Replacing the chipset on the motherboard

Looking through the archive of my photos recently, I found photos from my past work that would be interesting to see for many. The photos were taken for themselves by the Samsung Galaxy S mobile phone at different times, some are blurred, but, alas, there are no more.

Before being fascinated by development under Android, I repaired computers and laptops for a couple of years. Below, I will tell you about one of the most complicated operation for repairing motherboards and video cards - replacing the chipset, hereinafter referred to as the “chip”. And at the end of the article a little about why laptops break. I think it's worth warning - “don't try this at home”.

For work it is necessary:

Flux (BGA Gel Flux). Let's call it “liquid” (Fig. 1)

')

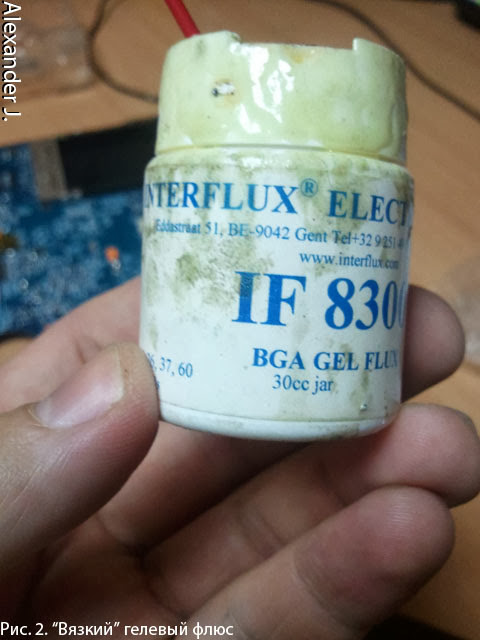

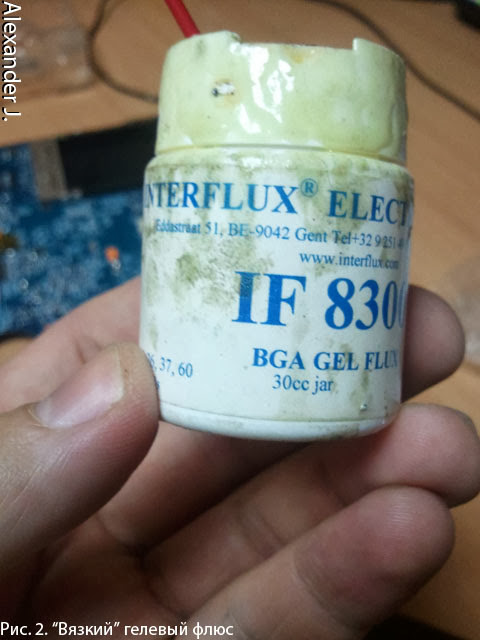

And "viscous" (Fig.2).

The first has a brush under the cap and is easy to apply when manipulated at room temperature, and the second is an amorphous mass that becomes liquid at temperatures close to the melting point of the solder.

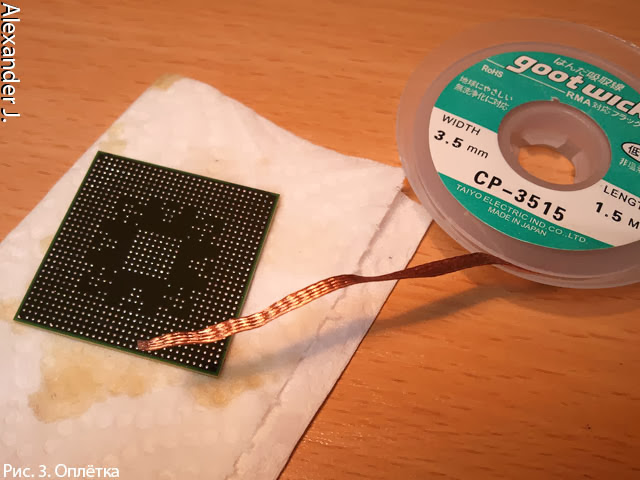

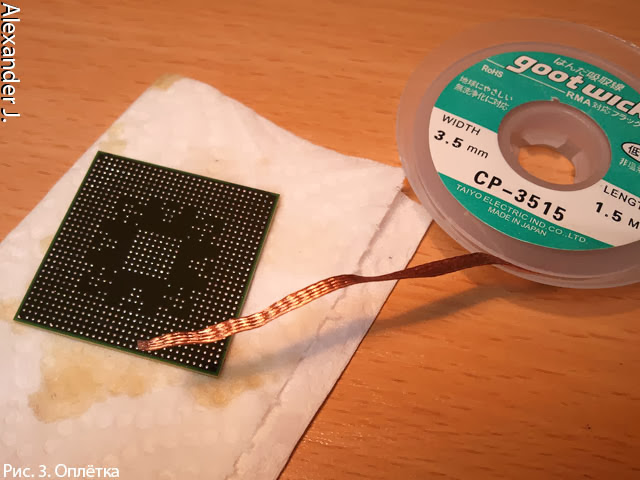

Braid (Fig.3) is used to clean the sites from the old solder.

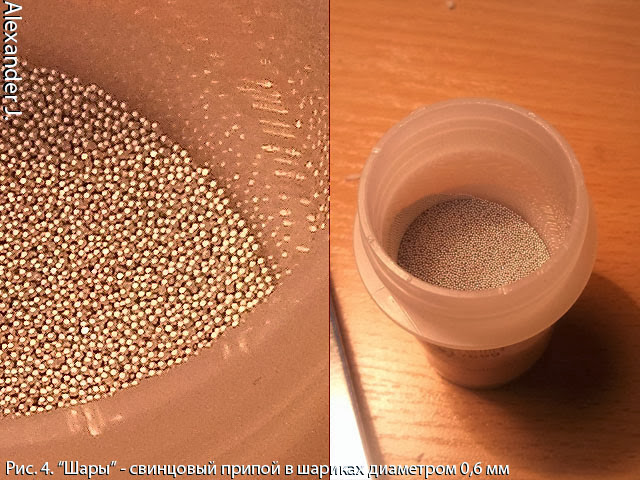

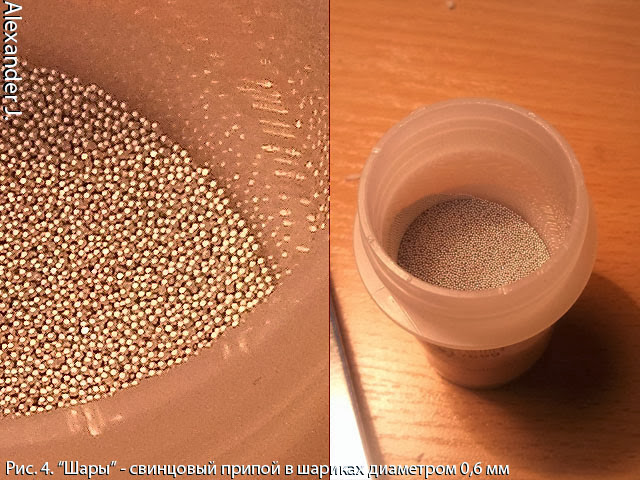

A can of solder in balls of the required diameter (Fig.4). Further in the text as "balls".

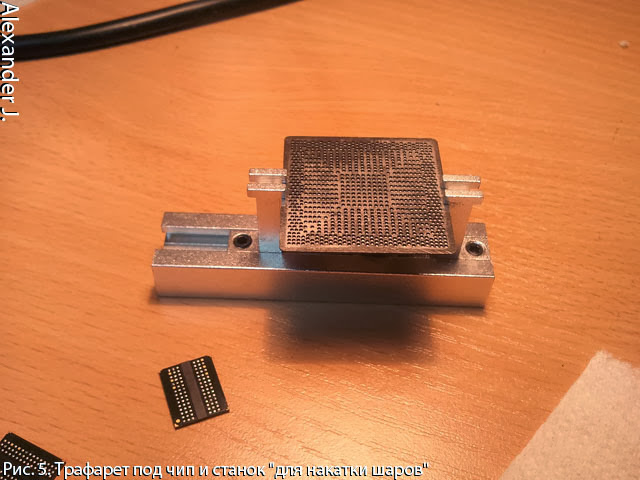

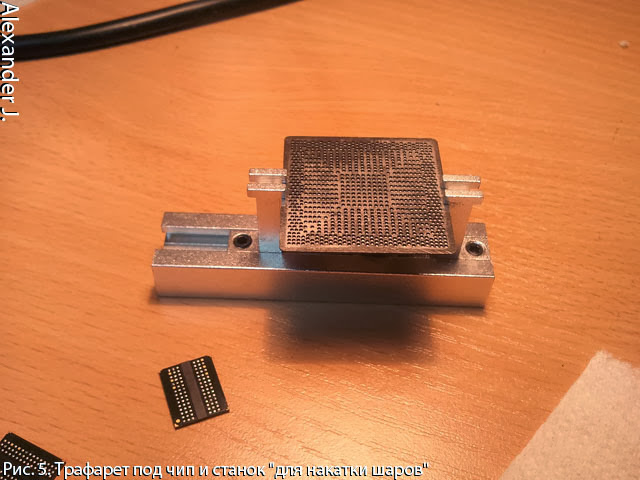

Stencil for this chip and the machine "for rolling balls". In the photo (Fig.5), the stencil and chip are mounted on the machine. In the foreground are two DDR2 RAM chips. For them, too, there are stencils.

The stencil shows the diameter of the holes and, accordingly, these are exactly what solder balls need. This is the easiest machine and not the most convenient. It rolls balls produced by heating the "air", so the stencil should be designed for heating. There is a more convenient machine that only positions the balls in place, and they are heated with a chip without a stencil. Stencils for such a machine are not designed for heating - are deformed.

Actually, two soldering stations (Fig. 6) are infrared and conventional with a soldering iron and air-vent (heat gun).

Infrared - on the right, on which the disassembly / assembly of the chip from the motherboard / video card and the "regular" one, with which a new chip is prepared for installation, is made.

The infrared solder heats the chip using a powerful irradiator located on the outrigger bar. The photo shows the feed in the parking position, in this photo to the left of the station on a tripod with a yellow triangle of the “HOT!” Badge. These stations evenly heat the chip, precisely controlling the temperature, which is impossible to do with the “air”.

This IR-SYSTEMS RE-7500 IR station is probably one of the simplest, and therefore working with it is difficult. The station has only one thermal sensor, which is installed and measures the temperature directly near the chip. A good station has, at a minimum, a second sensor measuring the heating of the motherboard from below. On the RE-7500, it is easy to damage the motherboard by simply overheating it - the station does not have any thermostat functions - by heating to the set temperatures and keeping the set temperature. By the way, the temperature readings are in slightly Chinese degrees, the solder melts at a slightly different temperature than it should.

Of the remaining tools, solder, tweezers, napkins, side cutters, isopropyl alcohol, a brush and, preferably, but not necessarily, an ultrasonic bath will be needed.

Chipset disassembly

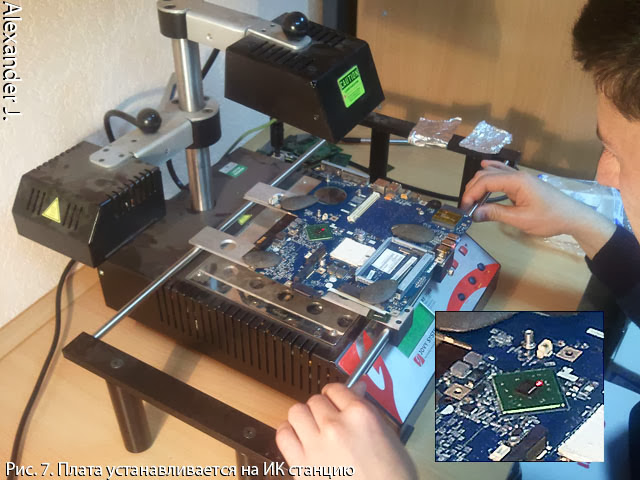

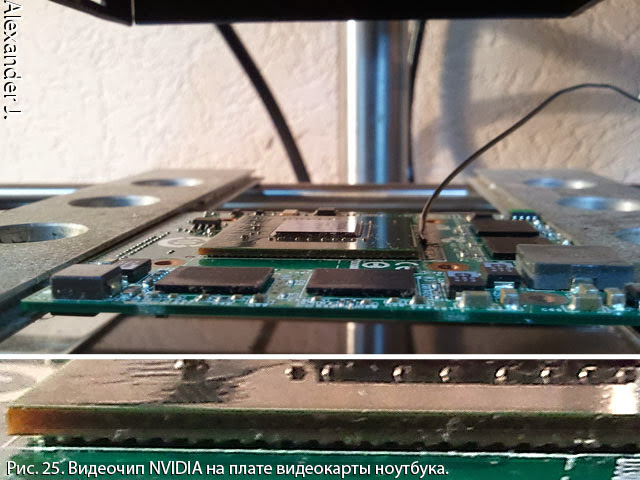

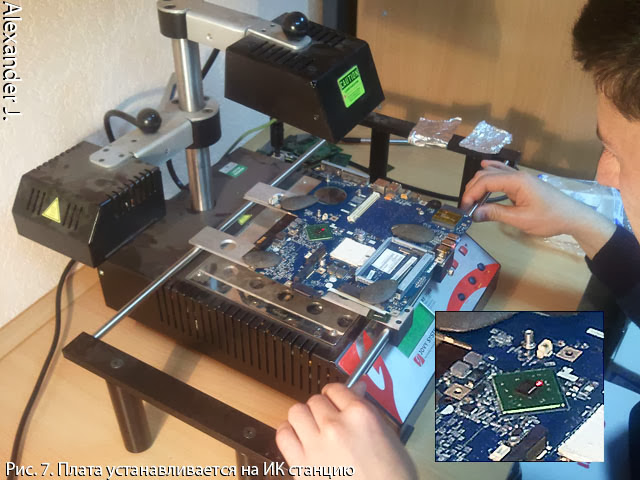

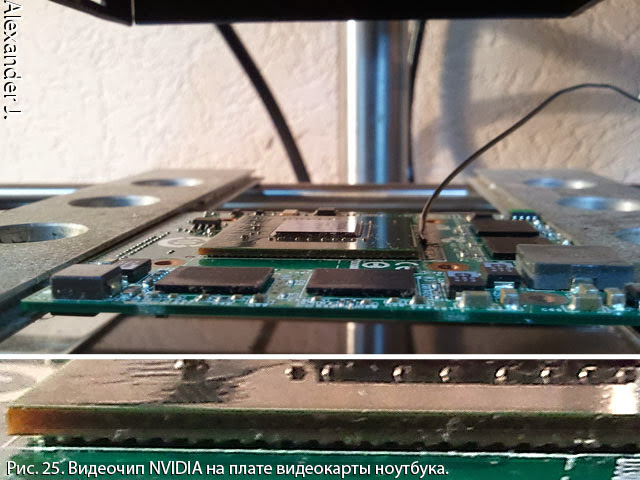

Before you put a new chip to solder, you need to solder the old one. The motherboard is being prepared - paper labels are removed on both sides in the heating zone, the board is installed and fixed at the station, the board is centered so that the chip is under the upper heater (feed) of the station (for convenience, the station has a laser sight (Fig. 7)).

