Superiority Mask. About the magic of "Merlin" put in a word

“There is no engine — and any most perfect rocket design with all its stuffing is dead.” V.P. Glushko

In recent years, the private space company Space X, headed by Elon Mask, never ceases to amaze the whole world with its fantastic successes. The main highlight of the space transport systems of this company are considered to be Falcon PH series, and in particular Merlin 1 engines, already nicknamed "the most efficient in the world."

It creates the false impression that Space X in a relatively short time was able to create an engine that eclipsed such giants as Energomash and Rocketdyne to develop in this area. Under the cut, we will familiarize ourselves with the modern world of rocket engines in a popular form and will try to understand such an unambiguous characterization as efficiency.

')

In 2012, the company Space X, conducted fire tests of the latest at the moment engine modifications Merlin 1 - D. During these tests, the engine's thrust-to-weight ratio was increased to 150 units, which allowed Space X to name it "the most effective in history . "

In the field of engine building, the thrust ratio is called the ratio of engine thrust (in ton) to its dry mass. In the case of rocket-propellant rocket engines, this ratio is usually the thrust of engines in vacuum (in ton), divided by its dry mass (in tons).

Merlin 1D is able to develop traction on the ground in 67t and 82t in vacuum (Melin 1D Vacuum), with a mass of about 600 kg. On the Falcon 9 1.1 PH, 9 such engines with a total load of 600 tf are used. The engine does not have its own thrust vector control system (UHT), and the rocket stage is controlled by changing the thrust of engines on opposite axes, as in the PH H 1 (throttling to reduce thrust and / or afterburner to increase thrust above nominal).

Merlin 1D engines on Falcon 9 1.1 PH

The difference between the engines at the ground and in vacuum is typical, and is associated with the deterioration of the characteristics of the engine in the dense layers of the planet’s atmosphere. The atmospheric resistance of the engine aerodynamics increases in proportion to the size of the engine exhaust nozzle (the total resistance of the atmospheric pressure only increases with increasing jet exhaust area). It would seem that you only need to minimize the size of the nozzle and improve engine performance. However, with increasing altitude, the resistance of the atmosphere decreases, and with it the engine characteristics, on the contrary, increase with increasing nozzle sizes.

The key in this case is not the absolute size of the nozzle, but the degree of expansion - the ratio of the largest cross-sectional area of the cone of the nozzle, to its smallest cross-sectional area. The higher this value, the higher the efficiency of the engine in this environment. Therefore, the size of the nozzle of the vast majority of engines of the first stage of launch vehicles, represent a compromise for the optimum characteristics of the engines, both in the atmosphere and in vacuum.

The thrust-to-weight ratio is indirectly dependent on the fuel used, and unlike characteristics such as thrust and specific impulse, it is not applicable to all types of engines - solid-propellant rocket systems are themselves engines.

The highest thrust ratio is distinguished by rocket engines working on a mixture of heptyl and diazoto tetraoxide. So the RD 275M (Energomash) engines of the Proton M launch vehicle have the highest thrust-weight ratio in the world - more than 170 (thrust in a vacuum of 187 tons, engine weight 1.1 tons). Their “elder” brother RD 270 , developed at one time for the non-flying LV 700, had a thrust-to-weight ratio of 200 units! Moreover, it is surprising that we are talking about closed-cycle engines (see below). Such characteristics are achieved due to the self-igniting fuel, due to which the design (and weight) of rocket engines is greatly simplified. At the same time, these engines have rather high specific impulse parameters (285s for RD 275M).

RD 275M, Russian modification of the base Soviet engine RD 253 for Proton series PH (payload mass increased by 750kg)

The specific impulse (sometimes referred to as specific gravity) expresses the time during which the engine develops a thrust of 1 newton (1N = 1kgs / 0.102) using 1kg of fuel. The higher i.i. the less fuel the engine needs to deliver a certain amount of movement to the payload. In contrast to the weight ratio, engineers often take this value as an indicator of engine efficiency.

