Thesis project or build Hexapod with your hands

In the third year of bachelor of electronic engineering, I needed to choose a dissertation project. It could be purely theoretical or practical, which includes the production of a demonstration product. The heart went to the second version, because the practical tasks are much more interesting than boring writing.

At that time I was fond of robotics. He had the experience of building drones and smaller robots, which then followed the line on the floor, then solved the maze in a short period of time. In addition, the motivation was raised by a recent trip to Los Angeles for the annual VEX Robotics World Championship, where, by the way, it was not possible to take a prize, but it was possible to recharge with positive energy for the whole subsequent year. In general, I decided to build Hexapod with my own hands, including mechanics, electronics and code.

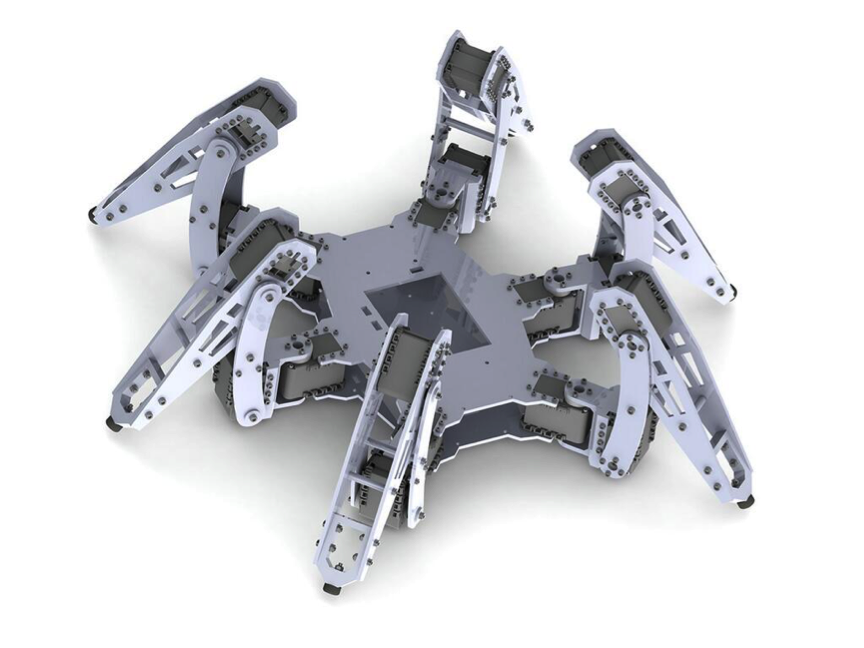

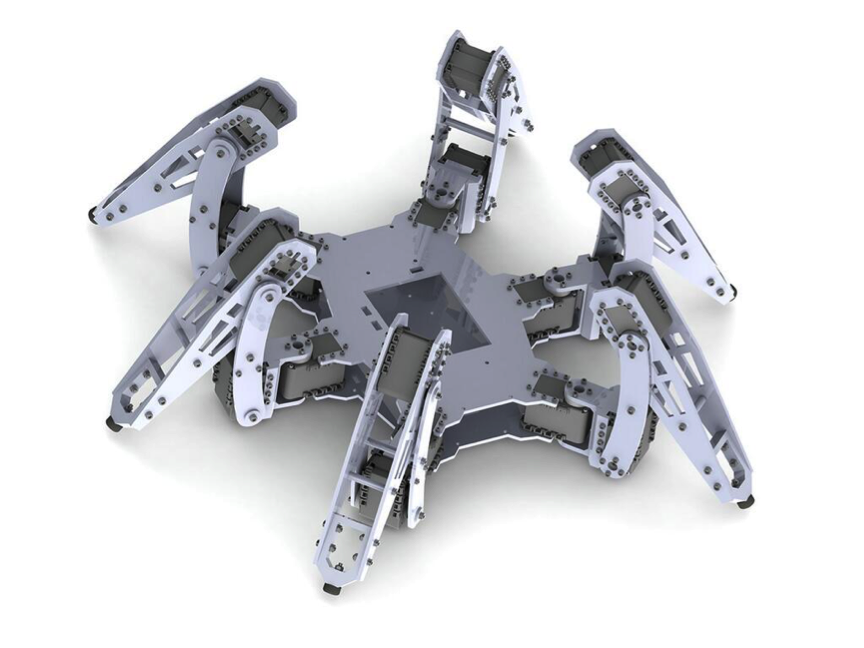

I spent half the summer in search of the muse, more precisely, I tried to review all the implementations and choose the best solution for the chassis design. Of particular admiration for the work: PhantomX, A-pod and Intel Hexapod. It was decided to draw inspiration from the PhantomX project - and this is what came of it. Looking ahead, I want to warn you that this is all that I could get from my robot for a year. But the process itself and a good dissertation ball were important to me.