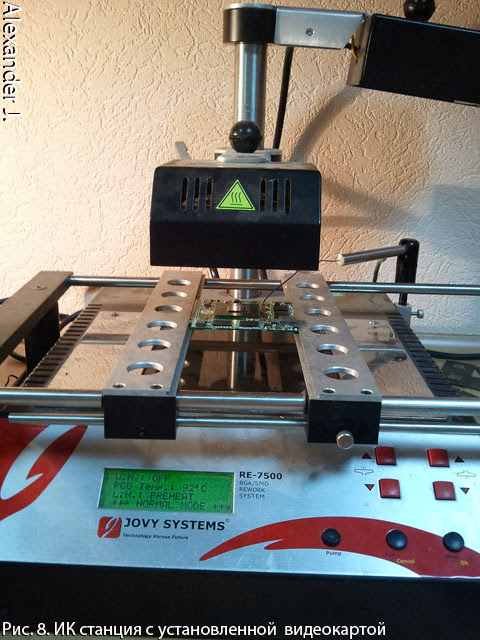

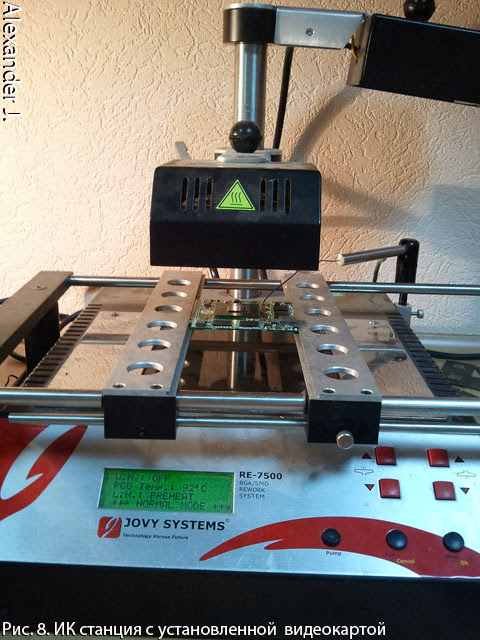

Thermal sensor is installed near the chip (Fig.8). If necessary, non-heat-resistant elements (for example, electrolytic capacitors) located on both sides of the board are covered with self-adhesive foil (in Fig. 7, two pieces of foil are visible above the right hand).

We turn on the lower heating in PREHEAT mode, the station slowly warms up to 95-100. There are 10-15 minutes to prepare a new chip.

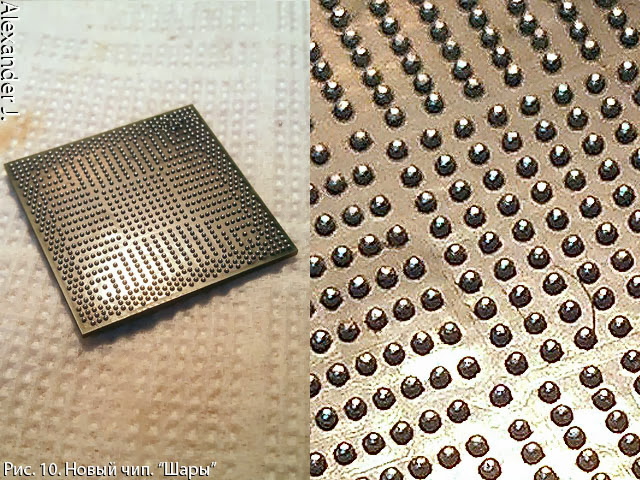

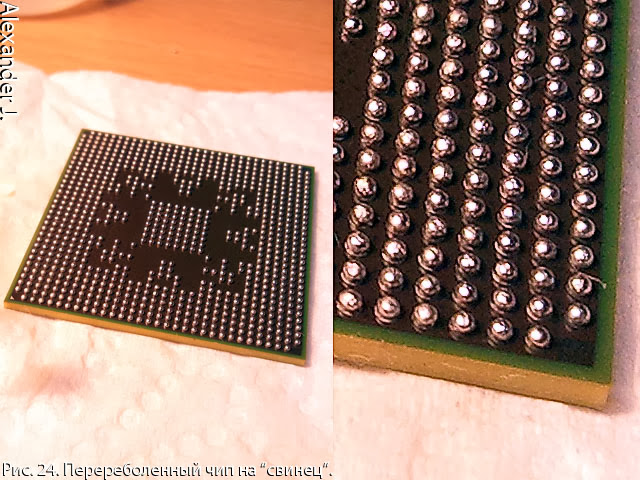

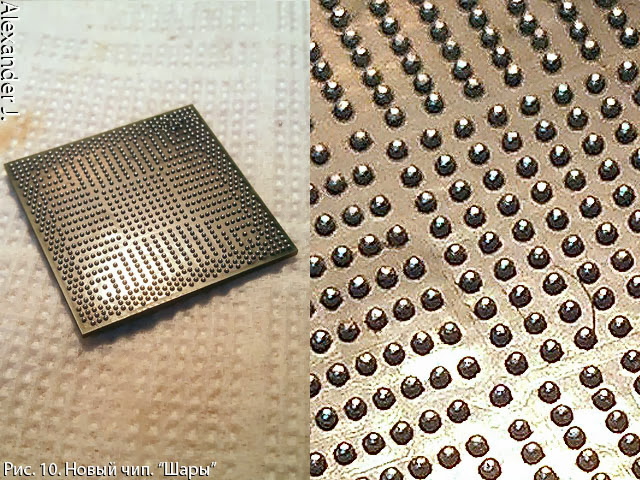

The lead-free solder used melts at temperatures of about 210 ° C, while lead lead - at 180 ° C. The new chip has already been eliminated (Fig.10) with lead-free solder.

Chiselled (dribble, roll balls) - the balls are soldered i. It is ready for installation.

By the way, a chip without balls, everyone saw the example of Intel processors (Fig.11).

Recently, Intel processors in laptops are soldered as a chip - minus the socket, minus the height of the socket. This is often found in ultra-thin laptops.

Temperature 210 is high, especially for such a cheap IR station.

When heated, PCB and metal conductors in a multilayer board do not expand equally. There are cases when boards from thin textolite “lead” —the board from flat becomes convex, curved, twisted. Such a fee only to throw out. There have also been cases of rupture of conductive paths, caps. In perfect infrared stations, there are profiles for heating the board according to certain temperature graphs, which makes it possible to reduce irregularity of deformations. If anyone noticed in the photo that the board at the soldering station is pressed against lead weights, this is just a precaution against possible deformations.

Thirdly, the heating of the chip itself, if it does not kill it, then it clearly increases the probability of its failure in the future. And for some types of repair, the chip has to be removed a couple of times, for example, when a defect is diagnosed, when the repair of a chip is not completed or the like Therefore, the chip must perebolit more light-alloyed lead solder.

Reboling a new chip

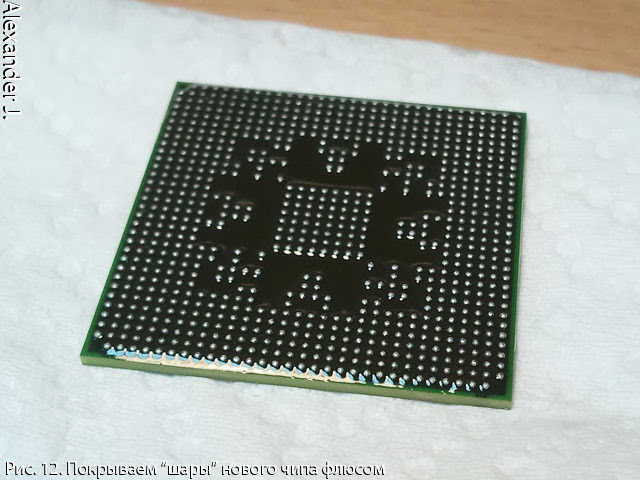

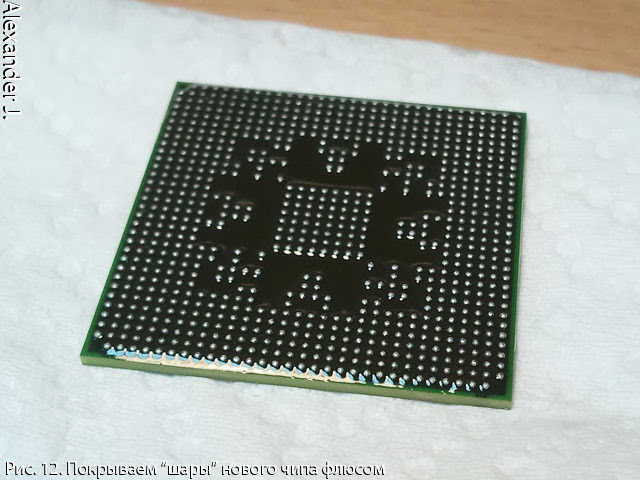

Getting to the reballing of the new chip. Put the chip on a napkin so as not to slide on the table. We cover the balls with “liquid flux”.

We heat the soldering iron to ... more than the melting point of lead-free solder. At the Lukey 852 soldering station, it is convenient to work at 380 Chinese degrees. The temperature should be such that the solder does not stick to the chip (to its contact pads), but rolls in the flux like mercury. But it’s also not important to keep the chip cool, so we don’t linger in one place for a long time. It is better to return there later.

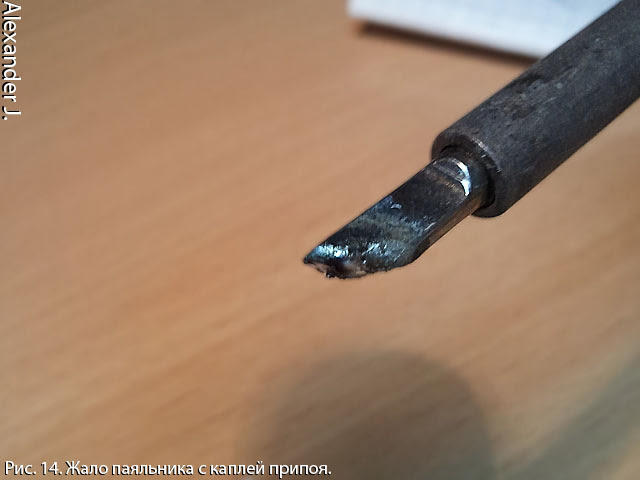

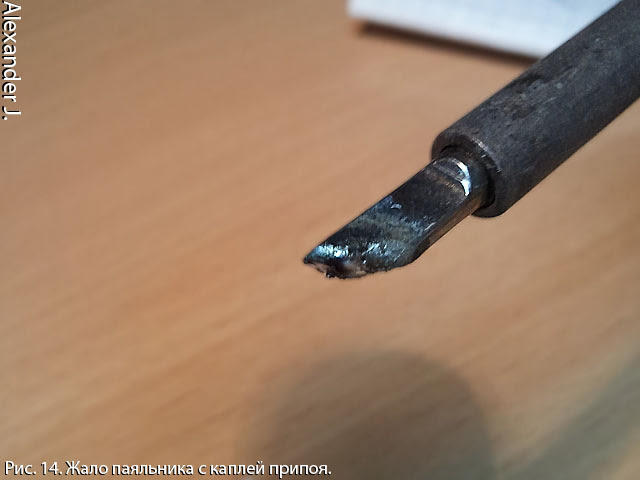

A drop of the usual lead solder is taken on the soldering tip, which easily “dissolves” lead-free balls. Periodically we shake an overgrown large drop from the sting and take a new one. If necessary, smear flux.

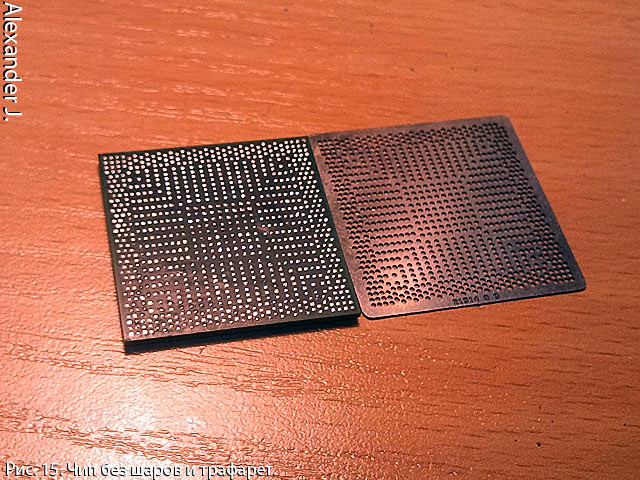

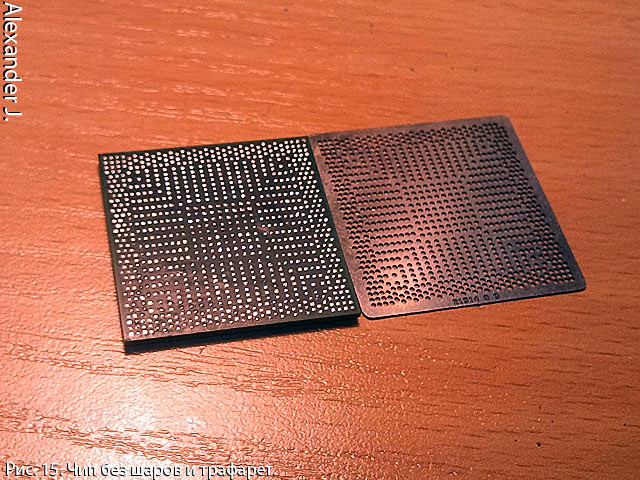

After a minute the balls were removed, but the surface is uneven. On contact pads solder residues. Fig.5 is not a macro photograph (telephone survey), but even on it there is a noticeable “torn”, “angular” shape of some contact pads (in the photo is an ATI / AMD chip and a stencil).

