How we mastered the vacuum magnetron deposition of films

Hello, friends.

Since we have passed a relatively complete stage in the development of the technology of vacuum deposition of thin films, I had a logical thought to share the accumulated experience with you. Of course, it may seem to you that there was little that lies at the very edge of science and technology in this movement. However, in our opinion, the experience itself can be useful.

So, the story began a little earlier, when we had a vacuum chamber. Her path to us was not close and can be described by a separate story, but this, as they say, is “a completely different story.” I can only say that even earlier it brought people some benefit in one of the laboratories of the University of Gottingen.

')

The first thing we began to exploit the vacuum chamber was to test the method of thermal deposition of metals on substrates. The way is simple and old, like the world. In the molybdenum crucible is placed the target of the sprayed metal, for example, silver. A heating element is placed around it. We used a wire of tungsten alloy, which was wound in the form of a spiral.

The complete device for thermal spraying is as follows:

Equipment for thermal spraying of metals. but. Assembled (protective screen and valve removed). Designations: 1 - crucible, 2 - heating element, 3 - steam pipe, 4 - current lead, 5 - thermocouple, 6 - sample frame.

After passing the current (into the vacuum chamber goes through the pressure leads) the spiral heats up, heats the boat, in which the target material also heats up and evaporates. A cloud of metallic vapor rises through the steam line and envelops the body on which it is necessary to deposit a metal film.

The method itself is simple and good, but there are also disadvantages: high power consumption, it is difficult to locate surfaces (bodies) on which a film is to be deposited in a cloud. Adhesion is also not the best. Applied to various materials, including metals, glass, plastic, etc. Mostly - for research purposes, since we only mastered the vacuum equipment.

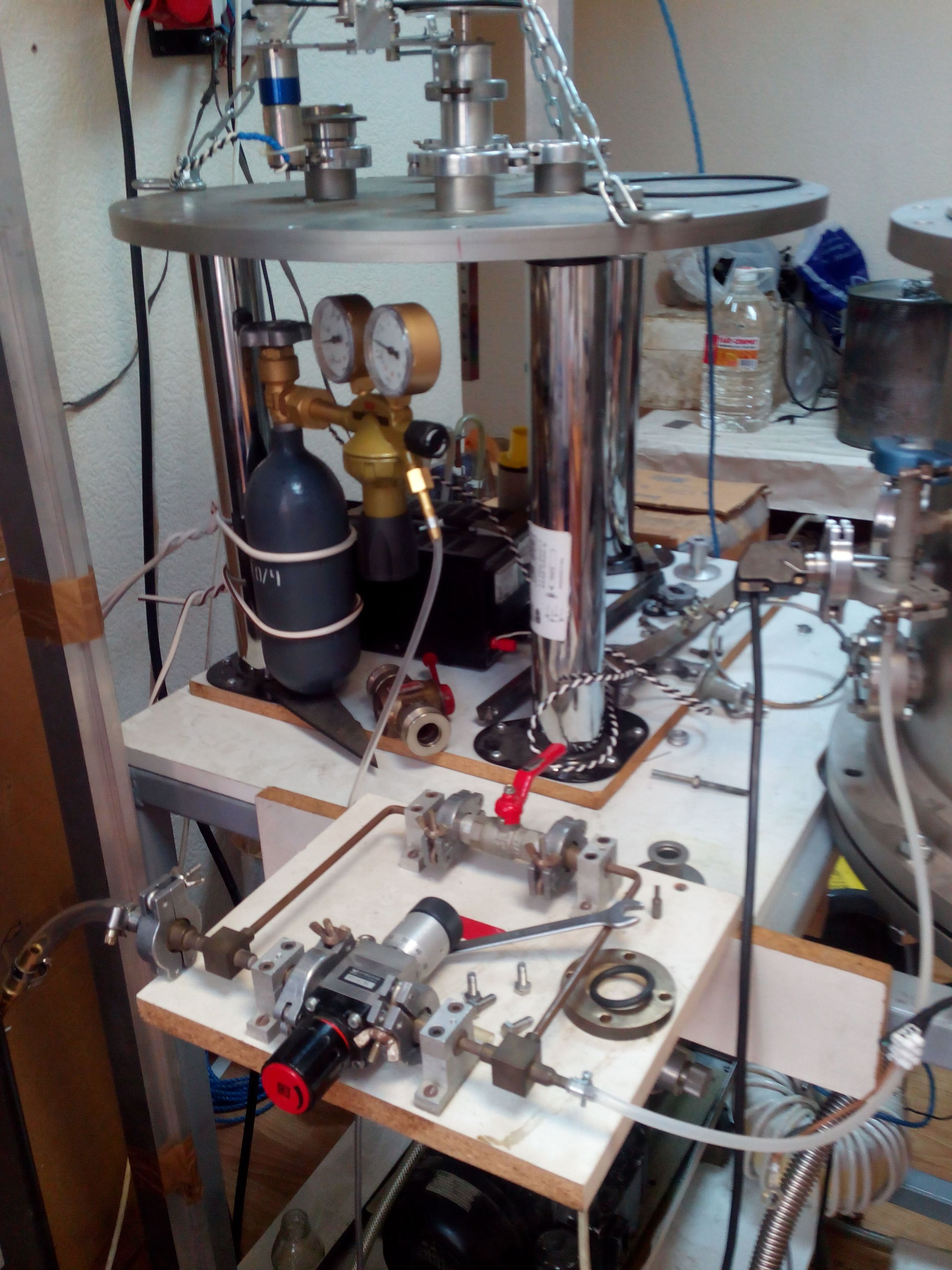

Now it is time to tell about the vacuum system. We carried out the experiments in a vacuum chamber equipped with a vacuum system consisting of a rotary forevacuum and a turbomolecular pump and providing a residual pressure of 9.5 • 10 -6 - 1.2 • 10 -5 mm Hg.

