How we assemble DDBP: huge flywheels in data centers and emergency reserve facility for responsible objects

DDIBP packaging in all-weather container

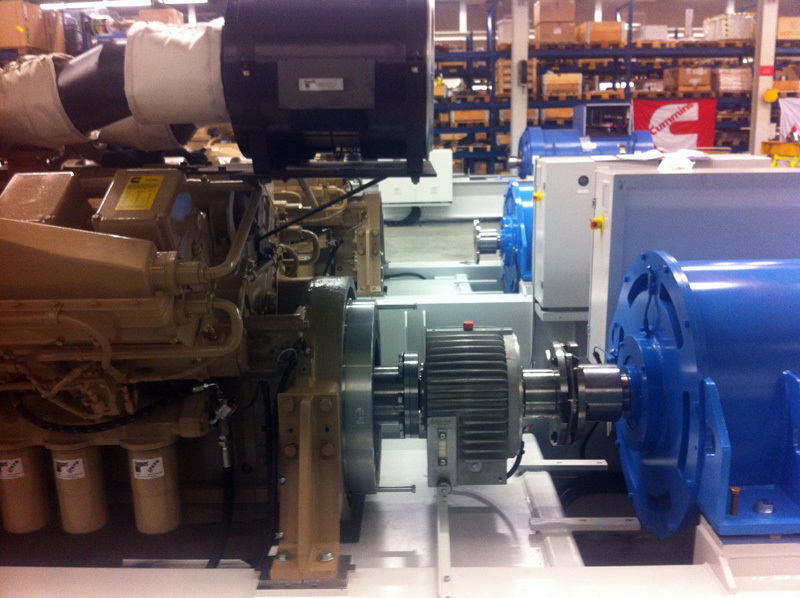

The latest domestic DDIBP stand at Baikonur. At some point in our country, the production technology of large kinetic drives was lost, and now we are taking them from Holland.

')

