Professional 3d hand scanners

According to the results of the survey in the article “How I used a 3d scanner to forge a key,” I decided to test and describe professional hand-held 3d scanners (you don’t often hold a piece of plastic at a price above a million rubles).

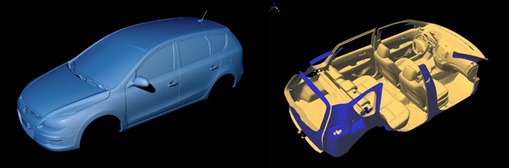

Three-dimensional or 3D scanning is the process of translating the physical form of a real object, a product into digital form, that is, obtaining a three-dimensional computer model (3d model) of an object.

')

3D scanning can be useful in solving problems of re-engineering, designing fixtures, accessories, spare parts in the absence of original computer documentation for the product, as well as the need to digitize surfaces of complex shape, including art forms and impressions.

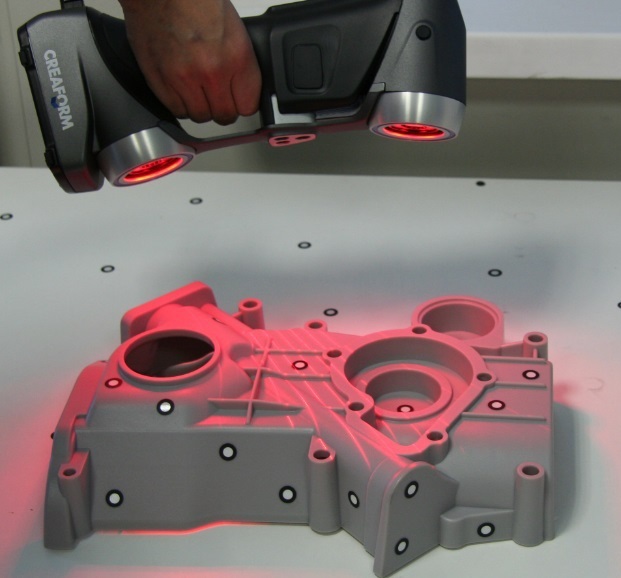

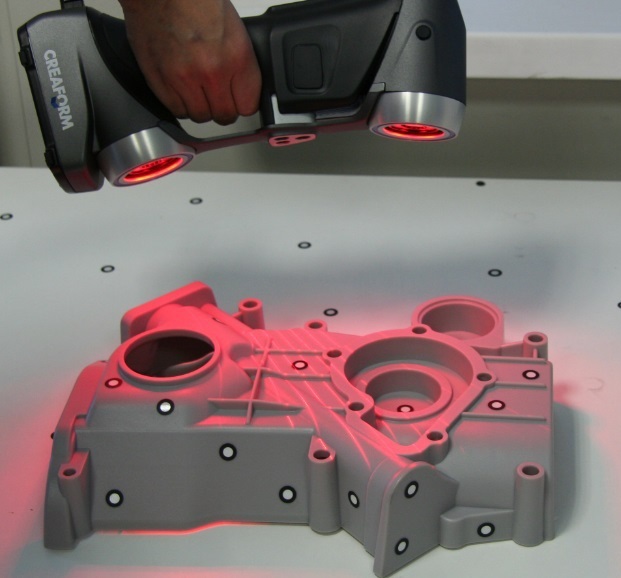

The work of the scanner is somewhat reminiscent of the human surround vision. As the brain builds a three-dimensional image of what he saw, so the 3D scanner obtains information by comparing two images that are offset from each other. To achieve the required accuracy of building a model, additional technological methods are used in the form of laser illumination or periodic flash.

Under the cut description and test drive Creaform HandyScan 700 and a little about 2 other scanners and one peephole about Surphaser. As well as examples of the use of scanners in the oil and space industries, medicine and reverse engineering.