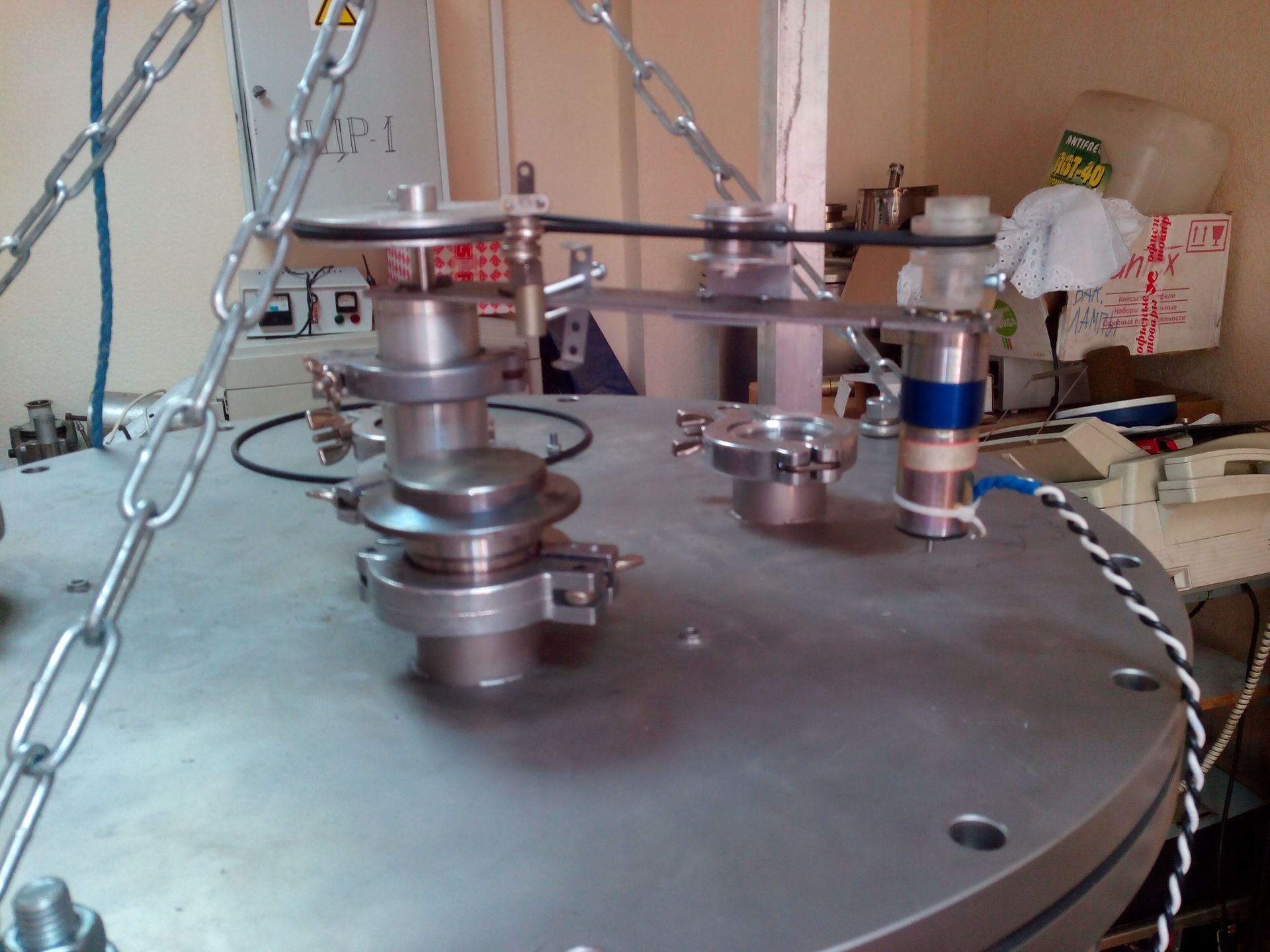

If at first glance it seems that it is not complicated, then in fact it is not. Firstly, the chamber itself must be leakproof, necessary to maintain a high vacuum. This is achieved by applying a seal on all functional flanges and openings. The upper and lower flange covers have the same, in principle, rubber seals, as well as the smallest holes designed for the installation of windows, sensors, devices, sealed inlets and other flange covers, only with a diameter much larger. For example, for reliable sealing of such a hole

Requires flange, gasket and fasteners, as in this photo.

This sensor measures the vacuum in the chamber, the signal comes from it to the device, which indicates the level of high vacuum.

The vacuum of the required level (for example 10-5 mm Hg) is achieved as follows. At first, a low vacuum is pumped out by a fore vacuum pump to a level of 10-2. Upon reaching this level, a high-vacuum pump (turbomolecular pump) is turned on, whose rotor can rotate at a speed of 40,000 rpm. At the same time, the foreline pump continues to work - it pumps out pressure from the turbo-molecular pump itself. The latter is a rather capricious unit and its “thin” device played a certain role in this narration. We use the Japanese turbomolecular pump from Osaka vacuum.