')

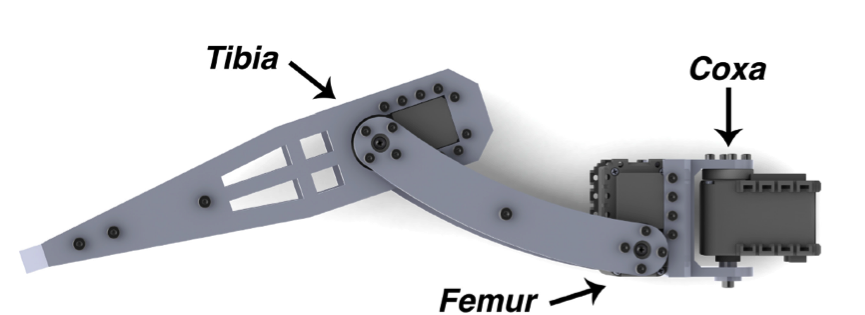

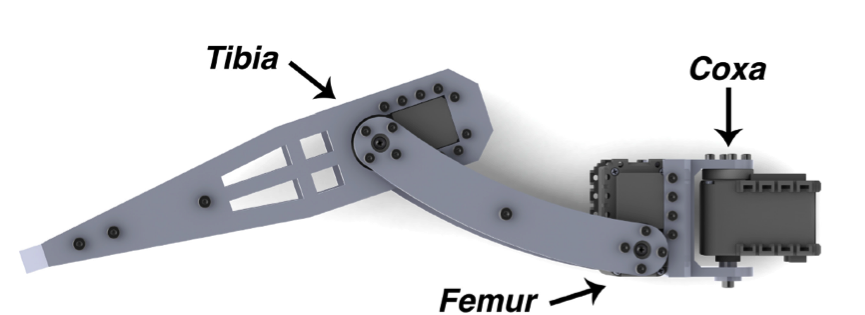

At the end of the summer, before the third year, I began to slowly loosen up and resolve administrative issues related to the project. My Integrated Systems lecturer, Dr. Tony Wilcox, happily agreed to become a supervisor for a year and assist in achieving the task. It was necessary to solve the issue of financing, as the eye fell on the excellent digital servo-wires, Dynamixel AX-12A, costing £ 26 apiece, and all it took was 18 pieces for complete happiness. Dr. Tony promised to resolve this issue. The next day, he ordered three servo drives and gave the task - to design one leg and demonstrate its performance. After the snowless English New Year, I returned to the laboratory with a wide smile, because by that time I had a working prototype of a leg in my hands.