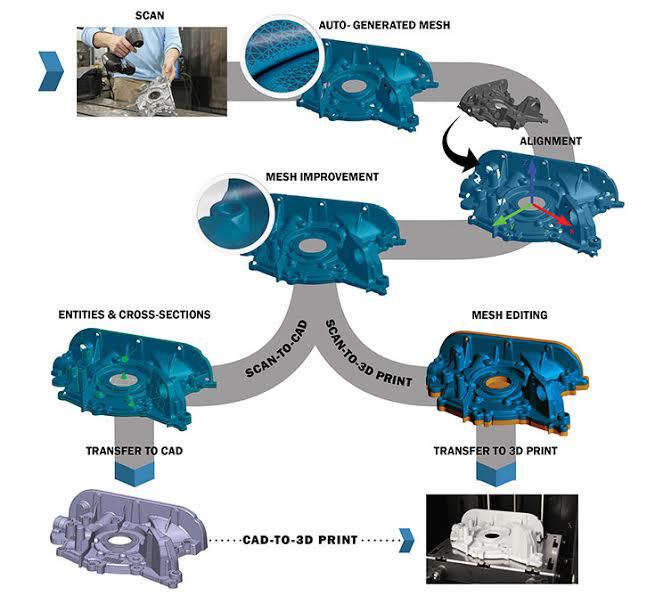

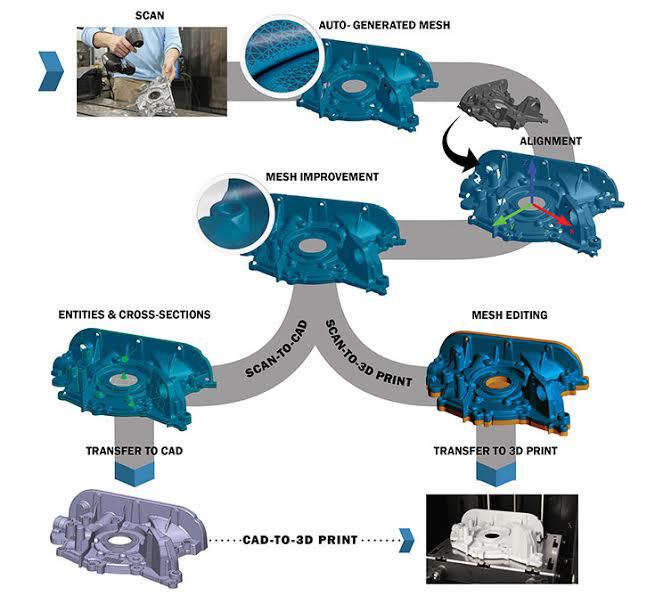

Stages of creating a 3d-model with a scanner

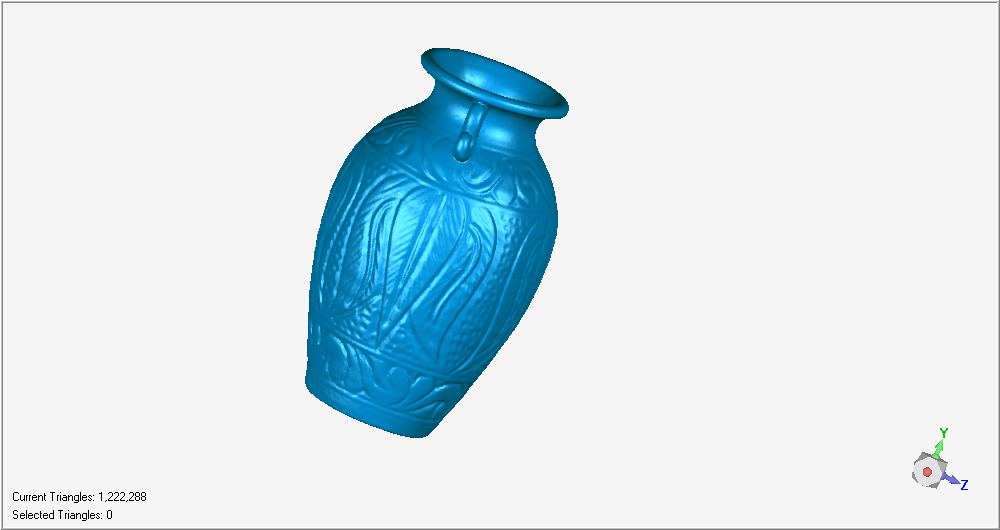

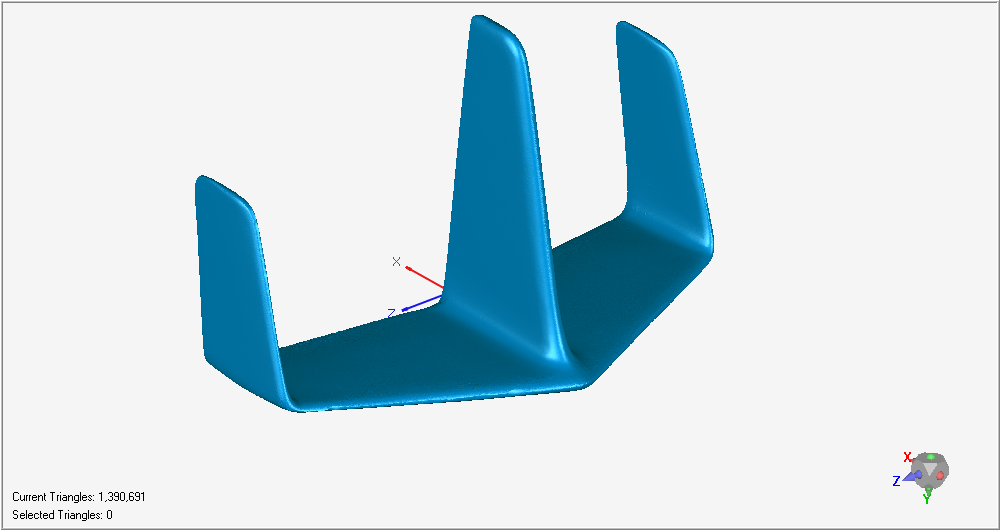

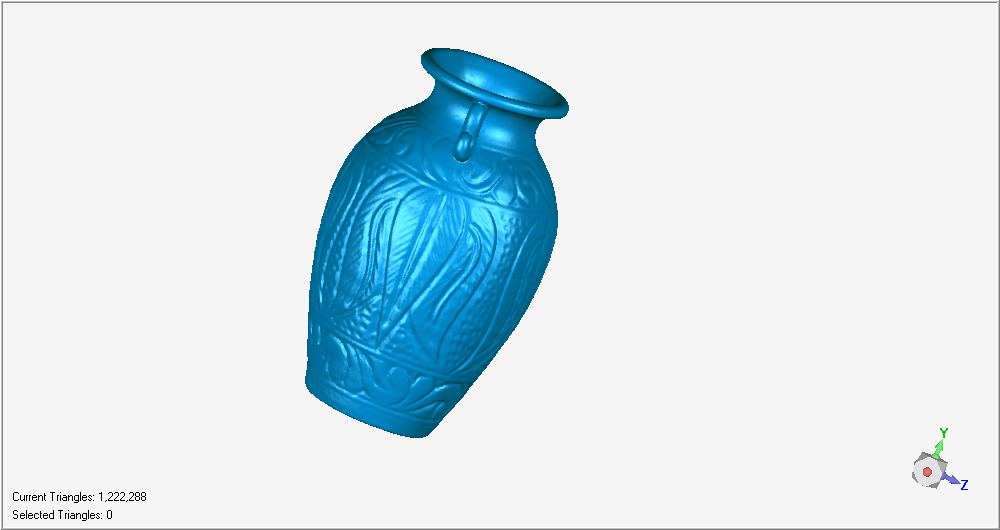

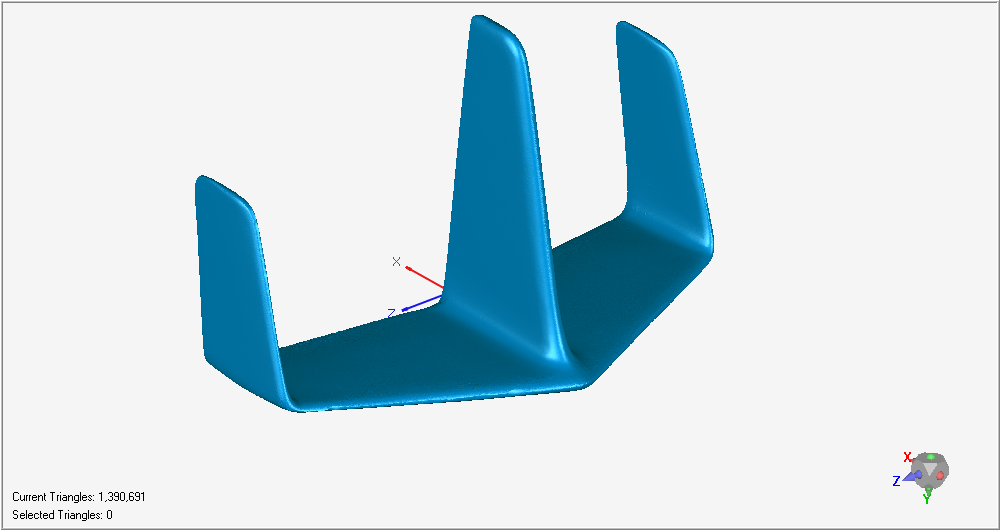

3D scanning is a tool for quickly obtaining the geometry of a three-dimensional object of almost any complexity. However, it must be remembered that a 3D scanner gives a cloud of points in three-dimensional space, arranged in the shape of an object or a polygonal model - the same points, but connected by lines so that you get a set of intersecting planes describing the geometry of the object.

Very few people need the geometry of the object, because often the purpose of a 3D scan is to obtain accurate drawings of the object being scanned, and not just coordinates in three-dimensional space.

But this issue has long been resolved: there is a special software on the market, such as Geomagic DesignX, which allows turning a cloud of points into a parametric model and transferring it to absolutely any CAD system.

Ie, with the help of this software, we remove any restrictions at all: we scan an object with a 3D scanner, parameterize it in a special software, transfer the resulting parametric or NURBS surfaces (to whom) to your CAD and work on the edited model with ease, obtaining drawings any section in the format we need.