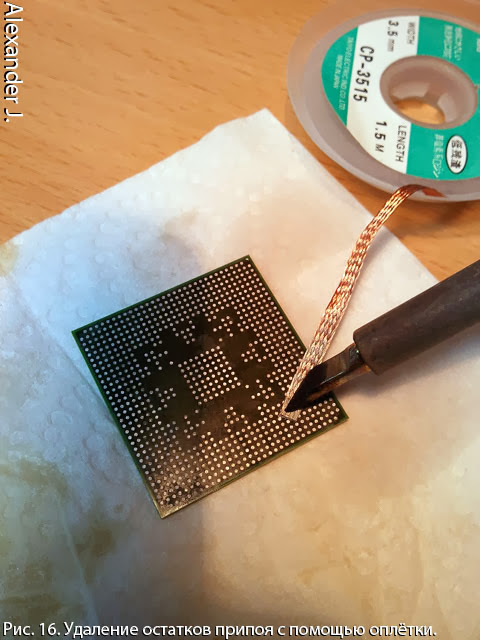

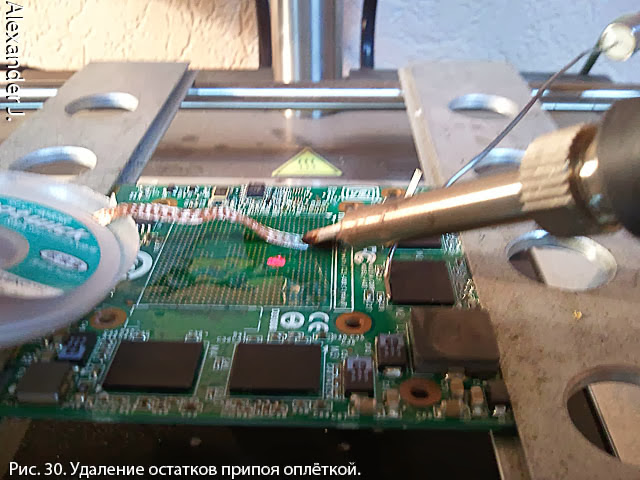

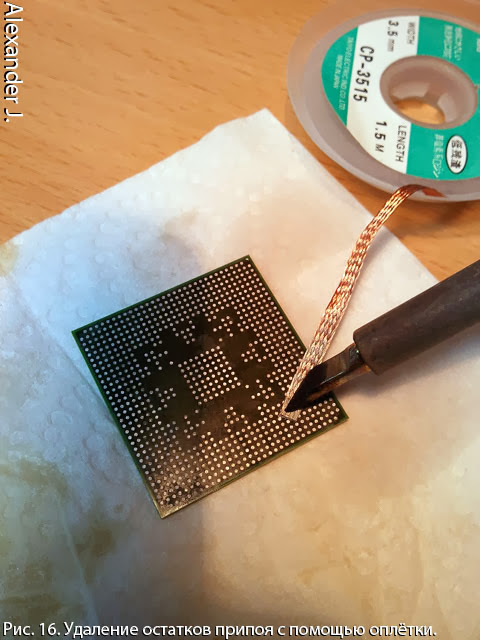

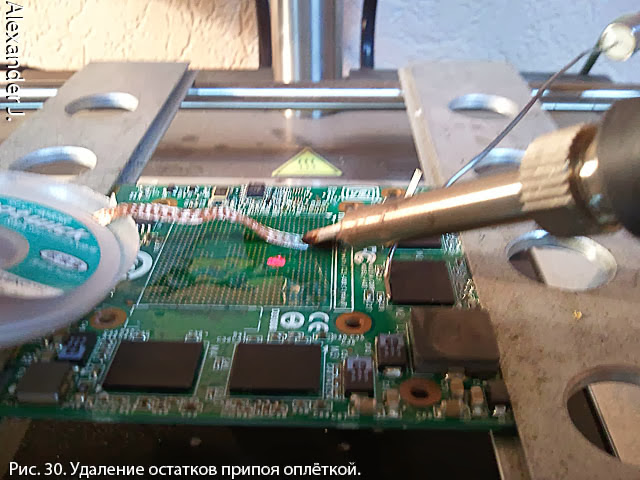

The ideal surface is obtained by braiding. We again apply liquid flux on the chip and, pressing the braid with the soldering iron tip, clean the surface to the ideal. The quality is easily controlled with your finger - there should not be roughness. Drunk solder, otkusyvay areas of the braid side cutters.

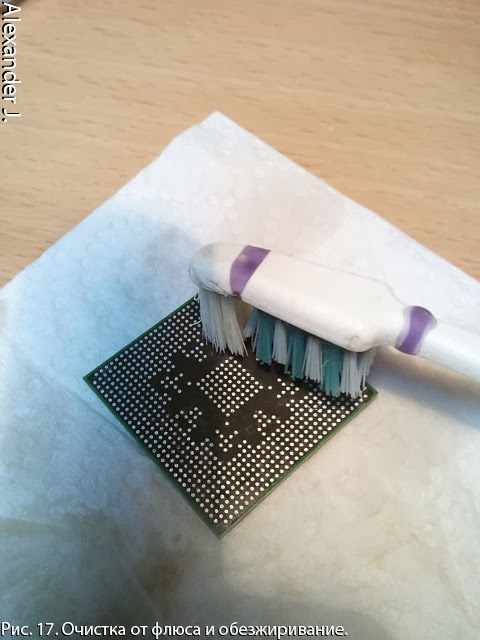

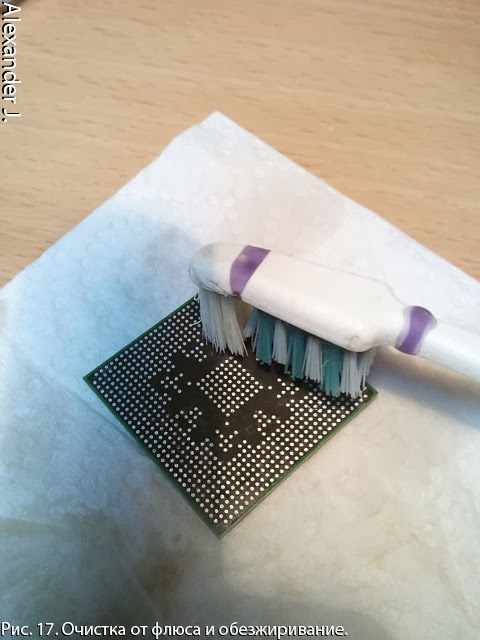

Now cleaned from flux and degreased. To do this, use a toothbrush and isopropyl alcohol. We look, if there is anything left, if necessary, then repeat the step with braid.

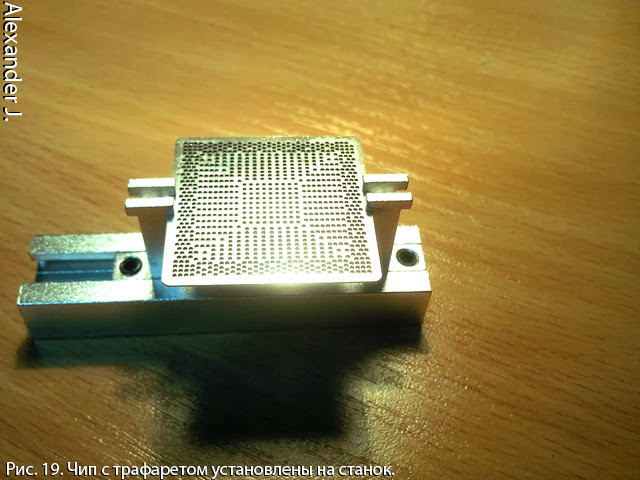

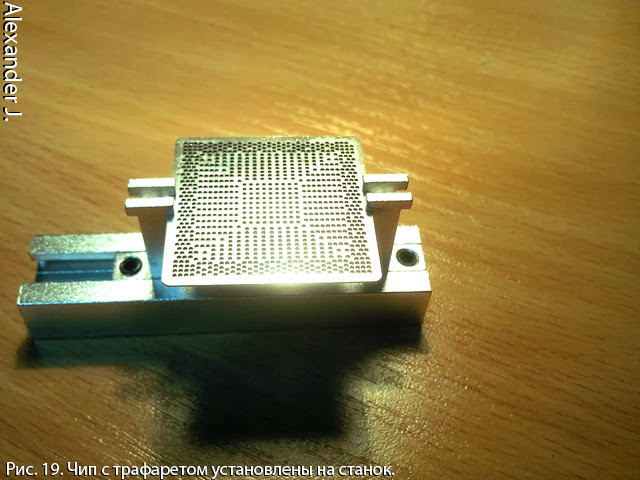

We put on the chip a very, well, very thin layer of flux. If the liquid flux is not boiling (high-temperature), then they, otherwise the finger smear viscous. Install the chip with a stencil in the machine.

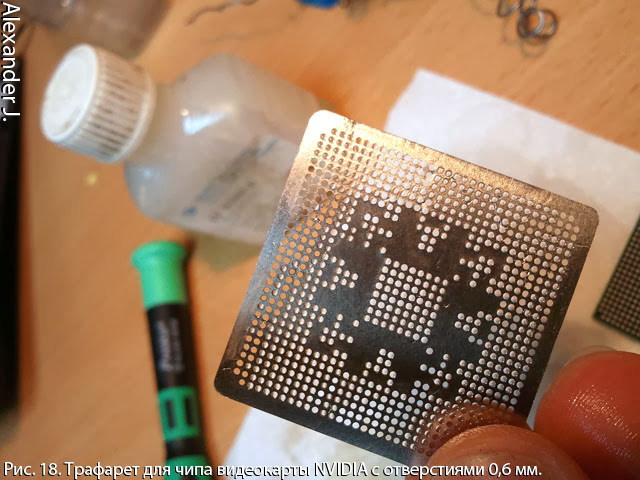

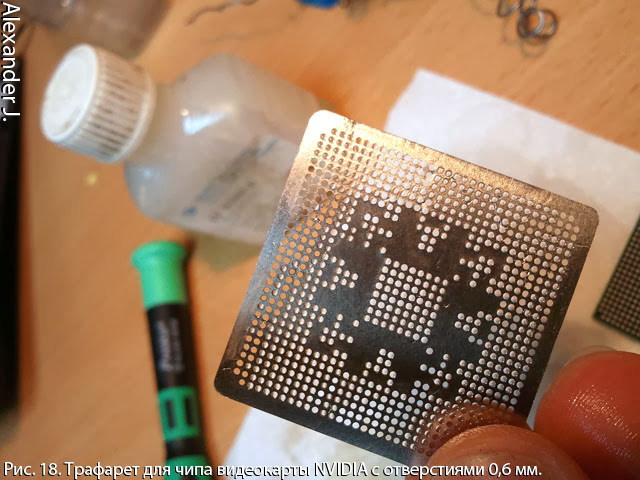

Here is the stencil. ATI / AMD has almost the same stencil for several generations of chips. NVIDIA has a lot of different.

We center the stencil in the machine - the holes opposite the contact pads of the chip.

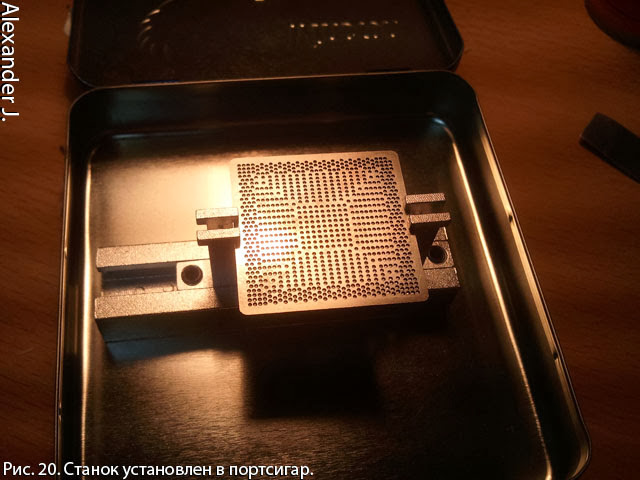

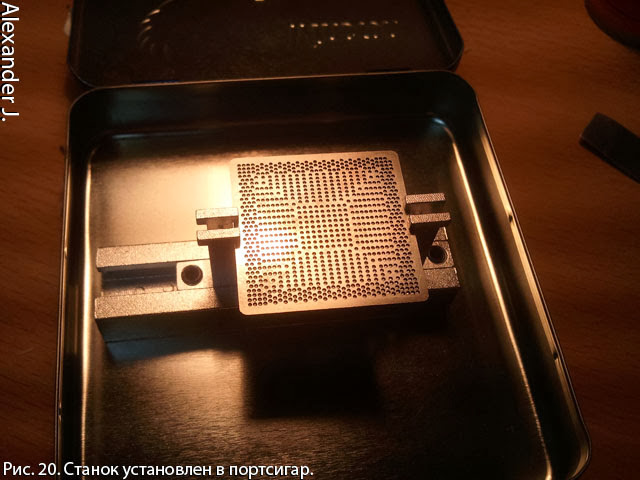

The machine itself is placed in a box in which part of the balls will wake up from the stencil. Then, balls not smeared with flux can be poured back into the jar. Saving.

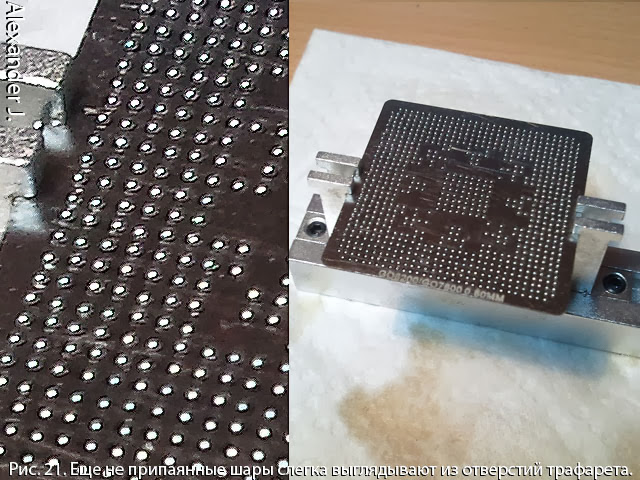

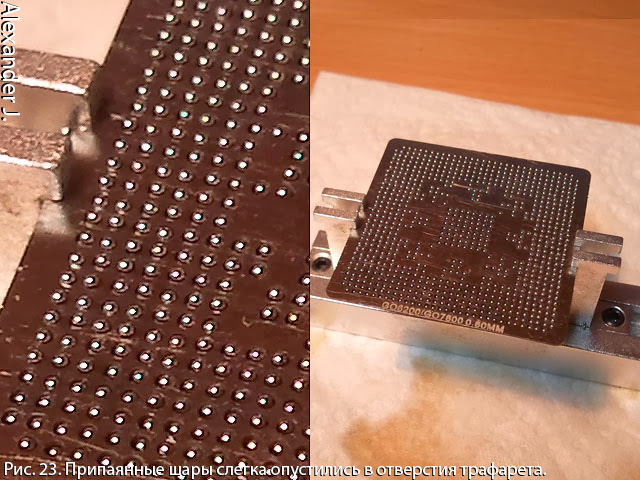

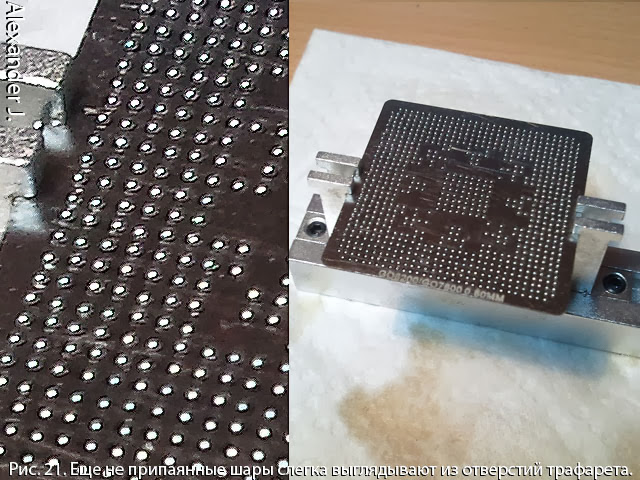

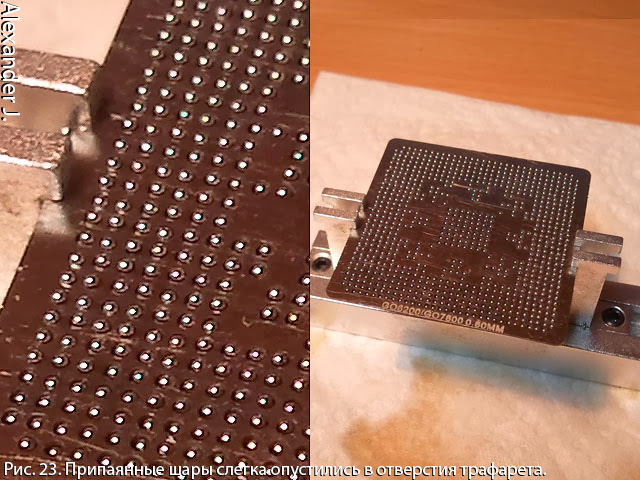

Balls are poured onto the stencil and pushed into the holes with a special spatula (complete with a machine tool), and then the last of them - with tweezers. This is what the not soldered balls look like in the machine. They slightly look out of the holes.