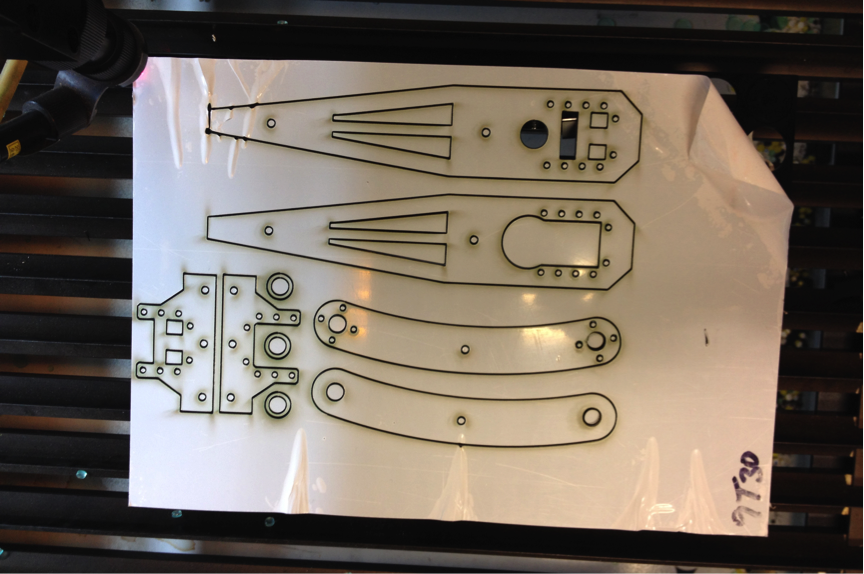

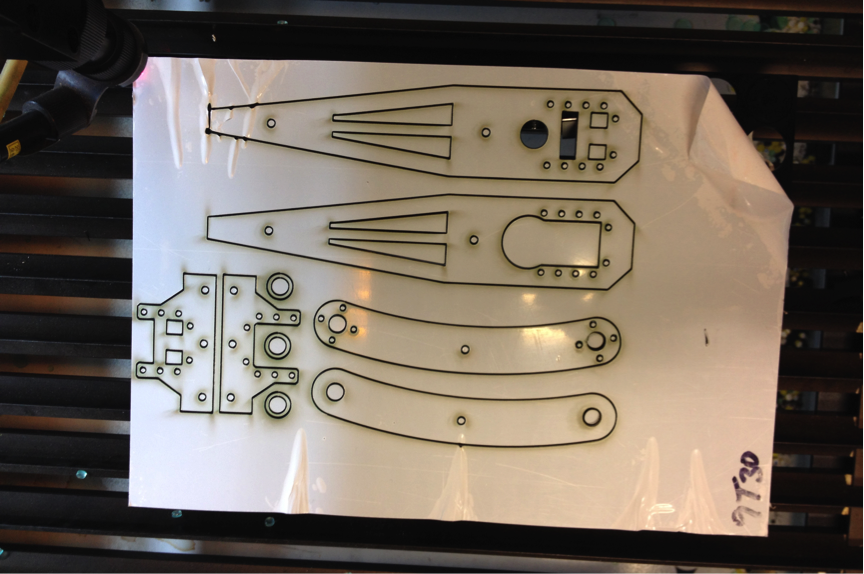

Most of the chassis was made of black thermoplastic and cut with a laser machine.

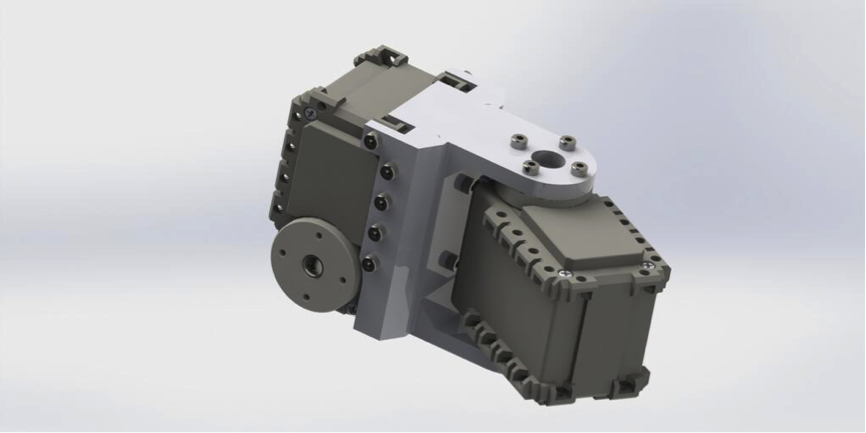

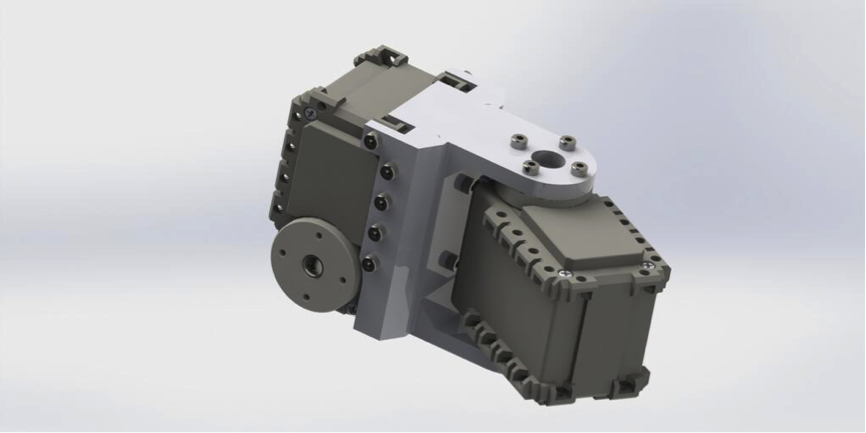

The bracket connecting Coxa & Femur was printed on a 3D printer.

