How we provided communication in the cities of the Arctic Circle

The Arctic Circle is low temperatures and permafrost underfoot. The climate in these regions is sharply continental and severe. But here you need a connection. For example, in Salekhard and Labytnangi.

The harsh winter climate in Salekhard

We have upgraded mobile communications equipment in these cities and launched a new core network. A mobile switch across the Ob River was carried out and subscribers were “teleported” to new equipment. I was responsible for the organizational and technical parts of this northern project.

')

Salekhard is a center of geological exploration expeditions and at the same time a city of developed fishing industry. The city is located on the Ob River and has its own river port. Despite its remoteness from the “big” land, the city is the regional center of the Yamalo-Nenets Autonomous District (Yamal-Nenets Autonomous Okrug or Yamal). In winter, the temperature here can drop to –40 degrees. The population of Salekhard is 47.9 thousand people. Next to this city, on the other bank of the Ob River, just 16 km away is another small town of Labytnangi, which has a population of 26,700. About a third of the population of these two northern cities are subscribers of our company.

Any organization of communications in the YNAO region is not easy: the average annual temperatures are always negative, and from late November to mid-February the polar night dominates over a large area of the region. At this time of year, the sun rises briefly above the horizon and sets again, which does not contribute to the construction of new communication facilities. However, it was in these places that we started not just building a remote cell tower with base stations “on board”, but decided to upgrade the backbone mobile network to switch voice traffic.

The network upgrade work has received the status of a special project in the company. It was the construction of a full-fledged 3G / 2G media gateway (what it is - more on that later), which is an integral part of our large switching system in the YaNAO region. By the way, to ensure the reliability of our networks, we have separate switching systems in each regional center, called mobile switches. But for Yamal it was necessary to deploy a more “flexible” system.

At first, it was not even easy to “see” where exactly the distant backbone network was designed: the operator technical conditions in the regions are similar everywhere and are based on the centralized principle of scaling the basic architecture. We “tasted” the design issues for Yamal a little later, when the project was “overgrown” with details. The main specificity we encountered was that the costs of deploying the “removed” core network needed to be carefully and carefully planned, since the issue constantly bordered on the profitability of the modernization being undertaken.

Region YNAO, geographical location of Salekhard and Labytnangi

Historically, our old 2G mobile switchboard serving subscribers in Salekhard and Labytnangi did not have the ability to configure new subscriber services, the platform simply did not allow this. In particular, the service of mobile number portability between operators did not “rise”, and this was only the tip of the iceberg from a number of restrictions.

Further more. The old machine hall, in which the 2G traffic of these cities of Yamal commuted, no longer had the opportunity for modernization, and there were no ways to expand it. The problem was that the racks of the new 3G / 2G media gate and all its modern “strapping” had nowhere else to be installed in the existing room. In recent years, our mobile networks in the regions began to grow so quickly with load, and the construction of base stations (BS) that “carry” subscriber traffic reached the level of a streamlined “conveyor” that, after only a few years, in such relatively small cities, it was again necessary to expand capacities networks for voice traffic. Moreover, the old machine hall was here in the small town of Labytnangi, not even in the larger Salekhard, and for good, in order to expand further, it was necessary to “move” across the river closer to the regional center and create a new mobile switching center there. All the staff of the company's branch, including technical, was located in Salekhard. It was necessary to somehow cut this "Gordian knot".

To further clarify the terminology, it is worth noting that the carrier-grade mobile switchboard is a large computer connecting subscriber calls and managing all 3G and 2G base stations providing cellular coverage in the region. The switch is the “heart” of the operator’s mobile network, a key element of its core architecture in the region. For 2G networks, the switch is called MSC (Mobile Switching Center), for 3G networks - MSS / MGW (Mobile Soft Switching / Media Gateway). The 3G switch is a universal network node and allows you to simultaneously process voice traffic of base stations of both 3G and 2G. (At present, 2G MSC switches have been decommissioned from all regional VimpelCom networks from Kaliningrad to Kamchatka and are no longer used, they are obsolete.) The principle of operation of a mobile switch is based on automatically switching tens of thousands of mobile voice calls from subscribers to each other. This “smart” multiprocessor machine is capable of optimally compressing and passing voice traffic of subscribers through the operator’s channels.

