Printing machines. The power and support of typography

Good day, Habr.

The seal surrounds us and permeates all spheres of human life. But is it always that printing was so simple and ordinary? By no means. Have old units disappeared from our lives? Also no. Something archaic surrounds us to this day, although it was wrapped up in modern technologies and robotic lines, but the basic principles of the design of printing machines do not change. I'm talking about typography in its classic, original form. Want to know a little more about how your favorite magazines are created or free newspapers are clogged up with a mailbox? The world of printing machines is much more diverse than you can expect.

In order to unload the material even more and make it even less academic, I reworked the publication. Now it is clearer and more interesting, yes editors-technologists will forgive me. Enjoy your reading.

')

Magdeburger Zeitung First Roll Printing Machine

Each of us at school heard about the first printers in the territory of our country. For Russia, this is Ivan Fedorov, for Belarus is Francis Skarin, but the name of Johann Gutenberg , a jeweler and inventor who lived in the 15th century, will remain forever in world history. Gutenberg's contribution as an inventor to the development of our civilization is difficult to overestimate. Having presented the world with such a thing as a printing press based on the technology of moving letters, this man from the estate of urban burghers made it possible to carry more effectively, now not handwritten, but the printed word to the masses.

What is typing? In fact, this is a process that allows you to get a given number of copies with given parameters with minimal differences between copies. Professional literature gives us the following definition:

Printing is the repeated acquisition of identical images with specified quality parameters.

In the industrial press, specifically in the method discussed in this article, the so-called forms are used, if you like, matrices. In the course of printing, ink is applied to the forms, which is transferred from it to the printed material. Professionals printed this way are called prints .

In order to avoid disputes and debates on the subject of who does what, technologists have clearly defined what set of actions and signs make up printing:

The process of printing itself cannot occur without the participation of paint, and also it does not cause irreversible deformations of the material on which the paint is applied. Each of us, reading a new book, noticed that if you hold your finger over the letters, they are greased. This is normal, because the paint does not permeate the paper but is applied with a thin layer on top of it. I will discuss the procedure for applying ink using form rollers below, but for now let's proceed to the definitions characterizing the methods of applying ink on paper that determine the technology, characteristics and quality of the printed impression.

In the previous edition of the article I wascrucified reproached in the comments for the fact that I did not reveal the essence of the methods mentioned. Specifically, in this material we will consider direct methods of printing using forms. Offset and inkjet printing, if you allow me, will receive separate articles, as they are more modern and more complex from this technology, which does not make sense in two words.

This type of printing machines is the most archaic at the moment, but it allows you to get the most complete picture of the classic print of things like newspapers, notebooks, books.

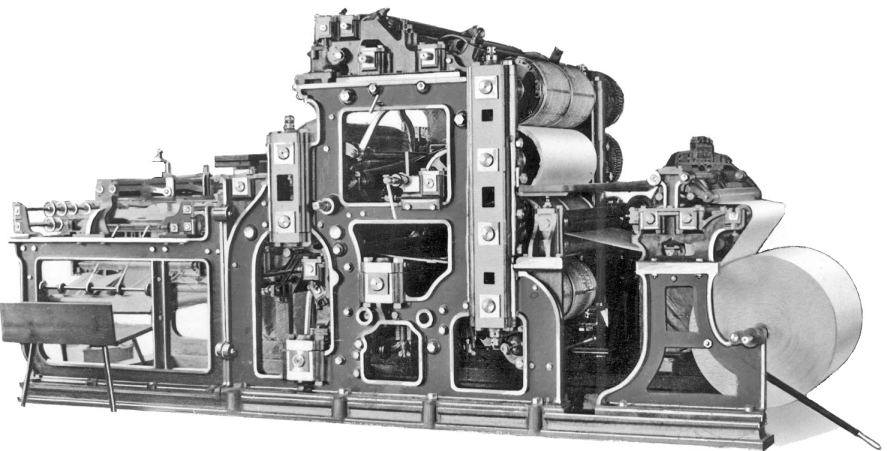

Roll rotary printing machine (hereinafter referred to as RRP-machine or simply RRP) is a food processor in the world of typography. These units have the broadest possibilities. RRP can not only print, but also fold , pick , cut and even sew the manufactured products with wire. Also, rotary machines are the first and in such a parameter as print speed. Some of them can produce up to ~ 350 sheets per minute (about 21,000 sheets per hour).