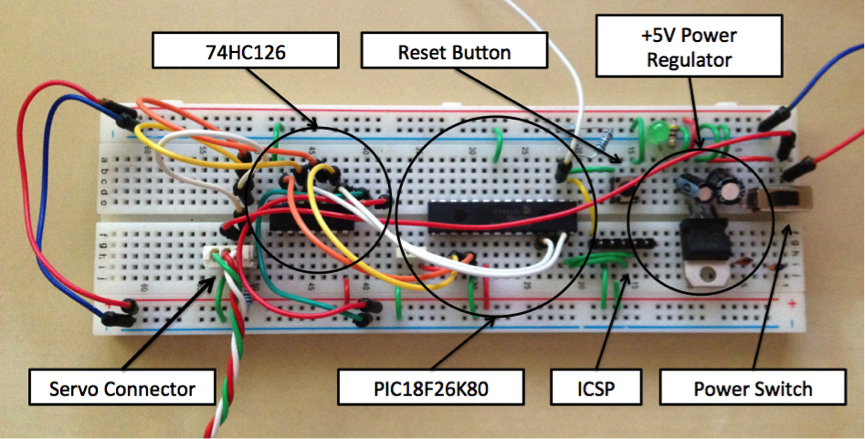

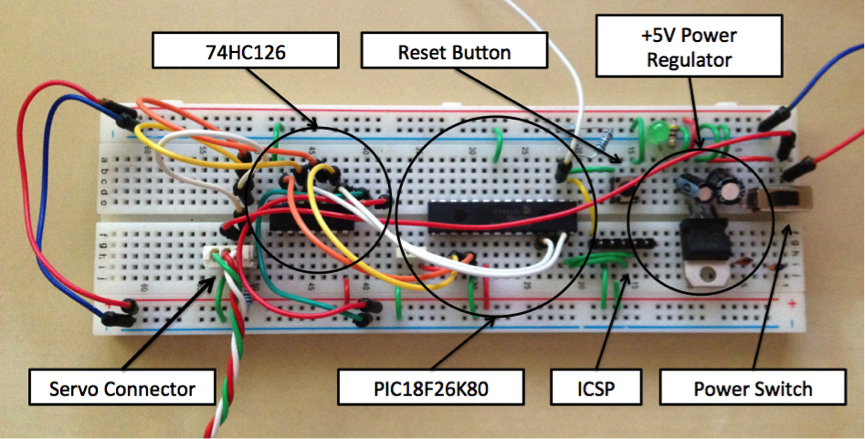

Prototype board

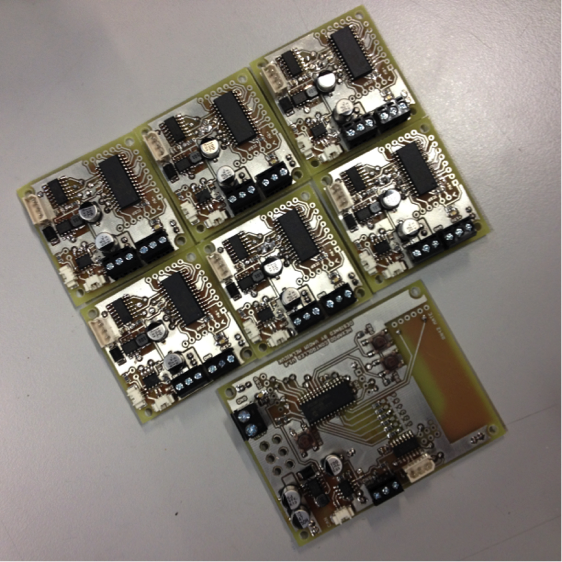

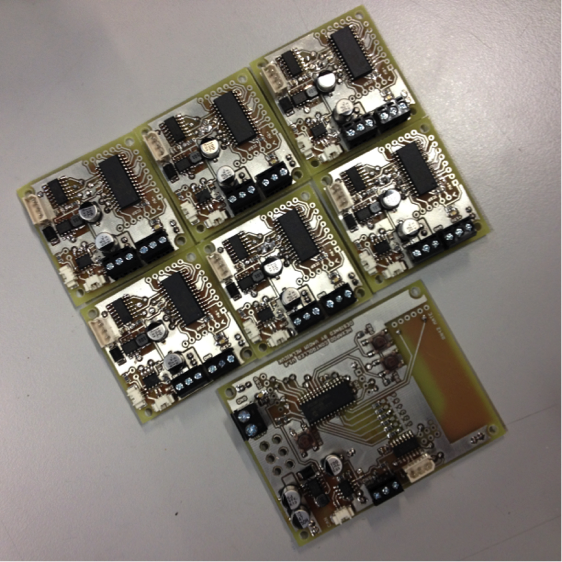

As promised by Tony, the university took care of the remaining twelve motors, and after a few days I unpacked the boxes and pasted the motors with numbered