Next, turn on the "air" on the Chinese 380 degrees.

From a height of 5 centimeters above the machine, a chip is blown in the machine for uniform heating. Then we descend to a height of 2-3 centimeters and move around in a circle - we observe how the balls in the holes "fall through" and slowly move further. But do not linger, if any of the balls from the row did not fail - it is stuck, then we push it with tweezers and warm it up. Last we warm the balls in the center under the crystal. In the center there is a good heat exchange with the crystal and the balls will melt a bit later than it was from the edge.

This is how the balls look after warming up - they fell just below the surface of the stencil less than half a ball diameter. Balls from a spherical shape took the form close to a hemisphere, as in Fig.10. One can only guess about the difference in the picture with a mobile phone. Perhaps in the picture one or more balls "do not sit down."

By the way, the marking is visible on the stencil - chips NVIDIA GO6200 / 7600, the diameter of the holes is 0.6 millimeter. But also suitable for the G8600, the work with which is shown in these pictures.

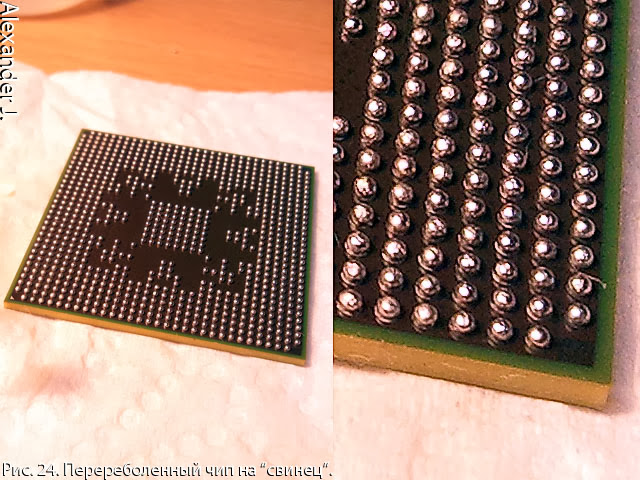

The chip is removed from the machine, the stencil is removed from the chip (it is better while it is warm, otherwise it is well glued to the chip with flux). Check if all the balls are soldered. Wash again with alcohol and a brush. Three good, better now bounce badly soldered balls.

If there is, then wash in an ultrasonic bath in the same alcohol. In it often bad soldered balls fall away. If the balls have disappeared, then we return to the previous step - we smear the flux, put the balls in the empty places, warm. A couple of balls are put without a stencil. In the end, we get a chip chip, as in the beginning, but already on the lead solder.

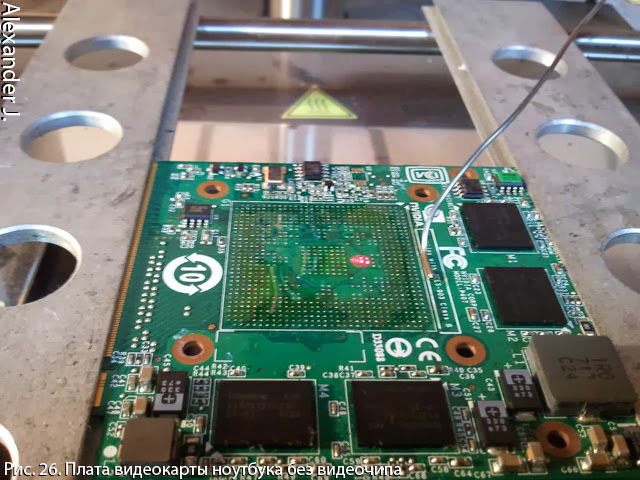

During this time, the station warmed up the fee to 95-100C. We remove the softened hot melt glue, which fixes the old chip in the corners (by the absence of glue, you can guess that the chip was previously removed / replaced). Switch the bottom heating to HEAT mode, wait a bit to 110 ° C, and turn on the top heating in HEAT. We sit and look at the creeping numbers. The station is low-power, any draft carries away the precious heat. At 200C, we carefully look under the chip - when the solder melts (about 210C), the chip drops noticeably under its own weight and the force of the surface tension of the melted solder, which attracts the chip to the board. Lightly push the chip to make sure it “floats” on the melted balls and nothing holds it.

At this moment we grab the chip for the crystal with vacuum tweezers and remove it. There is a great danger that the chip could not warm up either side and there the solder did not melt. Or a random draft cooled part of the chip. Or the chip may be poured from the bottom at the corners with glue that does not melt / does not soften when heated (found on Toshiba). In this case, trouble can happen - together with the chip contact pads come off on the motherboard. Well if it will be empty - unused. Or they can be restored ... Therefore, it is important to make sure that the chip "floated" on the balls. When it is obvious that the solder has already melted (the temperature is above 210C), and the chip does not fall and does not move, then you have to lightly glue on the pasted corners, hoping that it will not tear anything along with the glue.

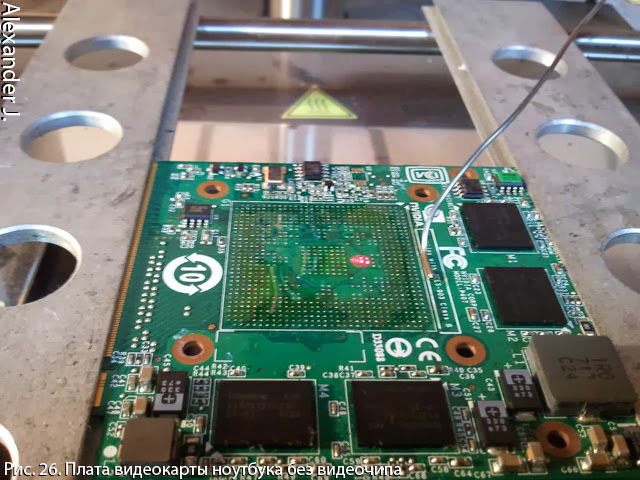

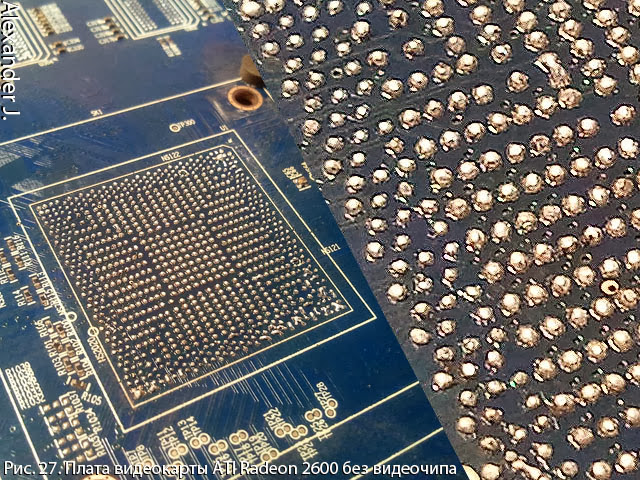

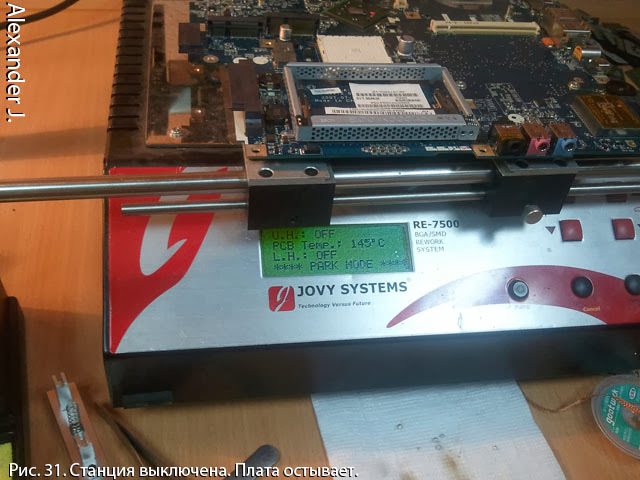

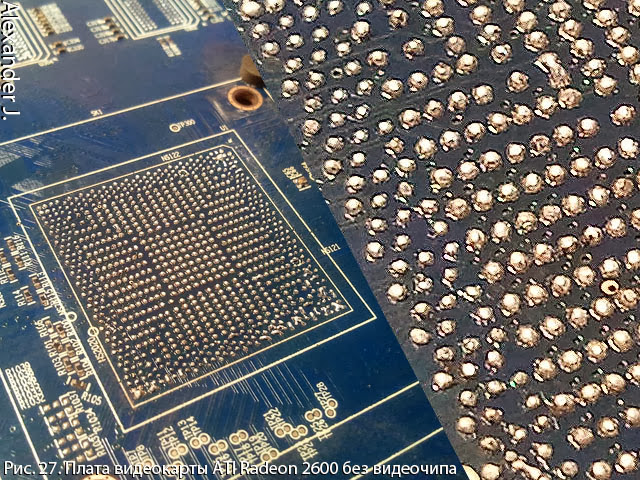

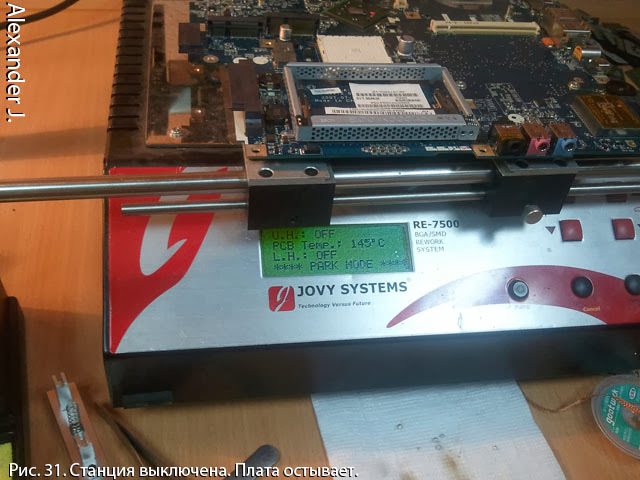

After removing the chip, we immediately turn off the upper heating, and transfer the lower one to PREHEAT, or turn it off, depending on future plans. Inspect the surface and make sure that all contact pads are intact. Here you need to repeat the same procedure as with chip rebolding - you need to remove the solder residues and get a perfectly clean, flat surface, but now this is done with the contact pads of the board. Most often, the old balls, almost completely, remain on the old chip, but sometimes, on the contrary, most of the balls remain on the board (Fig. 27).

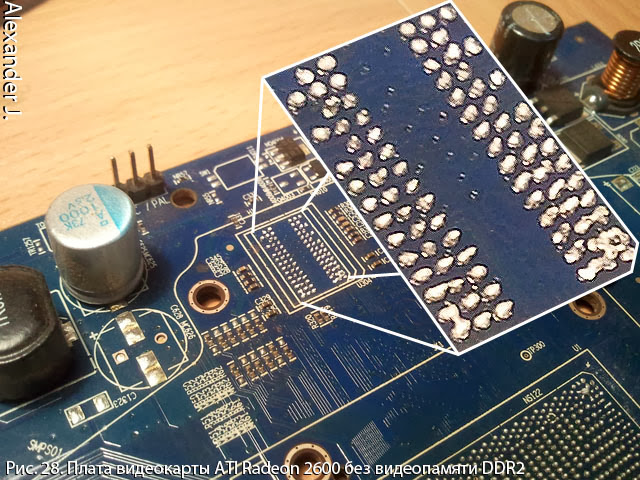

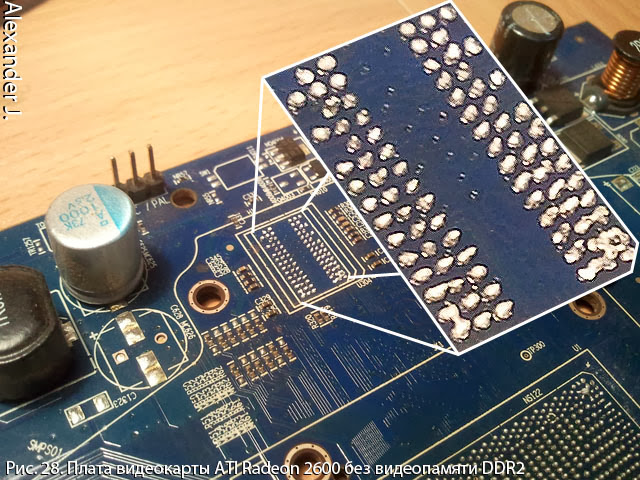

Sometimes video memory fails (and in ASUS laptops sometimes all the RAM is soldered - this trend is increasingly observed among electronics manufacturers), it can also be changed, only you first need to find the faulty chip. (Homeric laughter)

To do this, just remove the solder residues braided. Apply to the pads under the chip "liquid" flux.

A drop of solder collect most of the old lead-free solder. Braid clean up the remnants of solder. Everything is similar to Fig.14 -17.

Installation of a new chipset

Finger control the surface quality i. no roughness. Then wash the surface with a brush and alcohol.

Surface smear "viscous" flux. A very thin layer of smeared finger over the surface. The most important property of high-temperature flux is that it should not boil. Otherwise, the chip will shift when heated.

