What the 3D printing business is preparing for us: 3DPrintshow in London

In my first publication on Habré, I decided to tell in detail about what is happening in the world of 3D printing business. And the best reason for this is the last 3DPrintshow exhibition in London - essentially the biggest event in our industry, focused on the consumer side of the 3D printing business.

I introduce myself: my name is Konstantin, I am a co-founder and CEO of 3DPrintus . My interest in the exhibition is due to the fact that in the Russian market we are developing B2B and B2C areas of industrial 3D printing services, as well as the marketplace of products and the design community.

')

Likbez

To begin with, when developing a business in Russia, one always has to look to Europe and the USA, because our partners there are a few steps ahead of us and our task now is to accelerate the development of 3D printing in Russia and the CIS. Therefore, the efforts of each new company in our market is a big plus for the industry as a whole.

So, the most important thing you should know about the development of 3D printing in the world:

1. 3D printer in every home.

The technology has been around for over 30 years. Media hysteria about the “third industrial revolution” and the thesis that “now you can print iPhones and TVs at home” is somewhat premature, if not more.

2. Market

It is necessary to separate the market and business for the production of 3D-printers from the market for the provision of 3D printing services. Market volumes are completely different, as are the companies on them.

3. Technology

It is important to consider separately the market and technologies of "home" 3D printing and industrial. Industrial appeared much earlier and includes such technologies as SLA, SLS, MJM, PolyJet, 3DP, SLM, FDM. The main technology of home 3D printing is FDM. Also, printers based on SLA and SLS technologies have entered the market of "home" devices, which gives a certain qualitative leap forward.

4. Restrictions

Initially and until now, 3D printing is about the production of a limited number of products, products, prototypes and so on. The technology obviously will not allow making the cost of production of a unit of product cheaper than with mass production. But technologies allow to make a very cheap start of production of any product when you either a) make the first prototypes, b) test the market demand.

5. Application

The most active (and also cost-effective) 3D printing technologies are used for the following business and services:

- Prototyping

- Small batch production

- Prototype Manufacturing

- Architectural design

- Jewelry production

- Medical implants and prostheses

- Robotics

- Hardware startups

- Individual decor, accessories, decoration, art, fashion

- DIY

6. Stage of development

If you objectively look at the current stage of development of the market and technology, then I will draw the following conclusion:

At the moment, 3D printing is used as an effective tool for prototyping and small-scale production. The technology is also increasingly being used to solve business problems from various fields. The enterprise market accepts technologies approvingly and uses them in its work.

Of course, technologies are beginning to influence medicine in the most positive way, they are used in surgical operations.

And finally, the technology gets to our homes and hands: designers around the world use 3D printing technology to make various final goods, from plastics and metals. And in this area, in the near future, the business of such items made of steel and precious metals will most actively develop, since they are the most understandable for consumers.

However, this market will take more than one year to become massively in demand among consumers around the world.

The result for today is:

80% of the application - prototypes, small series, prototypes, medical prostheses and implants, architectural models and jewelry, 20% - consumer goods.

Exhibition

Let's go back to the exhibition. The 3DPrintshow event itself is taking place not for the first time. Last year, in the same London, where the development of 3D printing is leaps and bounds, I was also on the show, the report can be read here .

3DPrintshow goes for three days, each of which has its own theme. This year the themes of the day were as follows:

- Business day

- Design day

- Public day

Days differ in the composition of lectures that take place on 4 stages in parallel, all days. All lectures are conducted by designers, business owners, 3D evangelists, community managers and other interesting people. Each lecture lasts about half an hour + half an hour to questions from the audience. For 3 days there is every chance to get a good injection of useful information and insights.

The exposition itself this year consisted of the most interesting and promising companies in Europe and the United States and was conventionally divided into two parts - printer manufacturers and services / startups providing services. Very convenient to navigate inside.