Mr H

Modern hydrogen engines are the most efficient among all the types of LRE used. The highest value of u. possessed the Soviet RD 0120 (455s in a vacuum and a load of 200 ts). The highest U.I. at sea level, it has RS 68 (365s and a weight of 295 hp) from Rocketdyne, used on the world's only fully hydrogen pH Delta 4. Hydrogen rocket engines at the same time have the lowest thrust-weight ratio (within 50-75 units), which is ignored because high energy capabilities data LRE. This allows you to more than compensate for the "extra" several tons of the engine, compared with the other LRE with high thrust-to-weight ratio.

However, the high price of hydrogen fuel rocket engines (about $ 20 million for the RS 68) still forces engineers to use compromise options in the early stages, most often with kerosene fuel rocket engines.

An illustrative table of the influence of the degree of expansion on the efficiency of cryogenic engines in different environments

From left to right: RS 68, Vulcain, RS 25, RD 0120

Champion in the narrow sense.

The largest specific impulse at sea level (311 sec) among kerosene LREs are engines RD 171, RD 180 (trimmed by ½ version RD 171 with a thrust of 384 ts) and RD 191 (shortened by ¼ a version of DD 171 with a thrust of 196 ts) ". The thrust of these engines does not exceed 90 units. Against the background of these masterpieces of technical thought, the efficiency of the Merlin 1D looks rather modest (285 seconds), although it dominates in terms of thrust ratio among kerosene LREs.

171/180/191

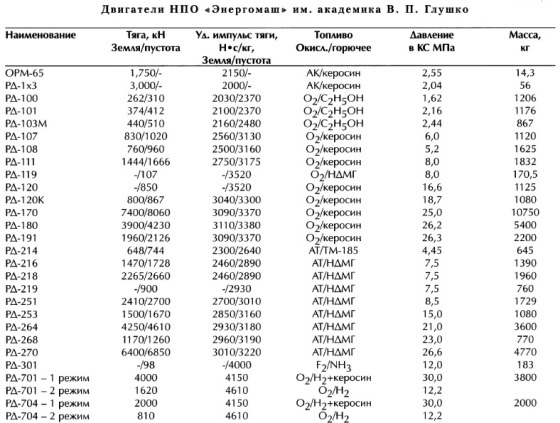

List of the most well-known LPRE NPO Energomash

A similar difference in performance is associated with a different design approach in engine design:

- RD “family” RD 170/171 is made according to the closed cycle scheme - to initiate engine operation, pressure is applied to the gas generator, the gases from which drive the turbine, which rotates the fuel and oxidizer pumps. The incoming fuel part goes to the cooling of the nozzle and then into the combustion chamber, the other part goes to support the operation of the gas generator along with the oxidizer and then after the turbine, the mixture enters the combustion chamber through the gas outlet. The entire closed cycle is repeated until the fuel in the tanks is exhausted. In this case, the combustion chamber of a closed-cycle LRE is substantially less than that of an open-cycle LRE. As you probably guessed, it provides high values of pressure in the combustion chamber (usually 200 atmospheres or more) and a greater degree of expansion of the engine nozzles, allowing the LRE to give a high efficiency (specific impulse) in the planet's atmosphere.

Disadvantages - high load on the turbine of the engine, the relatively high complexity and cost of such engines.

An approximate scheme of a liquid-rocket engine of a closed cycle on the example of Russian engines RD 191 and NK 33. 1 - Gas generator; 2 - Turbine; 3 - Fuel supply (kerosene); 4 - Supply of oxidant (oxygen); 5 - Fuel pump; 6 - oxidizer pump; 7 - Removal of part of the fuel to cool the nozzle; 8 - Removal of the gas generator fuel / oxidizer mixture from the turbine to the combustion chamber; 9 - Transfer the oxidizer to the gas generator

