Mounting wrap. Technology

Earlier, in order to debug an electronic circuit, I used prototyping boards , hung up snot , used an installation wire and trimmed resistors for connections. Tracing did on the go, often with errors, which sometimes resulted in parts in disrepair. Such an installation has many problems: it is difficult to change the circuit, the wires fall off from the vibration, it is difficult to reduce several wires at one point, etc.

There are other ways of prototyping, but today I’ll remind you of wrap-around installation [ 1 , 2 ], a time-tested technology that is convenient and reliable for prototyping and prototyping. Moreover, using this technology, you can create end devices that will work reliably for many years.

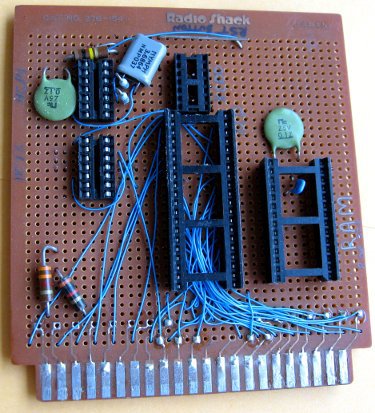

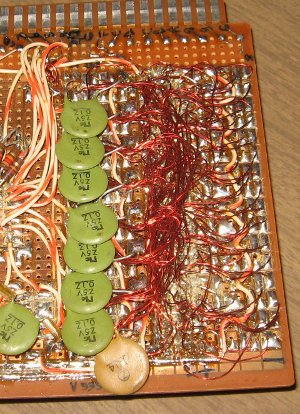

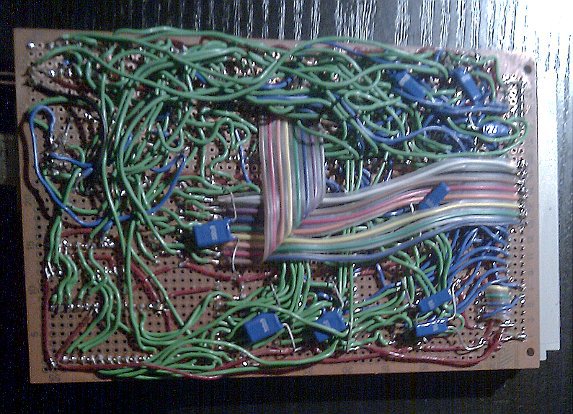

Examples of how NOT to make mockups

This is what prototyping on a breadboard with mounting wire can do. Is it worth talking about the reliability of such boards?

')

Wrap installation

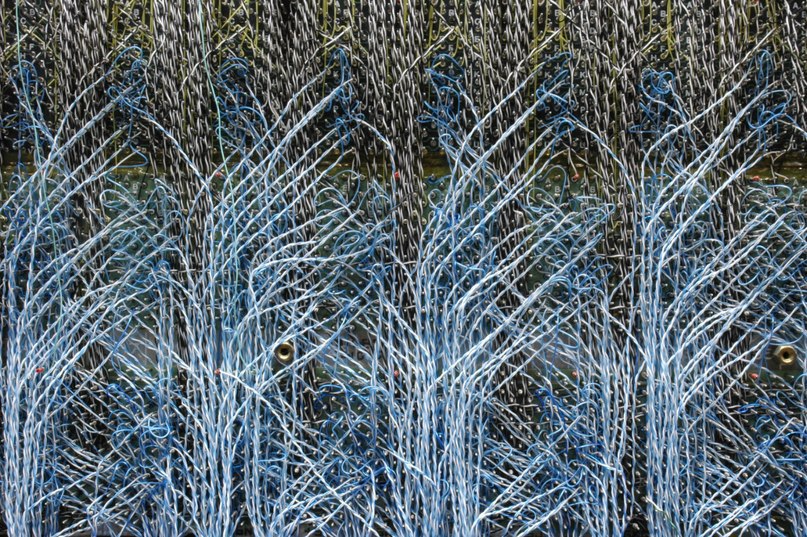

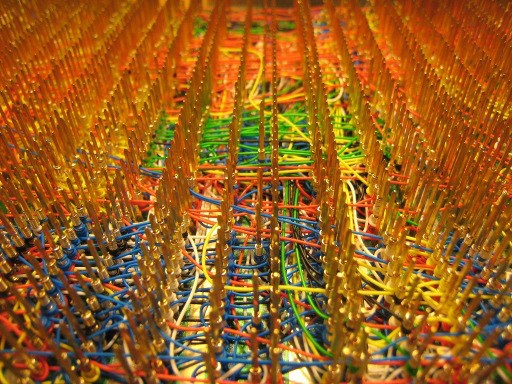

Wrap -around installation is a technology for constructing electronic circuit boards without manufacturing a printed circuit board . The wires are wrapped manually or with machines, and the connections can later be changed manually afterwards. The method was popular in mass production in the 60s and early 70s and continues to be used for small batches and prototypes.