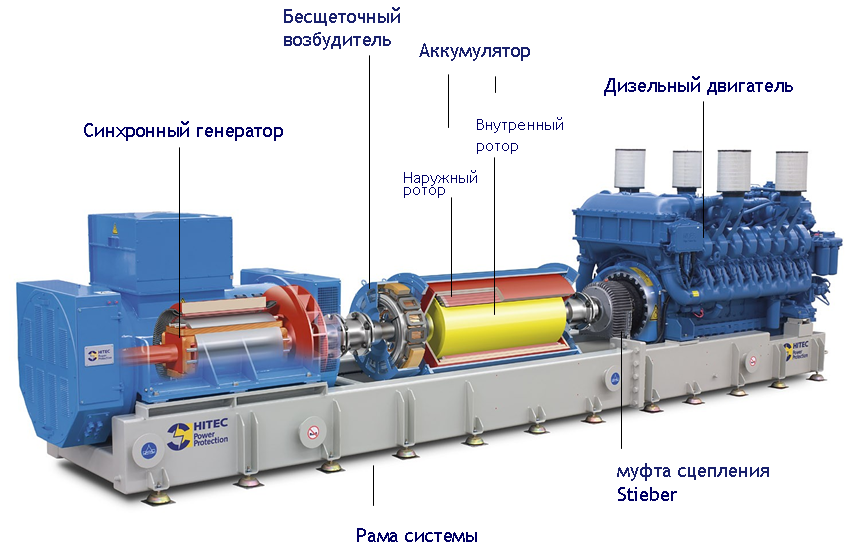

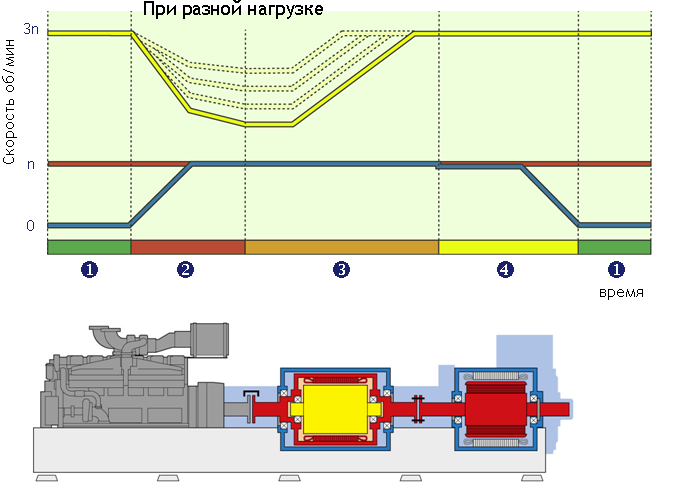

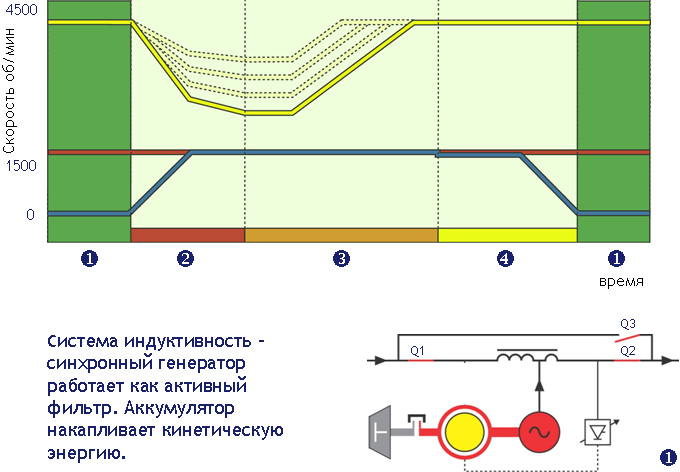

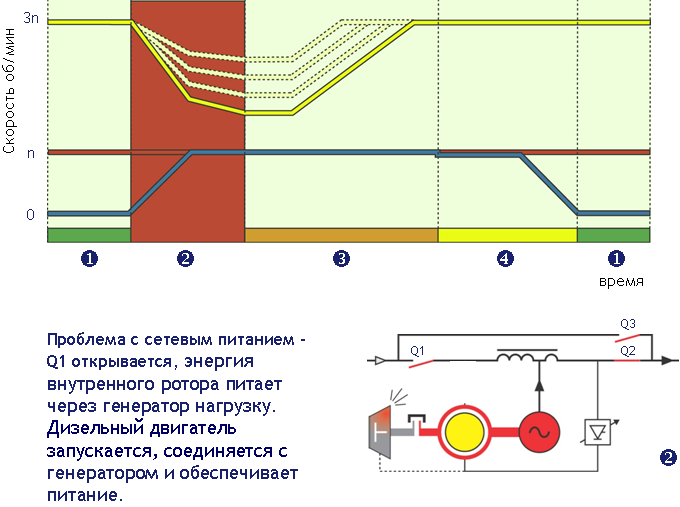

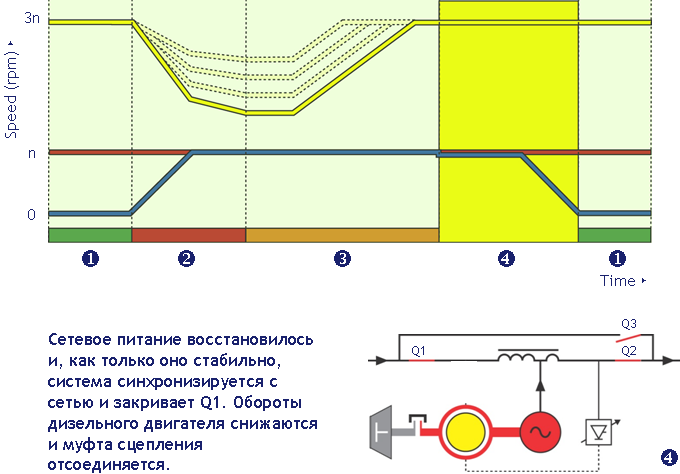

Roughly speaking, DDIBP is such a big top, mounted on a strictly horizontal shaft. The rotor of the three-phase asynchronous machine rotates at a speed of 3 thousand revolutions per minute, and the generator rotor (outside) operates at a speed of 1500 revolutions per minute. The main power circuit passes through this system. It’s time to power the abyss - and the untwisted heavy top will turn the generator through the electromagnetic field for some time. There are no switches in fact - the system continues to work without changing the voltage, frequency and current graphs. On modern installations, the “hot” diesel goes to the nominal 3-15 seconds.