Weight - 122 x 77 x 294 mm

Dimensions 150 x 171 x 251 mm

Measurement speed - 480,000 measurements per second

Scanning area - 275 x 250 mm

Light source - 7 laser crosses (+1 additional line)

Laser class - II (safe for the eyes)

Resolution 0.05 mm

Accuracy - up to 0.03 mm

Volumetric accuracy - 0.02 mm + 0.06 mm / m

The distance to the object when scanning - 300 mm

Depth of field - 250 mm

Lens size range (recommended) - 0.1 - 4 m

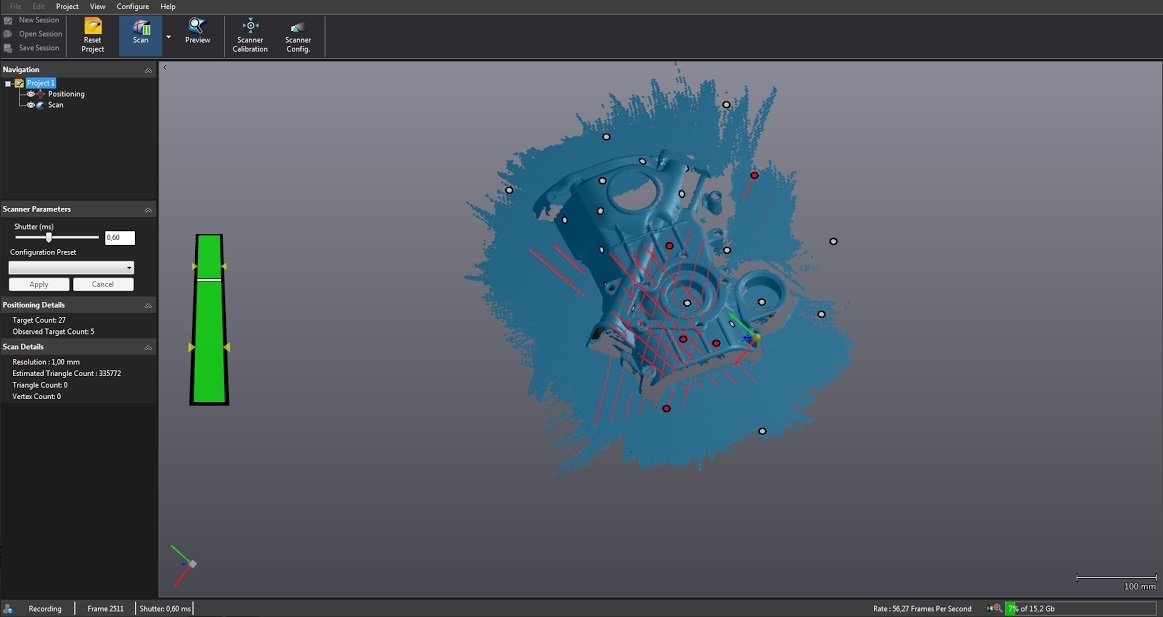

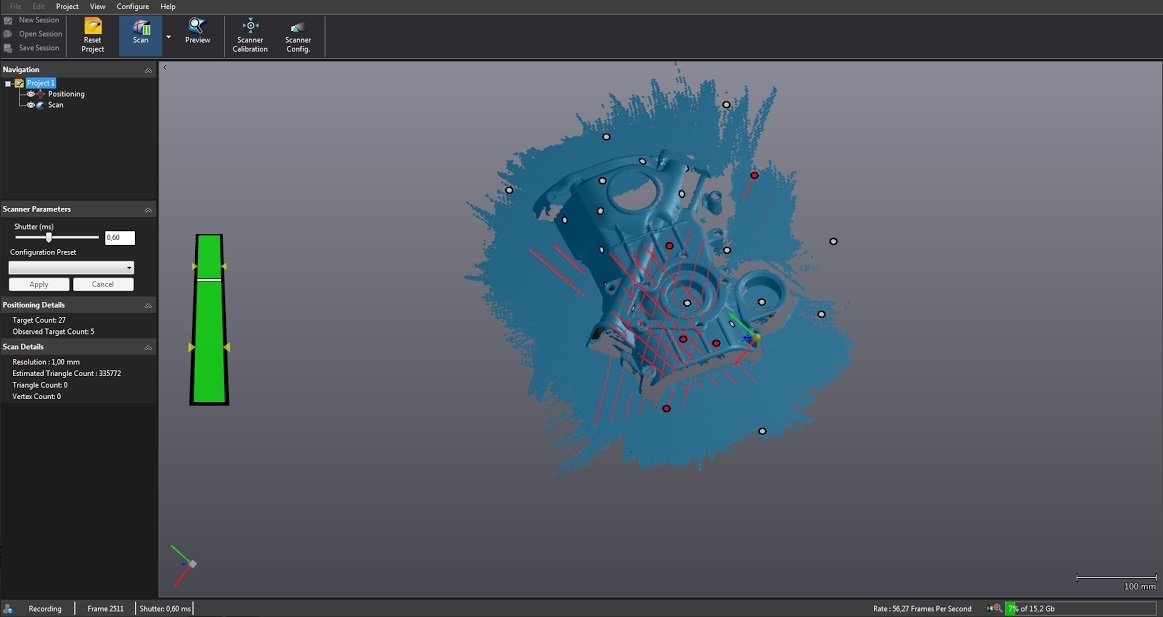

software - VXelements

Output formats are .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr

Compatible software - 3D Systems (Geomagic Solutions), InnovMetric Software (PolyWorks), Dassault Systèmes (CATIA V5 and SolidWorks), PTC (Pro / ENGINEER), Siemens (NX and Solid Edge), Autodesk (Inventor, Alias, 3ds Max, Maya , Softimage).

Connection standard - 1 x USB 3.0

Operating temperature range - 15-40 ° C

Operating humidity range (non-condensing) 10-90%

500black marks

The device itself determines the position. There is no need to use a coordinate measuring machine (CMM), measuring arm or other external positioning device.

Visualization of the scanned surface in real time.

Thanks to the dynamic snapping, the object can be moved during a 3D scan, which eliminates the need for a rigid installation.