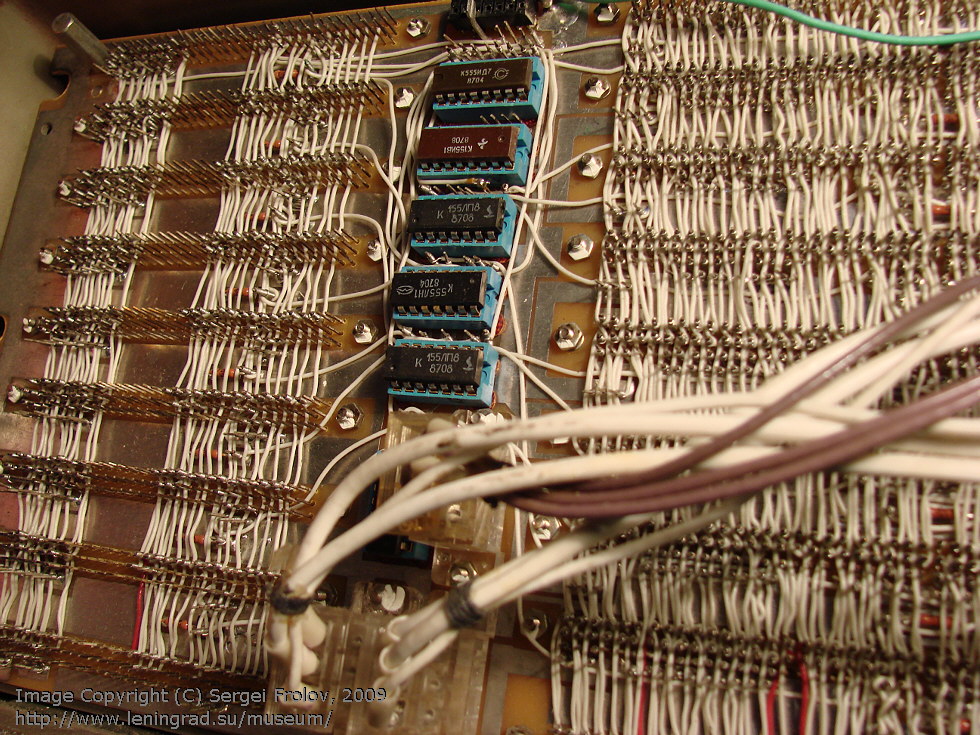

Personal computer compatible with IBM PC / XT - Neuron I9.66 - 1987

The method is popular now:

Project BMOW (clickable)

Symbolics 3600 Project

Project 6502

And many other modern hardware projects are prototyped using Wire Wrap

Frequently asked Questions

Q: Is the installation secure?

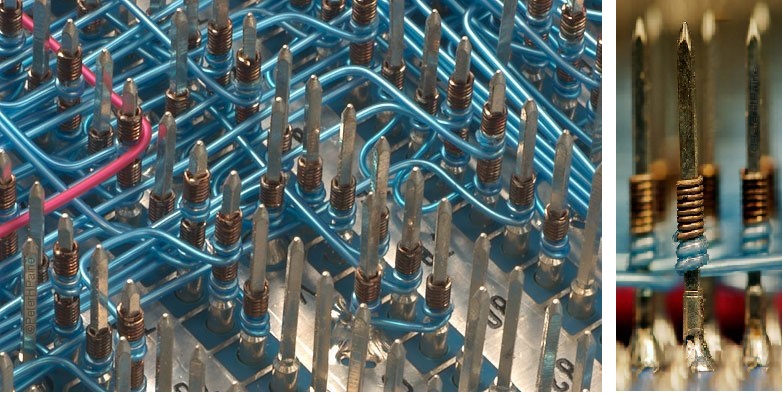

A: Yes, if everything is done correctly (the connections cannot be touched). From Wikipedia: a correctly made wire wrap connection is seven turns of the wire (4 × 7 = 28 contact zones), and one and a half turns of the insulated wire to reduce the possible mechanical stress . The idea is that tightly wrapping a clean wire on a clean pin contact, we do chemical welding on each edge of the pin contact. The quality of the electrical connection does not depend on the oxidation on the outside of the resulting helix, although over time it will not look beautiful. Also, the compound is not afraid of vibration. If you dismantle the twisted wire and try to touch it, you will understand what it is about.

