This is Science: 3D lithography to masses

Nowadays you will not surprise anyone with electronic lithography, they are predicting a very successful future in microelectronics. Even RosNano is planning to purchase an electron-beam lithograph Mapper. And what about the materials - what will be the basis of the photoresist of the future?

Ion-beam lithography , in the generalized sense of the word, should sooner or later replace traditional photolithography , since it has incomparable resolution and accuracy of creating patterns using particles (ions or electrons) with a very short wavelength (less than 1 Angstrom or 0.1 nm). In addition, this is a method of direct creation of patterns and schemes, which does not require the development of expensive masks (the price of which can reach hundreds of thousands of dollars apiece ), as is the case with photolithography.

For example, in the presented scheme of the photolithographic process, in the case of ion-beam lithography, we can safely exclude the mask at stage number 3:

')

However, in the world of capitalism, everything is decided by money, including the cost of equipment and raw materials - of course, photoresist, which is consumed in large volumes, since the most common chip can contain from a dozen of the most diverse layers. In fact, it is the photoresist that is responsible for how accurately the pattern will be reproduced on the substrate.

So, a group of Chinese scientists from Canada proposed a method of using extremely cheap polystyrene as a photoresist in electron beam lithography, allowing you to create 3D objects up to 1.5 microns in height with an unusually small thickness (below a hundred nanometers).

Polydimethylsiloxane polymer ( PDMS ) is usually used in electron lithography, but scientists have found a way to replace it with cheaper polystyrene (the market value is about 2 times lower). This increases the sensitivity, and with it, and the performance of the entire method as a whole, since it takes less time to create one "pixel".

The essence of the proposed method is that polystyrene is applied to the substrate due to thermal evaporation, and then after exposure to the electron beam, the exposed area can be easily dissolved with a mixture of xylenes. As a result, a cavity is formed, which can then be filled with various materials: aluminum (to create contacts), silicon dioxide (to create waveguides or insulating planes), and so on.