Details about the device

Once again: we are spinning a spinning top and almost free of charge we support its rotation any time. When the power is turned off, the accumulated mechanical energy is converted into electric current without switching the line. Smart automation ensures that the generator shaft at the same time rotates at the same speed. The deceleration time of the top is enough to start the diesel, and UPS batteries are not needed. By the way, this is important, I saw a business center, where DDIBP was set up because standard batteries would just break the overlap with their mass.

But let's look at the usual backup power scheme — these are the UPS battery lines:

When there is a power failure, they provide approximately 7–15 minutes of work before switching on and synchronizing diesel engines. The problem of data centers and other responsible objects is in this first period: then the diesel generator is started, and everything continues to work properly (or with the degradation of services to critical ones, for example, with semi-disabled lighting).

Batteries for small objects are practical, cheap, easily backed up and built up. First, at the same time they are physically very heavy (we had a case when power redundancy in a business center with a bearing capacity of overlaps of about a ton per meter was simply unrealistically expensive to implement and, in addition, because of the space occupied give for rent). Secondly, they slowly poison gas (hydrogen), and no matter what they write in the documents, this requires separate ventilation, and sometimes air conditioning. Thirdly, they have a limited resource, and they need to be changed on average once every 5 years. Replacement of 1 MW - 2.5 million rubles, taking into account the proper disposal of used modules. Fourthly, the batteries are very demanding to the climate: the usual plug - from 18 degrees Celsius to 22. Going beyond the temperature range - the service time is reduced. And the last thing that in Russia as a whole is not paying attention: lead batteries are terribly not friendly with the environment.

DDIBP, respectively, does not require such difficulties, but then:

- Reserved entirely (need the same second one)

- Requires a much higher technological level of the manufacturer. In our case, this means shipping from Holland and the corresponding prices.

- We need regular maintenance (this is still an engine with moving parts, and we need to take care of it). However, it is worth noting that static UPSs with batteries also require regular maintenance with the same frequency as the DDIBP, which equalize them with this indicator.

Pros - a smaller area for technological needs, a longer service life (25 years, but I personally do not have projects with such prescription, the maximum my installation worked for 12 years, but I saw my colleagues in Holland and 30-year-old samples), the choke combination and a synchronous generator operates as an external power filter (no peaks, frequency fluctuations, voltage drops and transients). As a rule, DDIBP is supplied by one complex from one company, therefore it is not necessary to coordinate the work of different modules. Power factor cos (f)> 0.98. The fact is that there are no rectifiers and inverters - instead of losses on the conversion from the UPS, there is a linear circuit. The efficiency of the traditional system is about 90–93%, while the kinetic drive is at least 97%.

It is worth adding one more very important thing: modern DDIBP are completed with a diesel engine that is in a “hot” mode, similar to the “sleeping” mode of a laptop. With a ready warm-up, the output to the nominal is 3 seconds. This is not a typo, really 3 seconds. The payback is approximately minus 20% of the estimated service life from the “cold” mode, but those who have seen the de-energized medical center at least once during the operation will appreciate.

And still DDIBP is quite regularly put on the street, the blessing its mode - from +5 to +40. In combination with a suitable all-weather container, it can generally be put in the field, which is often done in a mobile version.

Who uses

DDIBP is most often placed in data centers. In Russia, there are several objects of the class TIER III or similar in terms of reliability, where kinetic drives are installed. In addition, we put the car in office centers and closed objects. It got to the point that the list of critical equipment included not only elevators, lights and IT systems, but also a regular coffee maker, which must continue to support the work of the emergency situation center even in the event of a physical breakdown of all external power supply beams.