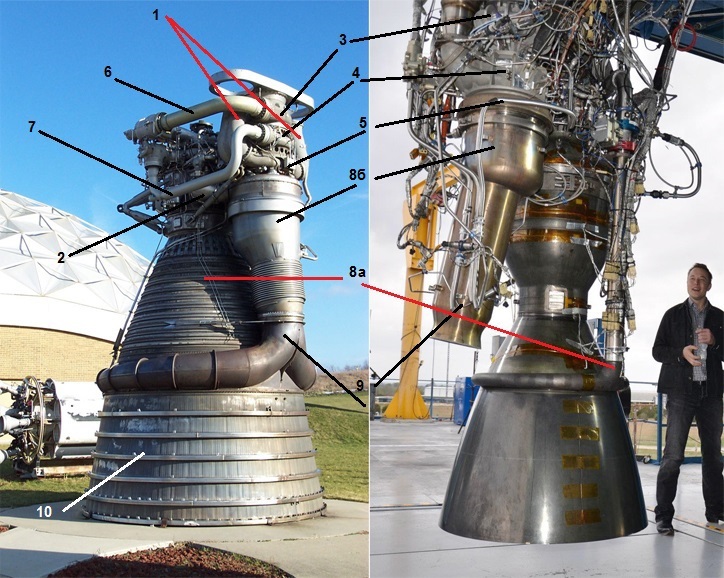

- LRE family Merlin and RD 107/108 (RN Union) are typical representatives of open-cycle engines. The working fluid of the engine turbine (coming from the gas generator) does not close on the combustion chamber, but is output to the external environment along with part of the fuel, only partially participating in the creation of additional thrust. To compensate for the loss of efficiency, you can increase the pressure in the gas generator, which increases the efficiency of the turbine and, accordingly, the pressure in the combustion chamber (which is about 100 atmospheres). Engines of this kind are simpler, more reliable, easier and cheaper than a closed-cycle LRE.

One of the disadvantages is the low degree of expansion of the engine nozzle and, accordingly, lower specific impulse values when operating in the planet's atmosphere (263 / 257s for the RD 107/108 and 255s for the RS 27A).

The scheme of open-cycle engines on the example of LRE F 1 and Merlin 1D. 1 - Supply of fuel and oxidizer from tanks; 2 - Gas generator; 3 - oxidizer pump (oxygen); 4 - Fuel pump (kerosene); 5 - Turbine; 6 - High pressure oxidizer line; 7 - High pressure fuel pipe; 8a - Fuel nozzle cooling system; 8b - gas generator heat pipe; 9 - Exhaust gas generator mixture (Merlin 1D) / gas generator gas outlet to cool the nozzle nozzle (F 1); 10 - Nozzle nozzles

Comparing the engines of the first stage, it should be noted that the thrust-to-weight ratio of the engine is not directly related to the thrust-weight ratio of the entire stage. With equal rocket engines, their relative thrust-to-weight ratio, namely, specific impulse, will be of decisive importance. As we said, the higher its value, the less fuel the LRE uses to accelerate a certain mass and, consequently, the higher the thrust-weight ratio of the launch vehicle stage.

So the Falcon 9 1.1 PH is 1.1 (thrust 600ts / 503t rocket mass) and the Zenit 2 PH with RD 171 1.5 (thrust 720t / 470t rocket mass) with a similar LEO payload of 13t.

To understand this approach, Russian designers should take into account the geographical specificity of the location of Russian and American space centers. The latter, being to the south, have a 15% energy advantage due to the greater contribution of the Earth's rotation (additional ~ 200 m / s). Therefore, high thrust-to-weight ratio is common for domestic launch vehicles (1.5–1.7 for RN Energy and H1, versus 1.1 for Saturn 5). And as we already understood, thrust-to-weight ratio of the rocket engine itself is not of key importance for this.

However, in the USSR, a kerosene engine was still created, combining high thrust-to-weight ratio and a large specific impulse. The LKD NK 33 from the Kuznetsov Design Bureau, created on the basis of the NK 15 engine of the N 1 lunar rocket, with a thrust-to-weight ratio of 136 (171 t / 1.25 t), had a specific impulse of 297 s (at sea level). A modern engine modification is used on the PH Anatheres, a private company Orbital Sciences (AJ26). The Russian version of the NK 33-1 used on the Soyuz 2.1V rocket, at the start, develops traction already at 185ts with a specific impulse of 305s! From the basic version of NK 33, this engine differs, first of all, by the presence of a thrust vectoring system (UHT).

