URANUS: the first working desktop SLA (stereolithography) printer

This time I want to talk about how I met the first (at the time of writing this article) normally working desktop stereolithography printer ( URANUS ) which is in Moscow.

The history of 3d-printers began in 1984 with a stereolithographic device. Nowadays, such printers are very often used by jewelers, since the accuracy of printing of such models is much better than FDM devices (which I print with plastic)

Under the cut there are some pictures of the printer's insides and the birth of a hydralisk from the “blood bath”

')

Spawn Hydralisk (H)

Appearance:

The first impression is similar to a paper bucket, but “behind a non-fancy interface lies a powerful algorithm”

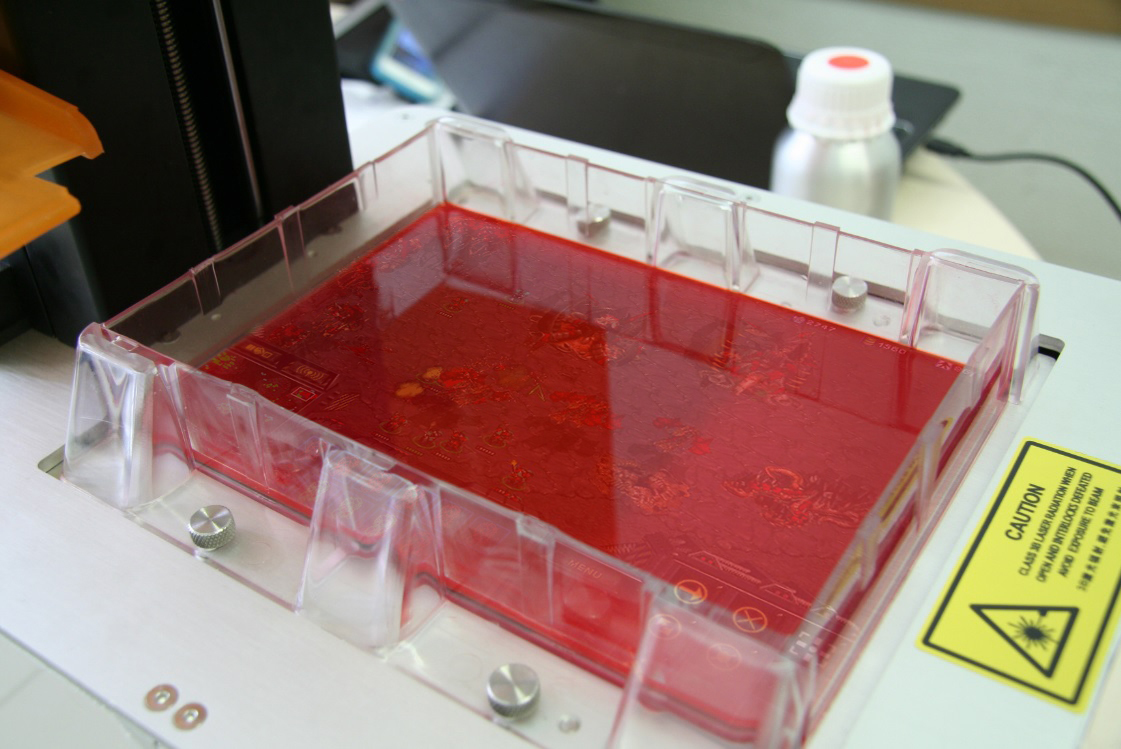

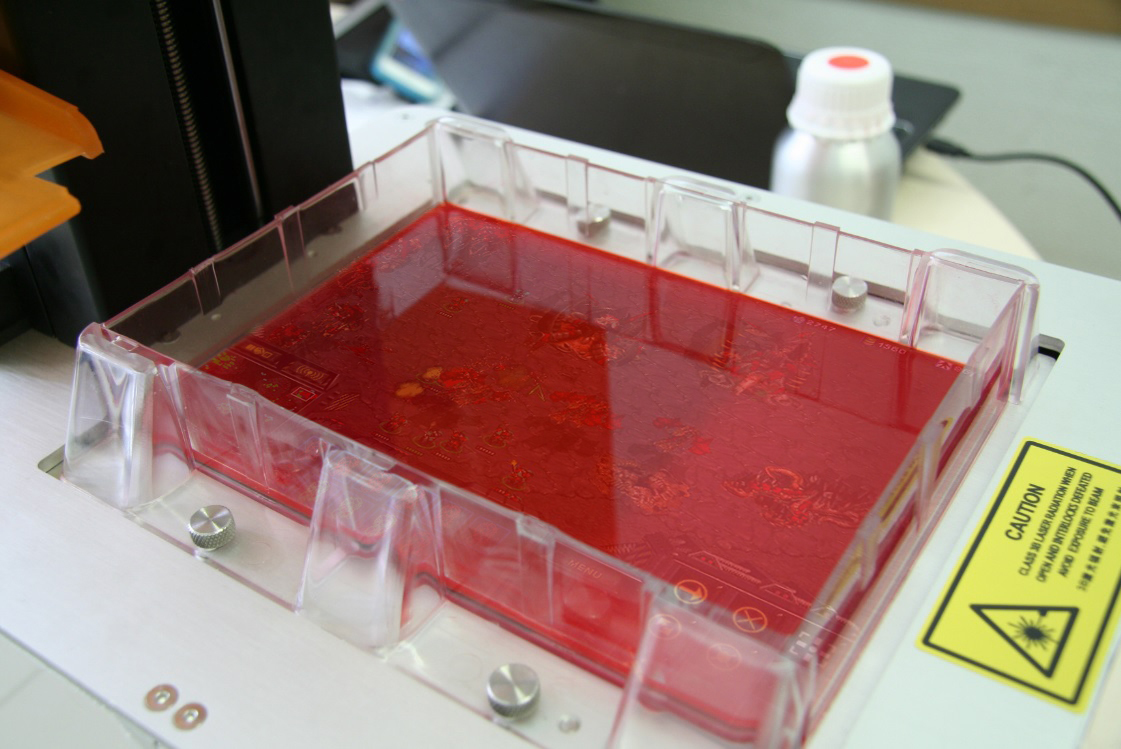

Raw material:

Photopolymer is bright red. Included with the printer is 0.5 liters of photopolymer resin, separately a 0.5 liter photopolymer resin costs 10,000 rubles (already taking into account the new course), but the printer is not limited to this resin and allows the use of other resins. Those. In essence, this SLA printer is universal for using resins of various manufacturers.

The change in photopolymer under the action of light

Printing examples

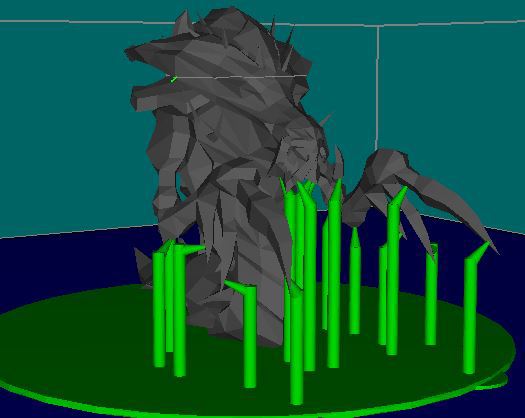

The printer has its own "native" software that allows you to do all the necessary manipulations

We choose the number and location of supports

You can choose the shape of the substrate

Initially, the platform is at the very depth of "minus delta"

Then the laser is turned on, which acts on those parts of the polymer that correspond to the walls of the target object, causing them to harden. After that, the entire platform rises a little higher, by an amount equal to the thickness of the layer.

(something lasers have come across often to me lately)

Laser and control mirrors

Laser Power: 50mW - the most powerful laser, allows you to use a wider range of resins.

Wavelength UV: 405NM

It took about an hour to print a hydralisk; all this time, the software has shown% complete and estimated time

After the end of the materialization, it is required to place the product in an alcohol bath with subsequent irradiation in the ultraviolet (pedicure is also suitable)