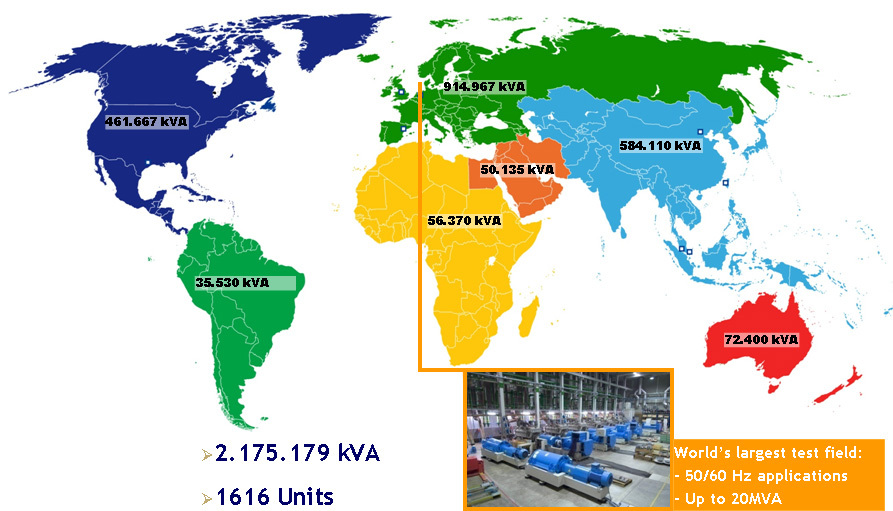

In other countries, large DDIBP are used at government and military facilities, in administrative buildings. Smaller - in medical centers for critical operating rooms, in a number of offices. As buyers of cars from our Dutch partners, Google noted for data centers, a number of major airlines for their dispatch facilities, Intel for semiconductor production, textile factories, Ford, Nokia, AT & T, NATO defense, heavy industry (the same Shell), banks, pharmaceuticals and health care .

The Chinese, for example, have recently been very actively reserved by them (probably, they also faced the problem of the thickness of the floors and the issue of storing UPS batteries, or simply learned to count money). We, for example, have an operator data center, where 3 floors are given for racks, and two more floors are for batteries with power units. Total 40% of usable area is occupied by power lines (auxiliary infrastructure).

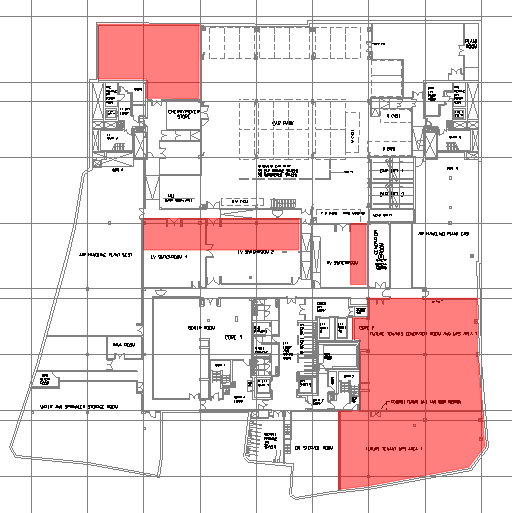

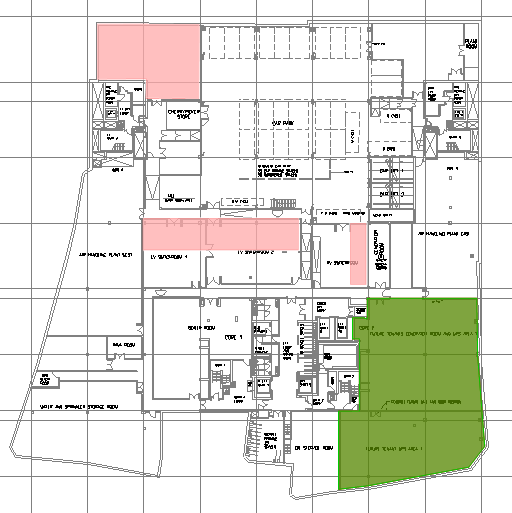

Example in the USA: 750 square meters of batteries versus 350 squares. DDPB + additional services

In Russia, I would not advise using DDIBP when consuming less than a megawatt, but, of course, in each case, when deciding on the use of uninterruptible power supply technology for important consumers, a full-fledged qualitative calculation and economic justification for applying the optimal solution is required.

In 2013, a real boom in requests for kinetics began. However, in practice, they still take the batteries, they are more profitable in a short-term case, less capital costs, and delivery is faster. And the engineer, who does not know, on the construction of most of the administrative facilities, is given on a residual basis, just to have enough money. If the plan is for 5–6 years and more, then people think about their costs, and here comes an understanding about the DDIBP, TCO, energy efficiency, etc. The work of my team begins.