In the future, on the NK 33-1, it is planned to use a nozzle nozzle, which moves forward at high altitudes, which significantly improves the engine's technical characteristics.

NK 33-1 with a nozzle nozzle. On the right, a graph of the increase in the characteristics of rocket engine with a nozzle

Price issue.

There is no doubt that one of the main "characteristics" of any type of equipment is its cost. Due to the large difference in engine specifications, it would be preferable to compare their relative price values. In this case, this value is approximately the ratio of the price of the LRE to its burden ($ / tf).

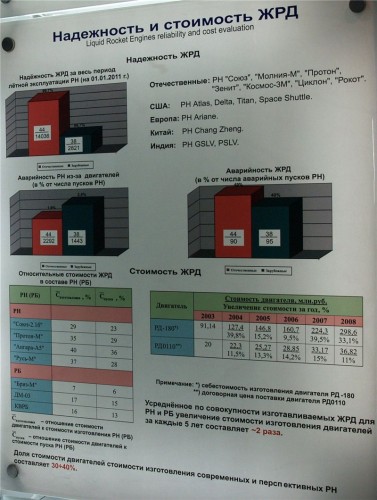

Poster "Energomash" showing the pricing scheme of LRE and their share in the price of the entire launch vehicle

Obviously, the price increases in proportion to the complexity of the engine and its efficiency.

So RS 68 standing on the Delta 4 PH cost NASA at $ 60,000 / ton of thrust ($ 20 million).

A kerosene oil rocket engine with a large, but smaller specific impulse RD 180 (RN Atlas 5) is nominally costing NASA twice as much - at $ 30,000 / ton ($ 11 million).

RD 191 standing on the "arms" of the RN Angara, in relative prices, is considered one of the most expensive kerosene LPR in the world - $ 36,000 / ton (RUB 250 million).

For comparison, the price of RD 171, on the basis of which RD 180/191 was created, is in the range of $ 22,000 / ton ($ 13-15 million). This variation is partly due to the fact that the last two engines were created for the US domestic market, in particular for the Atlas 5 PH (RD 180 as the main engine of the central unit, and RD 191 as the engine for the side units). However, the RD 191 remained unclaimed in the USA, even after the creation of a more budgetary RD 193 (version without UHT).

The most "cheap" engine of the closed cycle can be considered LRE NK 33-1. Provided production is restored, the price of the NK 33-1 modification for the new Soyuz 2-3 launch vehicle can be up to $ 25,000 / ton ($ 4.5 million). Officially, the NK 33-1 will be used until the exhaustion of the old stocks of the NK 33 and replaced with the RD 193 engines .

Merlin 1D with an approximate price of $ 15,000 / ton (~ $ 1 million), very successfully "joined" the domestic market of US rocket engines. After the closure of the Apollo program, the United States for half a century focused on the development of cryogenic (hydrogen), toxic (heptyl) and solid rocket systems. We see the consequences of this approach today - ahead of Russia in terms of the development and operation of cryogenic liquid rocket engines and turbojet engines, the United States is far behind in the development of already kerosene liquid fuel rocket engines.

Even with the development in the US of their own kerosene rocket engines, it is highly doubtful that they will be able to compete on the degree of perfection and price with Russian engines, and even more so with the “budget” brainchild of Space X. Therefore, Elon Mask and Co. have every reason to look optimistically at their developments. Developments of extremely successful, reliable and promising, to which it is not necessary to “try on” controversial epithets long deserved by other talented developers .

I recommend to read:

RD 170/171 , RD 180 , RD 191 , NK 33 , NK 33-1 , RD 253/275 , RD 107/108

PROSPECTS OF CREATING POWERFUL LIQUID ROCKET ENGINES

Promising methane projects in Russia

Another interesting topic on Habré:

Special rocket magic Ilona Mask

Imperceptible complexity of rocket technology. Part 3: types of liquid fuels, geometrical dimensions, transportation

Imperceptible difficulties of rocket technology: Part 4. More about engines and tanks

PS: When errors or inaccuracies are found, do not forget to knock on the PM.

Source: https://habr.com/ru/post/236761/

All Articles