Temperature control of fast thermal processes

This article is a continuation of the topic of fast thermal processes, which I do as part of my dissertation work. It is logical that after the identification task, which was considered in the previous topic , it is worth trying to solve this kind of process control problem.

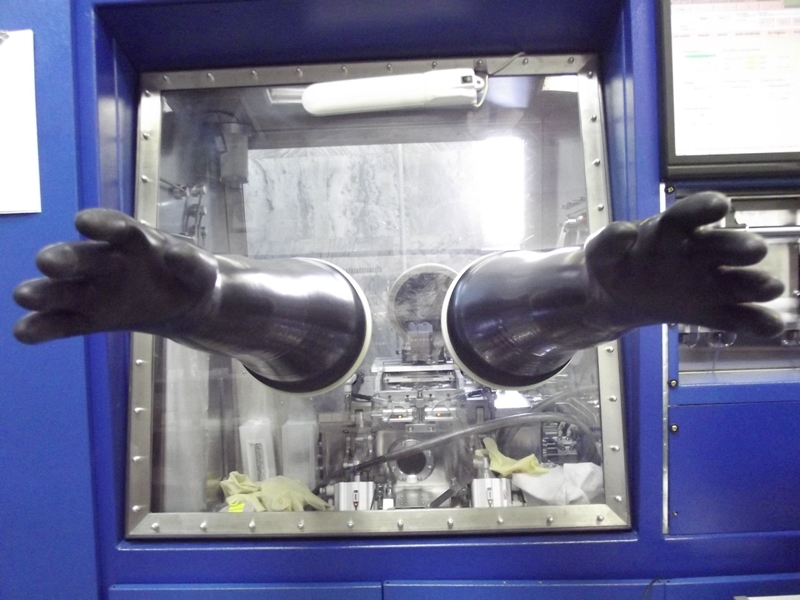

The installation is a high-temperature water-cooled chamber in which elements of organometallic compounds are deposited on sapphire substrates. Growth is performed at temperatures from 550 to 1000 degrees Celsius and atmospheric pressure. The semiconductors obtained in this way are reliable and highly efficient, which allows them to be used in space technologies.

The entire installation is controlled by the computer on which Windows is installed with TwinCAT. All the main electrical components manufactured by Beckhoff, therefore the installation is controlled by the above software. By the way, in the midst of the summer heat, it turned out that their electronics are very sensitive to room temperature, and the signal starts to make a lot of noise.

')

One of the main elements of the control circuit is a high-frequency generator with an inductive element.

Inside, this tube is hollow and coated with silver so as not to be oxidized by passing coolant. We transmit the control signal directly to the generator connected to the inductor circuit. In a tricky way, the generator adjusts the parameters of the inductor circuit and the frequency of the signal, minimizing the current in the inductive element, maximizing the Foucault currents on the receiver side.