Q: Do I need to solder the connection wrap?

A: This is not necessary, the boards have been working for decades. If problems arise, it is the result of inaccurate work. The exception is a cheat on the contacts of radio elements of circular cross section - they need to be soldered.

Q: Where is the wrap installation applied and to what frequencies does it work?

A: Wrap-up method was used to build prototypes of high-frequency and small circuits; including gigahertz microwave frequencies and supercomputers . The method is unique in that the length of the connection can be precisely controlled, and twisted pairs or magnetically shielded fours (four-wire) can be laid together. The installation of the onboard control computer of the Apollo spacecraft was made by just this method ( photo [ 5 ]).

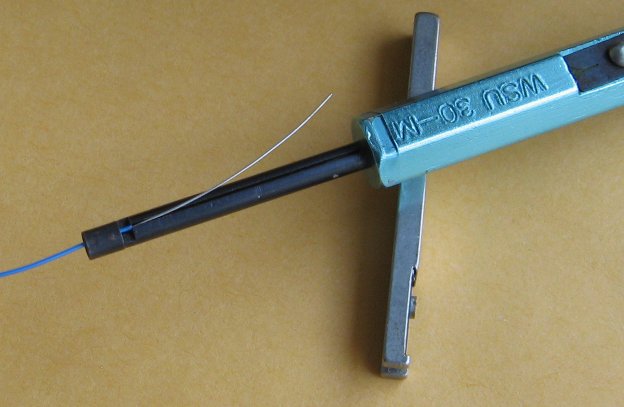

Q: What tool is used for installation?

A: There were fully automatic installation systems. Semiautomatic when the contact is wound with one touch. Fully hand tools. We will talk about hand tools.

The tools shown in the figure apply each to their own wire diameter, with one end they wind the wire, the other is used for dismantling. The handle has a hole and a knife for stripping the wire from the insulation.

Q: If the tool is not universal, what diameter can the conductor be used for?

A: On ebay you can find a tool with diameters of 19, 22 , 28, 30 - AWG (this is an American caliber, respectively 0.9, 0.6, 0.32, 0.25 mm)

Q: Any copper wire suitable?

A: I can not say for sure, it seems that the wire has a special coating. On ebay, the wire is called Wire-Wrapping Wire 30AWG . Although I have seen designs with copper wire.

Q: How to cheat?

A: First, we clean the wire a couple of centimeters with a tool. Do not touch the bare wire with your hands!

Insert the wire into the hole with the edge, and not only the bare part, but also about 4mm with insulation

Next, install the tool with the center hole on the contact and take a few turns. Skill quickly comes with experience. It should turn out 1.5 turns with insulation and 7 turns of the stripped wire. For most tools, the direction of rotation does not matter (clockwise or counterclockwise).

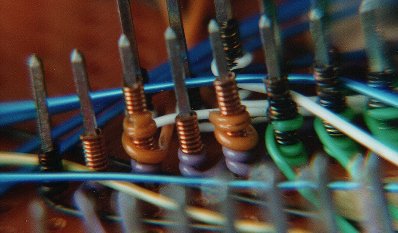

It should end up looking like this:

As can be seen in the photographs, the silver-plated wire oxidizes — darkens, as does copper. But the area where the wire connects to the pin is resistant to oxidation.