The air evacuated from the chamber with oil vapors is recommended to be discharged into the atmosphere, since fine oil droplets can “splash” the entire room.

Having dealt with the vacuum system and after working on thermal spraying, we decided to try out another method of applying films - magnetron. We had a long experience of communicating with one large laboratory, which applied functional nanocoatings for some of our developments to us using the magnetron sputtering method. In addition, we have fairly close ties with some departments of MEPI, Moscow Higher Technical School and other universities, which also helped us to master this technology.

But over time, we wanted to use more of the possibilities offered by the vacuum chamber.

Soon we had a small magnetron, which we decided to adapt for film application.

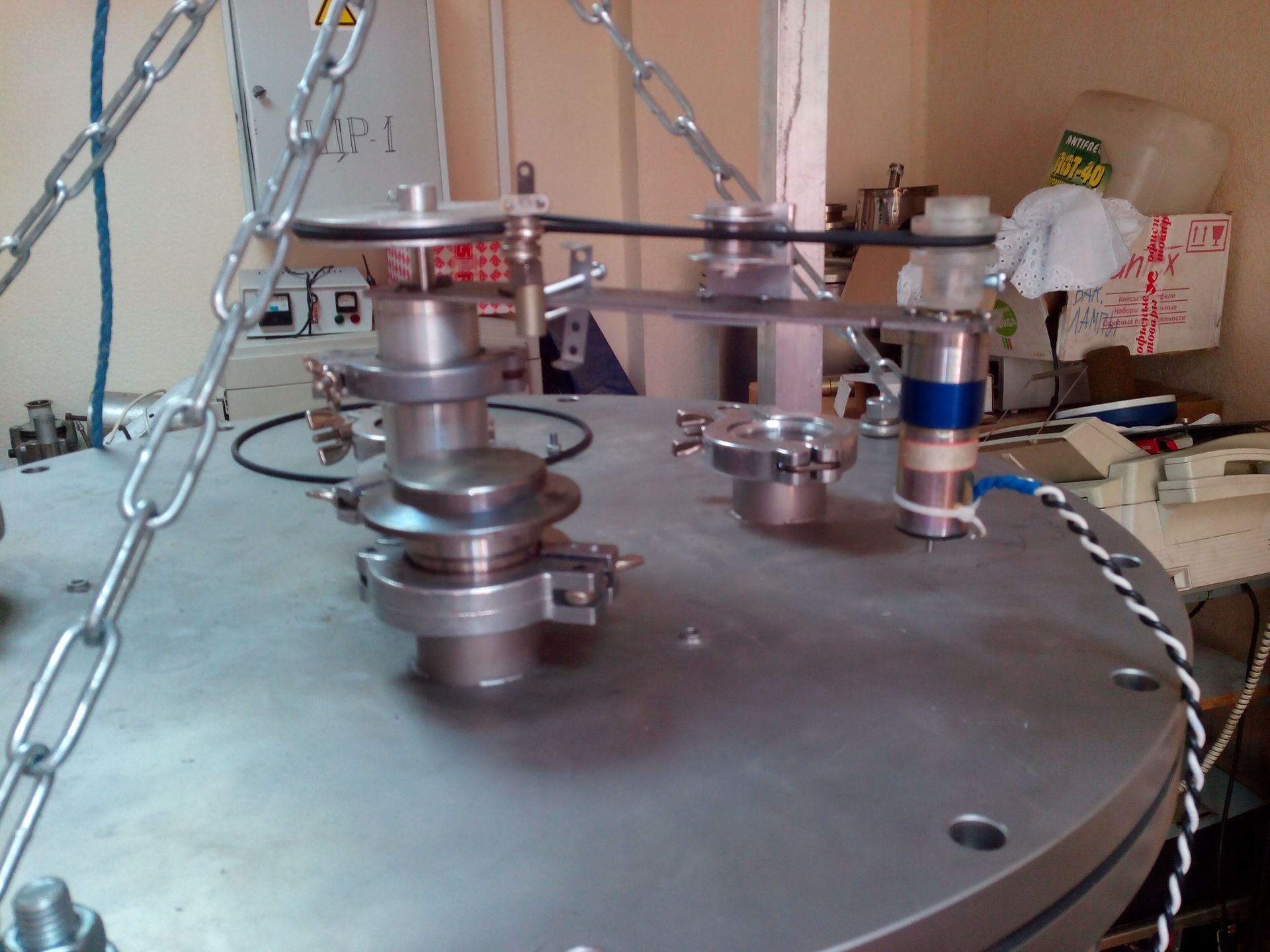

It is the magnetron vacuum method of spraying thin metal and ceramic films that is considered one of the most productive, economical and easy to use among all physical methods of sputtering: thermal evaporation, magnetron, ion, laser, electron beam. The magnetron is installed in one of the flanges, as is convenient for use. However, this is not enough for spraying, since it requires the application of a certain voltage, cooling water, and also gases to ensure the ignition of the plasma.

