Surface mounting: stencil and reflow oven at home

When you begin to look for opportunities to make a small batch of your own electronic devices for sale, you discover that this task can be solved without getting up from the chair. For example, this is how Seeed works, which organizes not only the production, but also the sale of your devices. If you are not sure whether there will be a demand, or just want to save money, then the best option, in my opinion, will be to order printed circuit boards somewhere in China, and leave yourself with the installation of surface ( SMD ) components at home. I want to tell you how you can significantly speed up surface mounting using improvised stencils and an improvised reflow oven.

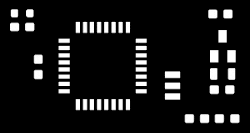

Making a stencil

Stencil (eng. Stencil ) in the context of surface mounting is a thin plate with holes cut out for the contact pads. It is applied to the printed circuit board and spread with solder paste with a spatula. Next, the stencil is removed, and on the pads there is an even layer of solder paste.

Stencil (eng. Stencil ) in the context of surface mounting is a thin plate with holes cut out for the contact pads. It is applied to the printed circuit board and spread with solder paste with a spatula. Next, the stencil is removed, and on the pads there is an even layer of solder paste.An example of using a stencil from EEVblog

Typically, stencils are cut from steel or plastic, but this can be costly in small batches. For example, when ordering 5x5 cm boards, I was offered to make a stencil for $ 25. I'm going to tell you how to make a stencil out of an aluminum can in half an hour using LUT !

Cut a rectangle from a beer can, align it with a hot iron. Do not worry that you can not completely eliminate the concavity - when applying a stencil to the board, we will press it with office pins!

Cut a rectangle from a beer can, align it with a hot iron. Do not worry that you can not completely eliminate the concavity - when applying a stencil to the board, we will press it with office pins!- We clean the inside of the rectangle with fine sandpaper to remove the protective layer. Some people write that they remove the top layer with caustic soda. Acetone acts on some types of cans after heating them with an iron. But generally sandpaper is done in a minute

- We print a negative on a special toner transfer paper with a laser printer. This paper completely gives its toner in one (!) Pass of the laminator, is surprisingly cheap, does not require deoxidation in water, and can be removed immediately after toner transfer

We attach the negative to the side of the rectangle that has been cleaned and rubbed with alcohol with the help of kapton tape . Its peculiarity is that it withstands high temperatures, while maintaining its adhesive properties. It simplifies the manufacture of double-sided boards, when you need to precisely fix the paper opposite the previously made holes

We attach the negative to the side of the rectangle that has been cleaned and rubbed with alcohol with the help of kapton tape . Its peculiarity is that it withstands high temperatures, while maintaining its adhesive properties. It simplifies the manufacture of double-sided boards, when you need to precisely fix the paper opposite the previously made holes We skip the resulting sandwich through the laminator (once), remove the paper. Toner paper completely switched to a rectangle. In order not to pick holes through accidental scratches, glue the workpiece with tape on both sides, except for the piece that needs to be etched. Probably, instead of the laminator, you can use a hot iron, as is usually done in LUT, but the laminator is still more convenient.

We skip the resulting sandwich through the laminator (once), remove the paper. Toner paper completely switched to a rectangle. In order not to pick holes through accidental scratches, glue the workpiece with tape on both sides, except for the piece that needs to be etched. Probably, instead of the laminator, you can use a hot iron, as is usually done in LUT, but the laminator is still more convenient. We etch out in the waste (after copper grass) solution of ferric chloride. This solution is a mixture of ferric chloride and copper chloride. According to my observations, this mixture interacts with aluminum much more rapidly than a pure solution of ferric chloride. When etching, we brush off the brown patches that form with a soft brush and periodically check whether it is time to get our stencil (so as not to overstrain!)