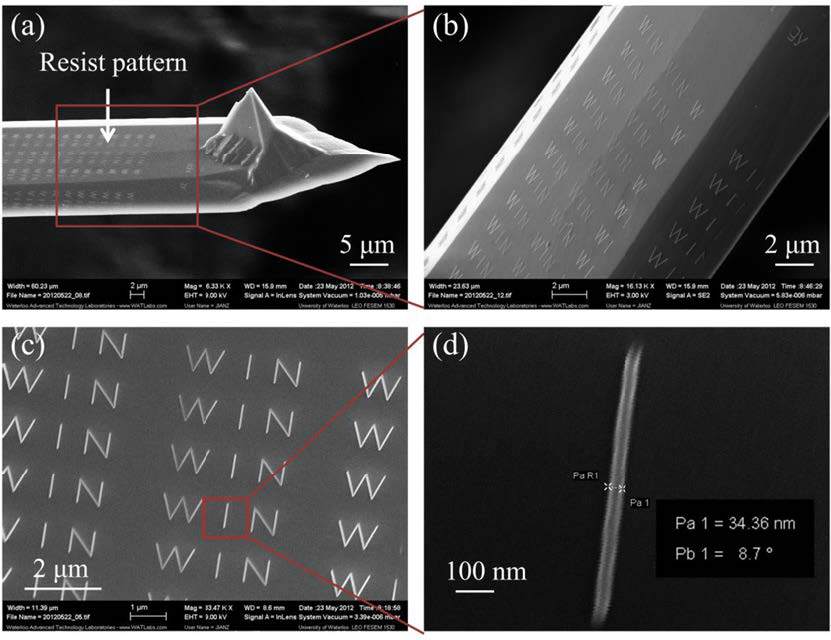

Examples of patterns obtained on polystyrene using electron beam lithography

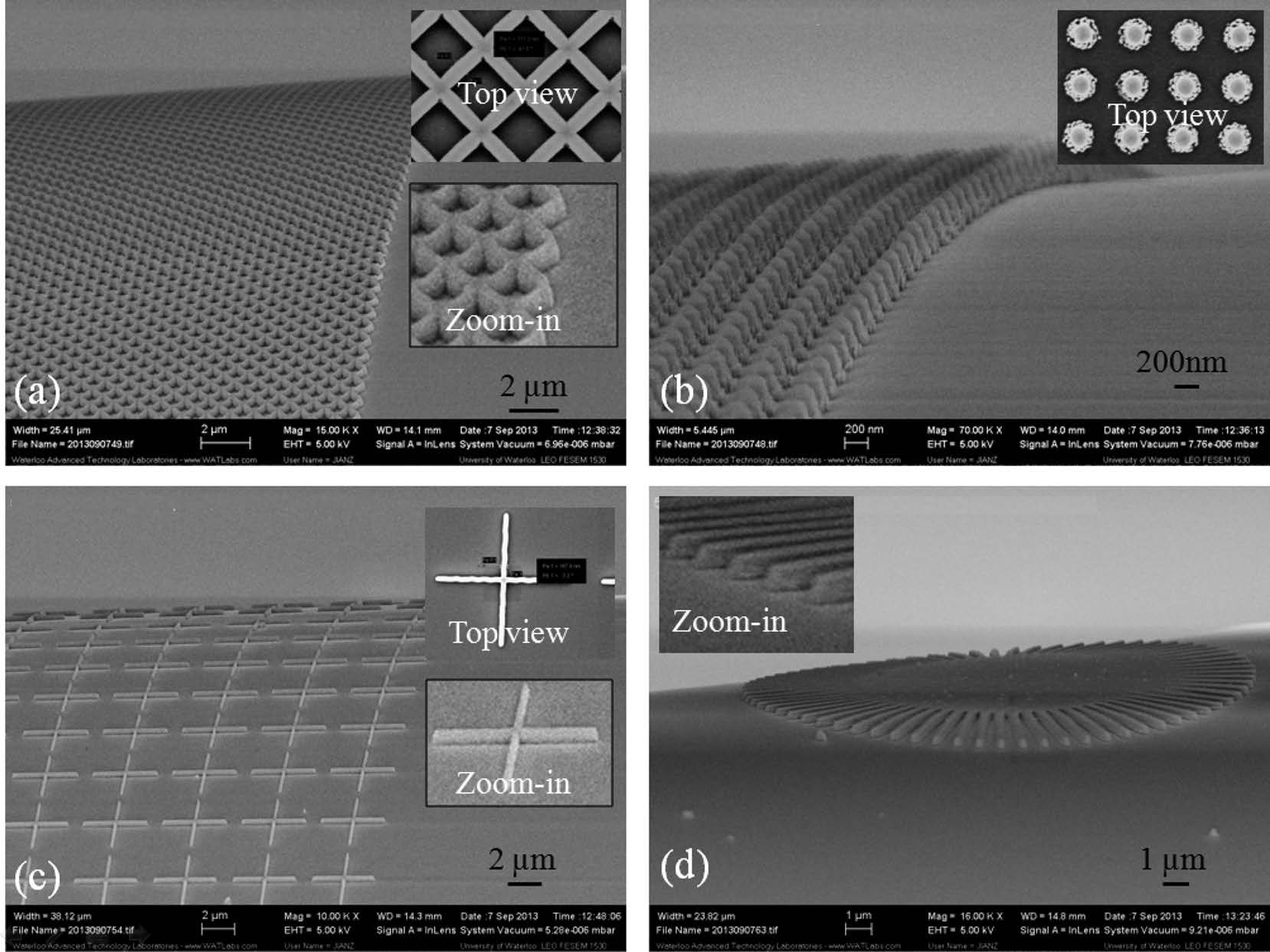

In addition, if desired, you can simultaneously "draw" on curved surfaces and even create waveguides on such surfaces:

With the electron beam, you can print on virtually any surface, creating complex patterns.

Thus, the combination of properties: low cost, low dose or short exposure time, combined with the ability to create patterns on curved surfaces - actually makes polystyrene popular in the emerging market of electronic industrial lithography.

Original article in ACSNano (DOI: 10.1021 / nn4064659)

Full list of published articles This is Science on GeekTimes:

This is Science: Simple and Cheap Solar Energy

This is Science: Is graphene life or death?

This is Science: Blow and Get Electricity

This is Science: Silicon Electronics: Bend Me Completely!

This is Science: Resilient quantum dot display

This is Science: Putting triboelectricity at the service of humanity

This is Science: 3D optical printing moves to the micro level

This is Science: What's inside a neuromorph chip?

This is Science: News from graphene fields

This is Science: 3D lithography to masses

This is Science: The discharge of alkaline batteries or why the battery jumps

This is Science: microcannons and nano-core

This is Science: wearable electronics and triboelectricity. Part 1

This is Science: wearable electronics and triboelectricity. Part 2

Sometimes briefly, and sometimes not so much about the news of science and technology, you can read on my Telegram channel - welcome;)

Source: https://habr.com/ru/post/236181/

All Articles