Simply, the magnetron is arranged as follows. On the base, which also serves as a magnetic conductor, are placed strong magnets that form a strong magnetic field. On the other hand, the magnets are covered with a metal plate, which serves as a source of the material being sprayed and is called a target. The potential is fed to the magnetron, and the ground is fed to the vacuum chamber housing. The potential difference formed between the magnetron and the camera body in a discharged atmosphere and magnetic field leads to the following. The argon plasma-forming gas atom enters the action of the magnetic and electric field lines and is ionized under their action. The outgoing electron is attracted to the camera body. The positive ion is attracted to the target of the magnetron and, having accelerated under the action of the force lines of the magnetic field, hits the target, knocking the particle out of it. That flies at an angle opposite that angle, under which the ion of an argon atom hit the target. A particle of metal flies from the target in the direction of the substrate opposite it, which can be made of any material.

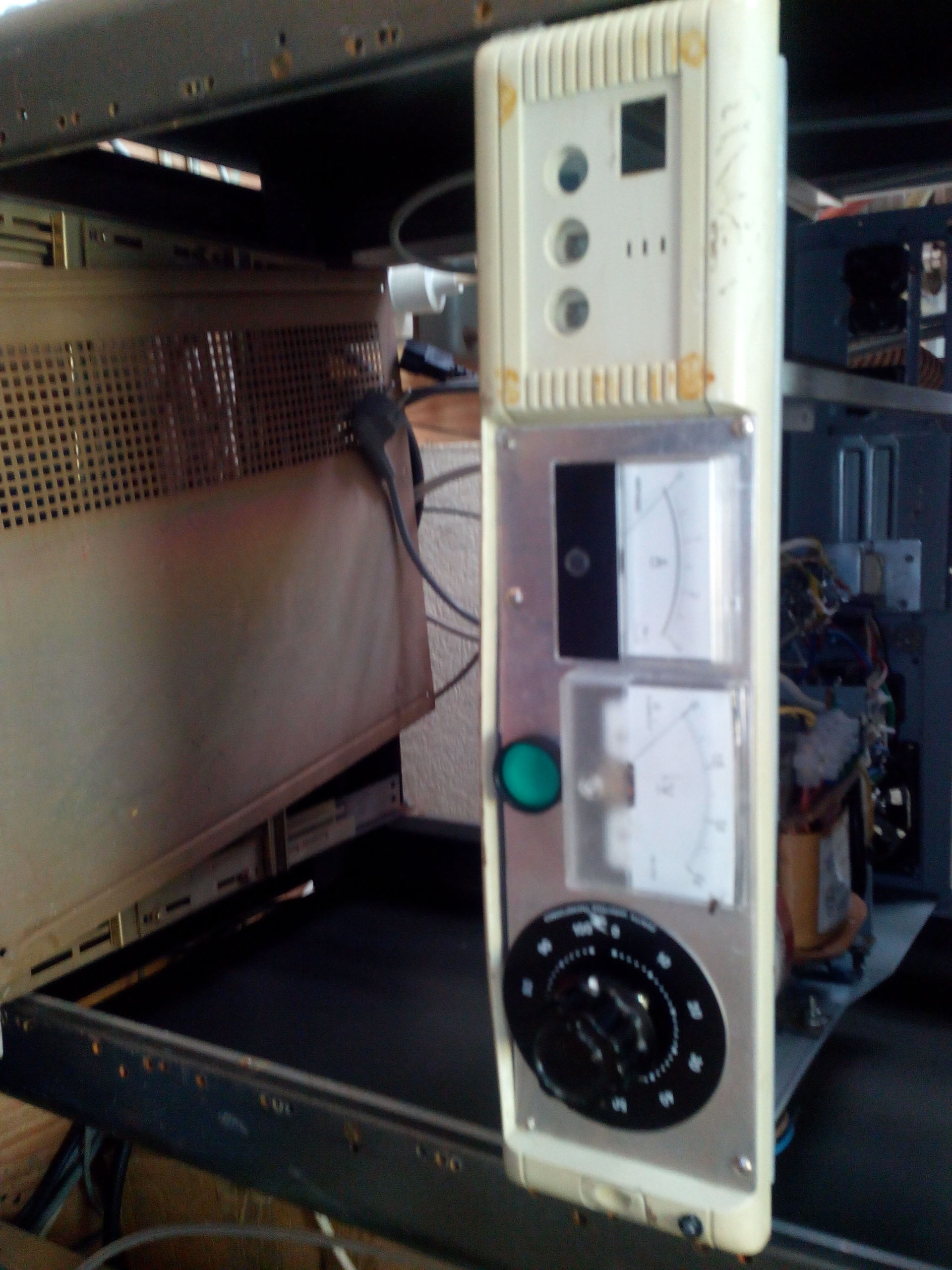

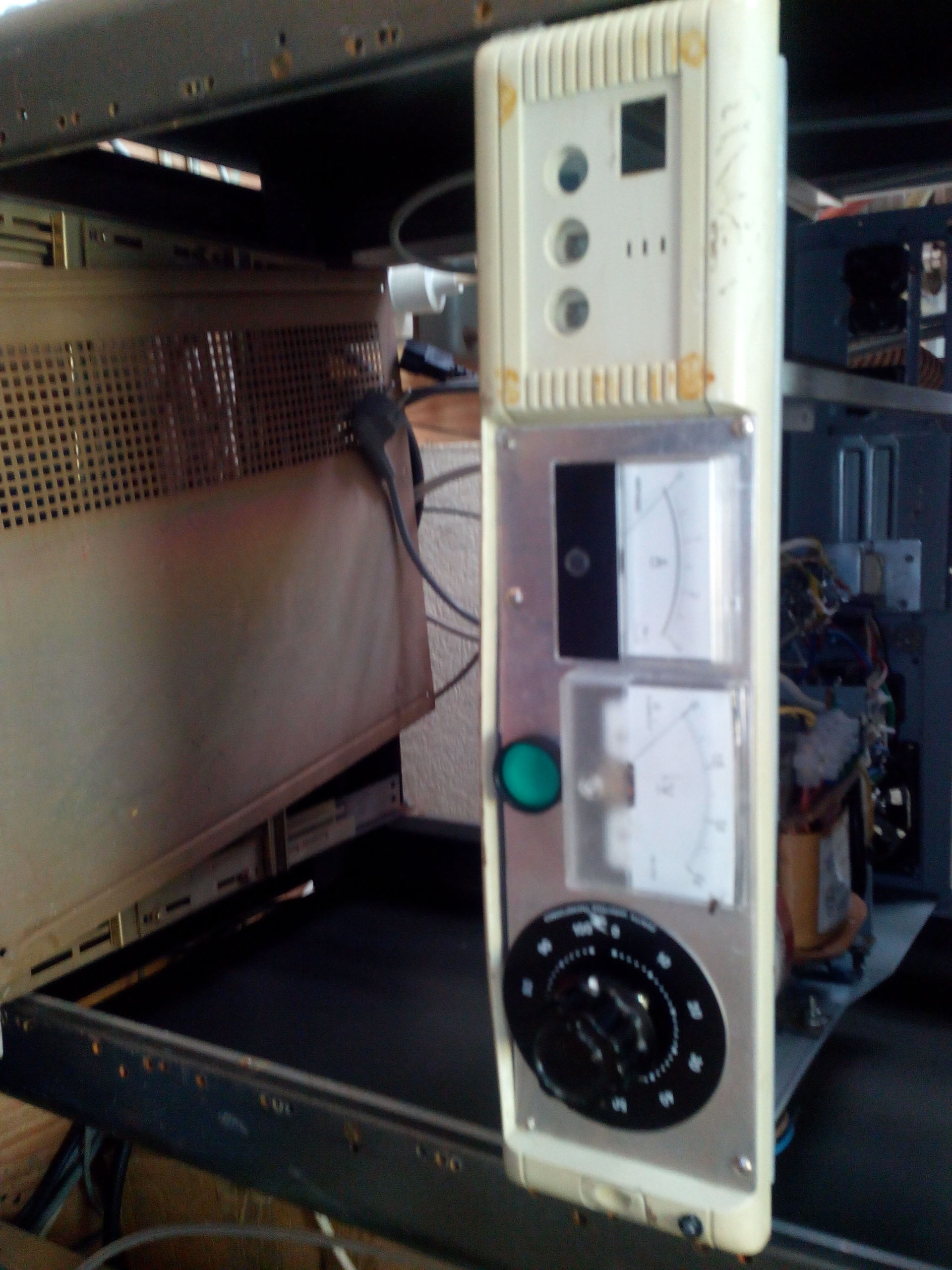

Our college friends made a DC power supply for this magnetron on the order of 500 watts for this magnetron.

