A revolution in computer simulation of the human body in motion

The modern world every day sets an ever higher bar for the manufacturer - mass-market products will not be able to withstand the competition of individually oriented offers. Consequently, the primary task of the companies of the future is to create affordable personalized solutions for each client.

Our bodies are not made under tracing paper - they are beautiful in their unique distinction from each other. The structure of the bodies varies depending on the race, gender, age, and even the bodies of the next of kin will not be identical. The development of new technologies already allows more and more items that surround us every day to adapt personally for themselves.

CAD tools that were previously used to design high-tech objects such as bridges, automobile engines, and aircraft wings can now be used to create everyday objects.

')

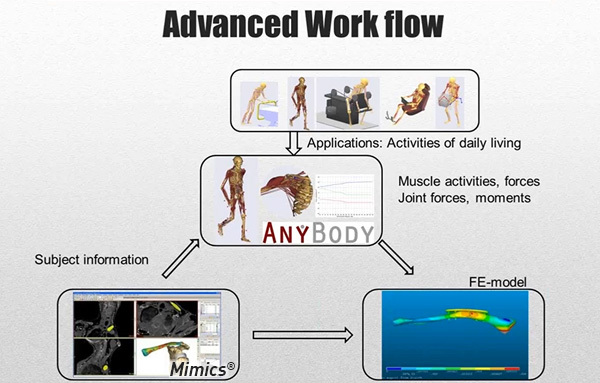

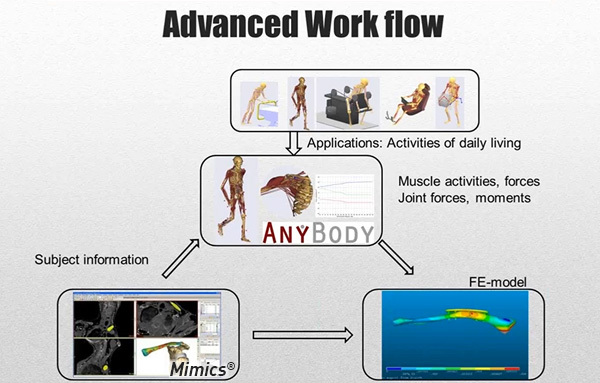

We will look at two software packages that make up a promising tandem for creating truly personalized products:

1. Mimics Innovation Suite, developed by Materialize for medical imaging

2. The AnyBody Modeling System is a computer system for simulating the mechanics of the functioning of the human body in interaction with the environment.

Mimics is a software package designed specifically for processing medical images obtained by any of the existing methods: X-ray, CT, MRI, micro CT, 3D ultrasound, and the subsequent import of this data into Mimics with the subsequent generation of a 3D model. Mimics has everything to create a highly accurate anatomical 3D client model.

Mimics allows you to:

● create an accurate 3D model based on image data

● Accurately take measurements in 2D and 3D

● export 3D model to STL format for additive manufacturing (3D printing)

The work cycle for creating a 3D model consists of the following steps:

● the client goes to the clinic, where they do a CT / MRI;

● Images are imported into Mimics;

● 3-dimensional models of bones / ligaments / muscles are created in the program, muscle attachment points are indicated;

● muscle attachment positions are adjusted for a specific anatomical model;

One of the typical tasks that is solved by the Mimics Innovation Suite is the design of knee implants and guides. When working with the knee, an engineer working with Mimics designates on three-dimensional STL models of bones points and lines corresponding to the axes and directions of rotation, bend and mutual pressure in the joint.

The result of Mimics is an anatomical 3D model, personalized for a specific client.

The AnyBody package, having the function of importing a model from Mimics, in the future can complement the process of designing implants with ultra-precise refinement. The 3D model built in Mimics can be used to calculate and optimize the kinematics of movements, taking into account the specific anatomy of the client and taking into account the model of the knee implant.

AnyBody workflow will include:

• modeling of kinematics of typical loads (for example, walking, jogging);

• import of a built human model - a skeleton with muscles, - from Mimics;

• reading and interpretation of the characteristics of the anatomical model with implant involved

After working in AnyBody, the implant can be customized individually already in the Mimics Innovation Suite.

The environment is defined in terms of external forces and boundary conditions, and the user can specify any type of posture for an anatomical model of a person, track the phases of his movement, measure the fatigue processes that occur in the muscles.

The process of working with a 3D model in the programs Mimics and Anybody

One of the most promising applications for the use of AnyBody + Mimics Innovation Suite packages is the aerospace industry.

The difference between our bodies can be uncritical in some areas, whereas in areas like astronautics, the technique of simulating the anatomy of a particular person, with all his muscles, joints, bones and connective tissues, is very important for accurate calculations.