We etch out in the waste (after copper grass) solution of ferric chloride. This solution is a mixture of ferric chloride and copper chloride. According to my observations, this mixture interacts with aluminum much more rapidly than a pure solution of ferric chloride. When etching, we brush off the brown patches that form with a soft brush and periodically check whether it is time to get our stencil (so as not to overstrain!) Remove the tape, cut the stencil to the size of the board. If in the windows of the stencil you can see the trimming of the protective layer of the can, you can remove them with the adhesive side of the adhesive tape

Remove the tape, cut the stencil to the size of the board. If in the windows of the stencil you can see the trimming of the protective layer of the can, you can remove them with the adhesive side of the adhesive tape- The stencil is pressed to the board with office pins, toner down. As a spatula, you can use a plastic card or cardboard. After use, do not forget to wipe the stencil and spatula with alcohol to clean them from the sticking paste.

Making oven

Little about the temperature profile

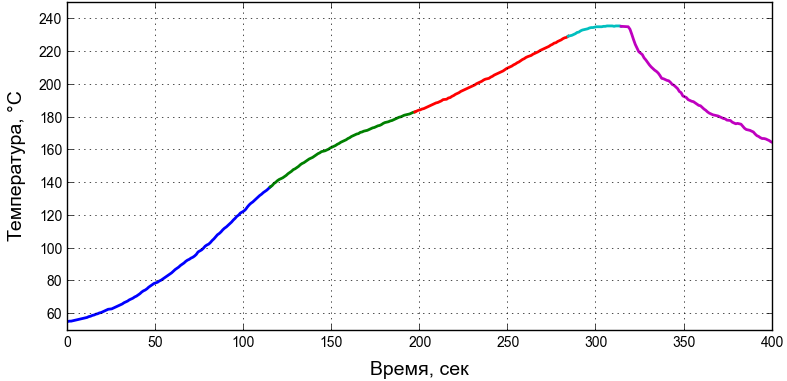

Proper melting of solder paste requires compliance with its temperature profile. For example, a profile for lead-free solder paste may be ( from Wikipedia ):

')

Rapid heating to 150 ° C, languor 1 - 2 minutes, rapid heating to 230 ° C, melting for 30 seconds, cooling. The meaning of all these temperature zones is that they initiate the processes necessary for the formation of reliable contacts without unnecessary overheating of the components. Flux is activated in one zone, solder melting in the other. There is an industry standard J-STD-20 that describes the recommended parameters for each zone.

')

Rapid heating to 150 ° C, languor 1 - 2 minutes, rapid heating to 230 ° C, melting for 30 seconds, cooling. The meaning of all these temperature zones is that they initiate the processes necessary for the formation of reliable contacts without unnecessary overheating of the components. Flux is activated in one zone, solder melting in the other. There is an industry standard J-STD-20 that describes the recommended parameters for each zone.

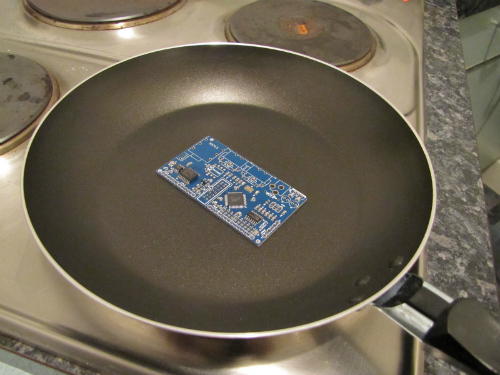

In general, the cheapest and easiest way to melt solder paste is this:

They say that the pan will do

You can also use a heat gun to reflow solder paste, blowing out individual components or areas until the paste melts and creates contact. I actively used this method for my devices, but it was a long time, leading to unreliable contacts and overheating of elements. For example, passive elements could change their values within 5-10%! This became especially true after switching to lead-free solder paste, which requires a higher temperature for reflow.