It is interesting to note that if you have an average reading speed of 200 words per minute for a person, then from the moment you start reading the article to this sentence, the RP-machine could print over a thousand sheets of text . Most likely, it is because of their productivity that they are so common for printing newspapers and books where large circulation is needed.

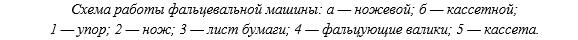

In the course of work, the paper is fed from the roll indicated in the diagram under No. 1. More complex on the device RP-machines are not limited to one roll and can work with several at once. Printing can be both one-sided and two-sided, as in our case. After start-up, the paper is fed through a system of rollers to the printing devices shown in diagrams No. 2 and No. 3. Each of them prints its side of the sheet.

The machine we are considering may have two different types of printing:

For printing newspapers and ordinary books, high printing is used, and for magazines - deep. Differences Between these types of prints, I will now explain below.

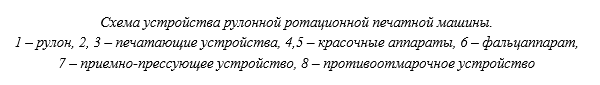

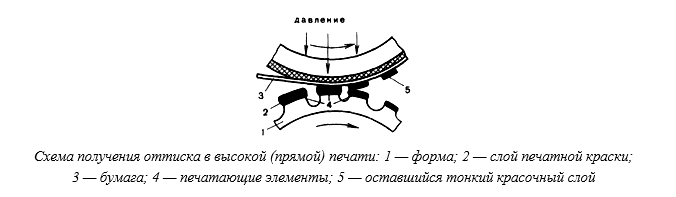

In the course of work, a paint, designated as # 2, is applied to the printing plate under No. 1. The form is pressed against the paper under pressure, which leads to tight contact between them. At the moment of contact, a part of the ink sticks to the paper and after scrolling the form on the material being printed, her paint, a thin layer, remains.

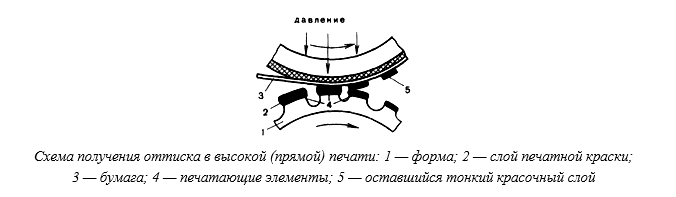

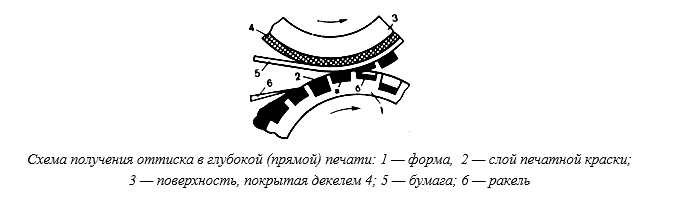

With receipt of a print of an intaglio printing everything is more difficult. The main feature is the application of paint to the entire printing form with its subsequent removal by the squeegee from the whitespace and partly from the printing elements, i.e. in fact, the paint is poured into special cells on the form, and not applied to protruding parts, as is the case with a letterpress printing. Squeegee is such an elastic flat steel knife with a thickness of 0.15–0.20 mm, the length of which is longer than the length of the plate cylinder. When the form scrolls over the paper, some of the ink from the cells sticks and remains on it. The thickness of the layer, depending on the required tonality of the image, ranges from 0.2–0.3 to 4.5–5.0 μm.

After the printing and, if necessary, cutting, the sheet enters the folding machine presented in the diagram under No. 6. Folding machine is a device that bends the fed sheets for further sorting, pressing or processing, if the cut material is a semi-finished product , in the pressing device No. 7.

Folding machines can also be different based on the principle of their work.