Put the chip on the motherboard according to the key, center along the lines. And further as when dismantling - warming up the bottom heated to 110C. And heating, together with the top heated to the melting point of the solder. In this case, it is a lower temperature - about 180C. As soon as the chip goes down on the melted solder, slightly push to make sure that the chip floats on completely melted balls. It also helps to solder in some problem areas. For example, under some ball turned a lot of flux. Turn off the upper and lower heating. And leave to cool. To accelerate cooling by blowing it is not necessary to avoid the deformations of some boards mentioned above.

Then build a laptop and test run.

After such a repair chip, will serve for a long time. At least as previous. But whether it will live so much a laptop is another question. This is the second part of the article.

Why do I have to change the chip? And why laptops break down?

From the effect we proceed to the cause.

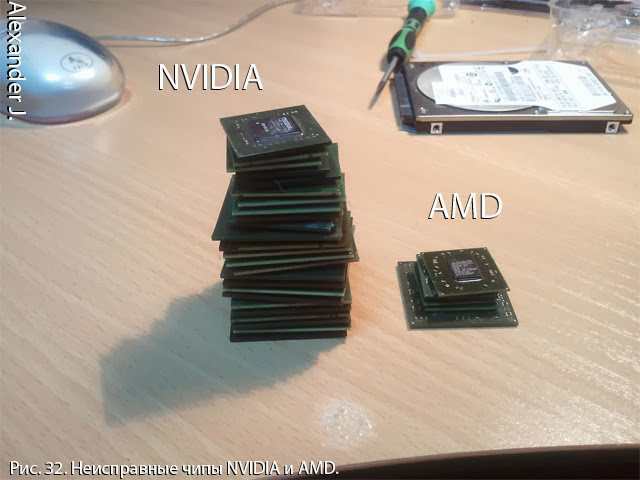

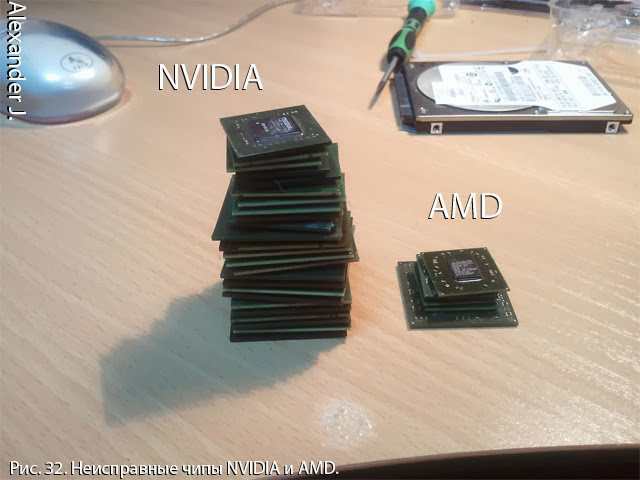

In this photo, I sorted out the chips replaced in six months into two turrets. NVIDIA and AMD. Intel chipsets were three, so they did not take pictures.

Here are the statistics in the table (for the design of the table, thanks to homm ):

Total: 101 pieces

Assuming that the owners of laptops, regardless of the chipset, use them equally, it’s obvious that NVIDIA is the leader, with a giant margin. The laptop (or video card, with some exceptions), which is NVIDIA chipset, was sentenced from the date of purchase.

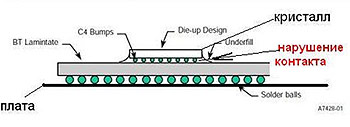

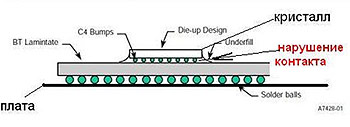

The defect usually appears as a black screen, i.e. the lack of an image after switching on, sometimes you can hear how Windows loads. Sometimes rarely there are colored stripes or rectangles. Or another defect related graphics. Sometimes there is no backlight on the matrix, or the lack of an image on the LCD matrix and the presence on HDMI or VGA and vice versa, and the replacement of the matrix or loop did not solve the problem.

It is easily diagnosed - the NVIDIA video chip chip heats up with a temperature of 260 for 30 seconds. If the image does not appear, then the temperature rises, for example, to 280, or the heating time increases. The chipset TEMPORARY restores performance . This is only a diagnosis, but not a repair. The problem is solved only by the repair described above with the replacement of the chipset with a new one.

This “temporary” can last several days, or several weeks, or even several months. By the way, some readers may recall the repair of video cards "baking in the oven" - this is the essence of the same thing. By the way, Tegra tablets also come to life after the chip warms up.

(Also, thanks to Tiberius for the link Opening the Nvidia 8600M GT chip , I recommend to look at the photos.)

Fraud

This method is used by bad people. Therefore, it is not possible to buy used laptops without a remaining store / factory warranty. Only with good friends or acquaintances, and it’s not a fact that they did not become a victim of “repair” by heating, or a laptop was removed from the factory warranty, for example, due to flooding, broken ports, etc. Most often, such heated laptops are sold on radio markets and on forums. A guarantee is given - a month. If he does not last so much, you can always warm up again. Therefore, if you buy an old laptop at random, then no more than $ 50. Then it makes sense to either repair, or you can sell LEDs and HDDs and offset the costs.

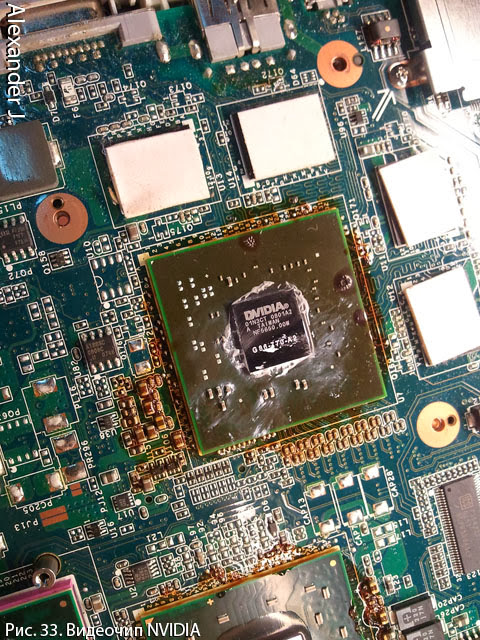

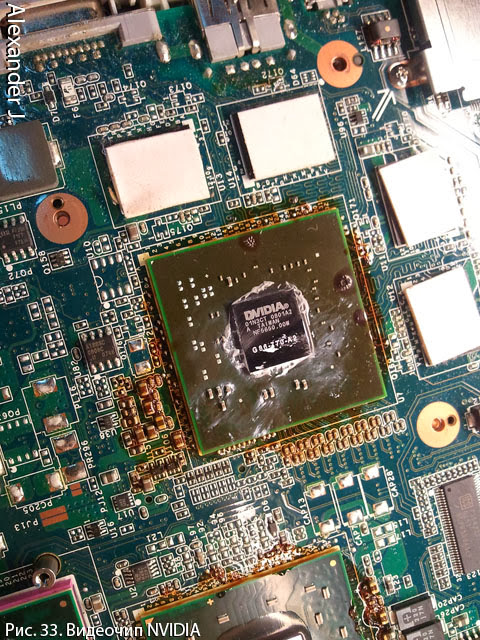

The second way of a bad “repair” is “reballing”. About reboling talk on radio markets and forums. They say that the chip’s contact with the motherboard disappeared, it is necessary to re-solder (for ~ $ 60) - “perebolit”, “debunk” the old chip and everything will be OK. The legend is quite common, especially among cell phone repairmen, who have the majority of phone repairs done by heating everything and everyone. After some heaters "at work," acne and everything else, repair does not make sense. The photo below is an example of such a repair - it worked for three months.

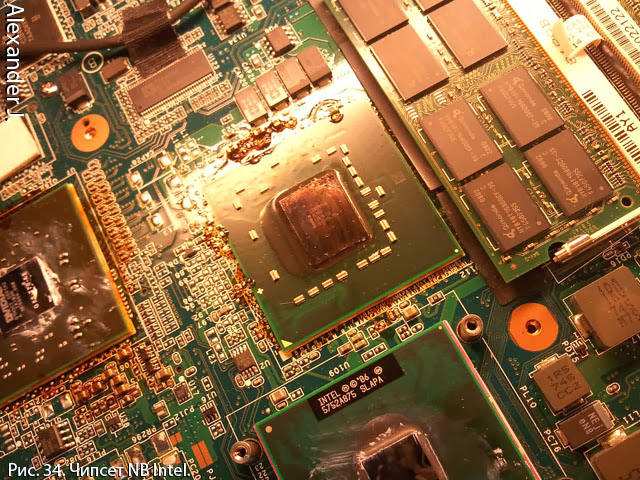

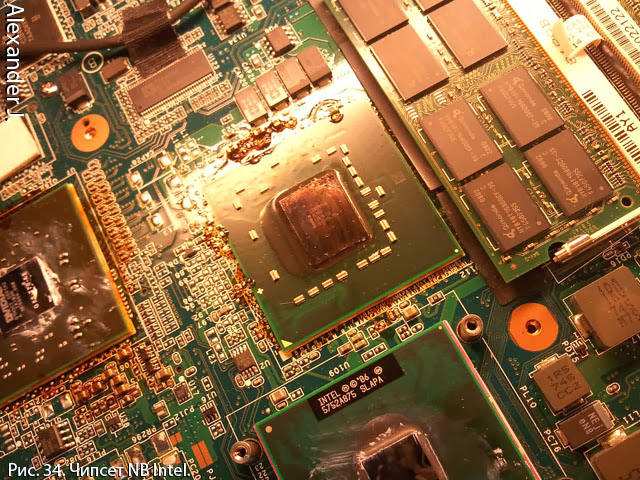

Corporate handwriting is alcohol-cocable. Legend has it that it needs to be poured under the chipset, heated by air and when the balls melt, move the chipset to re-establish contact. “Rosin does not happen much” was decided by the master and was not limited to the NVIDIA video chip, and otkanifolil, and the INTEL chipset, which almost never fail. And certainly not diagnosed by heating.

After such "repairs" a normal master or service center is not taken for repairs. Or replace the chipset without warranty. It is not known what was heated, and how long the heated components will live. Repair after "repair" - a thankless task and lost time.

Why laptops fail

And now a little about why laptops break.

Obviously, this is one of three reasons:

1. Chipset manufacturer ; Obviously, NVIDIA microcircuits are less “heat resistant” compared to their competitors, the higher operating temperatures are directly related to their lifetime. Probably, many may recall the mass appearance on the market of silent video cards several years ago, for example, NVidia 8500-8600 video cards with huge radiators without fans. Soon, these video cards also became massively out of order. And it is unlikely that these video cards have survived to the present day. At the same time, the top 8800 performed by such gurus as Gainward, with monstrous radiators on heat pipes, have survived to our days. She still lives with a friend - under the load, the temperature of a video card does not rise above 40C with a little (depending on room temperature). My friend's Gigabyte Geforce 9600 is alive, fanless, with a large heatsink with thermal tubes, but it has been “blown all his life” by a large case fan. But, however, there is a suspicion that NVIDIA may produce more reliable chipsets. In the MacBook, the chipsets of unique series that have not been found anywhere else. In those very rare cases when the chipset in the MacBook fails, there is difficulty in selecting a close analogue - not all video chipsets provide a picture or work normally, for example, in 3D mode. Therefore, I assume that NVIDIA, when it wants to, makes good chipsets. She wants when she gets paid for quality. By the way, AMD chipsets from the turrets in Figure 32 could be found on desktop motherboards, where they may still be working under their own radiators.

2. Laptop manufacturer ; As can be seen above, subject to certain conditions, chipsets can work for a long time. But for a laptop manufacturer, it is becoming more and more difficult to go beyond these conditions. Fashionable design, ultraslim and the like, leaves no room for maneuver. External attractiveness is more important than internal content. In the overwhelming number of cases, the buyer will choose a more beautiful laptop, without delving into its design. In the race for ultra-thin, elegant design laptops lost metal parts - stiffeners, which gave them extra strength. For example, often now the mechanical load applied to the lid of the laptop when opening and closing is attached to the metal frame of the LCD matrix (found on ASUS), which now also adds rigidity to the lid design. With tight loops, the matrix starts to deform strongly in the center (the matrix holds tight loops on each side, and the owner opens and closes behind the center of the top) and a defect appears on the matrix - vertical stripes in the center, first sometimes, then permanently. Another solution to make the laptop lid thin is to make an LCD matrix by assembling it in the lid body (Top case). Those. the lid is not collapsible, there is nothing to change, if the matrix is damaged, you need to change the entire lid ($ 300 instead of replacing the usual matrix for $ 100). Example - Acer S3.

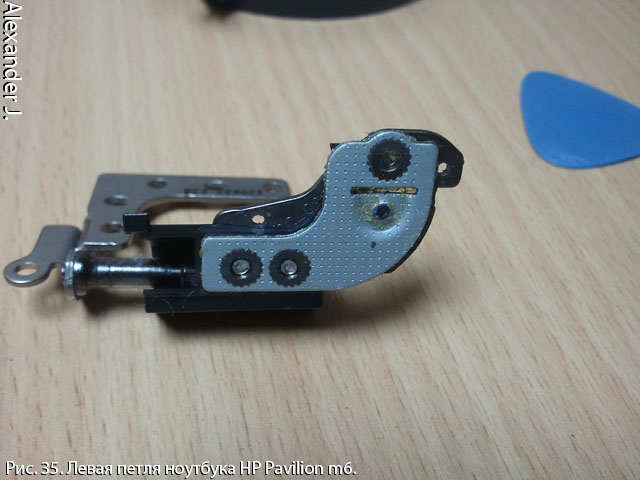

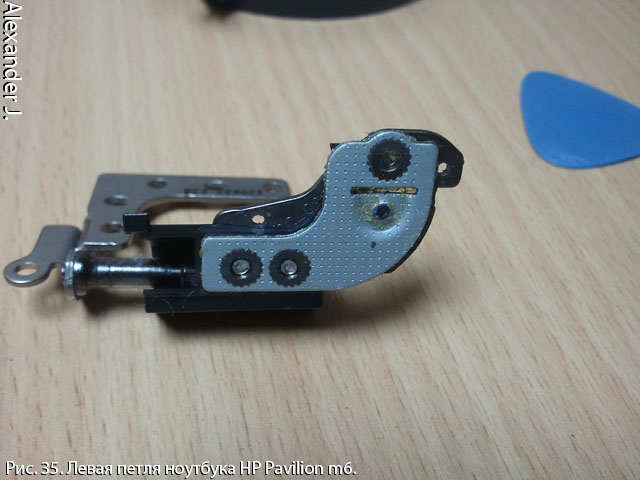

Another example in the photo - in the new models of the HP Pavilion m6, the hinges are glued to the back of the metal cover. It would be nice, but very tight loops (with time due to dust and dirt) come off the cover (Fig.35), breaking the screen frame.