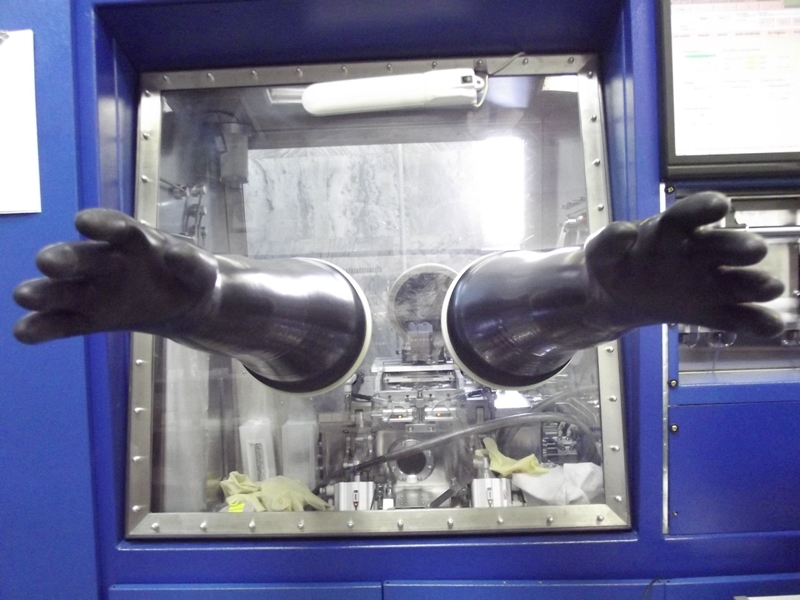

The receiver is a graphite substrate holder, in which there are three holes for sapphire substrates for growing semiconductors. Sapphire is necessary for the grown material to adopt a similar lattice structure. This allows you to get the material with the necessary structure, but if growth occurs at varying temperatures, the structure is uneven, which reduces the service life. Also, with significant fluctuations in temperature, destruction of graphite occurs. The photograph clearly shows the traces of long-term operation of the substrate holder.

The temperature is measured with an optical pyrometer in increments of 1 degree, the noise of the analog-to-digital converter is 0.2 degrees. Accordingly, the task was formulated: ensuring the highest possible accuracy of temperature maintenance, for this installation, in a steady state with a modulus of amplitude deviation equal to 1 degree. The secondary task was to minimize the time of the transition process and overshoot when reaching the operating temperature.

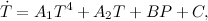

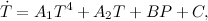

To begin with, a mathematical description of the temperature model of the reactor was obtained, after which its parameters were identified. The differential equation describing the process at the measuring point is as follows:

where T is the measured temperature, P is the control power of the inductor, B is the coefficient at the control action, A1 is the coefficient characterizing the radiant energy distribution, A2 is the coefficient characterizing convection, C is the heating rate of the measuring point from the environment. The experiments revealed that the coefficient A1 depends mainly on the type of material the receiver is made of (substrate holder), A2 increases with increasing temperature and speed of blowing chemicals through the liner (quartz casing, which localizes the chemical reaction zone). It turns out that for the qualitative result of the identification of parameters A1 and C, it is necessary to measure the gas temperature at the reactor inlet and outlet, and it would not hurt to know the temperature of the liner. But it still remains in the plans for the future.

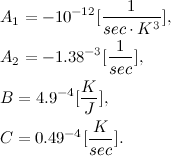

Then two mathematical models were obtained for the extreme modes. The parameters identified by the least squares method in the last post had to be corrected by minimizing the prediction error; we got two sets of parameters for the minimum and maximum temperatures of the working range.

All changes in parameter values are of a physical nature. In particular, with increasing graphite temperature, its electromagnetic characteristics change. We see a decrease in the efficiency of converting electromagnetic energy into heat by 17%. The remaining coefficients themselves are dependent on temperature.

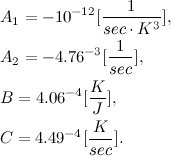

To the model obtained, a PI regulator was added and a closed system was obtained; for this case, there is evidence of stability, which is detailed in the text of the thesis .

The control system was run-in at extreme temperatures of the operating range, in order to make sure that the regulator was working with a significant change in the object's parameters.