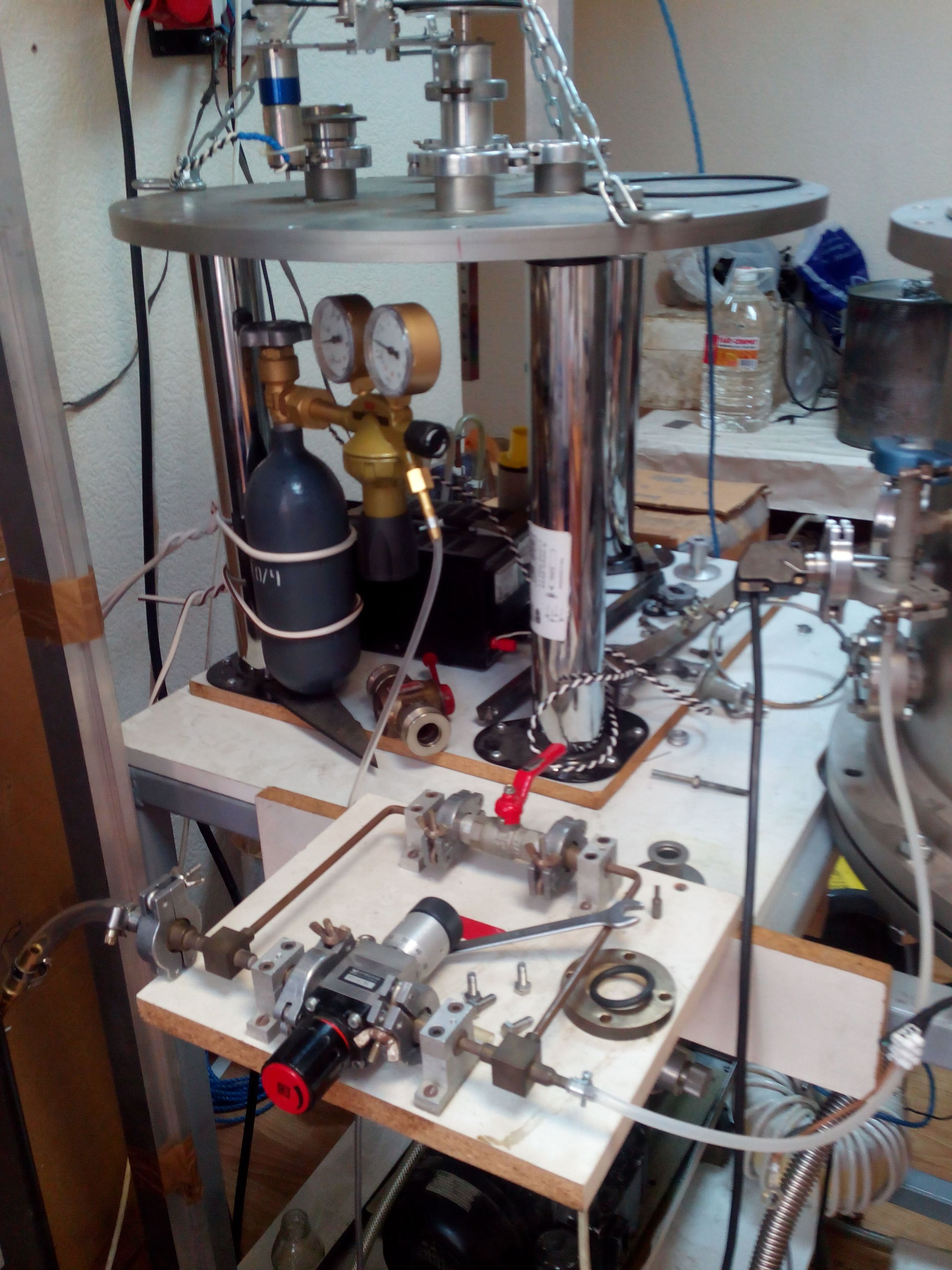

We also built a gas supply system for argon plasma-forming gas.

To accommodate objects that will be sprayed on the film, we built the following device. In the lid of the chamber there are technological openings in which you can install various devices: electric pressure conductions, pressure sealed leads, transparent windows, sensors, and so on. In one of these holes, we installed a pressure seal of the rotating shaft. Outside the camera on this shaft, we brought the rotation from a small electric motor. Having established the drum rotation speed of about 2-5 hertz, we achieved a good uniformity of film deposition around the drum circumference.

Bottom, i.e. inside the chamber, we fixed on the shaft a light metal basket on which you can hang objects. In a stationery store, such a standard drum is sold as a waste basket and costs about 100 rubles.

Now we had almost everything needed for film spraying. We used the following metals as targets: copper, titanium, stainless steel, aluminum, copper-chrome alloy.