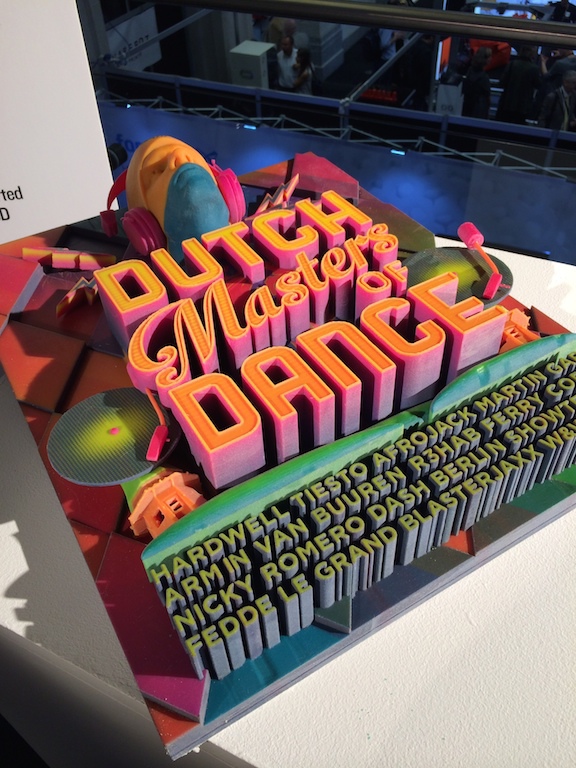

Also this year there was a separate balcony on which art objects and clothing were located, created by designers using all available 3D printing technologies. In fact, this is a reflection of the level of technology development. Yes, it should be noted that almost every one of them has a very high cost.

Full color printing from gypsum polymer

Durable and flexible plastic (polyamide) with painting

Detailed plastic (photopolymer)

Inserts of durable and flexible plastic (polyamide)

Translucent Detailed Plastic (Photopolymer)

PLA plastic

PLA plastic

Durable and flexible plastic (polyamide)

Detailed plastic (photopolymer) with painting

PLA plastic

PLA plastic

Interesting companies

Of course, the most interesting thing happens, which is called on the sidelines and in close contact with the participants and business owners. Only in this way can one obtain truly objective information about the situation on the market and prospects, exchange experience and opinion.

A nice bonus for me was that with most of these people I was already familiar from joint projects or at past exhibitions in London and New York, so getting the most interesting information was not difficult. I will share only the most interesting facts and forecasts.

Presumably, the most interesting event on the market was to be the launch of a new platform from the well-known and “beloved” company Autodesk.

For most non-professional users, the company has already had some pretty good 3D modeling products online for several years, such as 123Design, 123Catch, 123Sculpt, Tinkercad, and so on.

However, the company decided to go ahead and launch its own open source platform and printer - Spark , which will have to open a whole new market for epps, applications and addons for all enthusiasts and third-party developers.

The company announced this wonderful event a few months ago, but unfortunately, at the exhibition and during the lecture, it gave a minimum of information about the new project. They promised that in a couple of months this great event will still happen and the community of users of Autodesk systems will be able to start using its new brainchild.

Continuing the theme of software development in the field of 3D printing, I will note the excellent company, our partner, Uformia, and their product Uformit .

Colleagues, having gone through a long and many years of development in the field of modeling and mathematical calculations, created a product based on the principles of parametric design, which allows setting customization parameters for any three-dimensional objects created by designers. Their development is a Symvol plugin for Rhino.

At the same time, for end users and customers, everything looks like an uncomplicated interface for ordering a personalized pendant, ring, mask, and many other precious metals and high-quality plastics.

Let me draw your attention to the fact that Uformit does an excellent job in the medical field. With the help of their software and 3D scanning, a medical corset, clothed and personalized for a specific patient, was created.

I can not ignore the actively developing project Formlabs - the manufacturer of a professional "home" printer, on SLA technology.

Excellent and inexpensive printer for designers who need the fastest, but at the same time an accurate tool to test their ideas in practice.

The British company Digital Forming has focused its efforts on the development of an online system for designers, which makes it possible to make any model customizable. All the same basics, parametric design.

The next participant is 3DPrintUK , which operates in the format of a design bureau and product manufacturing using the only SLS technology available to them.

I must say that the guys are doing very high-quality projects, in terms of industrial design!

In addition to the external beauty of this solution, you can see an interesting engineering solution - lightweight construction. It is for such a design future!