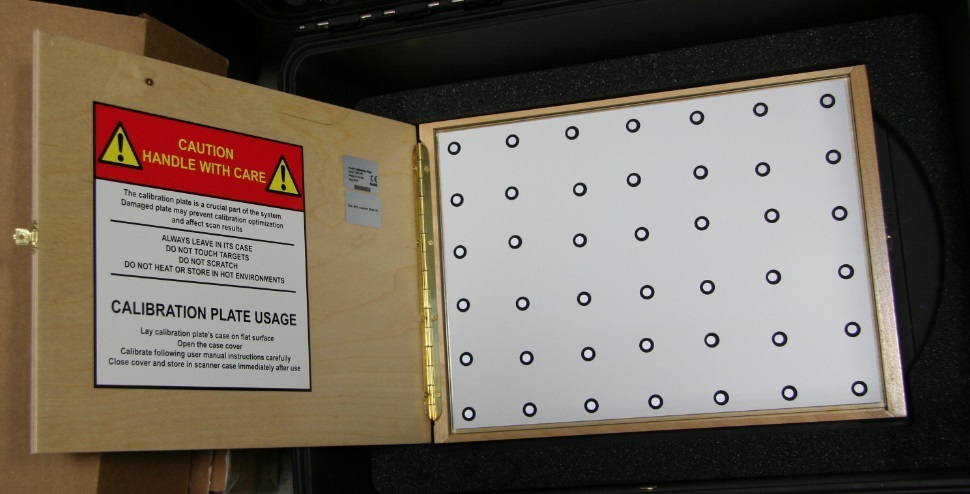

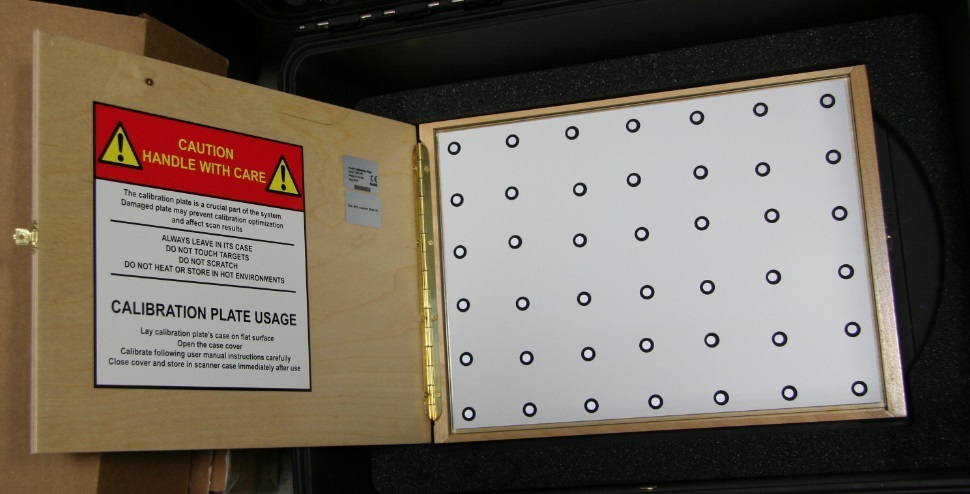

Individual calibration table

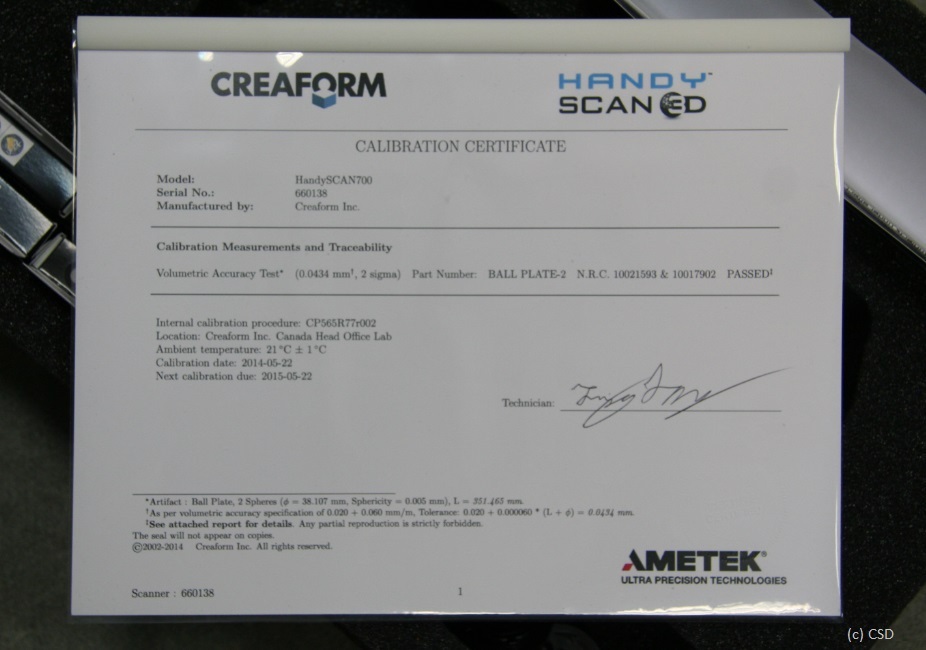

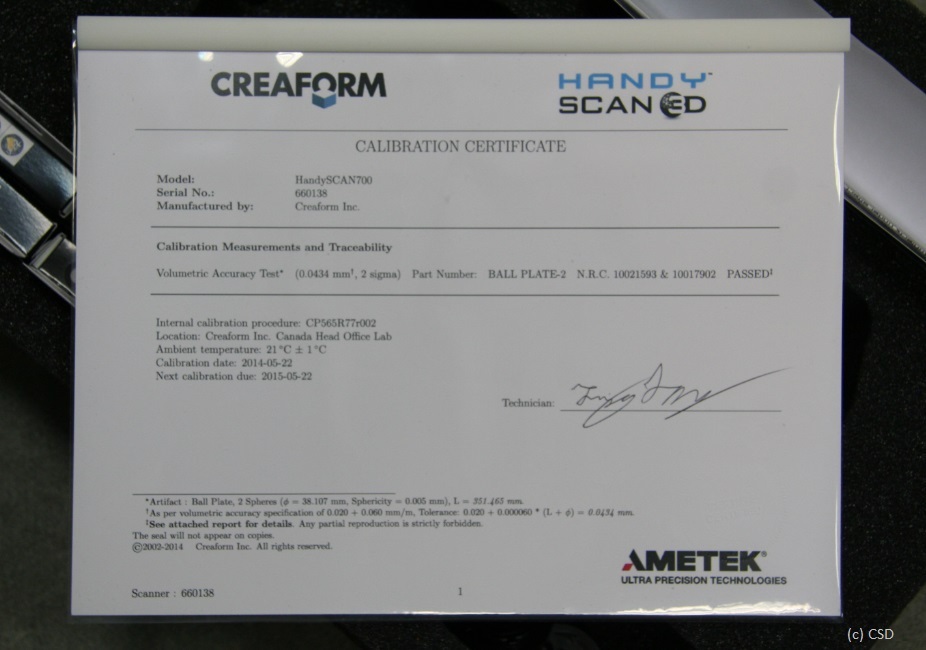

Certificate confirming quality and accuracy

Examples

“At the moment, three-dimensional scanning is used not only to obtain digitized models of various parts, statuettes, car bodies, etc. 3D scanning is also widely used in scanning people, and recently it is a particularly requested technology, because it is interesting to store not only family photos in frames on the nightstand, but also, for example, the entire family, printed on a 3D printer. In addition to entertainment purposes, three-dimensional technologies are increasingly used in medicine. For example, scanning a person's leg to create a convenient prosthesis, scanning a patient's jaw for further work in specialized dental software, scanning human organs ... As it may seem at first glance, at the moment 3D-technologies are entertaining in nature, but this has long been not this way. This is an innovation in almost any field. ” Alexey, Consistent Software Distribution specialist