An important for our task feature of the new 3G / 2G switches was that they are manufactured according to the principle of a distributed architecture. This circumstance makes it possible to maximally effectively “wrap up” the local voice traffic of subscribers in small cities, by means of the geographical “pullout” of a separate 3G / 2G MGW (i.e. voice media gateway), and connect local controllers of the base station chains to it. In essence, now, by installing a media gateway, you can build a “piece” of a mobile switchboard in remote cities closer to subscribers, and manage voice traffic using MSS “brains” on the “big earth”. Subscribers who call their friends and relatives, by “wrapping up” voice calls on the spot, decrease both the connection time and voice delays during a call, which significantly improves the quality of voice perception. It is the possibility of implementing the distributed architecture of new switches that allowed us to design in Salekhard the installation of a switch component, without loading a large regional switch MSS / MGW, and dock local voice traffic in place.

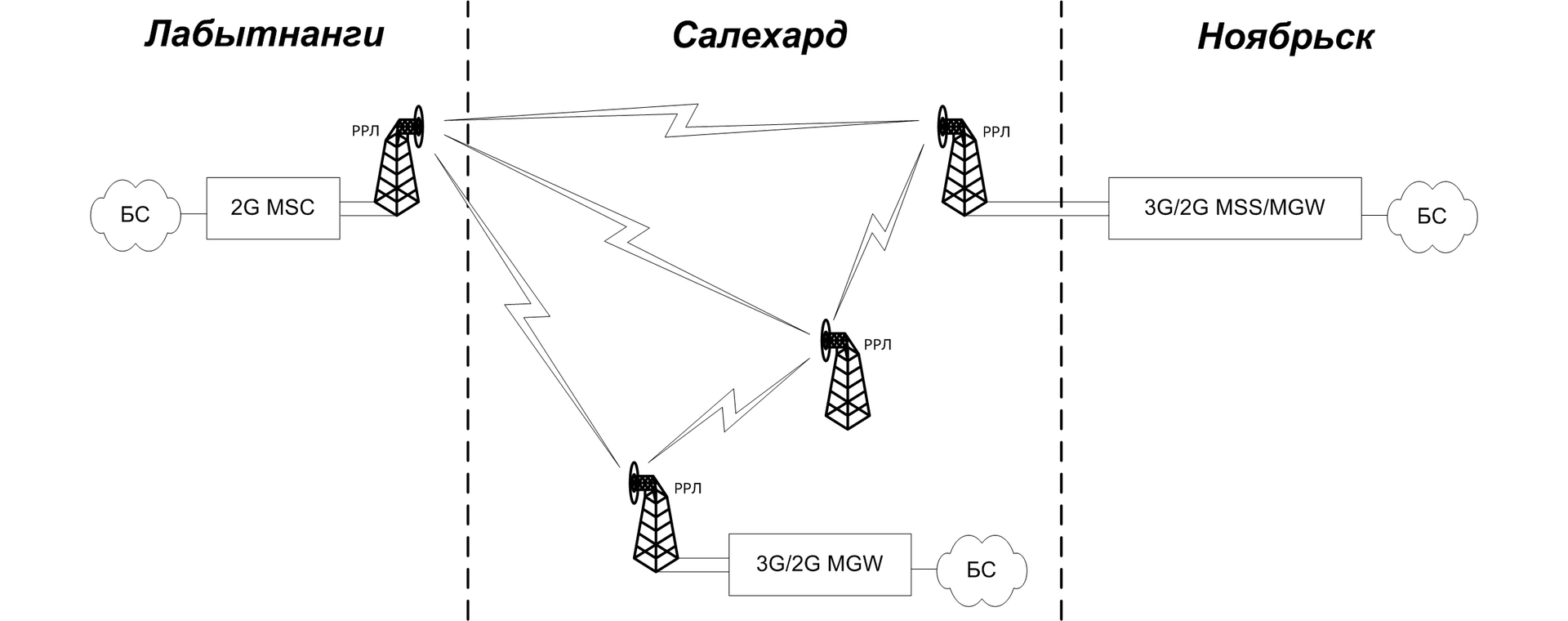

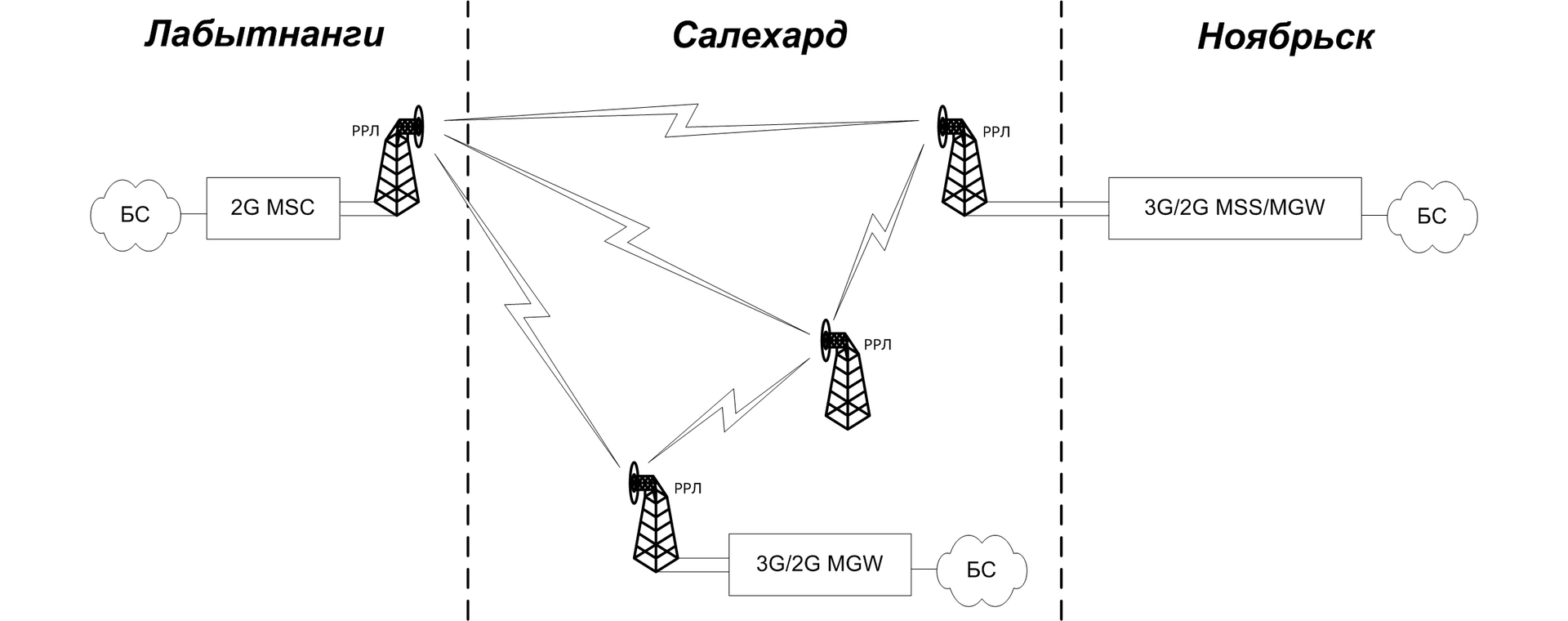

Labytnangi-Salekhard-Noyabrsk network diagram before modernization

The “big land” means, first of all, the “core” and the corresponding “strapping” of the large MSS / MGW switchboard of the YNAO region, which we have in the larger city of Noyabrsk (and hereinafter also refers to the remote support of colleagues from neighboring regional centers). According to our idea, now between November and Salekhard, separated by 600 km, the architecture allows only signal exchange to control subscriber traffic, but not voice traffic itself, which makes it possible to save on renting expensive transport channels to the northern cities of Yamal by reducing the consumed leased band.

Returning to the special project itself, one important fact should be noted. Our situation with the theoretical search for architecture for Yamal was finally pushed into practice by the fact that the supplier (or vendor) of the mobile switchboard serving subscribers in Salekhard and Labytnangi removed the 2G switching equipment of our type from production, and after some time intended to complete its technical support. And as is usually the case in such cases, all possible risks unexpectedly increased, and decisive actions needed to be taken. The planning phase of the project ended overnight. Further, we spent already on the implementation of the conceived idea of the optimal “wrapping” of voice traffic in local conditions in Salekhard.

Having developed and coordinated with the colleagues of the working group the order of interaction for all designed subsystems, we began preparations for construction. The first thing we did was to go to Salekhard “in the fields” to collect information about the places for the possible placement of a new machine hall for a media gateway.