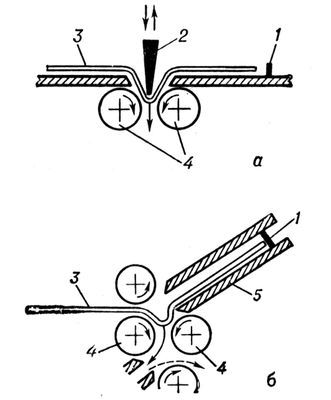

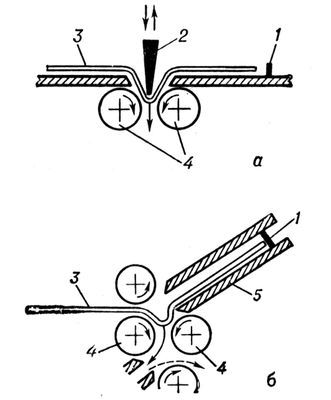

In knife machines, sheet No. 3 in the diagram is inserted between the rollers under No. 4 with the blow of a blunt knife under No. 2.

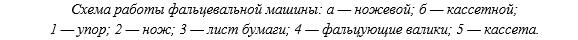

In cassette machines, however, the leading edge of the sheet supplied under No. 3 abuts against the strip of cassette No. 1, forming a loop, the edges of which are captured by the folding rollers No. 4. In operation, the cassette folding machine looks like this:

Also there are combined versions of the folding device. The first, parallel folds in them are made with the help of cassettes, and perpendicular - already with the help of knives. The folding machine can also include additional functions: sizing roots, stitching sheets with wire straps, perforation, etc.

All those described above. The process occurs, as can be seen from the gif-animation above, at tremendous speeds and with amazing accuracy. Something like this is still printed in newspapers, magazines, notebooks and books.

By the way, for the average time of reading the article, the same RP-machine would print almost 2,200 sheets . This is how it is.

With respect.

PS In this article I tried to describe in a general and accessible way the technical process that takes place in printing houses all over the world while printing, professional literature on this subject can damage consciousness. My, for example, cannot be saved (: If you liked the article, in the following publications I will be able, as I promised, to tell about offset printing, as well as about many other things, no less interesting from the point of view of implementation and the depth of technical thought of engineers and technologists.

The seal surrounds us and permeates all spheres of human life. But is it always that printing was so simple and ordinary? By no means. Have old units disappeared from our lives? Also no. Something archaic surrounds us to this day, although it was wrapped up in modern technologies and robotic lines, but the basic principles of the design of printing machines do not change. I'm talking about typography in its classic, original form. Want to know a little more about how your favorite magazines are created or free newspapers are clogged up with a mailbox? The world of printing machines is much more diverse than you can expect.

In order to unload the material even more and make it even less academic, I reworked the publication. Now it is clearer and more interesting, yes editors-technologists will forgive me. Enjoy your reading.

')

Magdeburger Zeitung First Roll Printing Machine

Introduction

Each of us at school heard about the first printers in the territory of our country. For Russia, this is Ivan Fedorov, for Belarus is Francis Skarin, but the name of Johann Gutenberg , a jeweler and inventor who lived in the 15th century, will remain forever in world history. Gutenberg's contribution as an inventor to the development of our civilization is difficult to overestimate. Having presented the world with such a thing as a printing press based on the technology of moving letters, this man from the estate of urban burghers made it possible to carry more effectively, now not handwritten, but the printed word to the masses.

A general scheme of the printing process

What is typing? In fact, this is a process that allows you to get a given number of copies with given parameters with minimal differences between copies. Professional literature gives us the following definition:

Printing is the repeated acquisition of identical images with specified quality parameters.

In the industrial press, specifically in the method discussed in this article, the so-called forms are used, if you like, matrices. In the course of printing, ink is applied to the forms, which is transferred from it to the printed material. Professionals printed this way are called prints .

The main features of the printing process:

In order to avoid disputes and debates on the subject of who does what, technologists have clearly defined what set of actions and signs make up printing:

- Transfer of paint to the material using a printing form, followed by fixing;

- The repetition of impressions and their identity, i.e. the possibility of creating a circulation .

The process of printing itself cannot occur without the participation of paint, and also it does not cause irreversible deformations of the material on which the paint is applied. Each of us, reading a new book, noticed that if you hold your finger over the letters, they are greased. This is normal, because the paint does not permeate the paper but is applied with a thin layer on top of it. I will discuss the procedure for applying ink using form rollers below, but for now let's proceed to the definitions characterizing the methods of applying ink on paper that determine the technology, characteristics and quality of the printed impression.