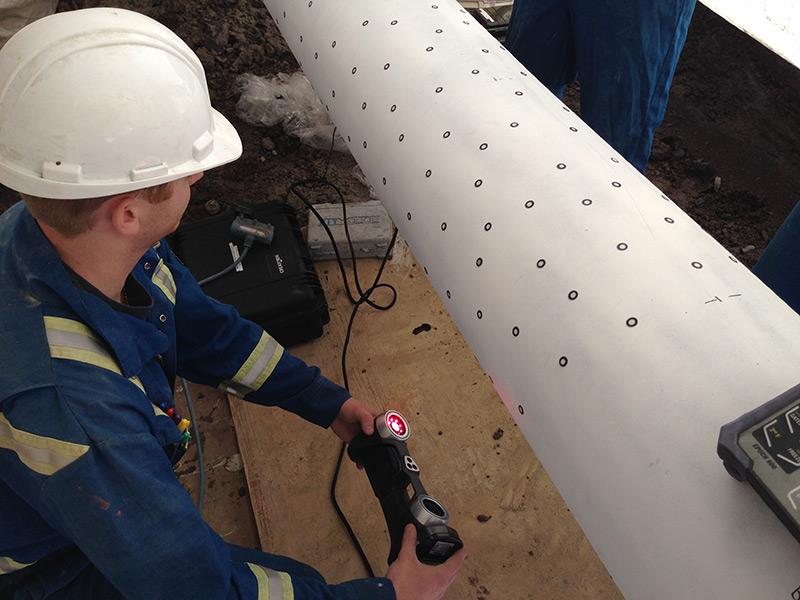

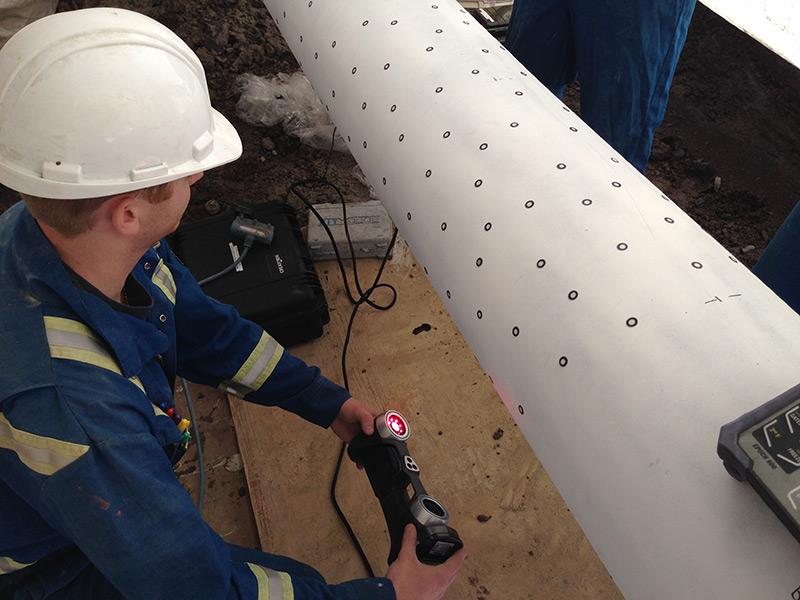

Severe techies check the pipeline

GoScan

EXAscan (~ 3 million rubles)

Surphaser (~ 3 million rubles)

Boss

It is used for scanning spacecraft and in the construction of the subway and the military for their own purposes.

Maintenance and repair is made in Russia. 3D scanners Surphaser assemble in Russia

About this thing is to write a separate article.

Scanning time: from the bow - 1.5 hours; from the tail - 1 hour

Used software: Cyclone for cleaning and data logging, RapidForm for modeling

Processing time: 10 hours from the formation of a cloud of points to the creation of three-dimensional models of the surface.

Total time: 30 hours from the start of the project to the flight with a new embedded product.

Scanning time: 2 hours

Processing time using PolyWork software for stitching and creating a multi-facet model: 4 hours

Layout: 15 scans, 90 million points

Scan time: 4 hours

Processing time using PolyWork software to align and create a multi-facet model: 6 hours

Three-dimensional or 3D scanning is the process of translating the physical form of a real object, a product into digital form, that is, obtaining a three-dimensional computer model (3d model) of an object.

')

3D scanning can be useful in solving problems of re-engineering, designing fixtures, accessories, spare parts in the absence of original computer documentation for the product, as well as the need to digitize surfaces of complex shape, including art forms and impressions.

The work of the scanner is somewhat reminiscent of the human surround vision. As the brain builds a three-dimensional image of what he saw, so the 3D scanner obtains information by comparing two images that are offset from each other. To achieve the required accuracy of building a model, additional technological methods are used in the form of laser illumination or periodic flash.

Under the cut description and test drive Creaform HandyScan 700 and a little about 2 other scanners and one peephole about Surphaser. As well as examples of the use of scanners in the oil and space industries, medicine and reverse engineering.

Stages of creating a 3d-model with a scanner

3D scanning is a tool for quickly obtaining the geometry of a three-dimensional object of almost any complexity. However, it must be remembered that a 3D scanner gives a cloud of points in three-dimensional space, arranged in the shape of an object or a polygonal model - the same points, but connected by lines so that you get a set of intersecting planes describing the geometry of the object.

Very few people need the geometry of the object, because often the purpose of a 3D scan is to obtain accurate drawings of the object being scanned, and not just coordinates in three-dimensional space.

But this issue has long been resolved: there is a special software on the market, such as Geomagic DesignX, which allows turning a cloud of points into a parametric model and transferring it to absolutely any CAD system.

Ie, with the help of this software, we remove any restrictions at all: we scan an object with a 3D scanner, parameterize it in a special software, transfer the resulting parametric or NURBS surfaces (to whom) to your CAD and work on the edited model with ease, obtaining drawings any section in the format we need.

3d scanner applications

- Automotive industry

- Transportation (buses, trucks, trains)

- Heavy equipment (agricultural technology, excavators, mining equipment)

- Sport, Hobby (ATV (ATV), mototechnics, aquatransport)

- Aerospace technology

- Consumer goods

- Production - metal

- Production - plastic and composites

- Army, Defense, Government

- Electrogeneration (wind, hydro, nuclear)

- Shipbuilding

- Gasoline and gas

- Education

- Health care

- Entertainment and Multimedia

- Museology, heritage preservation

- Architecture, construction, engineering

TTX

Weight - 122 x 77 x 294 mm

Dimensions 150 x 171 x 251 mm

Measurement speed - 480,000 measurements per second

Scanning area - 275 x 250 mm

Light source - 7 laser crosses (+1 additional line)

Laser class - II (safe for the eyes)

Resolution 0.05 mm

Accuracy - up to 0.03 mm

Volumetric accuracy - 0.02 mm + 0.06 mm / m

The distance to the object when scanning - 300 mm

Depth of field - 250 mm

Lens size range (recommended) - 0.1 - 4 m

software - VXelements

Output formats are .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr

Compatible software - 3D Systems (Geomagic Solutions), InnovMetric Software (PolyWorks), Dassault Systèmes (CATIA V5 and SolidWorks), PTC (Pro / ENGINEER), Siemens (NX and Solid Edge), Autodesk (Inventor, Alias, 3ds Max, Maya , Softimage).

Connection standard - 1 x USB 3.0

Operating temperature range - 15-40 ° C

Operating humidity range (non-condensing) 10-90%

500

If you really need, I do even like this

The device itself determines the position. There is no need to use a coordinate measuring machine (CMM), measuring arm or other external positioning device.

Visualization of the scanned surface in real time.

Thanks to the dynamic snapping, the object can be moved during a 3D scan, which eliminates the need for a rigid installation.

Individual calibration table

Certificate confirming quality and accuracy

Examples

Application

“At the moment, three-dimensional scanning is used not only to obtain digitized models of various parts, statuettes, car bodies, etc. 3D scanning is also widely used in scanning people, and recently it is a particularly requested technology, because it is interesting to store not only family photos in frames on the nightstand, but also, for example, the entire family, printed on a 3D printer. In addition to entertainment purposes, three-dimensional technologies are increasingly used in medicine. For example, scanning a person's leg to create a convenient prosthesis, scanning a patient's jaw for further work in specialized dental software, scanning human organs ... As it may seem at first glance, at the moment 3D-technologies are entertaining in nature, but this has long been not this way. This is an innovation in almost any field. ” Alexey, Consistent Software Distribution specialist