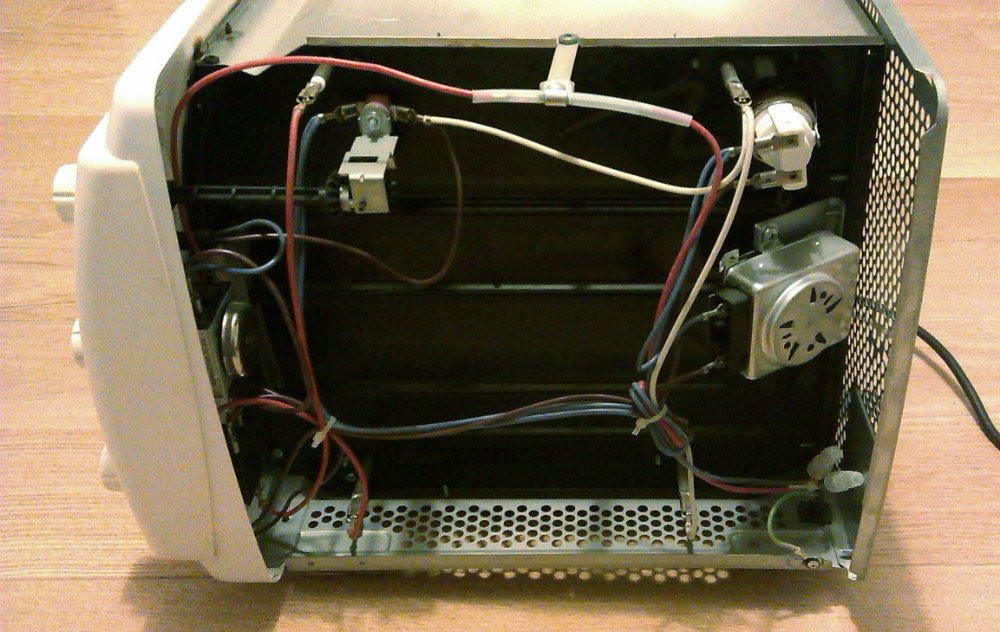

And it turns out that people on the Internet have long learned to convert cheap electric ovens into good reflow ovens (English reflow oven ) with the correct temperature profile. I also decided to follow their example and tell you what I did.

I began by monitoring the bulletin board for the sale of used electric ovens. After some time, an advertisement appeared to sell DeLonghi with a power of 2.2 kW with two heating elements for only $ 30. True, it later turned out that the heating elements were messed up during operation and emitted 300 watts of heat less.

Opening the case, I found that everything inside was very well organized, and it would be easy to connect to heating elements.

To control the heaters, I took the cheapest solid-state relays ( solid-state relay, SSR ) with optical isolation at 25A, for $ 3 apiece.

As a controller, I chose the ControLeo , buying it for $ 60 with a thermocouple and shipping from the USA. The device came in the form of a set, which still had to be soldered, drilled, assembled:

The controller has a two-line LCD screen, two control buttons and four + 5V relay outputs. The program code is open and can be uploaded to the device via USB and Arduino IDE. Through the control buttons implemented menu with the ability to configure and test outputs, as well as start the process of reflow. Settings are stored in permanent memory. In addition, when they change, a training mode is launched in which the controller adjusts the on / off time of the relay to meet the requirements of the industrial reflow standard

An example of the controller

In accordance with the standard, the heating rate of the reflow oven must be at least

- Warmed the furnace with basalt cotton wool wrapped in foil (in order not to breathe microscopic basalt dust)

- Added a new 800 watt heater - it turns out that it is very easy to buy them on the economic market, just tell me the size!

- He turned the stove upside down (!), Because large losses of heat went through the slit of the glass door.

Thus, the furnace earned. After several experiments, I came to the conclusion that the boards can be placed directly on the metal grid attached to the oven, and the thermocouple can be positioned above the board by fixing the wire with a clerical pin. Tests have shown that the change in the values of passive elements is minimal. In general, the oven is ready - take bake!

Source: https://habr.com/ru/post/249017/

All Articles