stickers so as not to get confused. Around the same time began to transfer electronic developments on printed circuit boards. It is worth noting that all the boards were created by hand in the university.

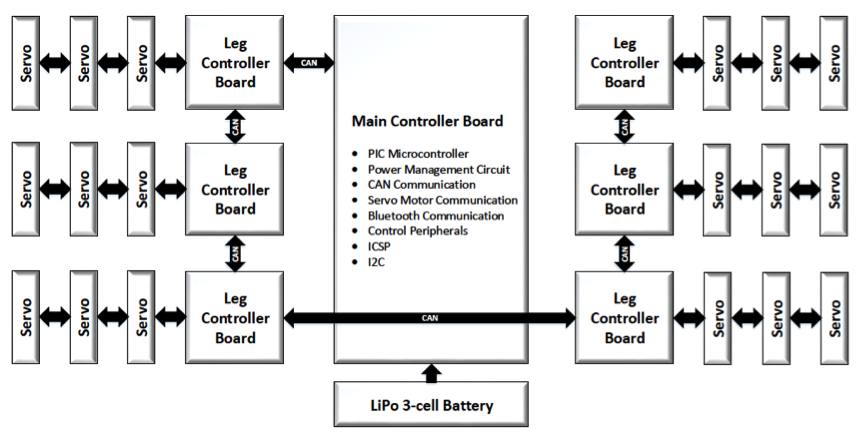

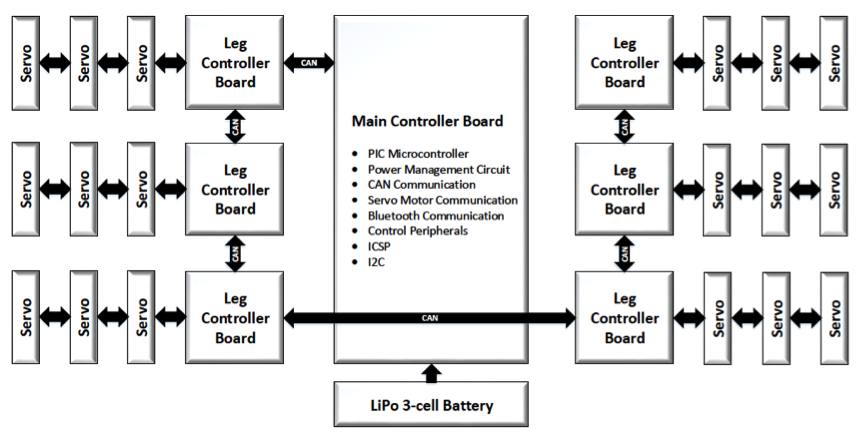

Chart with an explanation of the filling:

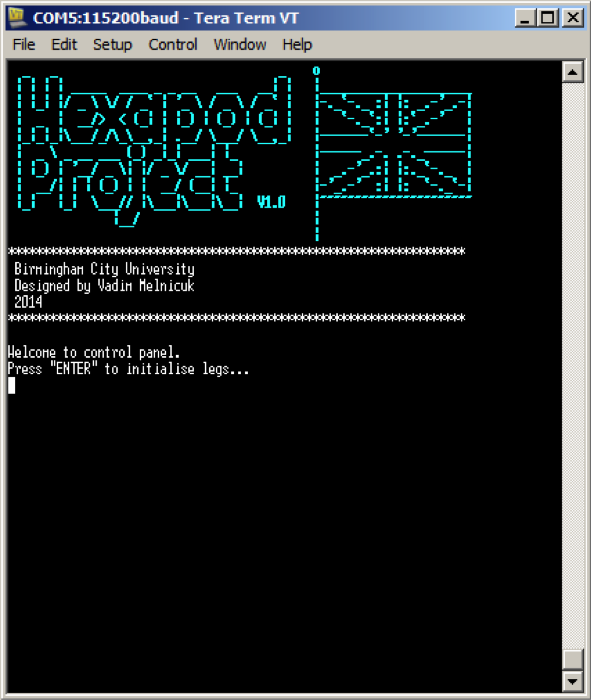

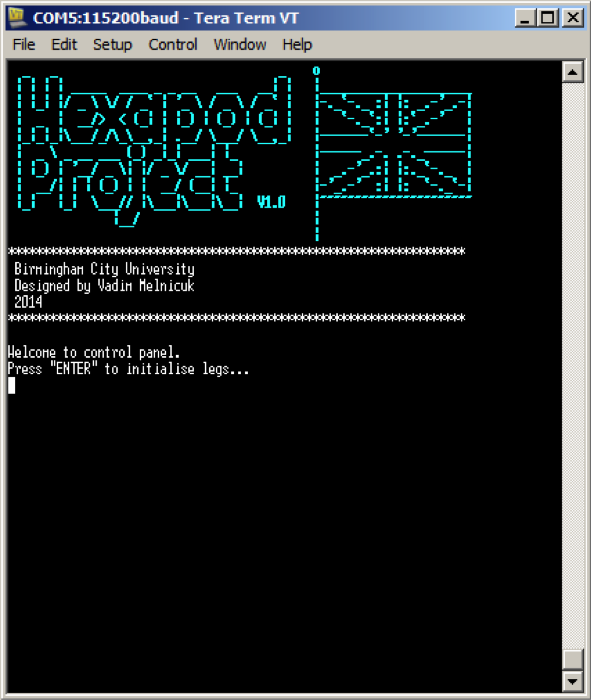

The robot is controlled from the terminal via Bluetooth:

I will be glad to answer any questions related to the material.

PS

In England, a term paper on a bachelor's degree is called a dissertation.

If there is interest, you can delve into the code on github .

Electronic circuits on google drive .

I can also put in open CAD files, write in the comments if you are interested.

At that time I was fond of robotics. He had the experience of building drones and smaller robots, which then followed the line on the floor, then solved the maze in a short period of time. In addition, the motivation was raised by a recent trip to Los Angeles for the annual VEX Robotics World Championship, where, by the way, it was not possible to take a prize, but it was possible to recharge with positive energy for the whole subsequent year. In general, I decided to build Hexapod with my own hands, including mechanics, electronics and code.

I spent half the summer in search of the muse, more precisely, I tried to review all the implementations and choose the best solution for the chassis design. Of particular admiration for the work: PhantomX, A-pod and Intel Hexapod. It was decided to draw inspiration from the PhantomX project - and this is what came of it. Looking ahead, I want to warn you that this is all that I could get from my robot for a year. But the process itself and a good dissertation ball were important to me.

')

At the end of the summer, before the third year, I began to slowly loosen up and resolve administrative issues related to the project. My Integrated Systems lecturer, Dr. Tony Wilcox, happily agreed to become a supervisor for a year and assist in achieving the task. It was necessary to solve the issue of financing, as the eye fell on the excellent digital servo-wires, Dynamixel AX-12A, costing £ 26 apiece, and all it took was 18 pieces for complete happiness. Dr. Tony promised to resolve this issue. The next day, he ordered three servo drives and gave the task - to design one leg and demonstrate its performance. After the snowless English New Year, I returned to the laboratory with a wide smile, because by that time I had a working prototype of a leg in my hands.

Most of the chassis was made of black thermoplastic and cut with a laser machine.

The bracket connecting Coxa & Femur was printed on a 3D printer.

Prototype board

As promised by Tony, the university took care of the remaining twelve motors, and after a few days I unpacked the boxes and pasted the motors with numbered stickers so as not to get confused. Around the same time began to transfer electronic developments on printed circuit boards. It is worth noting that all the boards were created by hand in the university.

Chart with an explanation of the filling:

The robot is controlled from the terminal via Bluetooth:

I will be glad to answer any questions related to the material.

PS

In England, a term paper on a bachelor's degree is called a dissertation.

If there is interest, you can delve into the code on github .

Electronic circuits on google drive .

I can also put in open CAD files, write in the comments if you are interested.

Source: https://habr.com/ru/post/241620/

All Articles