After reviewing a lot of buildings and spending a lot of time, we made a disappointing conclusion. We didn’t have any of the premises that could be converted into a machine room for carrier-class equipment. The price of renting a little bit of capital sites with all communications was rather high for us and unjustified. An important item of expenses indirectly invested in the price of the site was the cost of electricity in the city, taking into account two independent energy inputs and further expansion of the capacities of our 2G and 3G coverage (and in the future, 4G). And of course the difficult moment of choice was that we could not “pull” all our channels and communications to the points studied. This was a real “ambush” of a project that had not yet begun.

Having considered all possible options, we agreed that for these northern cities it was easier to build the machine hall in the “clean field from scratch” at the point we need according to our operator conditions. Easy to say, but not easy to do. After all, it was about the permafrost and harsh northern climate, and the "open field" meant that the basis for the realization of the machine room was to take the form of a sealed container on the ground. To it, first of all, as was noted, two independent power inputs were to be “pulled”, and in the second - duplicated transport channels of communication over air radio-relay lines (RRL) were “thrown”. Essentially, for the local 3G / 2G MGW media gateway, it remained to build its own “house”, reserved in every sense, equipping it with operator workplaces.

Having prepared all the necessary equipment racks in the drawing of the future machine hall, taking into account the expansion, we determined the appropriate dimensions of the container and chose a place, starting construction on our own. Construction work at the site was logically divided into 2 stages. Stage 1 - the construction of the main container, equipping it with life support systems for the machine room, connecting the video surveillance system, at the same time building a transformer substation in a separate container. Stage 2 - installation and installation of telecom equipment of the 3G / 2G core network, commissioning and integration of MGW, connecting it with the “core” of the large MSS / MGW switch of Noyabrsk, as well as with the old switchboard in Labytnangi, multivendor testing of all subsystems with all, verification of mobile services, and preparation of the entire system for pilot commercial operation.

The selection of construction contractors for our Wishlist was made through a tender. Permafrost is not a joke. Then, together with the contractors, in the spring we sent an order for the manufacture of the container to one of the steelworks in the Urals and began to wait for the end of production. Its impressive dimensions and weight were not typical for the standard proposed boxes for base stations, so the production was carried out "to order".

Piling and preparation of the foundation for the container

After an anxious wait, the container was received from the factory and delivered to the site. Immediately began assembling our "home". In general, it can be said that the construction of hardware boxes in the conditions of the north is a responsible and very laborious business. And our container for the new 3G / 2G media gateway was built in accordance with all the technological stages of building hardware boxes for these edges. We have not experienced any insurmountable difficulties, for example with soils, in this part of the project, the construction of the “house” was completed without force majeure.

The machine hall container turned out reliable, with enhanced thermal and waterproofing. In it were installed air conditioners and air heating system, operating in automatic mode. The working temperature in the container is constantly maintained at about 22x degrees, the full climate control works. Present fire sensors, flooding and a full range of monitoring, which allows you to detect cases of problems. In addition, a separate transformer substation with the necessary distribution devices was assembled at the site in a separate container.

Transformer substation switchgear

According to the results of the 1st construction stage with a small symbolic “housewarming”, we launched the machine building container into operation, and it was already possible to “live” on the site. Then it was necessary to accelerate with the 2nd stage, as we began to press the cold.

Simultaneously with the container fabrication, all the necessary 3G / 2G telecom equipment for the core network was purchased, and it was already waiting for us at the regional warehouse. But the delayed terms of manufacturing and delivering our "home" from the factory, as well as assembling it by contractors, and in addition - launching our own transformer substation at the site, shifted the deadlines for the 1st project phase to late autumn. Short summer and autumn ended, snow began to fall on the Arctic Circle, and it was important to “catch up” the implementation of the 2nd stage: delivery and tests of the purchased switching equipment.

Our experience with the north led us to the point that the dispatch of carrier equipment by rail from the warehouse that we have in Tyumen had to be done at least in a month, and better still earlier. The train with the racks could reach our place in the Arctic Circle only through Syktyvkar, passing at the same time bypassing 4 more regions, and reaching only the railway station in Labytnangi. There were no further paths, and the Ob River blocked the road to our site. The railway from Labytnangi to Salekhard does not yet exist, bridges too. Given this circumstance, we tried more than a month to send the equipment to the transport company to Labytnangi, promptly unload it from the railway upon arrival, and head for the ferry across the river. If only we knew then that planning the logistics on the “big” land so much in advance, we would be very much weakened by the deteriorating weather forecast.