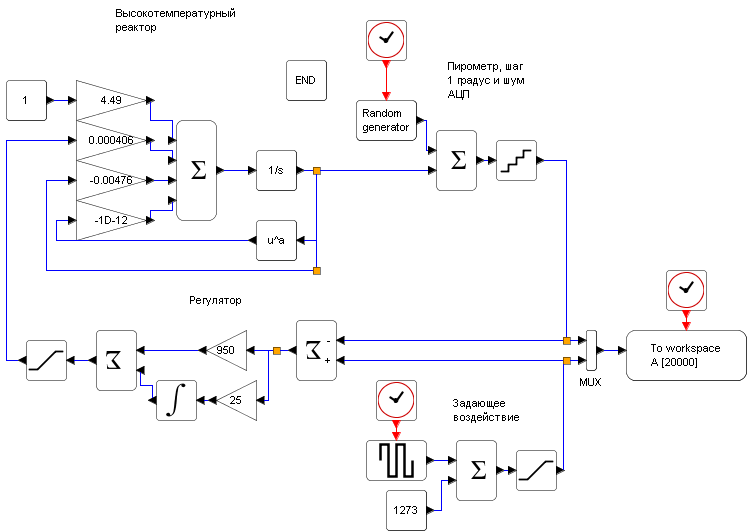

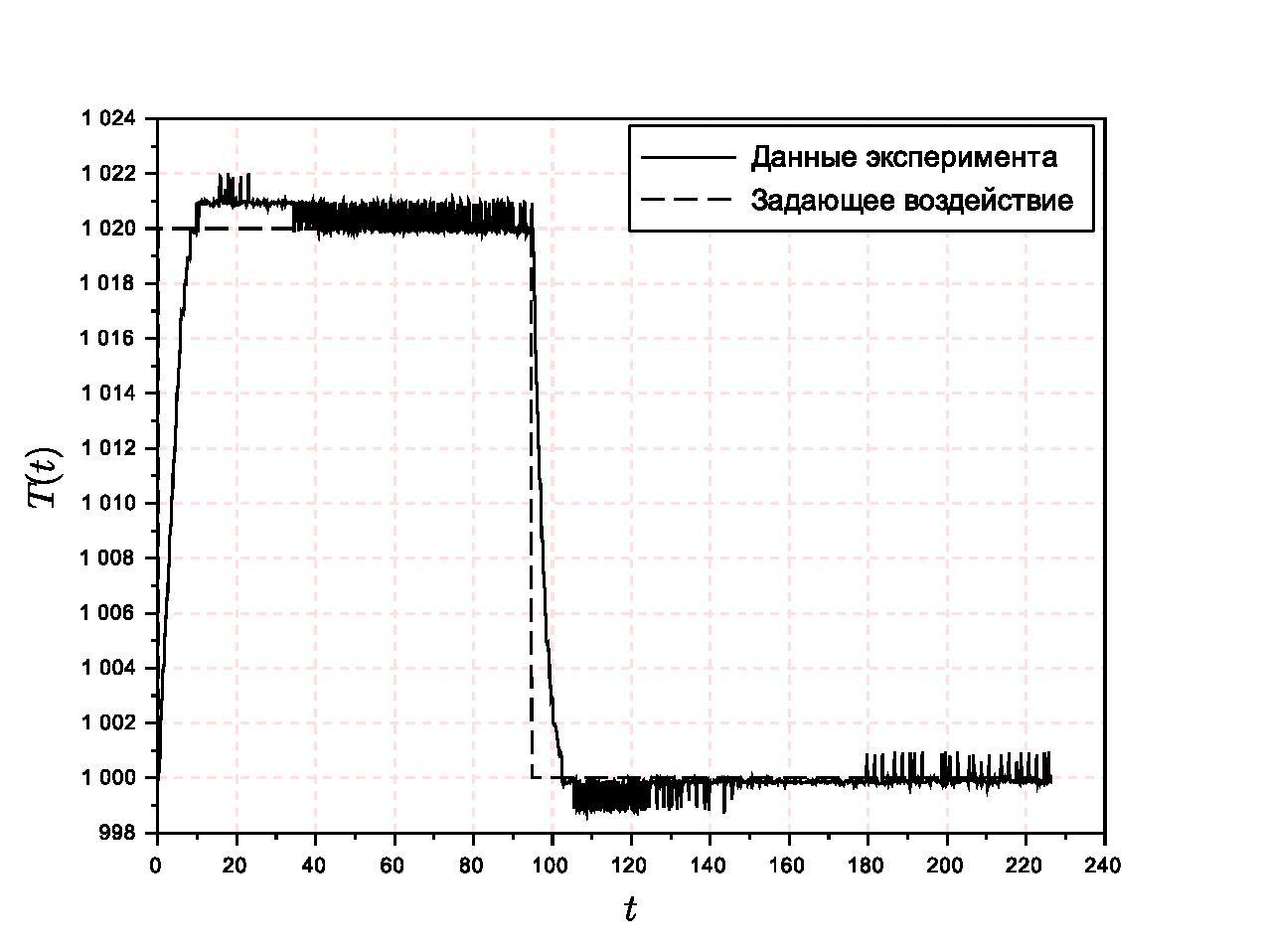

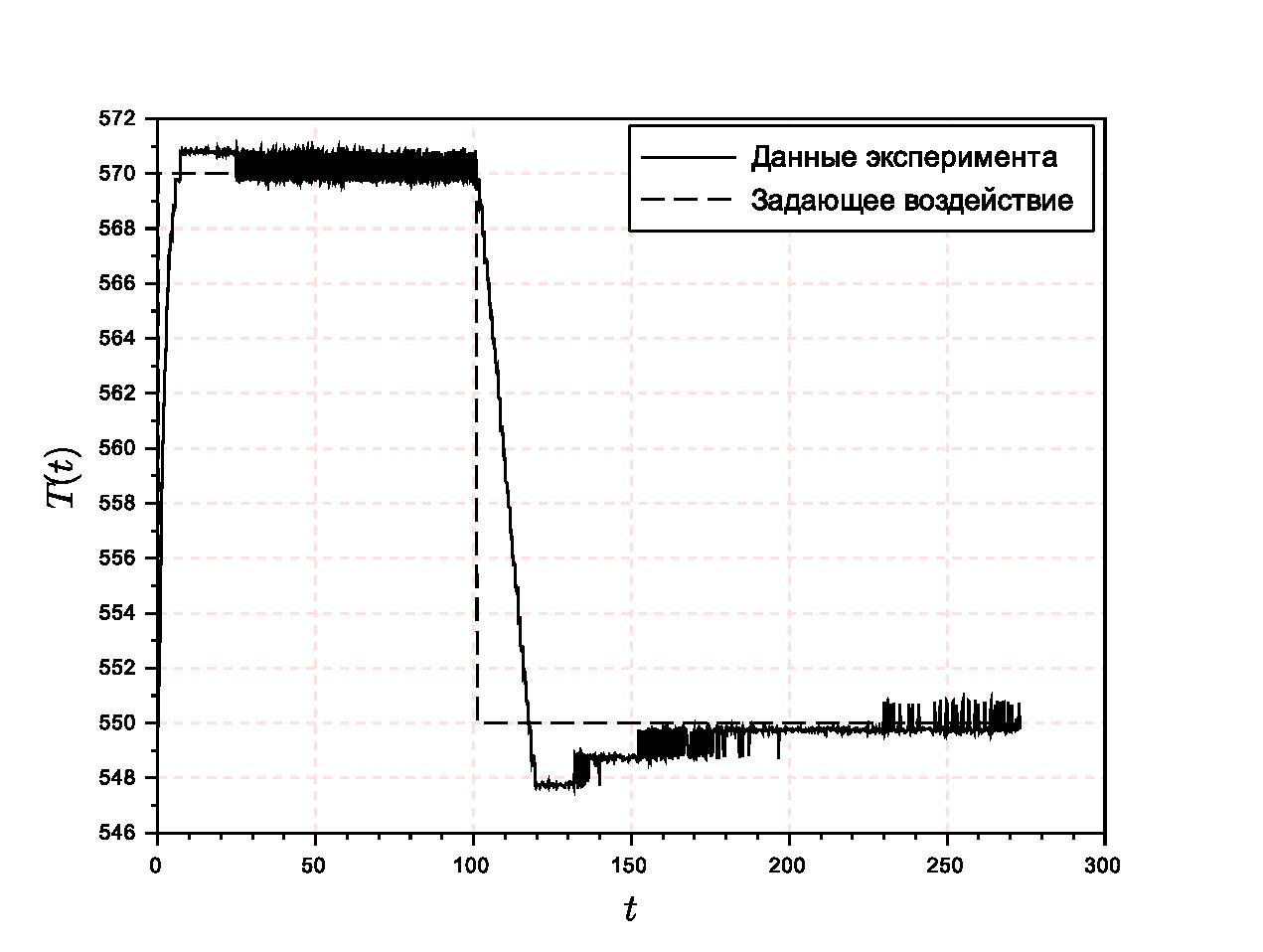