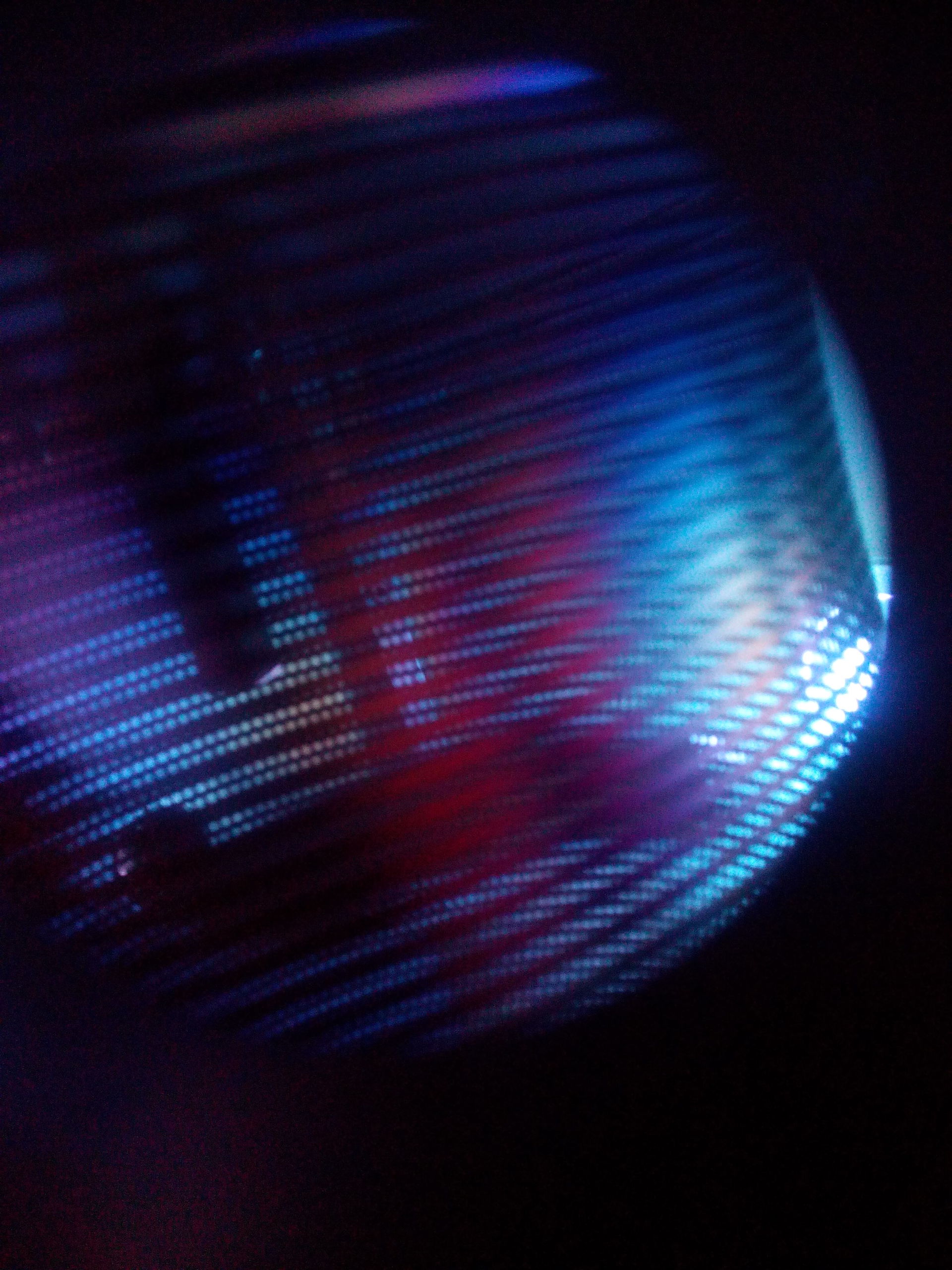

And they began to dust. Through the transparent windows in the chamber it was possible to observe the glow of the plasma on the surface of the magnetron target. So we controlled "by eye" the moment of plasma ignition and the deposition intensity.

The method of controlling the thickness of the deposition came up with quite simple. Placed on the drum the same piece of foil with a measured surface area and measured its mass before and after the spraying session. Knowing the density of the sprayed metal is easy to calculate the thickness of the applied coating. The coating thickness was adjusted either by varying the sputtering time or by adjusting the voltage at the magnetron power supply. This photo shows a precision balance that allows you to measure the mass of samples with an accuracy of ten thousandths of a gram.

We applied to different materials: wood, metals, foil, plastics, paper, plastic films, fabrics, in short, everything that could be placed in the chamber and attached to the drum. Basically, we focused on getting effects of a decorative nature - a change in color or tactile perception of the surface. On these samples of organic and inorganic origin, you can see the difference in color before and after applying various metallic films.

Even more vividly, the difference in color before and after spraying is visible on fabrics and films. Here, the right piece of the usual polyethylene film is not sprayed, and the left one is covered with a layer of copper.

Another effect that can be used for various needs is the conductivity of thin films on substrates. This photo shows the resistance of a piece of paper (in ohms), on which a film of titanium is slightly thicker than a micron.

For further development, we have chosen several areas. One of them is to improve the sputtering efficiency of films with magnetrons. We are going to "wipe" on our own design and manufacture of a more powerful magnetron with a chamber height and a power of 2 times more than that shown in this essay. We also want to try out the technology of reactive spraying, when, together with argon plasma-forming gas, oxygen or nitrogen is supplied to the chamber, and during the deposition of films, not purely metallic films are formed on the substrate surface, but oxides or nitrides, which have a different spectrum of properties than pure metal films.

Since we have passed a relatively complete stage in the development of the technology of vacuum deposition of thin films, I had a logical thought to share the accumulated experience with you. Of course, it may seem to you that there was little that lies at the very edge of science and technology in this movement. However, in our opinion, the experience itself can be useful.

So, the story began a little earlier, when we had a vacuum chamber. Her path to us was not close and can be described by a separate story, but this, as they say, is “a completely different story.” I can only say that even earlier it brought people some benefit in one of the laboratories of the University of Gottingen.

')

The first thing we began to exploit the vacuum chamber was to test the method of thermal deposition of metals on substrates. The way is simple and old, like the world. In the molybdenum crucible is placed the target of the sprayed metal, for example, silver. A heating element is placed around it. We used a wire of tungsten alloy, which was wound in the form of a spiral.

The complete device for thermal spraying is as follows:

Equipment for thermal spraying of metals. but. Assembled (protective screen and valve removed). Designations: 1 - crucible, 2 - heating element, 3 - steam pipe, 4 - current lead, 5 - thermocouple, 6 - sample frame.

After passing the current (into the vacuum chamber goes through the pressure leads) the spiral heats up, heats the boat, in which the target material also heats up and evaporates. A cloud of metallic vapor rises through the steam line and envelops the body on which it is necessary to deposit a metal film.

The method itself is simple and good, but there are also disadvantages: high power consumption, it is difficult to locate surfaces (bodies) on which a film is to be deposited in a cloud. Adhesion is also not the best. Applied to various materials, including metals, glass, plastic, etc. Mostly - for research purposes, since we only mastered the vacuum equipment.

Now it is time to tell about the vacuum system. We carried out the experiments in a vacuum chamber equipped with a vacuum system consisting of a rotary forevacuum and a turbomolecular pump and providing a residual pressure of 9.5 • 10 -6 - 1.2 • 10 -5 mm Hg.

If at first glance it seems that it is not complicated, then in fact it is not. Firstly, the chamber itself must be leakproof, necessary to maintain a high vacuum. This is achieved by applying a seal on all functional flanges and openings. The upper and lower flange covers have the same, in principle, rubber seals, as well as the smallest holes designed for the installation of windows, sensors, devices, sealed inlets and other flange covers, only with a diameter much larger. For example, for reliable sealing of such a hole

Requires flange, gasket and fasteners, as in this photo.

