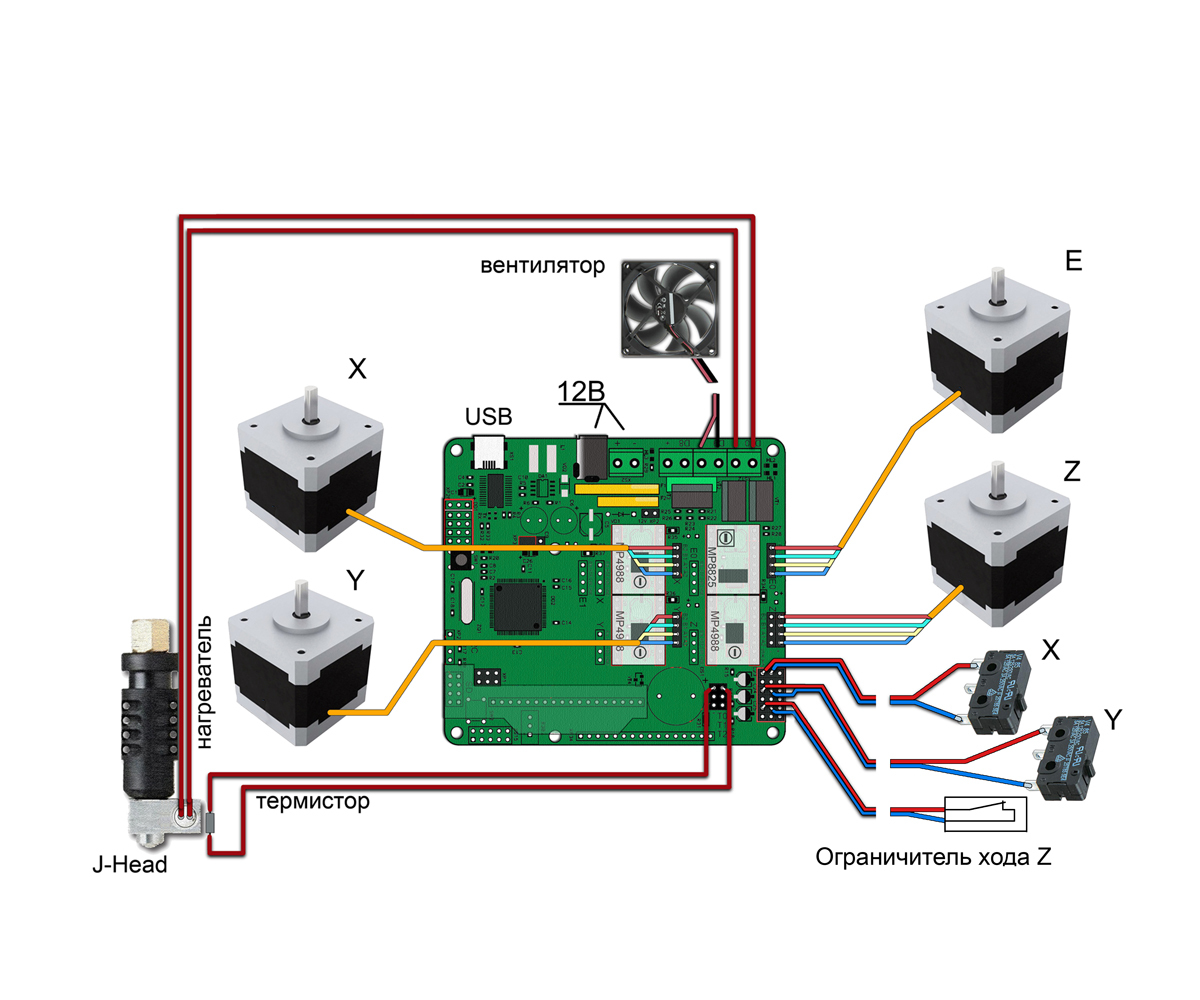

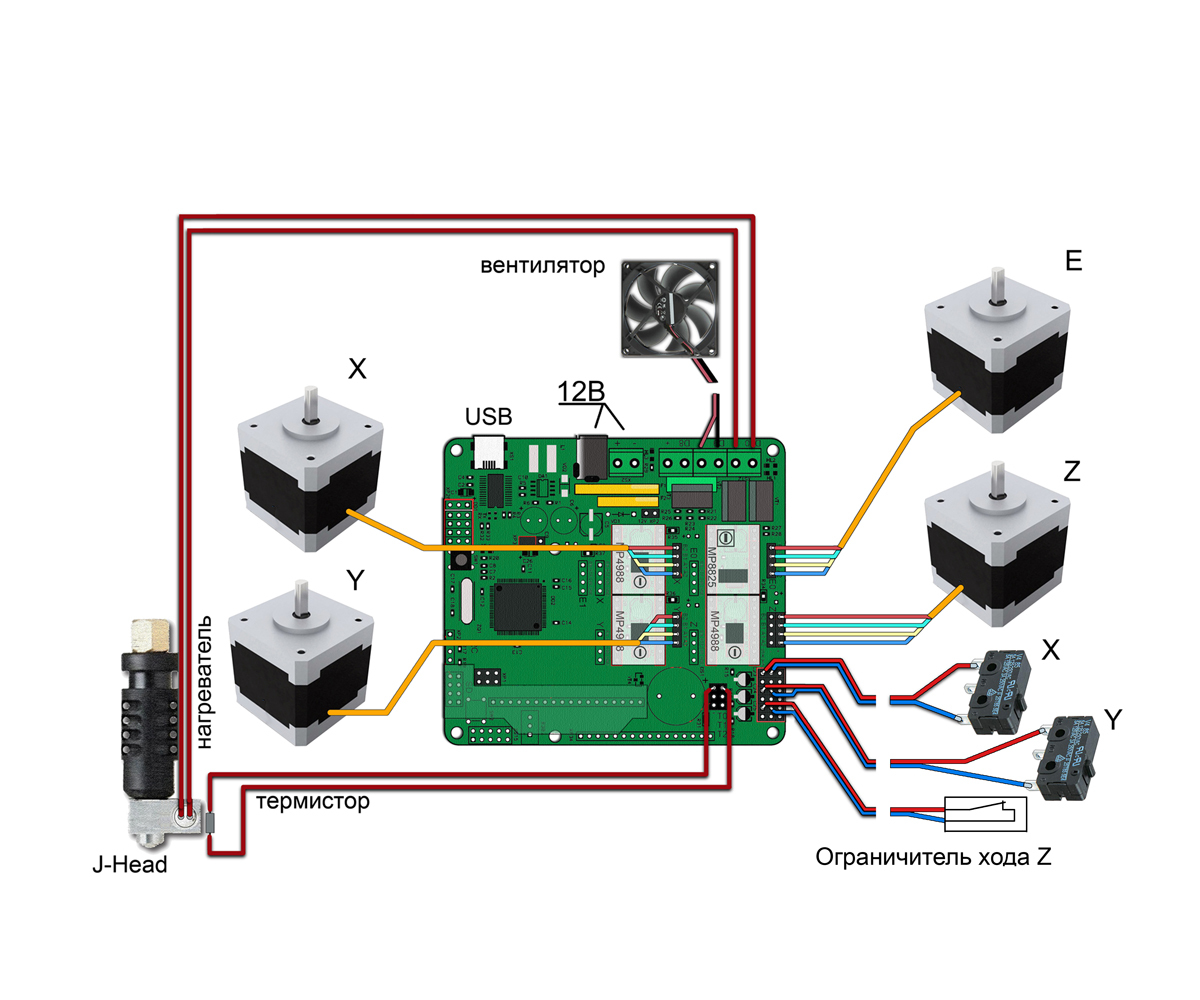

All wires and pins are marked. Open the scheme and stick where it is shown:

Pay attention to the driver of the extruder engine. I had all 4 drivers A4988 (MP4988), so they should be oriented with a trimmer in one direction, as shown in the diagram. Resistors do not need to turn.