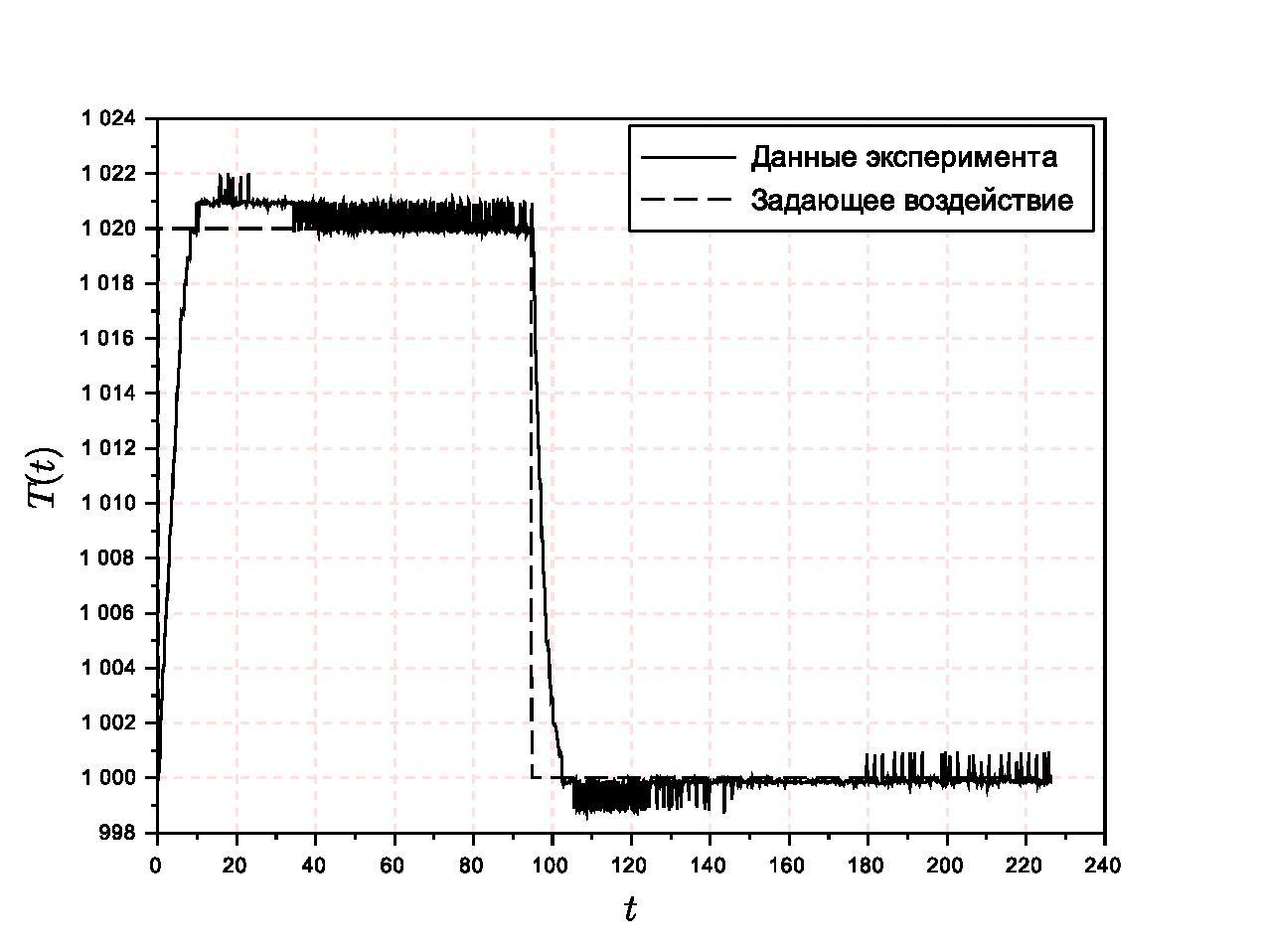

The following are some results of work for 550 and 1000 degrees Celsius. A stepped effect with an amplitude of 20 degrees was applied as a control.