This sensor measures the vacuum in the chamber, the signal comes from it to the device, which indicates the level of high vacuum.

The vacuum of the required level (for example 10-5 mm Hg) is achieved as follows. At first, a low vacuum is pumped out by a fore vacuum pump to a level of 10-2. Upon reaching this level, a high-vacuum pump (turbomolecular pump) is turned on, whose rotor can rotate at a speed of 40,000 rpm. At the same time, the foreline pump continues to work - it pumps out pressure from the turbo-molecular pump itself. The latter is a rather capricious unit and its “thin” device played a certain role in this narration. We use the Japanese turbomolecular pump from Osaka vacuum.

The air evacuated from the chamber with oil vapors is recommended to be discharged into the atmosphere, since fine oil droplets can “splash” the entire room.

Having dealt with the vacuum system and after working on thermal spraying, we decided to try out another method of applying films - magnetron. We had a long experience of communicating with one large laboratory, which applied functional nanocoatings for some of our developments to us using the magnetron sputtering method. In addition, we have fairly close ties with some departments of MEPI, Moscow Higher Technical School and other universities, which also helped us to master this technology.

But over time, we wanted to use more of the possibilities offered by the vacuum chamber.

Soon we had a small magnetron, which we decided to adapt for film application.

It is the magnetron vacuum method of spraying thin metal and ceramic films that is considered one of the most productive, economical and easy to use among all physical methods of sputtering: thermal evaporation, magnetron, ion, laser, electron beam. The magnetron is installed in one of the flanges, as is convenient for use. However, this is not enough for spraying, since it requires the application of a certain voltage, cooling water, and also gases to ensure the ignition of the plasma.

Theoretical excursion

Simply, the magnetron is arranged as follows. On the base, which also serves as a magnetic conductor, are placed strong magnets that form a strong magnetic field. On the other hand, the magnets are covered with a metal plate, which serves as a source of the material being sprayed and is called a target. The potential is fed to the magnetron, and the ground is fed to the vacuum chamber housing. The potential difference formed between the magnetron and the camera body in a discharged atmosphere and magnetic field leads to the following. The argon plasma-forming gas atom enters the action of the magnetic and electric field lines and is ionized under their action. The outgoing electron is attracted to the camera body. The positive ion is attracted to the target of the magnetron and, having accelerated under the action of the force lines of the magnetic field, hits the target, knocking the particle out of it. That flies at an angle opposite that angle, under which the ion of an argon atom hit the target. A particle of metal flies from the target in the direction of the substrate opposite it, which can be made of any material.

Our college friends made a DC power supply for this magnetron on the order of 500 watts for this magnetron.

We also built a gas supply system for argon plasma-forming gas.

To accommodate objects that will be sprayed on the film, we built the following device. In the lid of the chamber there are technological openings in which you can install various devices: electric pressure conductions, pressure sealed leads, transparent windows, sensors, and so on. In one of these holes, we installed a pressure seal of the rotating shaft. Outside the camera on this shaft, we brought the rotation from a small electric motor. Having established the drum rotation speed of about 2-5 hertz, we achieved a good uniformity of film deposition around the drum circumference.

Bottom, i.e. inside the chamber, we fixed on the shaft a light metal basket on which you can hang objects. In a stationery store, such a standard drum is sold as a waste basket and costs about 100 rubles.

Now we had almost everything needed for film spraying. We used the following metals as targets: copper, titanium, stainless steel, aluminum, copper-chrome alloy.

And they began to dust. Through the transparent windows in the chamber it was possible to observe the glow of the plasma on the surface of the magnetron target. So we controlled "by eye" the moment of plasma ignition and the deposition intensity.

The method of controlling the thickness of the deposition came up with quite simple. Placed on the drum the same piece of foil with a measured surface area and measured its mass before and after the spraying session. Knowing the density of the sprayed metal is easy to calculate the thickness of the applied coating. The coating thickness was adjusted either by varying the sputtering time or by adjusting the voltage at the magnetron power supply. This photo shows a precision balance that allows you to measure the mass of samples with an accuracy of ten thousandths of a gram.

We applied to different materials: wood, metals, foil, plastics, paper, plastic films, fabrics, in short, everything that could be placed in the chamber and attached to the drum. Basically, we focused on getting effects of a decorative nature - a change in color or tactile perception of the surface. On these samples of organic and inorganic origin, you can see the difference in color before and after applying various metallic films.

Even more vividly, the difference in color before and after spraying is visible on fabrics and films. Here, the right piece of the usual polyethylene film is not sprayed, and the left one is covered with a layer of copper.

Another effect that can be used for various needs is the conductivity of thin films on substrates. This photo shows the resistance of a piece of paper (in ohms), on which a film of titanium is slightly thicker than a micron.

For further development, we have chosen several areas. One of them is to improve the sputtering efficiency of films with magnetrons. We are going to "wipe" on our own design and manufacture of a more powerful magnetron with a chamber height and a power of 2 times more than that shown in this essay. We also want to try out the technology of reactive spraying, when, together with argon plasma-forming gas, oxygen or nitrogen is supplied to the chamber, and during the deposition of films, not purely metallic films are formed on the substrate surface, but oxides or nitrides, which have a different spectrum of properties than pure metal films.

Source: https://habr.com/ru/post/233729/

All Articles