With the thickness of the bottom of the laptop (Bottom case) manufacturers are also successfully fighting. Instead of 9 mm hard drives, they put 7 mm or replace them with flash memory. Processors and RAM are soldered to the motherboard, getting rid of a thick layer of sockets and connectors. The battery ceases to be removable, becomes flat and is placed inside the laptop (by the way in the MacBook so long ago). The size of the radiator also decreases. Although the heat dissipation is reduced, but still far from the ideal efficiency. Miracles do not happen. The processor and the video card, if there is a video card, operate in such modes that the radiator “suffices”. At the same time and save the battery. Not surprisingly, the work on many of these laptops is felt as a return to the desktop computer five years ago, although it would seem that the "new processor".

In addition to the fundamental working conditions, due to the external design, there is a factory defect. Single cases or massive, as a year ago at Acer with replacement in spare parts with part numbers 55.M41N7.003 and LK.15608.014.

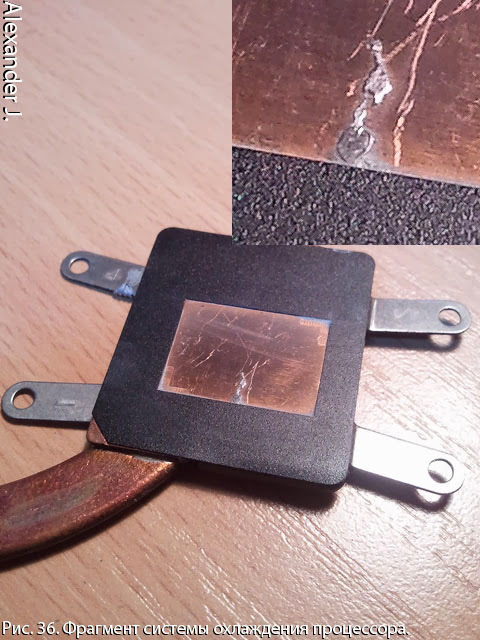

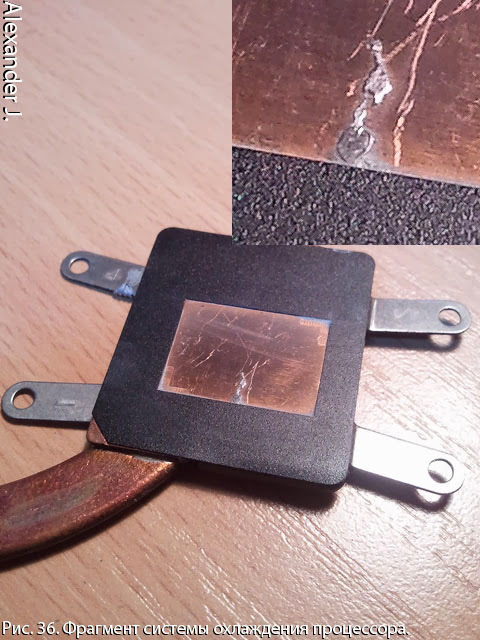

And an example of a single case is a drop of solder under thermal paste (Fig. 36).

It was the HP Pavilion warranty laptop. The motherboard failed, when replaced under the old thermal grease, there was such a surprise. Naturally, the processor was hotter than without this drop. The same HP Pavilion models with an AMD A4 processor with a radiator have a massive problem. The copper plate adjacent to the processor chip and transferring heat to the heat pipe, as it turned out, can slightly shift on different copies of the cooling system. Something about a millimeter. It would not matter where it was soldered, if the plate were made much more than a processor chip. But in practice it turned out that the face of the crystal often turns out to be on the very edge of a small radiator covering the copper plate, and sometimes the edge of the crystal is slightly outside the plate area, i.e. did not cool. This not only manifested itself as an unusually high temperature at idle — about 60 ° C, instead of 40 ° C, but also, in my opinion, was the cause of the output of some processors, both due to overheating and mechanical stress arising in the crystal, resulting from uneven temperature in the crystal. In practice, there was a case - a post-warranty laptop, an AMD A4 failed, it was discovered that the crystal was “peeping” from under the radiator. So that the client does not return the burnt new processor, which is already a guarantee of the service center, this plate was re-soldered to the correct position on the heat pipe. The burned-down processor was heated and revived hard, later it was used for diagnostics in the SC.

I also want to talk about the increasingly used powerful transistors, for example, in the TO-276 package, instead of the TO-263. It would seem, what's the problem? The fact is that in old transistors the metal substrate is large, through it the heat from the transistor crystal is well removed. New transistors have a smaller substrate area, as a result, heat transfer is worse, and at the same current there will be a higher temperature, overheating, and failure is more likely. Failure of transistors in power circuits often has a fatal effect on the power supply units — for example, passing a 19 volt supply voltage across a 3.3 volt circuit through a punctured transistor. Most likely, in this case, the laptop is beyond repair.

By the way, there are defects with transistors that restore, for a while, their work after warming up. Laptops returned a couple of times after replacing the chipset, after digging into the scheme, it turned out that a new transistor was to blame for a transistor near that same replaced chipset. Warming up the board when replacing the chip, for a while put it in order.

We continue the topic of overheating in the last "reason" "why laptops break."

3. Laptop user. A large army of laptop users buys laptops to destroy them. Some reach the goal in the first weeks. The most popular way is to pour a cup of coffee or a glass of beer, but some try other liquids, such as soup. Often they are helped by pets. Foreign objects or own weight are also successfully applied.

In all disputable cases, if it cannot be unequivocally said that it is the client’s fault - repairs are made under warranty. Some customers arrange the show. Especially often "prove" their non-involvement in flooding. Although sometimes the client is not aware of the reasons for the failure of the laptop, for example, there was a case when the wife “wiped” the keyboard with Mr. Muscle cleaner. Leaked fluid destroyed keyboard. Or the children had a hand on the laptop, or the two hind legs of the cat sat down. It was like that. By the way, there is a nuance of how to clean the surface of the screen, the body - you can not sprinkle or pour cleaning fluid on the surface to be cleaned. It simply flows down the screen, flows into the screen lid, flows under the keyboard. That's right - moisten a cloth to a wet, but not wet, condition and wipe with a cloth. So on the laptop there will be no excess liquid.

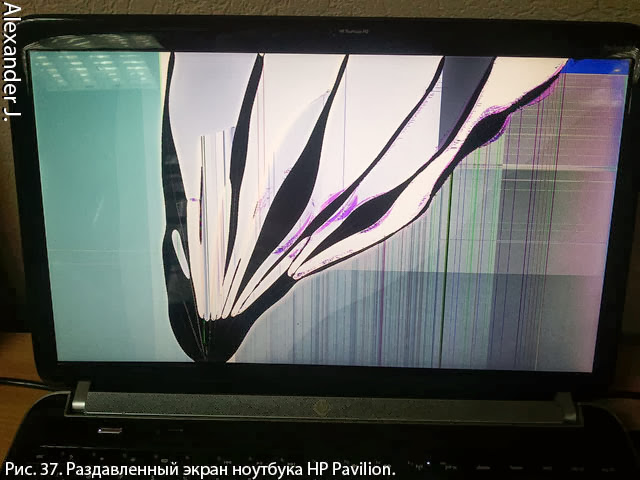

And here is an example that I saved forever because of the enchanting argument of a client.

Quote from the client:

The defect occurred due to a microexplosion in the matrix, which occurred under the influence of air heated to 100 degrees coming out of the cooling system of the HP Pavilion DV6-6175sr laptop. Hot air caused the evaporation and ignition of a special glue used by HP in the manufacture of LCD matrices. This is a well-known fact that is actively discussed in the forums.

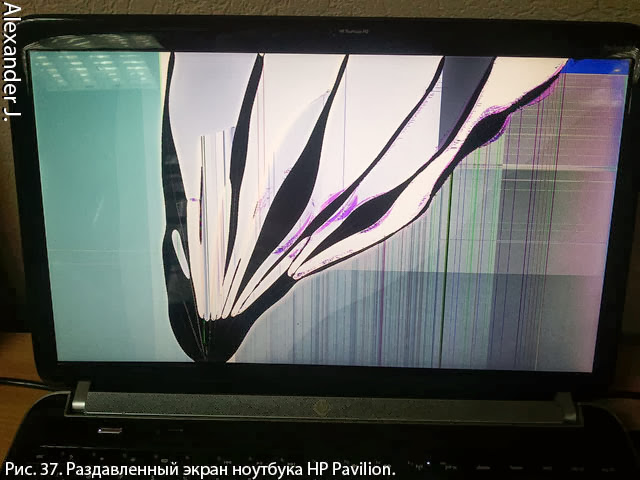

In the photo, a common defect that occurs when closing the laptop lid when a foreign object remains on the keyboard (for example, a ballpoint pen, a USB flash drive or a cap). Naturally, the scandalous client received from the official representative office an act of technical opinion on the removal of the laptop from the guarantee. And it was possible to quietly, without exposing the serial number of the laptop in such a scandal, to replace the matrix and the laptop for a fee (except the matrix) would remain under warranty.

Overheating of a laptop is a problem that all happy and not very owners of this technology face. Only there can be no talk about any explosions and fires. Excessive heating around the processor and video card - in addition to the above-mentioned transistors and chipset, is the cause of the failure of even capacitors - ceramics closes, electrolytes lose capacity. Finding a locked capacitor in the chipset power supply circuit is not the best pastime.

Unlike the desktop, which can become overgrown with dust for years and at the same time feel very bad, laptops have it much faster and most importantly with fatal consequences. Moreover, the laptop can be used on the lap, on the table with a tablecloth, and lying on the sofa tightly blocking the ventilation openings of the notebook. and do not need dust

Figure 39 is not the largest "boots" in the cooling system. But he completely closed the air outlet from the cooling system. The cooling system is quite simple - a heat pipe to which the radiator fins, blown by a fan, are soldered on one side. On the other hand, the copper (or brass - it is clear that the material contains copper) is a plate pressed against the processor. If there is a video card, then it may not have its own cooling system, and cuddle around the middle of the same heat pipe with its copper plate.

The cessation of air movement through the radiator will significantly increase the temperature, and the increased temperature, for example, the NVIDIA video card chip, leads to fig. 32.

In many cases, the radiator can be cleaned only completely or almost completely disassembling the laptop. Do not try to pierce the "felt boot" outside with wire, awl, etc ... This does not help, but you can still damage something. If there is a little dust, you can gently clean it with compressed air. Avoid continuously blowing inwards and spin the impeller - it will break the blades. Whenever possible, disassemble and remove debris from the radiator and fan. In some laptops, it is enough to remove the keyboard to gain access to the fan.

The advice here is prevention, sometimes to control the temperatures of the processor and video card with or without a load. If the temperature changes abruptly with the appearance of a load - for example, from 50 to 80, then cleaning is most likely necessary. If the cleaning did not help - most likely the thermotube failed. Need to replace the cooling system. And one more piece of advice - if there was a thermal interface plate between a chip, for example, a video card and a thermotube, then it should not be thrown out and replaced with thermal paste. Even if it is torn. This is not an equivalent replacement, and the chip will overheat. Unfortunately, few people are interested in temperatures and carry a laptop to the service center for cleaning when a very hot keyboard gets tired of hand.

And finally, about the battery. Not only the user is guilty of the premature demise of the battery, having attached the battery after purchase and never using it, but often the store.

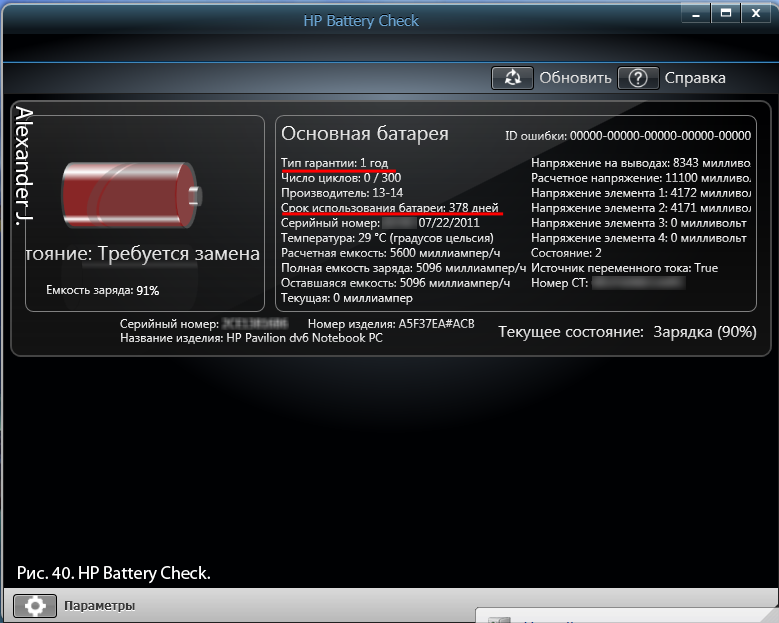

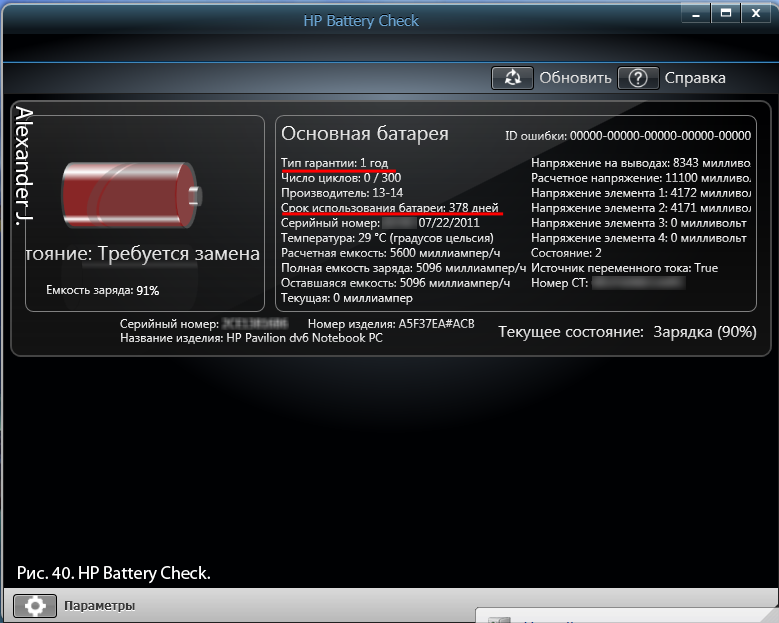

This is one of the most common cases with many laptops, but thanks to the HP software this can be seen clearly. This is the HP Battery Check utility, previously was a separate product, now it can be found as an option in the HP Support Assistant. If the HP Pavilion laptop was purchased from Windows, the program is preinstalled.