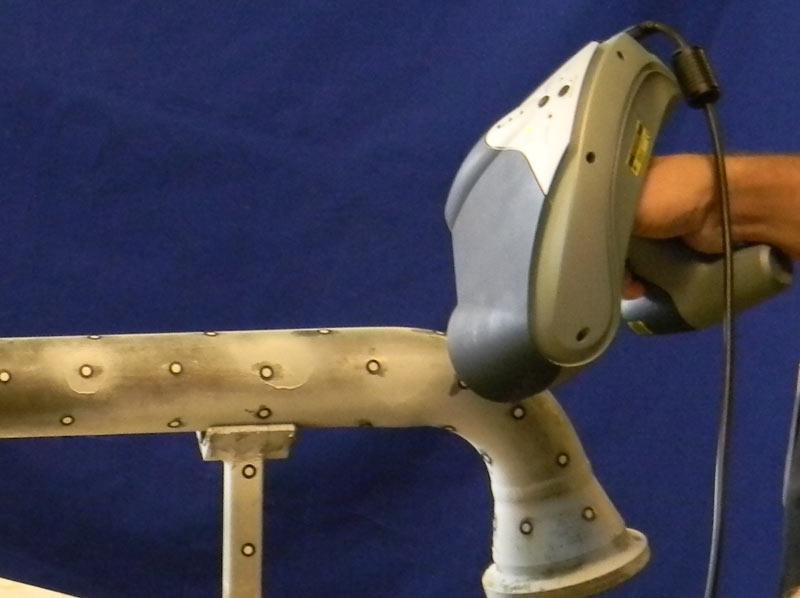

Severe techies check the pipeline

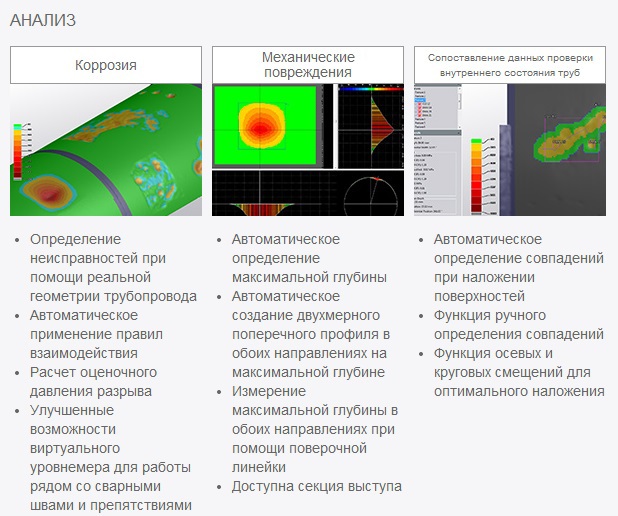

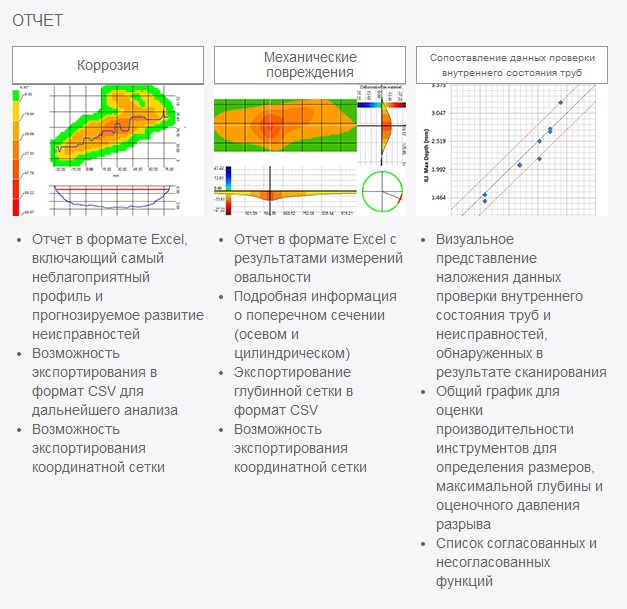

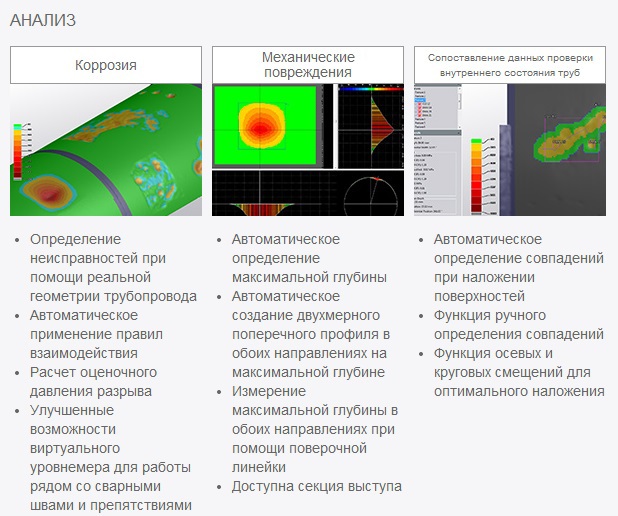

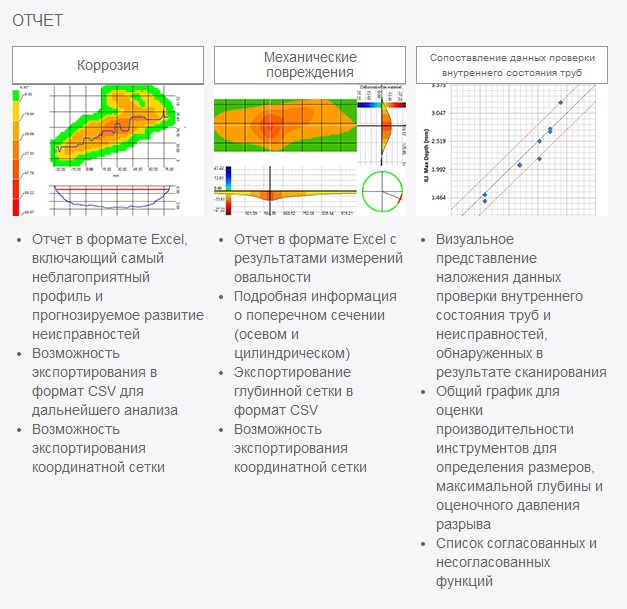

pipeline integrity assessment

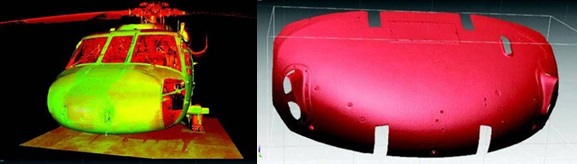

hail damage assessment

The impact of damage caused by hail on the aerodynamic properties of the aircraft is a difficult factor to assess, but at the same time, in the literal sense of the word, it is vital! - make this assessment as accurately as possible. The shape and size of the defects may vary depending on the strength of the squall, which falls into the plane. Consequently, the most common way to analyze damage is by measuring the geometry (length, width, and depth) of each dent in the surface area of the aircraft under consideration. There is also a need to control the geometry of parts on the production line.

internal pipe condition check

Pipeline operators are always torn between ensuring public safety and the economic consequences of earthworks in areas where, as it turns out, repair is not required. Direct assessment methods are used to confirm the measurement results obtained using tools to check the internal state of the pipes. These tools are not always accurate, and they sometimes require recalibration. Service companies spend a large amount of time comparing data from equipment suppliers to check the internal condition of pipes and data obtained using a level gauge (or any other tool for direct evaluation) to evaluate the operation of the tool. In order to properly evaluate the performance of the instrument for checking the internal state of pipes, pipeline operators must perform an annual analysis of statistically significant aggregates using a device that provides greater accuracy than magnetic flux dispersion technology.