Own experience

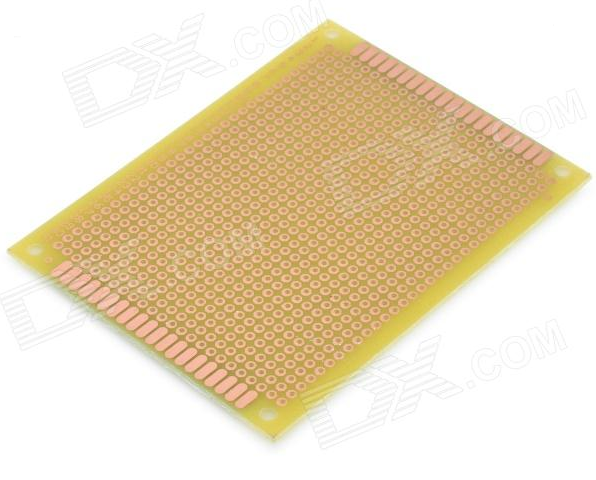

In my small projects I always use breadboard, although there is iron chloride, textolite, micro machine. I, unfortunately, can not find the time to trace the boards, as well as for LUT or photo-mode. The technology of cheating seemed convenient to me in order to take universal prototyping boards, contacts, wire, and without thinking about tracing, to perform any scheme that interests me. In the process of debugging the circuit, you may need to reconnect something and the method of wrapping allows you to do this an unlimited number of times: the removed wire can be thrown out, and the conductors on the printed circuit board will not fall off from multiple repacks. And in general, the prospect of making a scheme without a soldering iron seemed very tempting - sit and say.

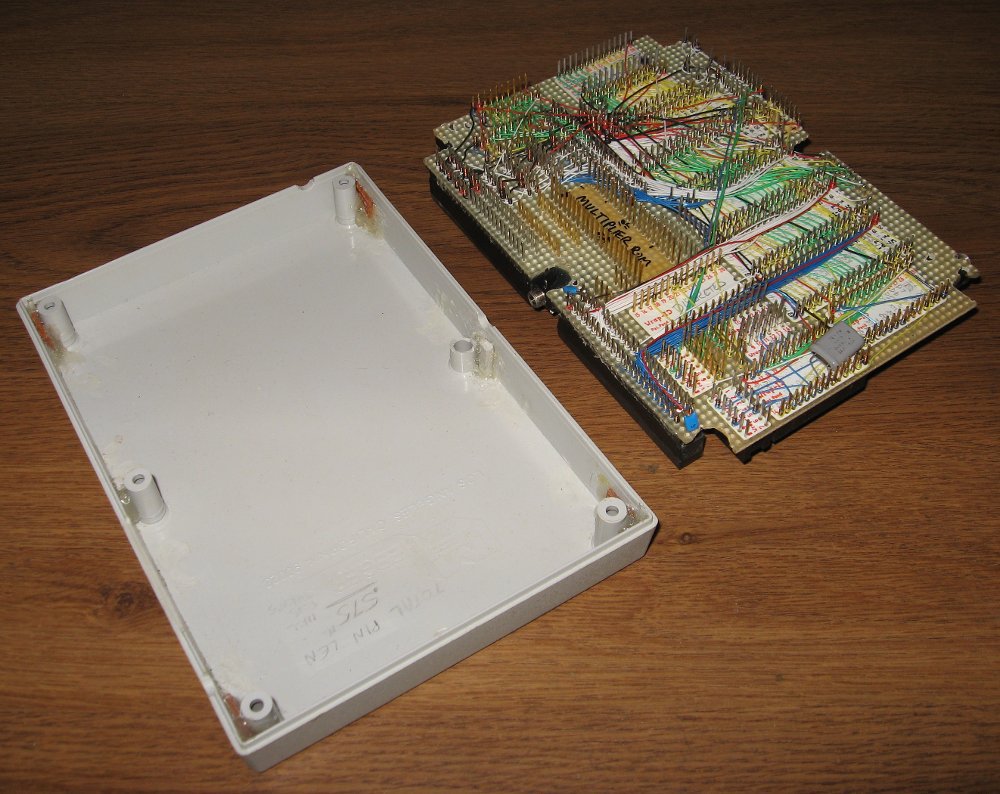

But in order to have everything you need to create any board, you need to think about the component parts that will be required. For myself, I decided that I would have enough stock of printed circuit boards and long pin contacts. The pins can be soldered to the board, the discrete elements can be soldered to these contacts on the one hand, and the circuit switching can be done by wrap on the other side of the board.

Ordered a board similar to these: on DX.COM or ebay

Pin contacts . Contact length 2.54mm.

And by this I decided to do without. Still, actually, you need a tool for cheating. It looks simple, it was not so cheap - about 600 rubles on ebay, and in Russia it is even more expensive. Therefore, from the entire set of possible diameters, I chose 30 AWG (0.25 mm) and a tool for it . In my opinion, the most suitable diameter for building boards with DIP packages.