We lacked only 5 hours on the last day of this route in order to ferry all our numerous boxes and boxes. By the way, it was an opportunity for people to cross the river; in the off-season, a hovercraft goes, like a city bus, but for freight transport the road across the river no longer existed. The river at once "cut off" all possible attempts to get to the remote site.

Salekhard – Labytnangi winter ferry across the Ob River

It happens sometimes. We stuffed our "parcel" to both northern cities with all the necessary "iron" and even with a reserve; we carried it by rail for a whole month, as we didn’t send such cargo by airmail and didn’t have time just a bit. And there was nothing left but to wait “for the weather by the sea” for three weeks, until a safe road again opened across the Ob River for the passage of cargo vehicles, but now on the winter ice called the winter road. But survived it. However, who would have thought then that this chain of timing and the arrival of prolonged negative temperatures to the north would only help us with the full launch of the new 3G / 2G media gateway in harsh climatic conditions.

As soon as all the necessary boxes with the telecom hardware were delivered to the machine hall, representatives of the vendors of the new equipment were successively “abandoned” on the site, and the work “boiled” at an accelerated pace. Engineers were notified of the work in advance, and on the appointed days and hours they flew to us at Salekhard one by one, without disturbing or delaying each other, waiting for their integration dates, which was very valuable. Together with our technical colleagues, vendors and their contractors docked various subsystems of the core network, exchanged experiences, tested and retested, and soon the work gained the necessary pace. The system began to grow together "on the eyes."

Installation of telecom equipment in the new machine room

Testing of the new 3G / 2G media gateway MGW was carried out on two test 3G and 2G base stations assembled here in a container, but connected to test antennas via attenuators. Having configured the necessary thresholds for the signal levels of the base stations, we confidently passed all the setup tests of the 3G-2G-3G mobile transitions on test smartphones. Similarly, all MSS – MGW signaling tests were performed between cities, then mobile services tests. As a result, all the necessary network elements of the core network and traffic management systems “went up” at the machine hall. And naturally, backup batteries were also checked and put into operation. Our 2nd construction stage at the site gradually came to an end and the tested backbone network was finally ready to receive traffic.

Battery backup power

It is worth noting here that the specificity of project management in Yamal was that we constantly lacked technical specialists in these northern cities. We had to search for engineers from neighboring regions specializing in similar mobile subsystems, and ask colleagues to be sent north to help vendors and local technical colleagues to optimally configure the hardware for the uniform requirements of a large company network. «», «», . « », «» .

, 3G/2G MGW. . , , «» « », «» . .

( ): , MGW, 3G

, , . , , . , . : , , , . , ? .

«», -, , «» . , 600 . , 2G: SMS- MMS-, , , -, - . , «» .

: , , , , , .. . .

, «» . «» - «», 3G 2G, , , , , --. .

,

, , - . - , , . . «», , , «» . «».

, «» , , . , , , , «» , . , , .

: – , —

«» «». , 3G 2G . , , . «».

, , «» . 3G/2G «» , , . «» , «» «». . , «» .

«» «» , . - , . . , «», , . 3G/2G MGW .

, – «» . , . «» . 3G/2G MGW «» . , , «» .

. , . «», , «» , . , « », .

3G/2G MGW . «» , . 3G 2G , 3G/2G MGW, «» .

« » . «» . , . - , «» .

3G/2G . «» , . .

–40 , , . , . .

, , : , , , «», . , . - «» . .

The harsh winter climate in Salekhard

We have upgraded mobile communications equipment in these cities and launched a new core network. A mobile switch across the Ob River was carried out and subscribers were “teleported” to new equipment. I was responsible for the organizational and technical parts of this northern project.

')

Background question

Salekhard is a center of geological exploration expeditions and at the same time a city of developed fishing industry. The city is located on the Ob River and has its own river port. Despite its remoteness from the “big” land, the city is the regional center of the Yamalo-Nenets Autonomous District (Yamal-Nenets Autonomous Okrug or Yamal). In winter, the temperature here can drop to –40 degrees. The population of Salekhard is 47.9 thousand people. Next to this city, on the other bank of the Ob River, just 16 km away is another small town of Labytnangi, which has a population of 26,700. About a third of the population of these two northern cities are subscribers of our company.

Any organization of communications in the YNAO region is not easy: the average annual temperatures are always negative, and from late November to mid-February the polar night dominates over a large area of the region. At this time of year, the sun rises briefly above the horizon and sets again, which does not contribute to the construction of new communication facilities. However, it was in these places that we started not just building a remote cell tower with base stations “on board”, but decided to upgrade the backbone mobile network to switch voice traffic.