Methods of transferring ink to the printed material:

- direct (contact)

- indirect (contact offset)

- contactless (inkjet)

In the previous edition of the article I was

The device and the operation of the roll rotary printing machine

This type of printing machines is the most archaic at the moment, but it allows you to get the most complete picture of the classic print of things like newspapers, notebooks, books.

Roll rotary printing machine (hereinafter referred to as RRP-machine or simply RRP) is a food processor in the world of typography. These units have the broadest possibilities. RRP can not only print, but also fold , pick , cut and even sew the manufactured products with wire. Also, rotary machines are the first and in such a parameter as print speed. Some of them can produce up to ~ 350 sheets per minute (about 21,000 sheets per hour).

It is interesting to note that if you have an average reading speed of 200 words per minute for a person, then from the moment you start reading the article to this sentence, the RP-machine could print over a thousand sheets of text . Most likely, it is because of their productivity that they are so common for printing newspapers and books where large circulation is needed.

In the course of work, the paper is fed from the roll indicated in the diagram under No. 1. More complex on the device RP-machines are not limited to one roll and can work with several at once. Printing can be both one-sided and two-sided, as in our case. After start-up, the paper is fed through a system of rollers to the printing devices shown in diagrams No. 2 and No. 3. Each of them prints its side of the sheet.

The machine we are considering may have two different types of printing:

- High printing

- Gravure printing

For printing newspapers and ordinary books, high printing is used, and for magazines - deep. Differences Between these types of prints, I will now explain below.

In the course of work, a paint, designated as # 2, is applied to the printing plate under No. 1. The form is pressed against the paper under pressure, which leads to tight contact between them. At the moment of contact, a part of the ink sticks to the paper and after scrolling the form on the material being printed, her paint, a thin layer, remains.

With receipt of a print of an intaglio printing everything is more difficult. The main feature is the application of paint to the entire printing form with its subsequent removal by the squeegee from the whitespace and partly from the printing elements, i.e. in fact, the paint is poured into special cells on the form, and not applied to protruding parts, as is the case with a letterpress printing. Squeegee is such an elastic flat steel knife with a thickness of 0.15–0.20 mm, the length of which is longer than the length of the plate cylinder. When the form scrolls over the paper, some of the ink from the cells sticks and remains on it. The thickness of the layer, depending on the required tonality of the image, ranges from 0.2–0.3 to 4.5–5.0 μm.

After the printing and, if necessary, cutting, the sheet enters the folding machine presented in the diagram under No. 6. Folding machine is a device that bends the fed sheets for further sorting, pressing or processing, if the cut material is a semi-finished product , in the pressing device No. 7.

Folding machines can also be different based on the principle of their work.

In knife machines, sheet No. 3 in the diagram is inserted between the rollers under No. 4 with the blow of a blunt knife under No. 2.

In cassette machines, however, the leading edge of the sheet supplied under No. 3 abuts against the strip of cassette No. 1, forming a loop, the edges of which are captured by the folding rollers No. 4. In operation, the cassette folding machine looks like this:

Also there are combined versions of the folding device. The first, parallel folds in them are made with the help of cassettes, and perpendicular - already with the help of knives. The folding machine can also include additional functions: sizing roots, stitching sheets with wire straps, perforation, etc.

All those described above. The process occurs, as can be seen from the gif-animation above, at tremendous speeds and with amazing accuracy. Something like this is still printed in newspapers, magazines, notebooks and books.

By the way, for the average time of reading the article, the same RP-machine would print almost 2,200 sheets . This is how it is.

With respect.

PS In this article I tried to describe in a general and accessible way the technical process that takes place in printing houses all over the world while printing, professional literature on this subject can damage consciousness. My, for example, cannot be saved (: If you liked the article, in the following publications I will be able, as I promised, to tell about offset printing, as well as about many other things, no less interesting from the point of view of implementation and the depth of technical thought of engineers and technologists.

PSS To better understand the preferences of the community screwed the vote. Determine what you want to read about, if at all.

Source: https://habr.com/ru/post/246439/

All Articles