During flights in space, an astronaut loses up to 2% of muscle mass per month due to microgravity. That is why we can observe how astronauts are practically taken out of the ship after the flight. It is no secret that it is very difficult to calculate what is happening with the muscles of astronauts during microgravity. But creating a 3D model using Mimics can help accurately predict the state of the astronaut's body and develop a special set of exercises and equipment to bring the body as close as possible to the state of normal gravity.

Also, this technique promises to be indispensable when modeling anatomical models for Formula 1, where the driver's life may depend on the accuracy in matching the structure of the body of the dummy.

With it, helicopter cabins are developed, because everyone understands that the life of its passengers depends on the pilot’s comfort and ergonomic cockpit structure and control panel. Using musculoskeletal modeling, it is possible to assess the influence of design parameters on the performance of the pilot and prevent muscle fatigue. The same applies to the seats for passengers.

Now, the ability to calculate the body's response to a specific anatomical model under any specific conditions would noticeably improve the quality of services and facilitate (and in some cases save) the lives of many people.

Our bodies are not made under tracing paper - they are beautiful in their unique distinction from each other. The structure of the bodies varies depending on the race, gender, age, and even the bodies of the next of kin will not be identical. The development of new technologies already allows more and more items that surround us every day to adapt personally for themselves.

CAD tools that were previously used to design high-tech objects such as bridges, automobile engines, and aircraft wings can now be used to create everyday objects.

')

We will look at two software packages that make up a promising tandem for creating truly personalized products:

1. Mimics Innovation Suite, developed by Materialize for medical imaging

2. The AnyBody Modeling System is a computer system for simulating the mechanics of the functioning of the human body in interaction with the environment.

Mimics is a software package designed specifically for processing medical images obtained by any of the existing methods: X-ray, CT, MRI, micro CT, 3D ultrasound, and the subsequent import of this data into Mimics with the subsequent generation of a 3D model. Mimics has everything to create a highly accurate anatomical 3D client model.

Mimics allows you to:

● create an accurate 3D model based on image data

● Accurately take measurements in 2D and 3D

● export 3D model to STL format for additive manufacturing (3D printing)

The work cycle for creating a 3D model consists of the following steps:

● the client goes to the clinic, where they do a CT / MRI;

● Images are imported into Mimics;

● 3-dimensional models of bones / ligaments / muscles are created in the program, muscle attachment points are indicated;

● muscle attachment positions are adjusted for a specific anatomical model;

One of the typical tasks that is solved by the Mimics Innovation Suite is the design of knee implants and guides. When working with the knee, an engineer working with Mimics designates on three-dimensional STL models of bones points and lines corresponding to the axes and directions of rotation, bend and mutual pressure in the joint.

The result of Mimics is an anatomical 3D model, personalized for a specific client.

The AnyBody package, having the function of importing a model from Mimics, in the future can complement the process of designing implants with ultra-precise refinement. The 3D model built in Mimics can be used to calculate and optimize the kinematics of movements, taking into account the specific anatomy of the client and taking into account the model of the knee implant.

AnyBody workflow will include:

• modeling of kinematics of typical loads (for example, walking, jogging);

• import of a built human model - a skeleton with muscles, - from Mimics;

• reading and interpretation of the characteristics of the anatomical model with implant involved

After working in AnyBody, the implant can be customized individually already in the Mimics Innovation Suite.

The environment is defined in terms of external forces and boundary conditions, and the user can specify any type of posture for an anatomical model of a person, track the phases of his movement, measure the fatigue processes that occur in the muscles.

The process of working with a 3D model in the programs Mimics and Anybody

One of the most promising applications for the use of AnyBody + Mimics Innovation Suite packages is the aerospace industry.

The difference between our bodies can be uncritical in some areas, whereas in areas like astronautics, the technique of simulating the anatomy of a particular person, with all his muscles, joints, bones and connective tissues, is very important for accurate calculations.

During flights in space, an astronaut loses up to 2% of muscle mass per month due to microgravity. That is why we can observe how astronauts are practically taken out of the ship after the flight. It is no secret that it is very difficult to calculate what is happening with the muscles of astronauts during microgravity. But creating a 3D model using Mimics can help accurately predict the state of the astronaut's body and develop a special set of exercises and equipment to bring the body as close as possible to the state of normal gravity.

Also, this technique promises to be indispensable when modeling anatomical models for Formula 1, where the driver's life may depend on the accuracy in matching the structure of the body of the dummy.

With it, helicopter cabins are developed, because everyone understands that the life of its passengers depends on the pilot’s comfort and ergonomic cockpit structure and control panel. Using musculoskeletal modeling, it is possible to assess the influence of design parameters on the performance of the pilot and prevent muscle fatigue. The same applies to the seats for passengers.

Now, the ability to calculate the body's response to a specific anatomical model under any specific conditions would noticeably improve the quality of services and facilitate (and in some cases save) the lives of many people.

Source: https://habr.com/ru/post/244103/

All Articles