The platform (printable area: 128x128 × 180mm) is easily removable, which facilitates work with freshly baked hydra.

After you look at / look at the details printed on a similar printer for an hour, what comes out from under the nozzle of “ordinary” 3d printers seems coarse and thick, the layers just hurt the eyes (but it will soon pass).

Scientific research. Since it is possible to get a model of almost any complexity for any purpose in a matter of hours, SLA-technology becomes indispensable helpers in various kinds of research and development. Models have sufficient strength and transparency, so there is the possibility of visualizing gas and hydrodynamic flows within the models.

The medicine. In maxillofacial surgery and orthodontics, with the advent of SLA, a new direction has emerged. The patient is made a magnetic resonance tomography of the problem area, a computer-generated 3d model is formed from it, and a real 3d model of bone tissue is grown on it. Thus, the doctor has the model of bones or teeth of a real patient the very next day.

Art. Sculptors, fashion designers and jewelers, thanks to stereolithography technology, are reaching a new level of production. The process of 3d-printing of prototypes significantly reduces the time for testing experimental samples, which has a positive effect on the speed and quality of the creation of a future piece of jewelry or sculpture. SLA-technology is very well suited for this: models are durable, easy to paint.

Casting on burning models. When a need arises to obtain a metal part, the following technology is applied: The SLA model is molded with molding sand, then calcined at high temperatures. In this case, the plastic completely burns out, and in its place the metal is poured into the formed form under vacuum. After it hardens, the form is destroyed and the part is removed.

Chip

One of the owners of the printer (from Belarus) managed to burn the resin in the furnace, that is, there is actual confirmation that when using the resin bundled with the URANUS printer, the resin can be burned out with temperature (the “ash” parameter). Jewelers and those who make crafts from metals will understand why.