Consumer market

Now I’ll turn to the story about those closest to me, in the business sphere, companies - 3Dhubs, Shapeways, Sculpteo and i.Materialise. It is they who, in many ways, are the driving force behind the development of the consumer sphere of 3D printing in the world!

Developing our company in Russia, we communicate with western colleagues very much and exchange information about prospects and new opportunities.

The motto of the guys from 3Dhubs is local 3d printing. At the moment, they have created, perhaps, the widest and most accessible network of owners of 3D printers in almost every city in the world. Using their website, anyone who has a 3D model has the opportunity to order its printing directly from the owner of the printer, who may be located in the next house. And get it from him.

Very comfortable and most importantly not expensive. 3Dhubs charge only 20% of the transaction between the customer and the owner of the printer.

By the way, I must say that 95% of network printers are home-made, hence a significant limitation on the quality and quantity of products manufactured.

In addition, just a week ago, the company received a new round of investment in the amount of $ 4.5 million for the development and expansion of the network. Serious funds and great prospects that investors see!

The Belgian company Materialize has long been known in the market. For most of its history, the company sells industrial printers and provides printing services for the aviation, auto, military and medical industries.

However, an equally important direction for the company is the development of the i.Materialise project - a 3D printing service and a marketplace for goods. The company allows designers to create their own stores and publish products for sale in them.

I note that i.materialise is closely monitoring the quality of published goods and trying to weed out what they think it will be impossible to sell. Although this is not officially regulated, but by the quantity of goods and communication with designers you can make just such an output.

For the company, the main market and earnings are 3D printing services for large clients from the business and the sale of printers.

French startup Sculpteo is positioning itself as a cloud system for 3D printing. And not with the simple. The company has developed a very powerful tool for working with 3D-models online.

In fact, professional designers and engineers can easily prepare any three-dimensional model directly in the personal account on the site, I don’t use desktop software: having made the model hollow inside, checking the thickness of all the walls, arranging all my order in the printer chamber and launching it.

The team spent 4 years to reach the current level of their IT product. Now they are launching a second production near Paris, where about 15 industrial printers will be located.

Investors are very promising to look at the trend of digital cloud production development, which provides access to the capacity of industrial 3D printers (read a mini-factory) and invest in the creation of the infrastructure of the future.

And finally, the favorites of the American (and not only) press - startup Shapeways .

Shapeways in the first place - this is the largest marketplace product, created by an army of designers (about 30,000) of the community.

The main positioning of the company is the creation of a community and a market of designer-entrepreneurs, with their own designer stores and products. Mix Etsy and Amazon. The company has existed for 7 years and has attracted about 40+ million dollars of investment. Two offices and production in NY and the Netherlands.