The network upgrade work has received the status of a special project in the company. It was the construction of a full-fledged 3G / 2G media gateway (what it is - more on that later), which is an integral part of our large switching system in the YaNAO region. By the way, to ensure the reliability of our networks, we have separate switching systems in each regional center, called mobile switches. But for Yamal it was necessary to deploy a more “flexible” system.

At first, it was not even easy to “see” where exactly the distant backbone network was designed: the operator technical conditions in the regions are similar everywhere and are based on the centralized principle of scaling the basic architecture. We “tasted” the design issues for Yamal a little later, when the project was “overgrown” with details. The main specificity we encountered was that the costs of deploying the “removed” core network needed to be carefully and carefully planned, since the issue constantly bordered on the profitability of the modernization being undertaken.

Region YNAO, geographical location of Salekhard and Labytnangi

Historically, our old 2G mobile switchboard serving subscribers in Salekhard and Labytnangi did not have the ability to configure new subscriber services, the platform simply did not allow this. In particular, the service of mobile number portability between operators did not “rise”, and this was only the tip of the iceberg from a number of restrictions.

Further more. The old machine hall, in which the 2G traffic of these cities of Yamal commuted, no longer had the opportunity for modernization, and there were no ways to expand it. The problem was that the racks of the new 3G / 2G media gate and all its modern “strapping” had nowhere else to be installed in the existing room. In recent years, our mobile networks in the regions began to grow so quickly with load, and the construction of base stations (BS) that “carry” subscriber traffic reached the level of a streamlined “conveyor” that, after only a few years, in such relatively small cities, it was again necessary to expand capacities networks for voice traffic. Moreover, the old machine hall was here in the small town of Labytnangi, not even in the larger Salekhard, and for good, in order to expand further, it was necessary to “move” across the river closer to the regional center and create a new mobile switching center there. All the staff of the company's branch, including technical, was located in Salekhard. It was necessary to somehow cut this "Gordian knot".

To further clarify the terminology, it is worth noting that the carrier-grade mobile switchboard is a large computer connecting subscriber calls and managing all 3G and 2G base stations providing cellular coverage in the region. The switch is the “heart” of the operator’s mobile network, a key element of its core architecture in the region. For 2G networks, the switch is called MSC (Mobile Switching Center), for 3G networks - MSS / MGW (Mobile Soft Switching / Media Gateway). The 3G switch is a universal network node and allows you to simultaneously process voice traffic of base stations of both 3G and 2G. (At present, 2G MSC switches have been decommissioned from all regional VimpelCom networks from Kaliningrad to Kamchatka and are no longer used, they are obsolete.) The principle of operation of a mobile switch is based on automatically switching tens of thousands of mobile voice calls from subscribers to each other. This “smart” multiprocessor machine is capable of optimally compressing and passing voice traffic of subscribers through the operator’s channels.

An important for our task feature of the new 3G / 2G switches was that they are manufactured according to the principle of a distributed architecture. This circumstance makes it possible to maximally effectively “wrap up” the local voice traffic of subscribers in small cities, by means of the geographical “pullout” of a separate 3G / 2G MGW (i.e. voice media gateway), and connect local controllers of the base station chains to it. In essence, now, by installing a media gateway, you can build a “piece” of a mobile switchboard in remote cities closer to subscribers, and manage voice traffic using MSS “brains” on the “big earth”. Subscribers who call their friends and relatives, by “wrapping up” voice calls on the spot, decrease both the connection time and voice delays during a call, which significantly improves the quality of voice perception. It is the possibility of implementing the distributed architecture of new switches that allowed us to design in Salekhard the installation of a switch component, without loading a large regional switch MSS / MGW, and dock local voice traffic in place.

Labytnangi-Salekhard-Noyabrsk network diagram before modernization

The “big land” means, first of all, the “core” and the corresponding “strapping” of the large MSS / MGW switchboard of the YNAO region, which we have in the larger city of Noyabrsk (and hereinafter also refers to the remote support of colleagues from neighboring regional centers). According to our idea, now between November and Salekhard, separated by 600 km, the architecture allows only signal exchange to control subscriber traffic, but not voice traffic itself, which makes it possible to save on renting expensive transport channels to the northern cities of Yamal by reducing the consumed leased band.