So, the client brought a laptop with a problem to the service center - “it doesn't work on battery”. A laptop bought just a couple of months ago. And already quickly discharged or even a laptop without a network turns off. See the result of the extended battery diagnostics (Fig.40) - The battery life is 378 days. Year and 13 days. And bought just a couple of months ago. There is a cashier's check and the receipt is very important - without it, there will be no warranty battery replacement. This is proof that the laptop was not really bought 378 days ago.

There are three explanations and all relate to the store where the purchase was made.

1. Pre-sale inspection upon receipt at the warehouse. The laptop is unpacked, the battery is connected, checked and packed back. The store is happy - the laptop is working. But the clock has already gone, and anyway, when it is sold, the battery life will be from the date the battery was first turned on.

2. Pre-sale check, and then installing the laptop on the storefront with a battery. The laptop is on display. The battery is not used, no necessary discharge-charge cycles. It is good if the laptop is purchased relatively quickly, otherwise “it does not work on battery”.

3. The client can return the laptop within 14 days, the client may demand a refund for long-term warranty repairs. As a result, a used laptop is in the store. The laptop is re-sold and the warranty case happens again. Here the store is in trouble - the laptop's serial number "lit up" during the previous repair. And if it was repaired by the previous owner more than a year ago, the warranty repair will be refused.If you suddenly found out about this (if it was you who brought it directly to the service shop, and did not hand over the laptop in the store), then ask for money from the store or a new laptop. From a used laptop, which has already been repaired, you can expect problems that you have not guessed.

And for those who have just bought a laptop and are considering the possibility of returning the laptop in 14 days, then save the pre-installed system - make a hard disk image before installing your OS. The product must return to the store in the form in which it was purchased.

If you cannot immediately buy another laptop, then do not buy laptops for children, do not buy yourself, if you like to eat and drink over the keyboard, if you need a laptop at home, just to lie on the sofa comfortably. Buy a tablet. Or a separate keyboard and eat on it.

Before being fascinated by development under Android, I repaired computers and laptops for a couple of years. Below, I will tell you about one of the most complicated operation for repairing motherboards and video cards - replacing the chipset, hereinafter referred to as the “chip”. And at the end of the article a little about why laptops break. I think it's worth warning - “don't try this at home”.

For work it is necessary:

Flux (BGA Gel Flux). Let's call it “liquid” (Fig. 1)

')

And "viscous" (Fig.2).

The first has a brush under the cap and is easy to apply when manipulated at room temperature, and the second is an amorphous mass that becomes liquid at temperatures close to the melting point of the solder.

Braid (Fig.3) is used to clean the sites from the old solder.

A can of solder in balls of the required diameter (Fig.4). Further in the text as "balls".

Stencil for this chip and the machine "for rolling balls". In the photo (Fig.5), the stencil and chip are mounted on the machine. In the foreground are two DDR2 RAM chips. For them, too, there are stencils.

The stencil shows the diameter of the holes and, accordingly, these are exactly what solder balls need. This is the easiest machine and not the most convenient. It rolls balls produced by heating the "air", so the stencil should be designed for heating. There is a more convenient machine that only positions the balls in place, and they are heated with a chip without a stencil. Stencils for such a machine are not designed for heating - are deformed.

Actually, two soldering stations (Fig. 6) are infrared and conventional with a soldering iron and air-vent (heat gun).

Infrared - on the right, on which the disassembly / assembly of the chip from the motherboard / video card and the "regular" one, with which a new chip is prepared for installation, is made.

The infrared solder heats the chip using a powerful irradiator located on the outrigger bar. The photo shows the feed in the parking position, in this photo to the left of the station on a tripod with a yellow triangle of the “HOT!” Badge. These stations evenly heat the chip, precisely controlling the temperature, which is impossible to do with the “air”.

This IR-SYSTEMS RE-7500 IR station is probably one of the simplest, and therefore working with it is difficult. The station has only one thermal sensor, which is installed and measures the temperature directly near the chip. A good station has, at a minimum, a second sensor measuring the heating of the motherboard from below. On the RE-7500, it is easy to damage the motherboard by simply overheating it - the station does not have any thermostat functions - by heating to the set temperatures and keeping the set temperature. By the way, the temperature readings are in slightly Chinese degrees, the solder melts at a slightly different temperature than it should.

Of the remaining tools, solder, tweezers, napkins, side cutters, isopropyl alcohol, a brush and, preferably, but not necessarily, an ultrasonic bath will be needed.

Chipset disassembly

Before you put a new chip to solder, you need to solder the old one. The motherboard is being prepared - paper labels are removed on both sides in the heating zone, the board is installed and fixed at the station, the board is centered so that the chip is under the upper heater (feed) of the station (for convenience, the station has a laser sight (Fig. 7)).

Thermal sensor is installed near the chip (Fig.8). If necessary, non-heat-resistant elements (for example, electrolytic capacitors) located on both sides of the board are covered with self-adhesive foil (in Fig. 7, two pieces of foil are visible above the right hand).

We turn on the lower heating in PREHEAT mode, the station slowly warms up to 95-100. There are 10-15 minutes to prepare a new chip.

The lead-free solder used melts at temperatures of about 210 ° C, while lead lead - at 180 ° C. The new chip has already been eliminated (Fig.10) with lead-free solder.

Chiselled (dribble, roll balls) - the balls are soldered i. It is ready for installation.

By the way, a chip without balls, everyone saw the example of Intel processors (Fig.11).

Recently, Intel processors in laptops are soldered as a chip - minus the socket, minus the height of the socket. This is often found in ultra-thin laptops.

Temperature 210 is high, especially for such a cheap IR station.

- First, the higher the melting point, the higher the probability that at this station not all the balls will melt and solder the chip.

- Secondly, the thermal deformation of the matplat.

When heated, PCB and metal conductors in a multilayer board do not expand equally. There are cases when boards from thin textolite “lead” —the board from flat becomes convex, curved, twisted. Such a fee only to throw out. There have also been cases of rupture of conductive paths, caps. In perfect infrared stations, there are profiles for heating the board according to certain temperature graphs, which makes it possible to reduce irregularity of deformations. If anyone noticed in the photo that the board at the soldering station is pressed against lead weights, this is just a precaution against possible deformations.

Thirdly, the heating of the chip itself, if it does not kill it, then it clearly increases the probability of its failure in the future. And for some types of repair, the chip has to be removed a couple of times, for example, when a defect is diagnosed, when the repair of a chip is not completed or the like Therefore, the chip must perebolit more light-alloyed lead solder.

Reboling a new chip

Getting to the reballing of the new chip. Put the chip on a napkin so as not to slide on the table. We cover the balls with “liquid flux”.

We heat the soldering iron to ... more than the melting point of lead-free solder. At the Lukey 852 soldering station, it is convenient to work at 380 Chinese degrees. The temperature should be such that the solder does not stick to the chip (to its contact pads), but rolls in the flux like mercury. But it’s also not important to keep the chip cool, so we don’t linger in one place for a long time. It is better to return there later.

A drop of the usual lead solder is taken on the soldering tip, which easily “dissolves” lead-free balls. Periodically we shake an overgrown large drop from the sting and take a new one. If necessary, smear flux.

After a minute the balls were removed, but the surface is uneven. On contact pads solder residues. Fig.5 is not a macro photograph (telephone survey), but even on it there is a noticeable “torn”, “angular” shape of some contact pads (in the photo is an ATI / AMD chip and a stencil).

The ideal surface is obtained by braiding. We again apply liquid flux on the chip and, pressing the braid with the soldering iron tip, clean the surface to the ideal. The quality is easily controlled with your finger - there should not be roughness. Drunk solder, otkusyvay areas of the braid side cutters.

Now cleaned from flux and degreased. To do this, use a toothbrush and isopropyl alcohol. We look, if there is anything left, if necessary, then repeat the step with braid.

We put on the chip a very, well, very thin layer of flux. If the liquid flux is not boiling (high-temperature), then they, otherwise the finger smear viscous. Install the chip with a stencil in the machine.

Here is the stencil. ATI / AMD has almost the same stencil for several generations of chips. NVIDIA has a lot of different.

We center the stencil in the machine - the holes opposite the contact pads of the chip.

The machine itself is placed in a box in which part of the balls will wake up from the stencil. Then, balls not smeared with flux can be poured back into the jar. Saving.

Balls are poured onto the stencil and pushed into the holes with a special spatula (complete with a machine tool), and then the last of them - with tweezers. This is what the not soldered balls look like in the machine. They slightly look out of the holes.

Next, turn on the "air" on the Chinese 380 degrees.

From a height of 5 centimeters above the machine, a chip is blown in the machine for uniform heating. Then we descend to a height of 2-3 centimeters and move around in a circle - we observe how the balls in the holes "fall through" and slowly move further. But do not linger, if any of the balls from the row did not fail - it is stuck, then we push it with tweezers and warm it up. Last we warm the balls in the center under the crystal. In the center there is a good heat exchange with the crystal and the balls will melt a bit later than it was from the edge.

This is how the balls look after warming up - they fell just below the surface of the stencil less than half a ball diameter. Balls from a spherical shape took the form close to a hemisphere, as in Fig.10. One can only guess about the difference in the picture with a mobile phone. Perhaps in the picture one or more balls "do not sit down."

By the way, the marking is visible on the stencil - chips NVIDIA GO6200 / 7600, the diameter of the holes is 0.6 millimeter. But also suitable for the G8600, the work with which is shown in these pictures.

The chip is removed from the machine, the stencil is removed from the chip (it is better while it is warm, otherwise it is well glued to the chip with flux). Check if all the balls are soldered. Wash again with alcohol and a brush. Three good, better now bounce badly soldered balls.

If there is, then wash in an ultrasonic bath in the same alcohol. In it often bad soldered balls fall away. If the balls have disappeared, then we return to the previous step - we smear the flux, put the balls in the empty places, warm. A couple of balls are put without a stencil. In the end, we get a chip chip, as in the beginning, but already on the lead solder.

During this time, the station warmed up the fee to 95-100C. We remove the softened hot melt glue, which fixes the old chip in the corners (by the absence of glue, you can guess that the chip was previously removed / replaced). Switch the bottom heating to HEAT mode, wait a bit to 110 ° C, and turn on the top heating in HEAT. We sit and look at the creeping numbers. The station is low-power, any draft carries away the precious heat. At 200C, we carefully look under the chip - when the solder melts (about 210C), the chip drops noticeably under its own weight and the force of the surface tension of the melted solder, which attracts the chip to the board. Lightly push the chip to make sure it “floats” on the melted balls and nothing holds it.

At this moment we grab the chip for the crystal with vacuum tweezers and remove it. There is a great danger that the chip could not warm up either side and there the solder did not melt. Or a random draft cooled part of the chip. Or the chip may be poured from the bottom at the corners with glue that does not melt / does not soften when heated (found on Toshiba). In this case, trouble can happen - together with the chip contact pads come off on the motherboard. Well if it will be empty - unused. Or they can be restored ... Therefore, it is important to make sure that the chip "floated" on the balls. When it is obvious that the solder has already melted (the temperature is above 210C), and the chip does not fall and does not move, then you have to lightly glue on the pasted corners, hoping that it will not tear anything along with the glue.

After removing the chip, we immediately turn off the upper heating, and transfer the lower one to PREHEAT, or turn it off, depending on future plans. Inspect the surface and make sure that all contact pads are intact. Here you need to repeat the same procedure as with chip rebolding - you need to remove the solder residues and get a perfectly clean, flat surface, but now this is done with the contact pads of the board. Most often, the old balls, almost completely, remain on the old chip, but sometimes, on the contrary, most of the balls remain on the board (Fig. 27).

Sometimes video memory fails (and in ASUS laptops sometimes all the RAM is soldered - this trend is increasingly observed among electronics manufacturers), it can also be changed, only you first need to find the faulty chip. (Homeric laughter)

To do this, just remove the solder residues braided. Apply to the pads under the chip "liquid" flux.

A drop of solder collect most of the old lead-free solder. Braid clean up the remnants of solder. Everything is similar to Fig.14 -17.

Installation of a new chipset

Finger control the surface quality i. no roughness. Then wash the surface with a brush and alcohol.

Surface smear "viscous" flux. A very thin layer of smeared finger over the surface. The most important property of high-temperature flux is that it should not boil. Otherwise, the chip will shift when heated.

Put the chip on the motherboard according to the key, center along the lines. And further as when dismantling - warming up the bottom heated to 110C. And heating, together with the top heated to the melting point of the solder. In this case, it is a lower temperature - about 180C. As soon as the chip goes down on the melted solder, slightly push to make sure that the chip floats on completely melted balls. It also helps to solder in some problem areas. For example, under some ball turned a lot of flux. Turn off the upper and lower heating. And leave to cool. To accelerate cooling by blowing it is not necessary to avoid the deformations of some boards mentioned above.

Then build a laptop and test run.

After such a repair chip, will serve for a long time. At least as previous. But whether it will live so much a laptop is another question. This is the second part of the article.

Why do I have to change the chip? And why laptops break down?

From the effect we proceed to the cause.

In this photo, I sorted out the chips replaced in six months into two turrets. NVIDIA and AMD. Intel chipsets were three, so they did not take pictures.

Here are the statistics in the table (for the design of the table, thanks to homm ):

| Chip | Quantity, pieces | Manufacturer |

|---|---|---|

| G84-600-A2 | eleven | Nvidia |

| G86-730-A2 | 2 | Nvidia |

| G86-770-A2 | 7 | Nvidia |

| G96-650-C1 | one | Nvidia |

| MCP79MX-B2 | one | Nvidia |

| G86-771-A2 | 2 | Nvidia |

| G86-750-A2 | one | Nvidia |

| GF-GO7600-N-A2 | 2 | Nvidia |

| G84-625-A2 | one | Nvidia |

| GF-GO7300-BN-A3 | one | Nvidia |

| 216PABGA13F | one | ATI |

| 216MJ8KA15FG | one | ATI |

| 216MGAKC13FG | one | ATI |

| MCP67MV-A2 | 9 | Nvidia |

| NF-G6150-N-A2 | 2 | Nvidia |

| G96-630-C1 | one | Nvidia |

| NF-G6100-N-A2 | 2 | Nvidia |

| G86-603-A2 | 7 | Nvidia |

| G86-630-A2 | 6 | Nvidia |

| G86-635-A2 | one | Nvidia |

| 215-0674034 | 9 | AMD |

| 216-0728018 | four | AMD |

| 218S6ECLA13FG | one | AMD |

| 216-0674026 | 3 | AMD |

| 216-0674024 | one | AMD |

| 216-0752001 | eight | AMD |

| 216-0674022 | 3 | AMD |

| 216MQA6AVA12FG | one | AMD |

| NF-G6100-A2 | one | Nvidia |

| 216-0774009 | one | AMD |

| GF-GO7400-N-A3 | one | Nvidia |

| G86-631-A2 | one | Nvidia |

| G73-N-B1-X | one | Nvidia |

| 216-0683013 | one | AMD |

| 218S4RBSA12G | 2 | AMD |

| NH82801 | 2 | Intel |

| QG82945GSE | one | Intel |

Total: 101 pieces

Assuming that the owners of laptops, regardless of the chipset, use them equally, it’s obvious that NVIDIA is the leader, with a giant margin. The laptop (or video card, with some exceptions), which is NVIDIA chipset, was sentenced from the date of purchase.