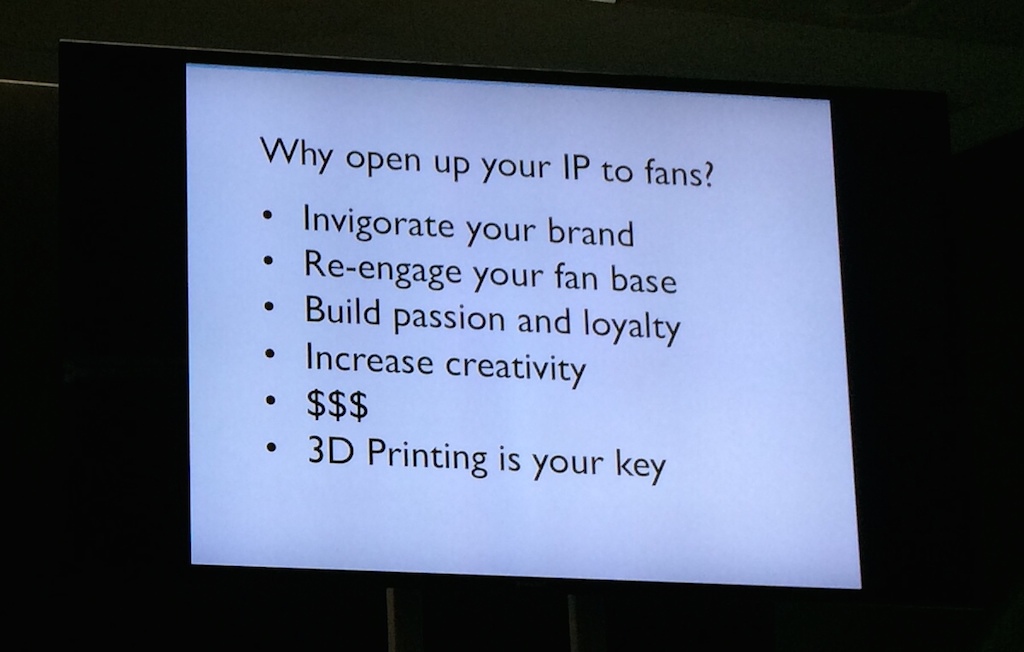

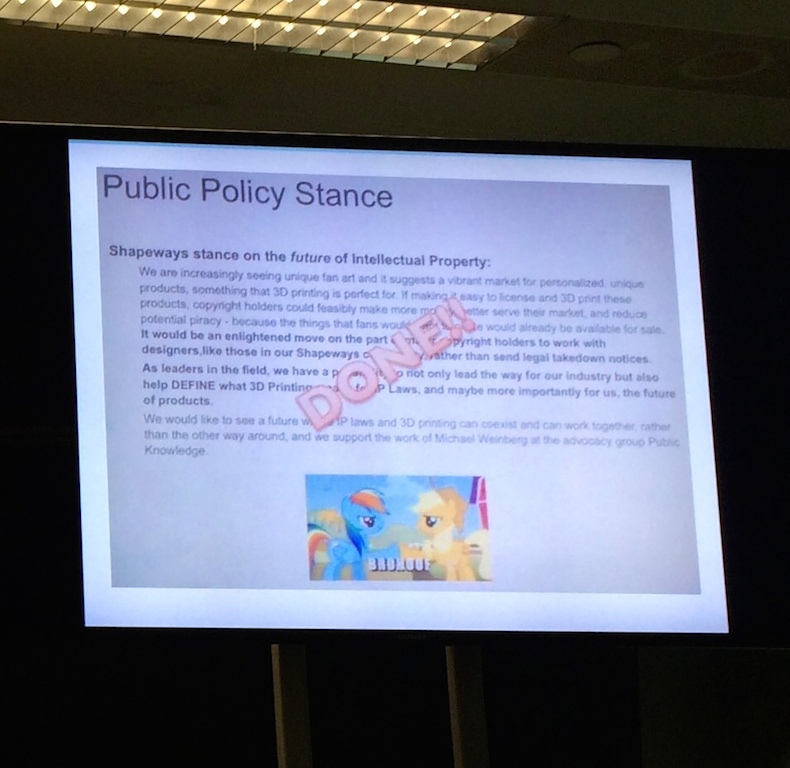

More recently, the press was blown up by the information that Shapeways, together with well-known toy maker Hasbro, launched a project where any designer can create his version of the characters from the Ponyes series, publish them as part of the competition. Later, the company chose winners whose work went to mass production. And all the others are available for ordering on the Shapeways website.

Thus, Hasbro was one of the first to open (with certain limitations, of course) the ability to reproduce characters without violating intellectual property. The project was very successful and now, Shapeways launches a number of characters on similar topics.

This is a very important "bell" for the entire industry. The same revolution in its time made the company Apple with the iTunes store.

Results

Summing up the exhibition, I want to send a message to all those who are now in search of a new field of application of their knowledge and skills: whether entrepreneurial or professional.

3D printing and the eco-system that is currently being created around it is a huge, not yet filled niche for hundreds and thousands of projects. It will take more than one year until the technology is popularized among the end customers, but for business this is already a reality today.

The intersection of technologies of additive production and Internet services gives, it seems to me, an incredible mix, which I call Digital Manufacturing . And it is this trend that will continue to gain momentum in the coming years.

Bonus:

For all those who want to make an express tour of the entire exhibition - video from the first person.

Source: https://habr.com/ru/post/236183/

All Articles