For aesthetes there are connectors with gold pins ( 6 , 8 or 10 pins). There are easier .

and sockets for chips

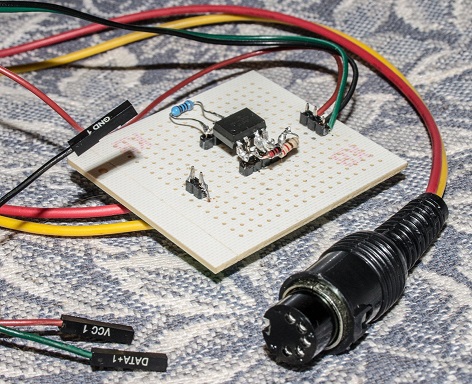

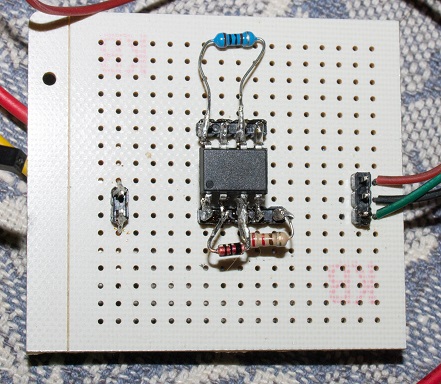

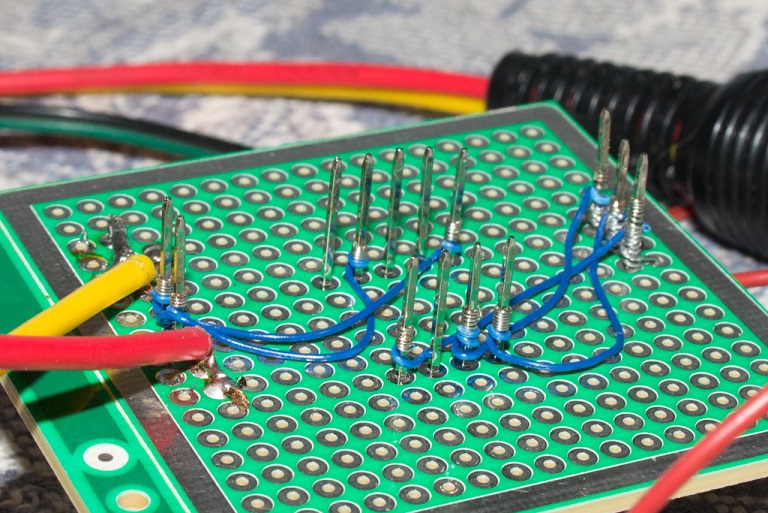

As part of my FPGA synthesizer project, I needed to make the MIDI-IN module. It consists essentially of an optocoupler and two mounted elements.

In principle, cheating here - unnecessary complexity, but I wanted to check the technology. That's what happened.

findings

Completely get rid of the soldering iron failed. In the process of creating a circuit, I made a mistake: I did not correctly turn on the KD522 (thanks to our for marking!), Which required a soldering. Another mistake was that I basically soldered the elements on top of one another. If I soldered all the elements (the microcircuit, the resistor and the diode) separately to my pin contacts, then I would not need a soldering iron at all to correct errors. All connections would be made by wrapping and corrections too.

However, in the process of working I changed the circuit several times, until I understood why it does not work and appreciated the convenience of quick installation and dismantling of conductors. It was not always possible to wind it up right the first time, but when the connection is correct, it can be seen immediately. If the connection is not correct or the piece of wire is shorter than necessary, then removing the wire is a matter of a few seconds. At the same time without harm to connections that have already been made. Only the moments when a soldering iron was required slowed down. It can be concluded that the technology is convenient and I will use it further!

I read a short video from me here:

List of used sources

1. http://en.wikipedia.org/wiki/Wire_wrap

2. http://ru.wikipedia.org/wiki/Montazh_nakrutkoy

3. http://wilsonminesco.com/6502example/WireWrap.html

4. http://www.tecratools.com/pages/tecalert/wirewrap_guide.html

5. http://www.ibiblio.org/apollo/yaAGC.html - Virtual AGC

6. "Journal of network solutions / LAN", No. 11, 2002 - Installation by wrapping

7. Solder methods of permanent connections: cheat

8. Neuron I9.66 - Personal computer compatible with IBM PC / XT . There is a fee with wrap .

9. FPGA VGA Resistor DAC - wire-wrap prototype design!

Other technologies:

10. Layout on the Veroboard stripboard and on simple stripboards and CAD for this

Source: https://habr.com/ru/post/238675/

All Articles