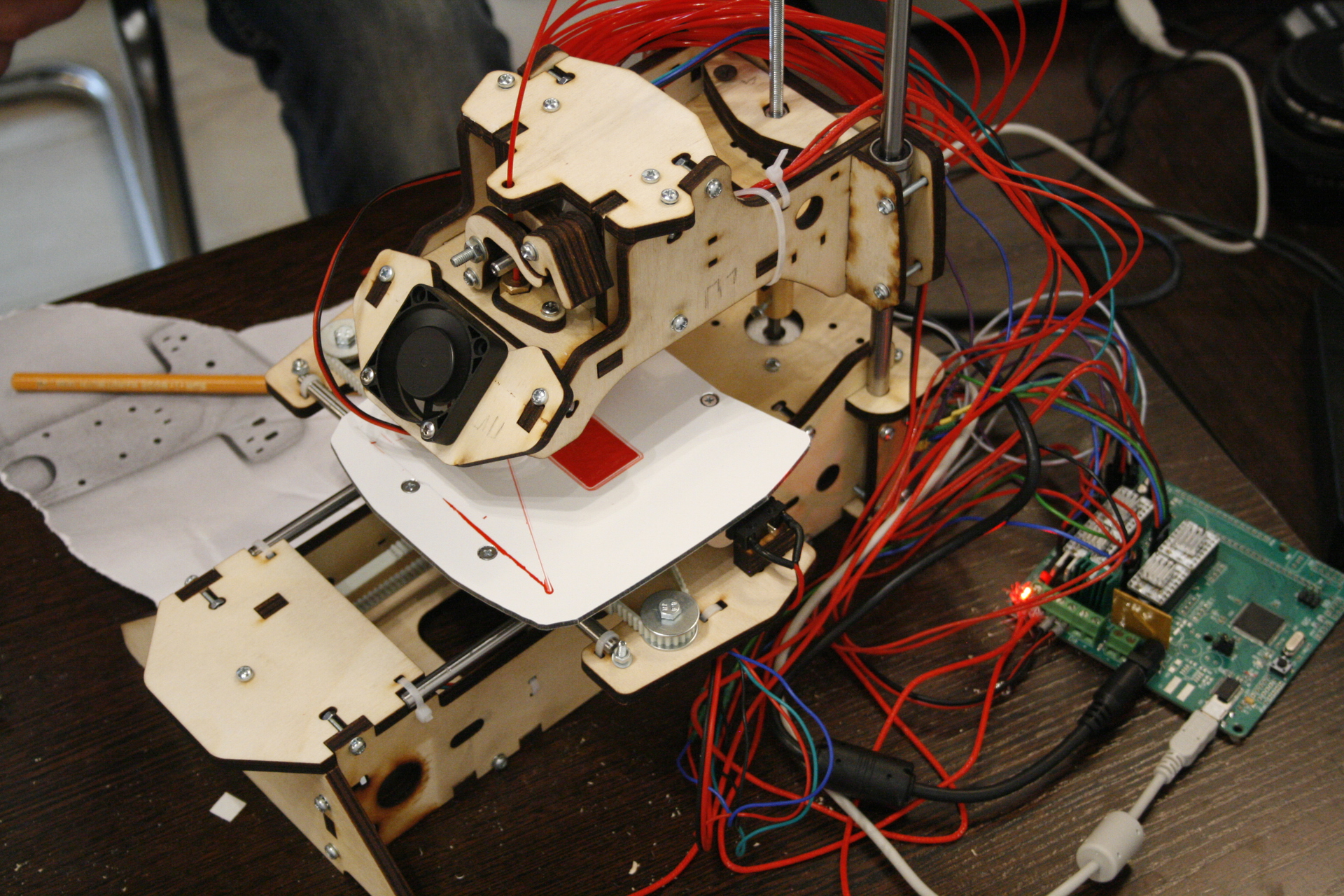

View assembled 3D printer:

Wires hide and fasten immediately - I do not advise. Be patient a little.