Comics "One Day of Russian Food"

Until we go further, let's show once more, than a top is better than a standard scheme. So, while we have food, and DDIBP just works as a filter:

Hop! It's time to go into diesel mode:

With a continuous supply of fuel, the operating time is not limited by anything:

And back to normal mode:

The figure shows a dual starter, preheating, continuous lubrication, self-flowing fuel delivery system, anti-vibration damper, free-wheeling clutch. Normal mode - active filter. Diesel mode - powered by a generator.

Project and supply

Now back to the progress of work. So first project. 9–10 months is spent on all project documentation, including the building engineering systems. Of these, 2 months is for the DDIBP project itself, the rest is for related engineering systems and coordination. This is fast, because there is, again, an important point. We make out DDB as a mobile object with a diesel engine.

So, the fact is that diesel in a mobile version is much easier to coordinate, much less permits are required. On the stationary option - paper from firefighters, paper on ecology, paper about what to do if diesel fuel flowed. And it is convenient for the customer when moving: he drove a crane, picked up a container, took it away. The container is made noise-proof, so you can hear everything outside according to the rules and regulations (but you need earplugs inside). Usually we complete the container with a silencer and a catalyst so that there are no exhausts: engineers joke that if the DDIBP is on the Moscow Ring Road, it is better to breathe right near the exhaust pipe, the air is cleaner. Lines are taken out of the container to be monitored and controlled, if there is a common console of the operation service, go there. As a rule, installation is 4 containers: 2 DDBP installations with diesel engines and two smaller containers each with power shields. Cooling - like a regular diesel engine.

Then, in fact, the finished project is an order for production. In about 4 months, the car for the project is ready, assembled and tested, it can be transported to Russia.

Installation is always going for a specific project. First, the development of the project, then the order of components from dozens of companies around the world (about how going to "Boeing"). Tests, verification, debugging. Then, mandatory testing of all operating modes of the assembled equipment with the presence of a customer representative (this is to confirm that everything worked in the specified parameters prior to transportation, ideally). The manufacturer for 50 years has made a little more than 1600 cars, this is the world's largest figure in the industry. Here is the world distribution of all installations with total capacities based on their equipment:

At the factory - test stand:

At the exit, the kit consists of two glasses and a piece about 10 meters long. Customer engineers accompany her to the final and assist in the installation. As a rule, after runs at the factory, the machine is disassembled (one-piece shaft is not carried), and sent to customers by sea or by land. In our case, wagons drag components to the assembly site in the Moscow region. There she is going inside the container. If there is no container and installation inside the building, then the assembly is already in place in the prepared room.

Container height normal, but in size - non-standard. Permits, DPS car with flasher, thoughtful route - and early in the morning or at night we carry a container. In this place, all the more nervous - the requirements are very high. Of course, everything is insured, but if this thing falls or hits something, another 4 months at least for assembling a new car. The same lines are taken with a large margin, the iron is heavy. Last carried four long-lengths on public roads.

Loading in the shipping container from the manufacturer

Commissioning - our specialists and two manufacturer's engineers. A week or two chase full tests. Tolerances are very serious, they look at everything: contacts, connections, chains. Next - start. If the customer permits, we provide real-time telemetry directly in support of the manufacturer. Rarely collect the log on the installation site and send by mail. In general, you can not do it, but all enjoy the support and guarantee.

From time to time, routine maintenance is done. You need to prepare for it in advance: not less than 1 month you need to order the necessary supplies and spare parts. In general, the most important parts are in our own warehouses of operational reserve, but the manufacturer itself reserves more serious details, such as rotors. Replacing parts from the operational warehouse takes 4–6 hours.

If the representative of the manufacturer arrives at the TO, then this is the whole idea. They have a man-ear who walks with a stethoscope and listens to moving parts. He knows from experience what, where, and how he should growl. But, of course, she does strictly regulated work on a clear set of instructions.

Of the unexpected things, we had a case when, instead of the set 5 months, the engineer had to meet for 2 (the builders were late, this is the norm in this area). Tested without interruption, missed. There was a moment when one big chief at the construction site said: “Well, this, this, and those two should not be let out of the territory until everything is finished.” So part of the team could not get home.

If you have questions, I will answer the theoretical ones in the comments, and the practical ones for your particular object - in the mail Pvashkevich@mail.ru.

Source: https://habr.com/ru/post/245553/

All Articles