Returning to the special project itself, one important fact should be noted. Our situation with the theoretical search for architecture for Yamal was finally pushed into practice by the fact that the supplier (or vendor) of the mobile switchboard serving subscribers in Salekhard and Labytnangi removed the 2G switching equipment of our type from production, and after some time intended to complete its technical support. And as is usually the case in such cases, all possible risks unexpectedly increased, and decisive actions needed to be taken. The planning phase of the project ended overnight. Further, we spent already on the implementation of the conceived idea of the optimal “wrapping” of voice traffic in local conditions in Salekhard.

Construction of the machine room and equipment setup

Having developed and coordinated with the colleagues of the working group the order of interaction for all designed subsystems, we began preparations for construction. The first thing we did was to go to Salekhard “in the fields” to collect information about the places for the possible placement of a new machine hall for a media gateway.

After reviewing a lot of buildings and spending a lot of time, we made a disappointing conclusion. We didn’t have any of the premises that could be converted into a machine room for carrier-class equipment. The price of renting a little bit of capital sites with all communications was rather high for us and unjustified. An important item of expenses indirectly invested in the price of the site was the cost of electricity in the city, taking into account two independent energy inputs and further expansion of the capacities of our 2G and 3G coverage (and in the future, 4G). And of course the difficult moment of choice was that we could not “pull” all our channels and communications to the points studied. This was a real “ambush” of a project that had not yet begun.

Having considered all possible options, we agreed that for these northern cities it was easier to build the machine hall in the “clean field from scratch” at the point we need according to our operator conditions. Easy to say, but not easy to do. After all, it was about the permafrost and harsh northern climate, and the "open field" meant that the basis for the realization of the machine room was to take the form of a sealed container on the ground. To it, first of all, as was noted, two independent power inputs were to be “pulled”, and in the second - duplicated transport channels of communication over air radio-relay lines (RRL) were “thrown”. Essentially, for the local 3G / 2G MGW media gateway, it remained to build its own “house”, reserved in every sense, equipping it with operator workplaces.

Having prepared all the necessary equipment racks in the drawing of the future machine hall, taking into account the expansion, we determined the appropriate dimensions of the container and chose a place, starting construction on our own. Construction work at the site was logically divided into 2 stages. Stage 1 - the construction of the main container, equipping it with life support systems for the machine room, connecting the video surveillance system, at the same time building a transformer substation in a separate container. Stage 2 - installation and installation of telecom equipment of the 3G / 2G core network, commissioning and integration of MGW, connecting it with the “core” of the large MSS / MGW switch of Noyabrsk, as well as with the old switchboard in Labytnangi, multivendor testing of all subsystems with all, verification of mobile services, and preparation of the entire system for pilot commercial operation.

The selection of construction contractors for our Wishlist was made through a tender. Permafrost is not a joke. Then, together with the contractors, in the spring we sent an order for the manufacture of the container to one of the steelworks in the Urals and began to wait for the end of production. Its impressive dimensions and weight were not typical for the standard proposed boxes for base stations, so the production was carried out "to order".

Piling and preparation of the foundation for the container

After an anxious wait, the container was received from the factory and delivered to the site. Immediately began assembling our "home". In general, it can be said that the construction of hardware boxes in the conditions of the north is a responsible and very laborious business. And our container for the new 3G / 2G media gateway was built in accordance with all the technological stages of building hardware boxes for these edges. We have not experienced any insurmountable difficulties, for example with soils, in this part of the project, the construction of the “house” was completed without force majeure.

The machine hall container turned out reliable, with enhanced thermal and waterproofing. In it were installed air conditioners and air heating system, operating in automatic mode. The working temperature in the container is constantly maintained at about 22x degrees, the full climate control works. Present fire sensors, flooding and a full range of monitoring, which allows you to detect cases of problems. In addition, a separate transformer substation with the necessary distribution devices was assembled at the site in a separate container.

Transformer substation switchgear

According to the results of the 1st construction stage with a small symbolic “housewarming”, we launched the machine building container into operation, and it was already possible to “live” on the site. Then it was necessary to accelerate with the 2nd stage, as we began to press the cold.

Simultaneously with the container fabrication, all the necessary 3G / 2G telecom equipment for the core network was purchased, and it was already waiting for us at the regional warehouse. But the delayed terms of manufacturing and delivering our "home" from the factory, as well as assembling it by contractors, and in addition - launching our own transformer substation at the site, shifted the deadlines for the 1st project phase to late autumn. Short summer and autumn ended, snow began to fall on the Arctic Circle, and it was important to “catch up” the implementation of the 2nd stage: delivery and tests of the purchased switching equipment.