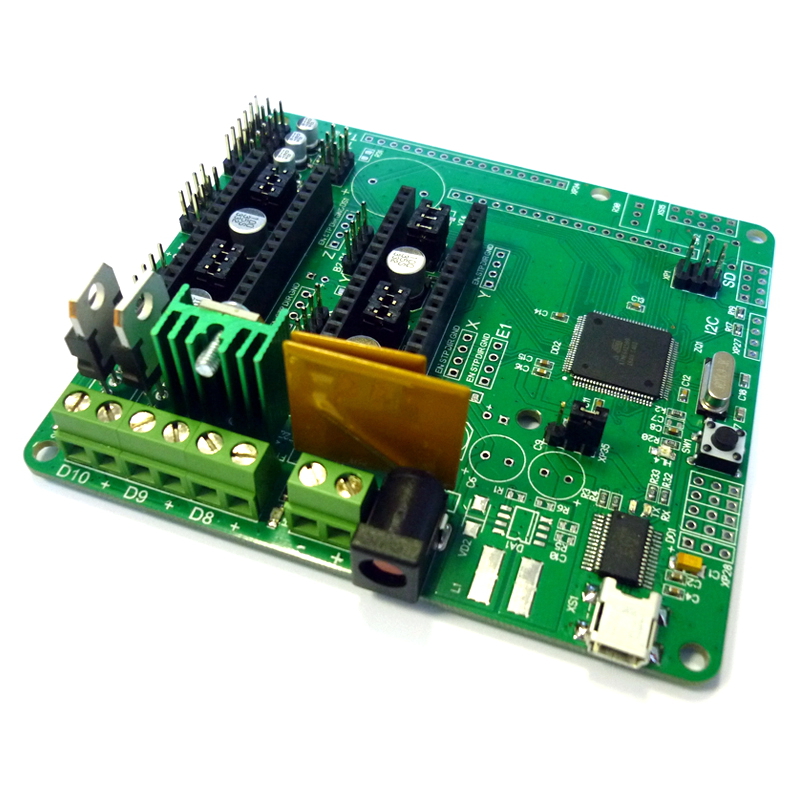

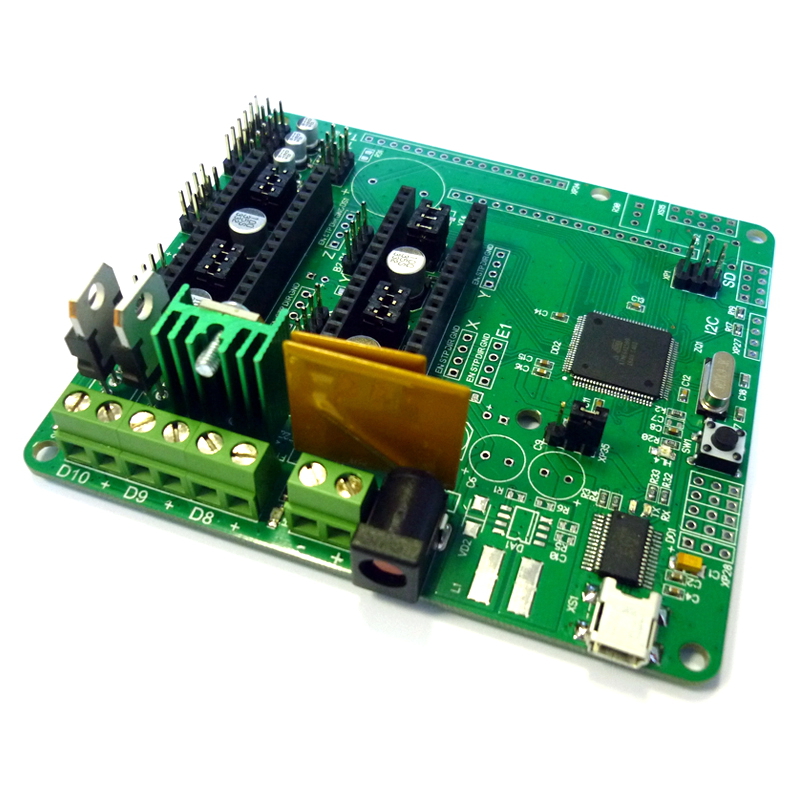

The control board uses an open hardware and software architecture: Mastertronics (it was the one that came with it) is a hybrid of the Arduino MEGA 2560 and shield for 3D printers Ramps 1.4:

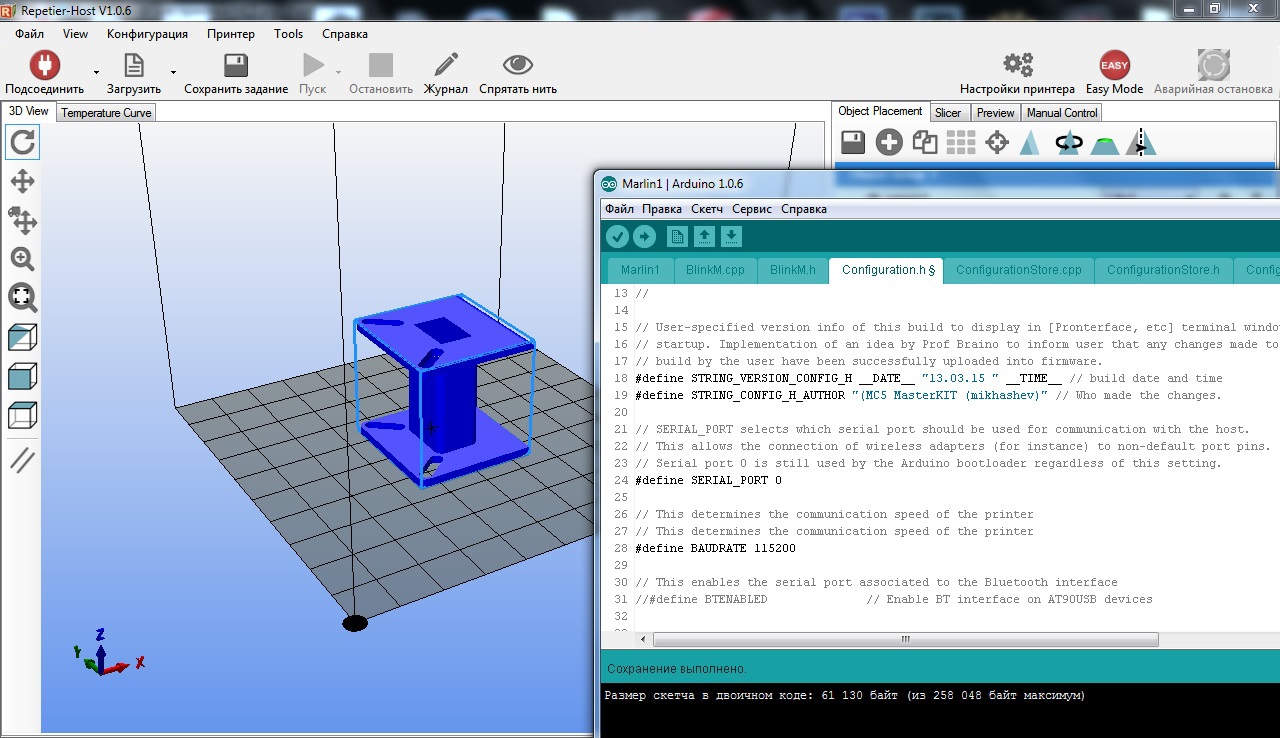

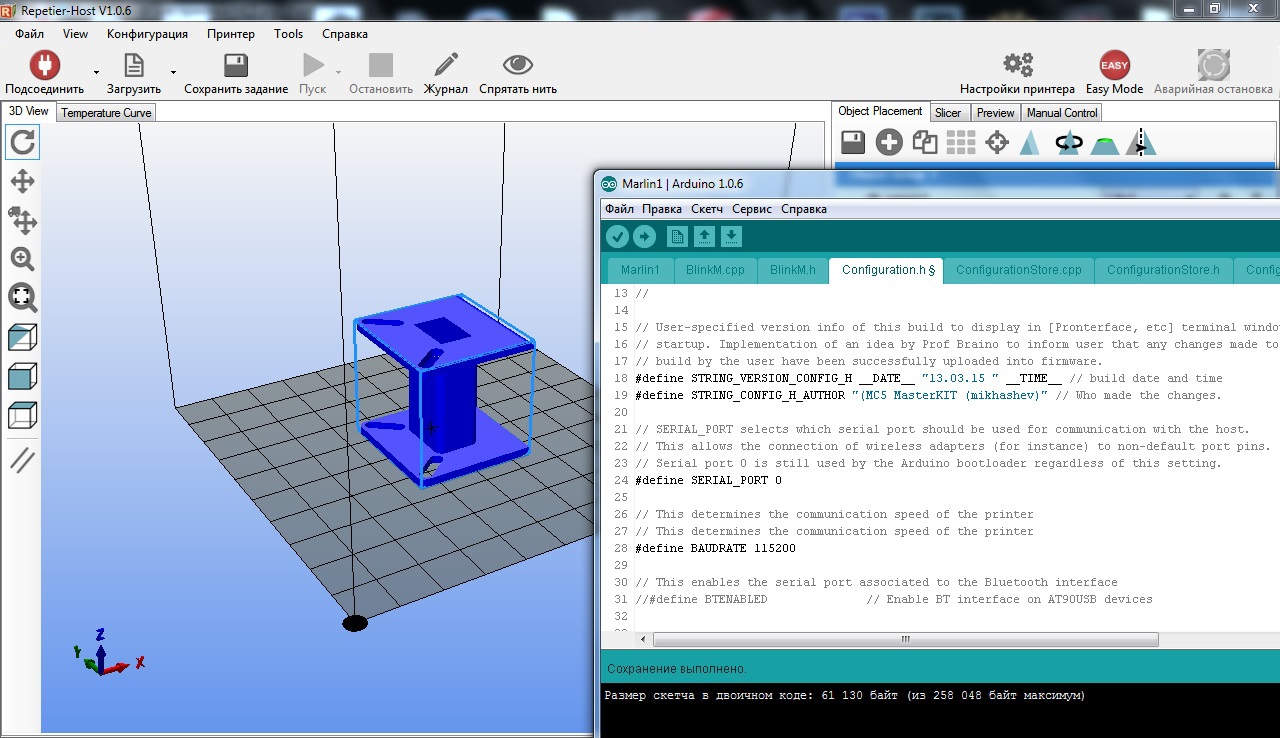

Therefore, feel free to downloadopen source free software: Repetier-host (for connecting a PC with a 3D printer control card) and Arduino IDE (for dividing the microcontroller firmware code). The subtleties of setting this software will be discussed in the second part:

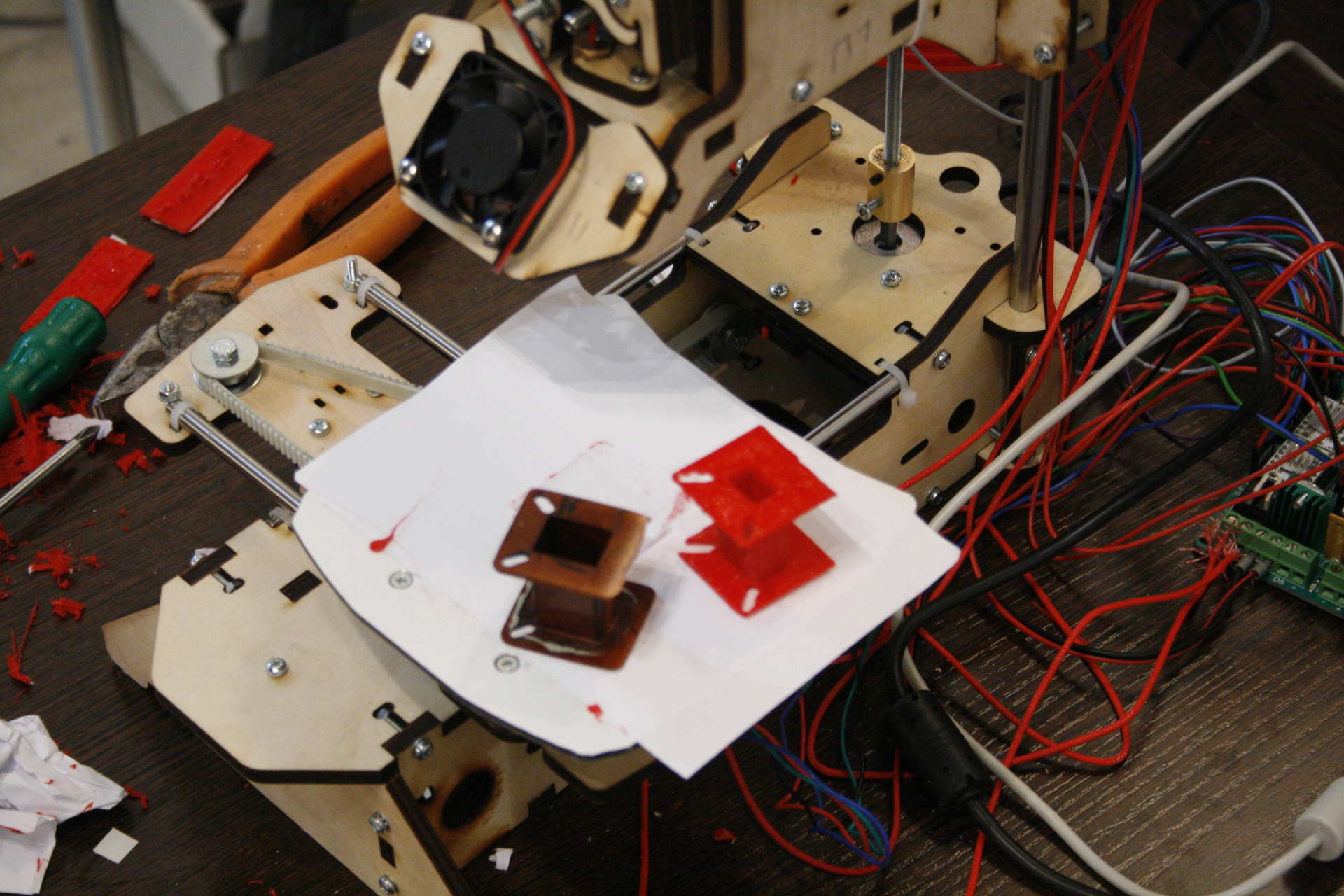

After setting up the software, you can print:

Especially for Habr Master Kit provided the promotional code HABR, which gives a discount of 7% on any order on the website 3d.masterkit.ru

I recently published a post about the constructor Hwatohod. Now we are preparing for the training of people of different ages in design and electronics, in our coworking center. To do this, you also need to pick up equipment.

')

According to the task set by the management, the construction equipment must meet the following requirements:

- cost no more than 30 thousand rubles

- open architecture (software and hardware)

- easy maintenance and availability of parts

- operational safety

- the possibility of manufacturing on it complex products

- quick payback

I previously had over 1.5 years experience in the field of 3D printing. Therefore, the choice was made in favor of a 3D printer.

For the design and electronics classes, a DIY kit (Do It Yorself), an MC5 3D printer by MasterCit, was created, which was created on the basis of one of the Russian manufacturers of 3D printers:

The set for assembly, is created to

The amount of coffee consumed can be calculated in the time-lapse assembly process, which took only 12 hours:

The whole process is quite trivial, if the weight of the screwdriver in your hand does not scare you. There is quite clear, Russian-language instructions . Before starting the assembly process, it is better to mark parts made of plywood with a pencil for easy perception:

I recommend to wear linear bearings immediately on the axle to avoid misalignment, loss of balls and nerves:

When assembling the printhead assembly in attaching the J-Head extruder to the body, there was a controversial point. The instructions need to put the washer M8, tried different options, but the head J-Head still dangling:

J-Head printhead:

A temporary solution was found using a ring from a laser pointer, which was planted instead of the specified washer:

Also, I did not manage to find the indicated holes in the details for fixing the nut on the stud of the vertical Z axis and for the wires from the print head:

But the process does not stop. With the help of a

It remains to tighten the belts on the

All wires and pins are marked. Open the scheme and stick where it is shown:

Pay attention to the driver of the extruder engine. I had all 4 drivers A4988 (MP4988), so they should be oriented with a trimmer in one direction, as shown in the diagram. Resistors do not need to turn.

View assembled 3D printer:

Wires hide and fasten immediately - I do not advise. Be patient a little.

The control board uses an open hardware and software architecture: Mastertronics (it was the one that came with it) is a hybrid of the Arduino MEGA 2560 and shield for 3D printers Ramps 1.4:

Therefore, feel free to download

After setting up the software, you can print:

Especially for Habr Master Kit provided the promotional code HABR, which gives a discount of 7% on any order on the website 3d.masterkit.ru

Source: https://habr.com/ru/post/253240/

All Articles