The Germans invented a way to print flexible touch displays on a regular printer.

Do not rush to throw out your old inkjet printers: in 3D , of course, you don’t care for them, but you can experiment with the technology of printing flexible touchscreen displays presented at the technology symposium held in Honolulu (Hawaii, USA).

Inventors from the Saar University and the Max Planck Institute for Computer Science (Germany) showed how to print flexible thin single or double-sided color touch displays on virtually any material: wood, marble, leather, metal, and paper itself. Unlike conventional production of flexible / touch displays, complex equipment is not required: they can be printed in almost any environment, including home ones, and with the help of the simplest equipment like an inkjet printer and standard visual editors.

Usually, to integrate the display into your product, you need to buy a set of such components:

')

The technology offered by German inventors is much simpler. All that is needed for printing is special ink. You can create a display design in any graphic editor:

- and then you just need to follow the order of applying layers. If you use paper, a regular inkjet printer will do:

Two layers of conductors are sandwiched with a phosphor layer that glows when the charge passes through the ink. Display thickness - from 120 microns (0.12 mm). The display may contain highly detailed segments with a resolution comparable to a laser print resolution of 250 dpi. To make the display two-sided - just turn the surface and repeat the process, but in principle nothing prevents to collect from it at least origami.

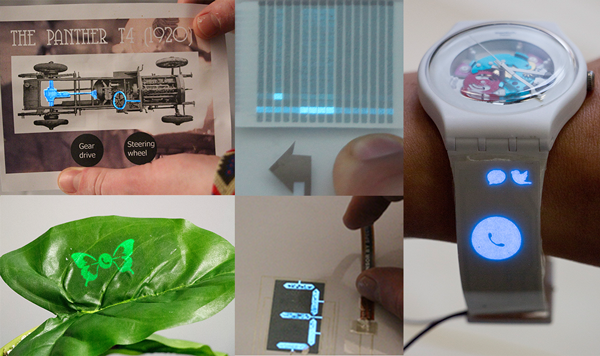

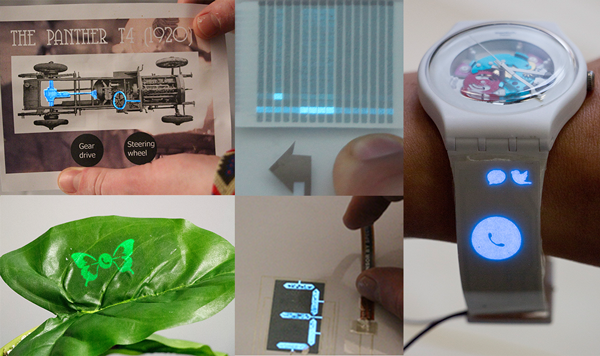

In their report, scientists have demonstrated several prototypes, their capabilities and methods of using displays printed on a Canon IP-100 inkjet printer:

Even manufacturers of smart watches did not think so to use the strap:

This is just the first sketches of ideas on how such displays can be applied - we expect thousands of them in the near future from those who decide to repeat the method of German scientists in practice.

Printing the given examples took 2-4 hours per person - the duration of the process depends not only on the complexity of the display design, but also on its size and the number of colors used. The cost of the used silver ink Mitsubishi NBSIJ-MU10 based on a fully covered A4 sheet was 19 euros.

via

If users learn

embroider displays beads -

we will start selling threads and needles

[ inform andorro news ]

Inventors from the Saar University and the Max Planck Institute for Computer Science (Germany) showed how to print flexible thin single or double-sided color touch displays on virtually any material: wood, marble, leather, metal, and paper itself. Unlike conventional production of flexible / touch displays, complex equipment is not required: they can be printed in almost any environment, including home ones, and with the help of the simplest equipment like an inkjet printer and standard visual editors.

Usually, to integrate the display into your product, you need to buy a set of such components:

')

The technology offered by German inventors is much simpler. All that is needed for printing is special ink. You can create a display design in any graphic editor:

- and then you just need to follow the order of applying layers. If you use paper, a regular inkjet printer will do:

- silver conductor layer

- dielectric layer

- phosphor layer,

- transparent conductor.

Two layers of conductors are sandwiched with a phosphor layer that glows when the charge passes through the ink. Display thickness - from 120 microns (0.12 mm). The display may contain highly detailed segments with a resolution comparable to a laser print resolution of 250 dpi. To make the display two-sided - just turn the surface and repeat the process, but in principle nothing prevents to collect from it at least origami.

In their report, scientists have demonstrated several prototypes, their capabilities and methods of using displays printed on a Canon IP-100 inkjet printer:

Even manufacturers of smart watches did not think so to use the strap:

This is just the first sketches of ideas on how such displays can be applied - we expect thousands of them in the near future from those who decide to repeat the method of German scientists in practice.

Printing the given examples took 2-4 hours per person - the duration of the process depends not only on the complexity of the display design, but also on its size and the number of colors used. The cost of the used silver ink Mitsubishi NBSIJ-MU10 based on a fully covered A4 sheet was 19 euros.

- A detailed description of the process with a listing of all the used nomenclature of technology and printing capabilities on different surfaces.

via

If users learn

embroider displays beads -

we will start selling threads and needles

[ inform andorro news ]

Source: https://habr.com/ru/post/239605/

All Articles