The peculiarity is that a special temperature map will be supplied to the printer, which will contain information at what temperatures (approximately 600-650 degrees Celsius) and time it is necessary to hold the craft to achieve the decomposition of the resin in the furnace.

Speed higher than FDM

Very large print size (in comparison with ProJet 1200 about 4x4 cm)

Completely silent (but there is a smell)

Details are much higher than plastic 3d printers (FDM)

The price is lower than the analogs

Economical consumption of consumables

There is one more "minus". If you can watch the work of a plastic printer for hours, it is fascinating like a flight of snowflakes or like a flutter of flames, then with SLA printers everything is very pragmatic - I pressed a button - an hour later I received a part from the box. The birth process will not be able to peep. But still, the thing seems magical.

The history of 3d-printers began in 1984 with a stereolithographic device. Nowadays, such printers are very often used by jewelers, since the accuracy of printing of such models is much better than FDM devices (which I print with plastic)

Under the cut there are some pictures of the printer's insides and the birth of a hydralisk from the “blood bath”

')

Spawn Hydralisk (H)

Appearance:

The first impression is similar to a paper bucket, but “behind a non-fancy interface lies a powerful algorithm”

Raw material:

Photopolymer is bright red. Included with the printer is 0.5 liters of photopolymer resin, separately a 0.5 liter photopolymer resin costs 10,000 rubles (already taking into account the new course), but the printer is not limited to this resin and allows the use of other resins. Those. In essence, this SLA printer is universal for using resins of various manufacturers.

The change in photopolymer under the action of light

SLA principle of operation

Printing examples

Production of hydralisk from bloodbath

The printer has its own "native" software that allows you to do all the necessary manipulations

We choose the number and location of supports

You can choose the shape of the substrate

Initially, the platform is at the very depth of "minus delta"

Then the laser is turned on, which acts on those parts of the polymer that correspond to the walls of the target object, causing them to harden. After that, the entire platform rises a little higher, by an amount equal to the thickness of the layer.

(something lasers have come across often to me lately)

Laser and control mirrors

Laser Power: 50mW - the most powerful laser, allows you to use a wider range of resins.

Wavelength UV: 405NM

It took about an hour to print a hydralisk; all this time, the software has shown% complete and estimated time

After the end of the materialization, it is required to place the product in an alcohol bath with subsequent irradiation in the ultraviolet (pedicure is also suitable)

The platform (printable area: 128x128 × 180mm) is easily removable, which facilitates work with freshly baked hydra.

After you look at / look at the details printed on a similar printer for an hour, what comes out from under the nozzle of “ordinary” 3d printers seems coarse and thick, the layers just hurt the eyes (but it will soon pass).

More examples of works printed on URANUS

Application area

Scientific research. Since it is possible to get a model of almost any complexity for any purpose in a matter of hours, SLA-technology becomes indispensable helpers in various kinds of research and development. Models have sufficient strength and transparency, so there is the possibility of visualizing gas and hydrodynamic flows within the models.

The medicine. In maxillofacial surgery and orthodontics, with the advent of SLA, a new direction has emerged. The patient is made a magnetic resonance tomography of the problem area, a computer-generated 3d model is formed from it, and a real 3d model of bone tissue is grown on it. Thus, the doctor has the model of bones or teeth of a real patient the very next day.

Art. Sculptors, fashion designers and jewelers, thanks to stereolithography technology, are reaching a new level of production. The process of 3d-printing of prototypes significantly reduces the time for testing experimental samples, which has a positive effect on the speed and quality of the creation of a future piece of jewelry or sculpture. SLA-technology is very well suited for this: models are durable, easy to paint.

Casting on burning models. When a need arises to obtain a metal part, the following technology is applied: The SLA model is molded with molding sand, then calcined at high temperatures. In this case, the plastic completely burns out, and in its place the metal is poured into the formed form under vacuum. After it hardens, the form is destroyed and the part is removed.

Chip

One of the owners of the printer (from Belarus) managed to burn the resin in the furnace, that is, there is actual confirmation that when using the resin bundled with the URANUS printer, the resin can be burned out with temperature (the “ash” parameter). Jewelers and those who make crafts from metals will understand why.

The peculiarity is that a special temperature map will be supplied to the printer, which will contain information at what temperatures (approximately 600-650 degrees Celsius) and time it is necessary to hold the craft to achieve the decomposition of the resin in the furnace.

Findings.

Speed higher than FDM

Very large print size (in comparison with ProJet 1200 about 4x4 cm)

Completely silent (but there is a smell)

Details are much higher than plastic 3d printers (FDM)

The price is lower than the analogs

Economical consumption of consumables

There is one more "minus". If you can watch the work of a plastic printer for hours, it is fascinating like a flight of snowflakes or like a flutter of flames, then with SLA printers everything is very pragmatic - I pressed a button - an hour later I received a part from the box. The birth process will not be able to peep. But still, the thing seems magical.

PS The former does not happen

Source: https://habr.com/ru/post/239057/

All Articles