Our experience with the north led us to the point that the dispatch of carrier equipment by rail from the warehouse that we have in Tyumen had to be done at least in a month, and better still earlier. The train with the racks could reach our place in the Arctic Circle only through Syktyvkar, passing at the same time bypassing 4 more regions, and reaching only the railway station in Labytnangi. There were no further paths, and the Ob River blocked the road to our site. The railway from Labytnangi to Salekhard does not yet exist, bridges too. Given this circumstance, we tried more than a month to send the equipment to the transport company to Labytnangi, promptly unload it from the railway upon arrival, and head for the ferry across the river. If only we knew then that planning the logistics on the “big” land so much in advance, we would be very much weakened by the deteriorating weather forecast.

We lacked only 5 hours on the last day of this route in order to ferry all our numerous boxes and boxes. By the way, it was an opportunity for people to cross the river; in the off-season, a hovercraft goes, like a city bus, but for freight transport the road across the river no longer existed. The river at once "cut off" all possible attempts to get to the remote site.

Salekhard – Labytnangi winter ferry across the Ob River

It happens sometimes. We stuffed our "parcel" to both northern cities with all the necessary "iron" and even with a reserve; we carried it by rail for a whole month, as we didn’t send such cargo by airmail and didn’t have time just a bit. And there was nothing left but to wait “for the weather by the sea” for three weeks, until a safe road again opened across the Ob River for the passage of cargo vehicles, but now on the winter ice called the winter road. But survived it. However, who would have thought then that this chain of timing and the arrival of prolonged negative temperatures to the north would only help us with the full launch of the new 3G / 2G media gateway in harsh climatic conditions.

As soon as all the necessary boxes with the telecom hardware were delivered to the machine hall, representatives of the vendors of the new equipment were successively “abandoned” on the site, and the work “boiled” at an accelerated pace. Engineers were notified of the work in advance, and on the appointed days and hours they flew to us at Salekhard one by one, without disturbing or delaying each other, waiting for their integration dates, which was very valuable. Together with our technical colleagues, vendors and their contractors docked various subsystems of the core network, exchanged experiences, tested and retested, and soon the work gained the necessary pace. The system began to grow together "on the eyes."

Installation of telecom equipment in the new machine room

Testing of the new 3G / 2G media gateway MGW was carried out on two test 3G and 2G base stations assembled here in a container, but connected to test antennas via attenuators. Having configured the necessary thresholds for the signal levels of the base stations, we confidently passed all the setup tests of the 3G-2G-3G mobile transitions on test smartphones. Similarly, all MSS – MGW signaling tests were performed between cities, then mobile services tests. As a result, all the necessary network elements of the core network and traffic management systems “went up” at the machine hall. And naturally, backup batteries were also checked and put into operation. Our 2nd construction stage at the site gradually came to an end and the tested backbone network was finally ready to receive traffic.

Battery backup power

It is worth noting here that the specificity of project management in Yamal was that we constantly lacked technical specialists in these northern cities. We had to search for engineers from neighboring regions specializing in similar mobile subsystems, and ask colleagues to be sent north to help vendors and local technical colleagues to optimally configure the hardware for the uniform requirements of a large company network. «», «», . « », «» .

, 3G/2G MGW. . , , «» « », «» . .

( ): , MGW, 3G

, , . , , . , . : , , , . , ? .

«», -, , «» . , 600 . , 2G: SMS- MMS-, , , -, - . , «» .

: , , , , , .. . .

, «» . «» - «», 3G 2G, , , , , --. .

,

, , - . - , , . . «», , , «» . «».

, «» , , . , , , , «» , . , , .

: – , —

«» «». , 3G 2G . , , . «».

, , «» . 3G/2G «» , , . «» , «» «». . , «» .

«» «» , . - , . . , «», , . 3G/2G MGW .

, – «» . , . «» . 3G/2G MGW «» . , , «» .

. , . «», , «» , . , « », .

Results

3G/2G MGW . «» , . 3G 2G , 3G/2G MGW, «» .

« » . «» . , . - , «» .

3G/2G . «» , . .

–40 , , . , . .

, , : , , , «», . , . - «» . .

Source: https://habr.com/ru/post/249455/

All Articles