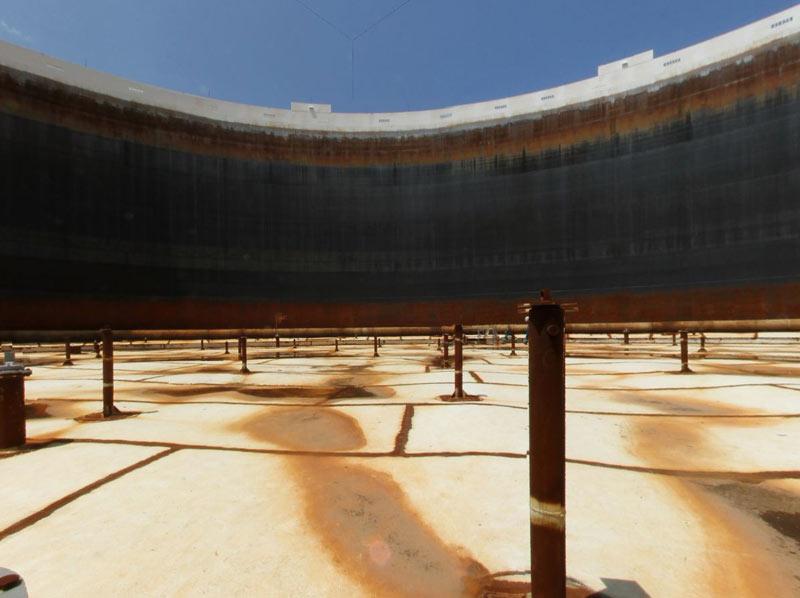

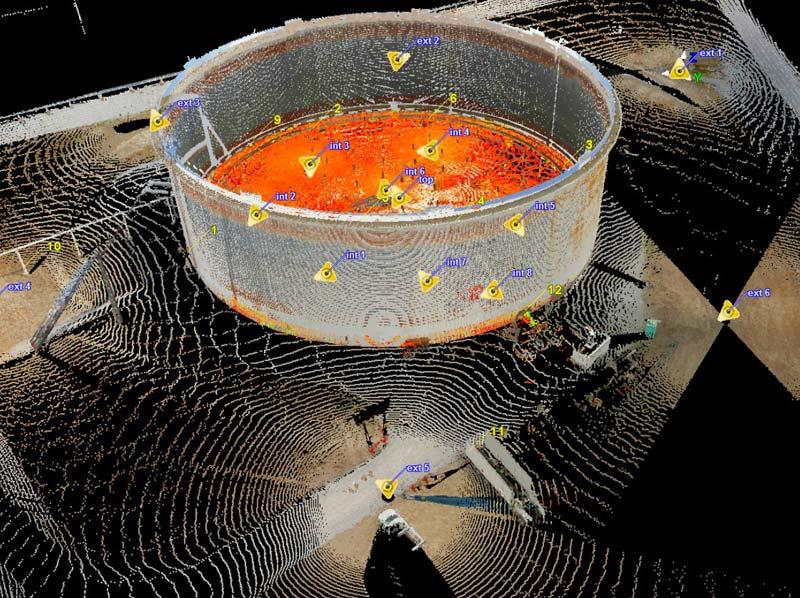

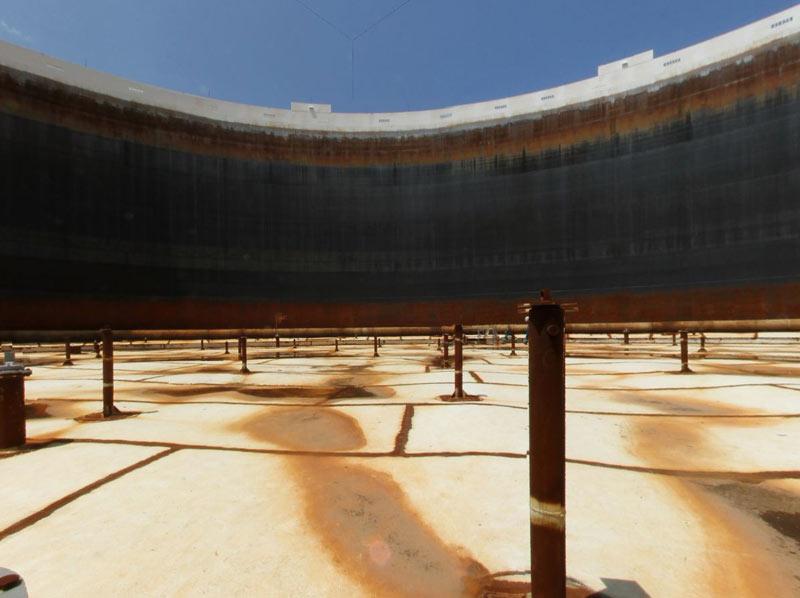

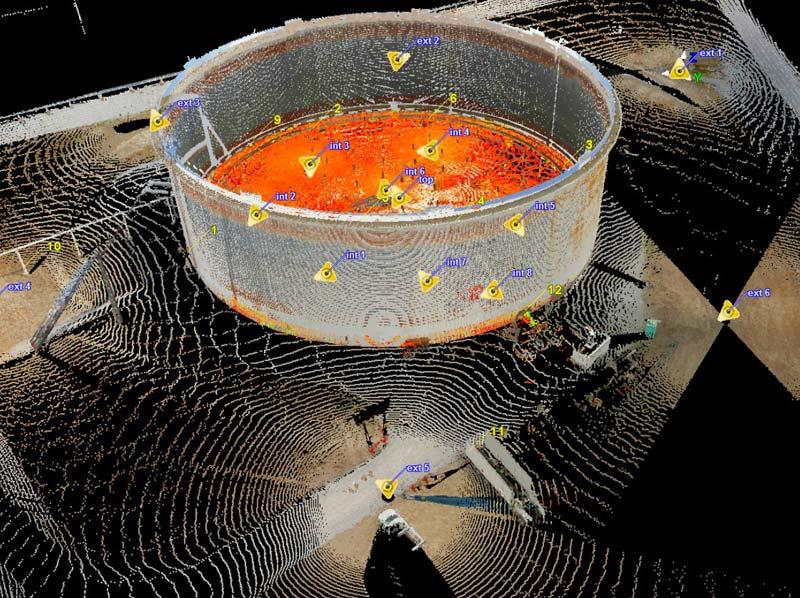

inspection and measurement of tanks

Public concern over environmental issues is forcing oil companies to improve safety practices in relation to environmental protection and health. Inspection of tanks has traditionally been a lengthy procedure, but now companies can satisfy public interests thanks to 3D scanning technology, which allows to increase the accuracy and efficiency of these works. The same tool can be used for other purposes, for example for measuring tanks. In fact, building an exact capacity table is one of the main requirements of the industry ...

The tank inspection reports generated by the Creaform systems contain important information — such as bottom profiles, vertical profiles and circular patterns — necessary to assess tank subsidence.

Calibration capacity tables are used to determine the amount of product in a tank. The form of reports can be changed in accordance with the needs of the client. The data in the report may or may not include the volume of the internal structures of the tank, the effect on the parameters of the floating roof of the tank, etc.

Tank installation

The tank inspection reports generated by the Creaform systems contain important information — such as bottom profiles, vertical profiles and circular patterns — necessary to assess tank subsidence.

Construction of calibration capacity tables

Calibration capacity tables are used to determine the amount of product in a tank. The form of reports can be changed in accordance with the needs of the client. The data in the report may or may not include the volume of the internal structures of the tank, the effect on the parameters of the floating roof of the tank, etc.