The defect usually appears as a black screen, i.e. the lack of an image after switching on, sometimes you can hear how Windows loads. Sometimes rarely there are colored stripes or rectangles. Or another defect related graphics. Sometimes there is no backlight on the matrix, or the lack of an image on the LCD matrix and the presence on HDMI or VGA and vice versa, and the replacement of the matrix or loop did not solve the problem.

It is easily diagnosed - the NVIDIA video chip chip heats up with a temperature of 260 for 30 seconds. If the image does not appear, then the temperature rises, for example, to 280, or the heating time increases. The chipset TEMPORARY restores performance . This is only a diagnosis, but not a repair. The problem is solved only by the repair described above with the replacement of the chipset with a new one.

This “temporary” can last several days, or several weeks, or even several months. By the way, some readers may recall the repair of video cards "baking in the oven" - this is the essence of the same thing. By the way, Tegra tablets also come to life after the chip warms up.

(Also, thanks to Tiberius for the link Opening the Nvidia 8600M GT chip , I recommend to look at the photos.)

Fraud

This method is used by bad people. Therefore, it is not possible to buy used laptops without a remaining store / factory warranty. Only with good friends or acquaintances, and it’s not a fact that they did not become a victim of “repair” by heating, or a laptop was removed from the factory warranty, for example, due to flooding, broken ports, etc. Most often, such heated laptops are sold on radio markets and on forums. A guarantee is given - a month. If he does not last so much, you can always warm up again. Therefore, if you buy an old laptop at random, then no more than $ 50. Then it makes sense to either repair, or you can sell LEDs and HDDs and offset the costs.

The second way of a bad “repair” is “reballing”. About reboling talk on radio markets and forums. They say that the chip’s contact with the motherboard disappeared, it is necessary to re-solder (for ~ $ 60) - “perebolit”, “debunk” the old chip and everything will be OK. The legend is quite common, especially among cell phone repairmen, who have the majority of phone repairs done by heating everything and everyone. After some heaters "at work," acne and everything else, repair does not make sense. The photo below is an example of such a repair - it worked for three months.

Corporate handwriting is alcohol-cocable. Legend has it that it needs to be poured under the chipset, heated by air and when the balls melt, move the chipset to re-establish contact. “Rosin does not happen much” was decided by the master and was not limited to the NVIDIA video chip, and otkanifolil, and the INTEL chipset, which almost never fail. And certainly not diagnosed by heating.

After such "repairs" a normal master or service center is not taken for repairs. Or replace the chipset without warranty. It is not known what was heated, and how long the heated components will live. Repair after "repair" - a thankless task and lost time.

Why laptops fail

And now a little about why laptops break.

Obviously, this is one of three reasons:

1. Chipset manufacturer ; Obviously, NVIDIA microcircuits are less “heat resistant” compared to their competitors, the higher operating temperatures are directly related to their lifetime. Probably, many may recall the mass appearance on the market of silent video cards several years ago, for example, NVidia 8500-8600 video cards with huge radiators without fans. Soon, these video cards also became massively out of order. And it is unlikely that these video cards have survived to the present day. At the same time, the top 8800 performed by such gurus as Gainward, with monstrous radiators on heat pipes, have survived to our days. She still lives with a friend - under the load, the temperature of a video card does not rise above 40C with a little (depending on room temperature). My friend's Gigabyte Geforce 9600 is alive, fanless, with a large heatsink with thermal tubes, but it has been “blown all his life” by a large case fan. But, however, there is a suspicion that NVIDIA may produce more reliable chipsets. In the MacBook, the chipsets of unique series that have not been found anywhere else. In those very rare cases when the chipset in the MacBook fails, there is difficulty in selecting a close analogue - not all video chipsets provide a picture or work normally, for example, in 3D mode. Therefore, I assume that NVIDIA, when it wants to, makes good chipsets. She wants when she gets paid for quality. By the way, AMD chipsets from the turrets in Figure 32 could be found on desktop motherboards, where they may still be working under their own radiators.

2. Laptop manufacturer ; As can be seen above, subject to certain conditions, chipsets can work for a long time. But for a laptop manufacturer, it is becoming more and more difficult to go beyond these conditions. Fashionable design, ultraslim and the like, leaves no room for maneuver. External attractiveness is more important than internal content. In the overwhelming number of cases, the buyer will choose a more beautiful laptop, without delving into its design. In the race for ultra-thin, elegant design laptops lost metal parts - stiffeners, which gave them extra strength. For example, often now the mechanical load applied to the lid of the laptop when opening and closing is attached to the metal frame of the LCD matrix (found on ASUS), which now also adds rigidity to the lid design. With tight loops, the matrix starts to deform strongly in the center (the matrix holds tight loops on each side, and the owner opens and closes behind the center of the top) and a defect appears on the matrix - vertical stripes in the center, first sometimes, then permanently. Another solution to make the laptop lid thin is to make an LCD matrix by assembling it in the lid body (Top case). Those. the lid is not collapsible, there is nothing to change, if the matrix is damaged, you need to change the entire lid ($ 300 instead of replacing the usual matrix for $ 100). Example - Acer S3.

Another example in the photo - in the new models of the HP Pavilion m6, the hinges are glued to the back of the metal cover. It would be nice, but very tight loops (with time due to dust and dirt) come off the cover (Fig.35), breaking the screen frame.

With the thickness of the bottom of the laptop (Bottom case) manufacturers are also successfully fighting. Instead of 9 mm hard drives, they put 7 mm or replace them with flash memory. Processors and RAM are soldered to the motherboard, getting rid of a thick layer of sockets and connectors. The battery ceases to be removable, becomes flat and is placed inside the laptop (by the way in the MacBook so long ago). The size of the radiator also decreases. Although the heat dissipation is reduced, but still far from the ideal efficiency. Miracles do not happen. The processor and the video card, if there is a video card, operate in such modes that the radiator “suffices”. At the same time and save the battery. Not surprisingly, the work on many of these laptops is felt as a return to the desktop computer five years ago, although it would seem that the "new processor".

In addition to the fundamental working conditions, due to the external design, there is a factory defect. Single cases or massive, as a year ago at Acer with replacement in spare parts with part numbers 55.M41N7.003 and LK.15608.014.

And an example of a single case is a drop of solder under thermal paste (Fig. 36).

It was the HP Pavilion warranty laptop. The motherboard failed, when replaced under the old thermal grease, there was such a surprise. Naturally, the processor was hotter than without this drop. The same HP Pavilion models with an AMD A4 processor with a radiator have a massive problem. The copper plate adjacent to the processor chip and transferring heat to the heat pipe, as it turned out, can slightly shift on different copies of the cooling system. Something about a millimeter. It would not matter where it was soldered, if the plate were made much more than a processor chip. But in practice it turned out that the face of the crystal often turns out to be on the very edge of a small radiator covering the copper plate, and sometimes the edge of the crystal is slightly outside the plate area, i.e. did not cool. This not only manifested itself as an unusually high temperature at idle — about 60 ° C, instead of 40 ° C, but also, in my opinion, was the cause of the output of some processors, both due to overheating and mechanical stress arising in the crystal, resulting from uneven temperature in the crystal. In practice, there was a case - a post-warranty laptop, an AMD A4 failed, it was discovered that the crystal was “peeping” from under the radiator. So that the client does not return the burnt new processor, which is already a guarantee of the service center, this plate was re-soldered to the correct position on the heat pipe. The burned-down processor was heated and revived hard, later it was used for diagnostics in the SC.

I also want to talk about the increasingly used powerful transistors, for example, in the TO-276 package, instead of the TO-263. It would seem, what's the problem? The fact is that in old transistors the metal substrate is large, through it the heat from the transistor crystal is well removed. New transistors have a smaller substrate area, as a result, heat transfer is worse, and at the same current there will be a higher temperature, overheating, and failure is more likely. Failure of transistors in power circuits often has a fatal effect on the power supply units — for example, passing a 19 volt supply voltage across a 3.3 volt circuit through a punctured transistor. Most likely, in this case, the laptop is beyond repair.

By the way, there are defects with transistors that restore, for a while, their work after warming up. Laptops returned a couple of times after replacing the chipset, after digging into the scheme, it turned out that a new transistor was to blame for a transistor near that same replaced chipset. Warming up the board when replacing the chip, for a while put it in order.

We continue the topic of overheating in the last "reason" "why laptops break."

3. Laptop user. A large army of laptop users buys laptops to destroy them. Some reach the goal in the first weeks. The most popular way is to pour a cup of coffee or a glass of beer, but some try other liquids, such as soup. Often they are helped by pets. Foreign objects or own weight are also successfully applied.

In all disputable cases, if it cannot be unequivocally said that it is the client’s fault - repairs are made under warranty. Some customers arrange the show. Especially often "prove" their non-involvement in flooding. Although sometimes the client is not aware of the reasons for the failure of the laptop, for example, there was a case when the wife “wiped” the keyboard with Mr. Muscle cleaner. Leaked fluid destroyed keyboard. Or the children had a hand on the laptop, or the two hind legs of the cat sat down. It was like that. By the way, there is a nuance of how to clean the surface of the screen, the body - you can not sprinkle or pour cleaning fluid on the surface to be cleaned. It simply flows down the screen, flows into the screen lid, flows under the keyboard. That's right - moisten a cloth to a wet, but not wet, condition and wipe with a cloth. So on the laptop there will be no excess liquid.

And here is an example that I saved forever because of the enchanting argument of a client.

Quote from the client:

The defect occurred due to a microexplosion in the matrix, which occurred under the influence of air heated to 100 degrees coming out of the cooling system of the HP Pavilion DV6-6175sr laptop. Hot air caused the evaporation and ignition of a special glue used by HP in the manufacture of LCD matrices. This is a well-known fact that is actively discussed in the forums.

In the photo, a common defect that occurs when closing the laptop lid when a foreign object remains on the keyboard (for example, a ballpoint pen, a USB flash drive or a cap). Naturally, the scandalous client received from the official representative office an act of technical opinion on the removal of the laptop from the guarantee. And it was possible to quietly, without exposing the serial number of the laptop in such a scandal, to replace the matrix and the laptop for a fee (except the matrix) would remain under warranty.

Overheating of a laptop is a problem that all happy and not very owners of this technology face. Only there can be no talk about any explosions and fires. Excessive heating around the processor and video card - in addition to the above-mentioned transistors and chipset, is the cause of the failure of even capacitors - ceramics closes, electrolytes lose capacity. Finding a locked capacitor in the chipset power supply circuit is not the best pastime.

Unlike the desktop, which can become overgrown with dust for years and at the same time feel very bad, laptops have it much faster and most importantly with fatal consequences. Moreover, the laptop can be used on the lap, on the table with a tablecloth, and lying on the sofa tightly blocking the ventilation openings of the notebook. and do not need dust

Figure 39 is not the largest "boots" in the cooling system. But he completely closed the air outlet from the cooling system. The cooling system is quite simple - a heat pipe to which the radiator fins, blown by a fan, are soldered on one side. On the other hand, the copper (or brass - it is clear that the material contains copper) is a plate pressed against the processor. If there is a video card, then it may not have its own cooling system, and cuddle around the middle of the same heat pipe with its copper plate.

The cessation of air movement through the radiator will significantly increase the temperature, and the increased temperature, for example, the NVIDIA video card chip, leads to fig. 32.

In many cases, the radiator can be cleaned only completely or almost completely disassembling the laptop. Do not try to pierce the "felt boot" outside with wire, awl, etc ... This does not help, but you can still damage something. If there is a little dust, you can gently clean it with compressed air. Avoid continuously blowing inwards and spin the impeller - it will break the blades. Whenever possible, disassemble and remove debris from the radiator and fan. In some laptops, it is enough to remove the keyboard to gain access to the fan.

The advice here is prevention, sometimes to control the temperatures of the processor and video card with or without a load. If the temperature changes abruptly with the appearance of a load - for example, from 50 to 80, then cleaning is most likely necessary. If the cleaning did not help - most likely the thermotube failed. Need to replace the cooling system. And one more piece of advice - if there was a thermal interface plate between a chip, for example, a video card and a thermotube, then it should not be thrown out and replaced with thermal paste. Even if it is torn. This is not an equivalent replacement, and the chip will overheat. Unfortunately, few people are interested in temperatures and carry a laptop to the service center for cleaning when a very hot keyboard gets tired of hand.

And finally, about the battery. Not only the user is guilty of the premature demise of the battery, having attached the battery after purchase and never using it, but often the store.

This is one of the most common cases with many laptops, but thanks to the HP software this can be seen clearly. This is the HP Battery Check utility, previously was a separate product, now it can be found as an option in the HP Support Assistant. If the HP Pavilion laptop was purchased from Windows, the program is preinstalled.

So, the client brought a laptop with a problem to the service center - “it doesn't work on battery”. A laptop bought just a couple of months ago. And already quickly discharged or even a laptop without a network turns off. See the result of the extended battery diagnostics (Fig.40) - The battery life is 378 days. Year and 13 days. And bought just a couple of months ago. There is a cashier's check and the receipt is very important - without it, there will be no warranty battery replacement. This is proof that the laptop was not really bought 378 days ago.

There are three explanations and all relate to the store where the purchase was made.

1. Pre-sale inspection upon receipt at the warehouse. The laptop is unpacked, the battery is connected, checked and packed back. The store is happy - the laptop is working. But the clock has already gone, and anyway, when it is sold, the battery life will be from the date the battery was first turned on.

2. Pre-sale check, and then installing the laptop on the storefront with a battery. The laptop is on display. The battery is not used, no necessary discharge-charge cycles. It is good if the laptop is purchased relatively quickly, otherwise “it does not work on battery”.

3. The client can return the laptop within 14 days, the client may demand a refund for long-term warranty repairs. As a result, a used laptop is in the store. The laptop is re-sold and the warranty case happens again. Here the store is in trouble - the laptop's serial number "lit up" during the previous repair. And if it was repaired by the previous owner more than a year ago, the warranty repair will be refused.If you suddenly found out about this (if it was you who brought it directly to the service shop, and did not hand over the laptop in the store), then ask for money from the store or a new laptop. From a used laptop, which has already been repaired, you can expect problems that you have not guessed.

And for those who have just bought a laptop and are considering the possibility of returning the laptop in 14 days, then save the pre-installed system - make a hard disk image before installing your OS. The product must return to the store in the form in which it was purchased.

If you cannot immediately buy another laptop, then do not buy laptops for children, do not buy yourself, if you like to eat and drink over the keyboard, if you need a laptop at home, just to lie on the sofa comfortably. Buy a tablet. Or a separate keyboard and eat on it.

Source: https://habr.com/ru/post/246715/

All Articles