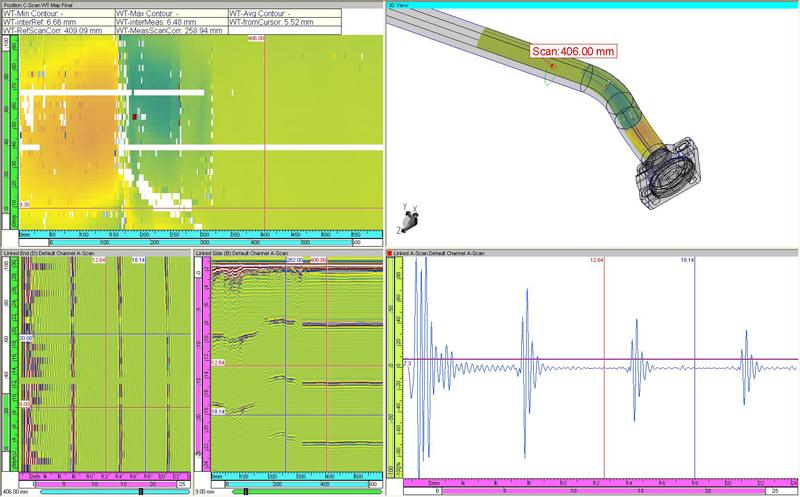

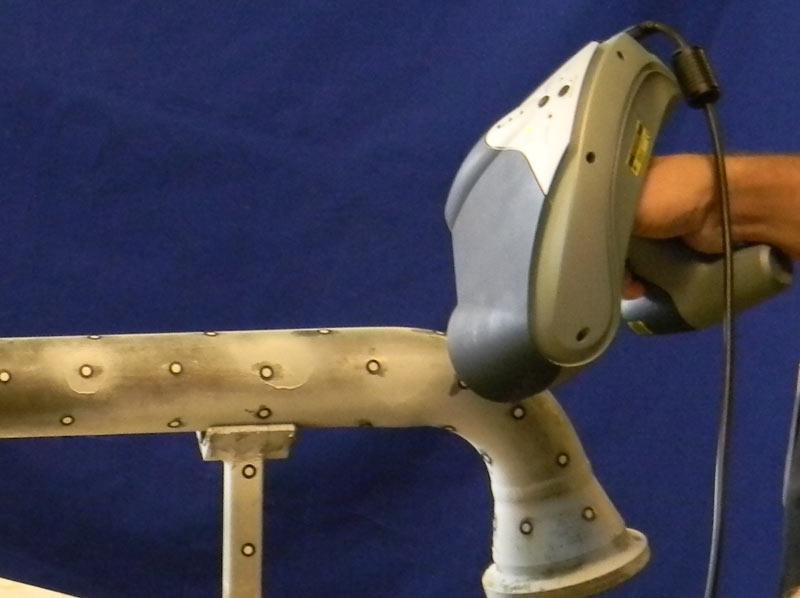

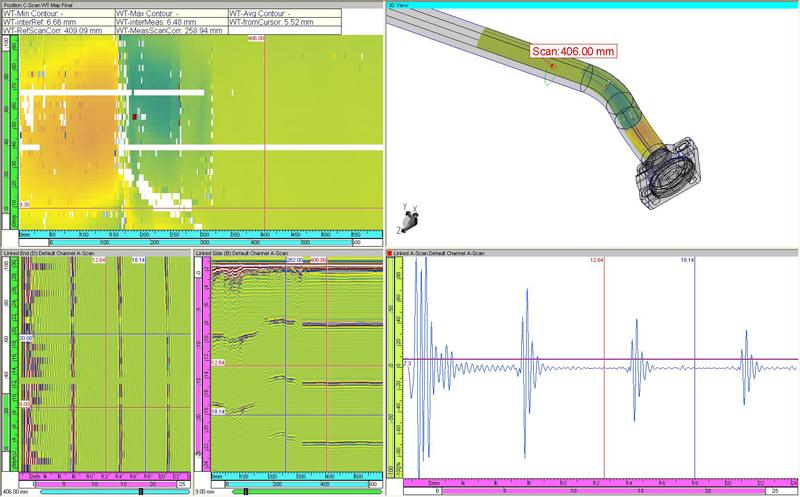

3d modeling for phased array control

for the aerospace industry

Service aircraft and their components and structures need to monitor and assess the level of degradation and remaining life. Aircraft designers and air carriers face the challenge of controlling complex components (for example, gas turbines, engine compartments, fairings, cockpit, etc.), which are parts of very complex components and cannot be removed for inspection. To solve this problem, one usually turns to the control using the phased array method.

The simulation of the phased array focal law is used to predict the results of monitoring and optimize the configuration of the sensor and the wedge. Control of components of complex shape using a two-dimensional matrix can be a difficult task. In the absence of a better solution, the 3D model is usually taken from a CAD file or from a theoretical structural model. However, the actual form of the component is different from the ideal theoretical model and, therefore, the accuracy of ultrasound scanning and the probability of detection deteriorate.

The simulation of the phased array focal law is used to predict the results of monitoring and optimize the configuration of the sensor and the wedge. Control of components of complex shape using a two-dimensional matrix can be a difficult task. In the absence of a better solution, the 3D model is usually taken from a CAD file or from a theoretical structural model. However, the actual form of the component is different from the ideal theoretical model and, therefore, the accuracy of ultrasound scanning and the probability of detection deteriorate.

for energy

Components and designs of power plants need to monitor and assess the level of degradation and the remaining life. Energy companies face the challenge of controlling complex components (dovetail parts, nozzles, feed pipes, etc.), which are parts of very complex assemblies and cannot be extracted for inspection. To solve this problem, one usually turns to the control using the phased array method.

The simulation of the focal law of the phased array is widely used, especially in the nuclear industry, to predict the results of monitoring and optimizing the configuration of the sensor and the wedge. Control of components of complex shape using a two-dimensional matrix can be a difficult task. In the absence of a better solution, the 3D model is usually taken from a CAD file or from a theoretical structural model. However, the actual form of the component is different from the ideal theoretical model and, therefore, the accuracy of ultrasound scanning and the probability of detection deteriorate.

Components and designs of power plants need to monitor and assess the level of degradation and the remaining life. Energy companies face the challenge of controlling complex components (dovetail parts, nozzles, feed pipes, etc.), which are parts of very complex assemblies and cannot be extracted for inspection. To solve this problem, one usually turns to the control using the phased array method.

The simulation of the focal law of the phased array is widely used, especially in the nuclear industry, to predict the results of monitoring and optimizing the configuration of the sensor and the wedge. Control of components of complex shape using a two-dimensional matrix can be a difficult task. In the absence of a better solution, the 3D model is usually taken from a CAD file or from a theoretical structural model. However, the actual form of the component is different from the ideal theoretical model and, therefore, the accuracy of ultrasound scanning and the probability of detection deteriorate.

Other models

GoScan

EXAscan (~ 3 million rubles)

Surphaser (~ 3 million rubles)

Boss

It is used for scanning spacecraft and in the construction of the subway and the military for their own purposes.

Maintenance and repair is made in Russia. 3D scanners Surphaser assemble in Russia

About this thing is to write a separate article.

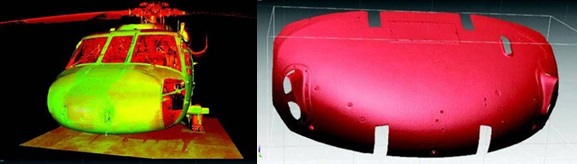

Scanning time: from the bow - 1.5 hours; from the tail - 1 hour

Used software: Cyclone for cleaning and data logging, RapidForm for modeling

Processing time: 10 hours from the formation of a cloud of points to the creation of three-dimensional models of the surface.

Total time: 30 hours from the start of the project to the flight with a new embedded product.

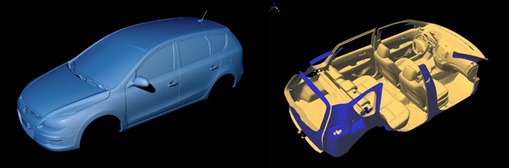

Scanning time: 2 hours

Processing time using PolyWork software for stitching and creating a multi-facet model: 4 hours

Layout: 15 scans, 90 million points

Scan time: 4 hours

Processing time using PolyWork software to align and create a multi-facet model: 6 hours

Source: https://habr.com/ru/post/232387/

All Articles