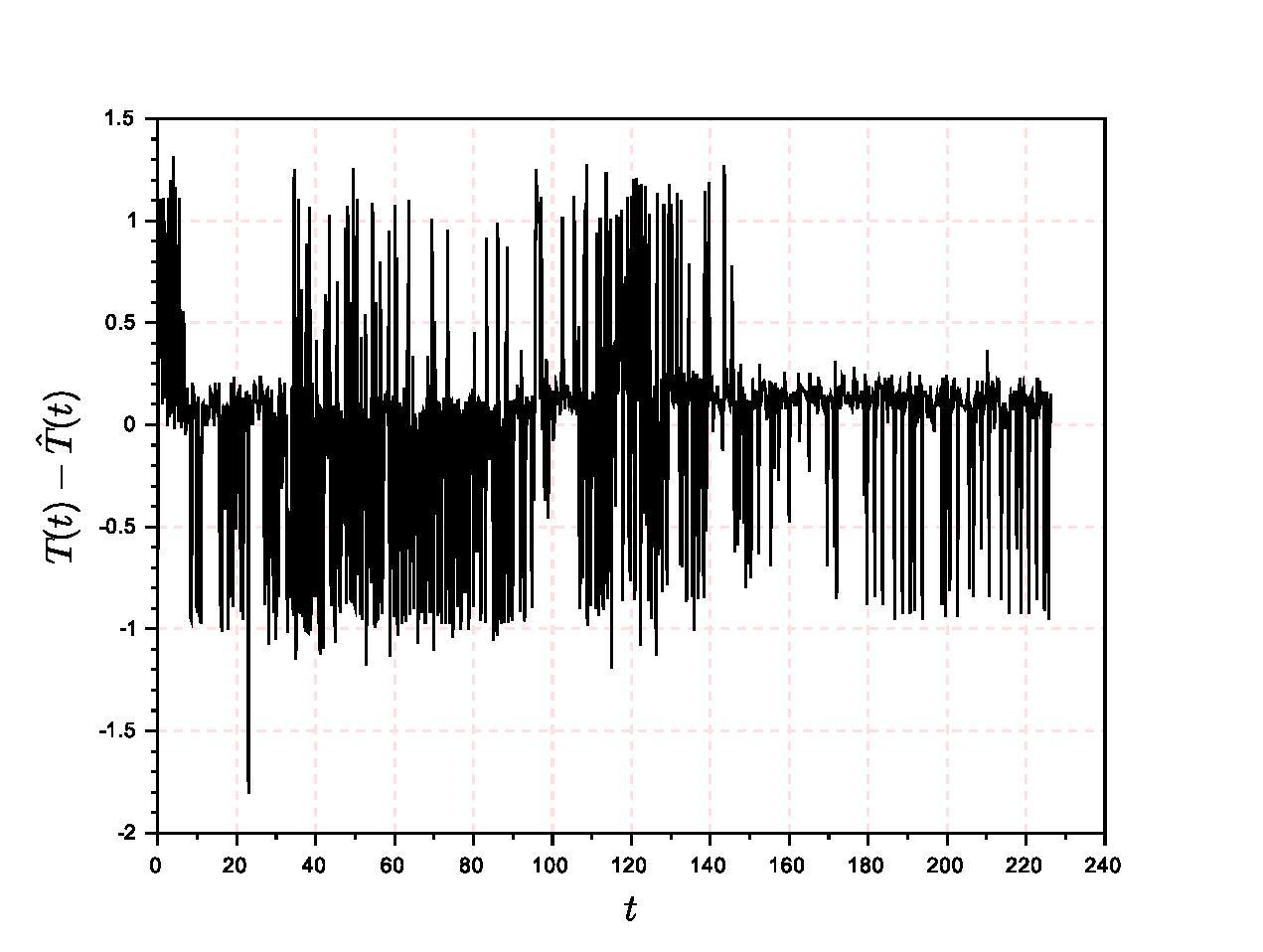

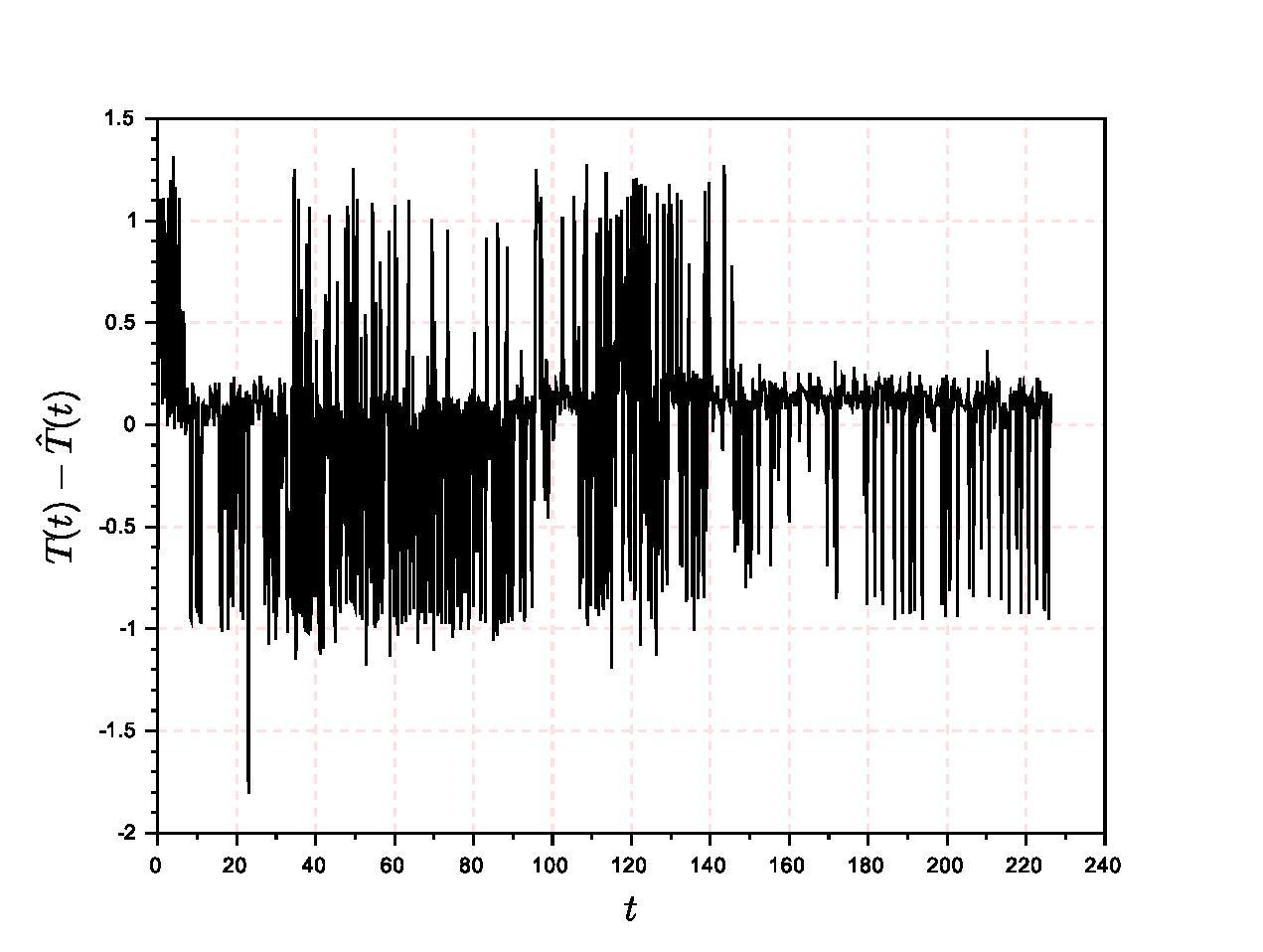

It is worth noting that the proportional coefficient of the regulator is too high, since an overshoot of 2 degrees can be seen in the hold mode of 550 degrees. Mathematical modeling and experimental data have the following residual graph for the 1000 degree mode. It looks very good, although it is difficult to talk about the quality of the model of a closed system.

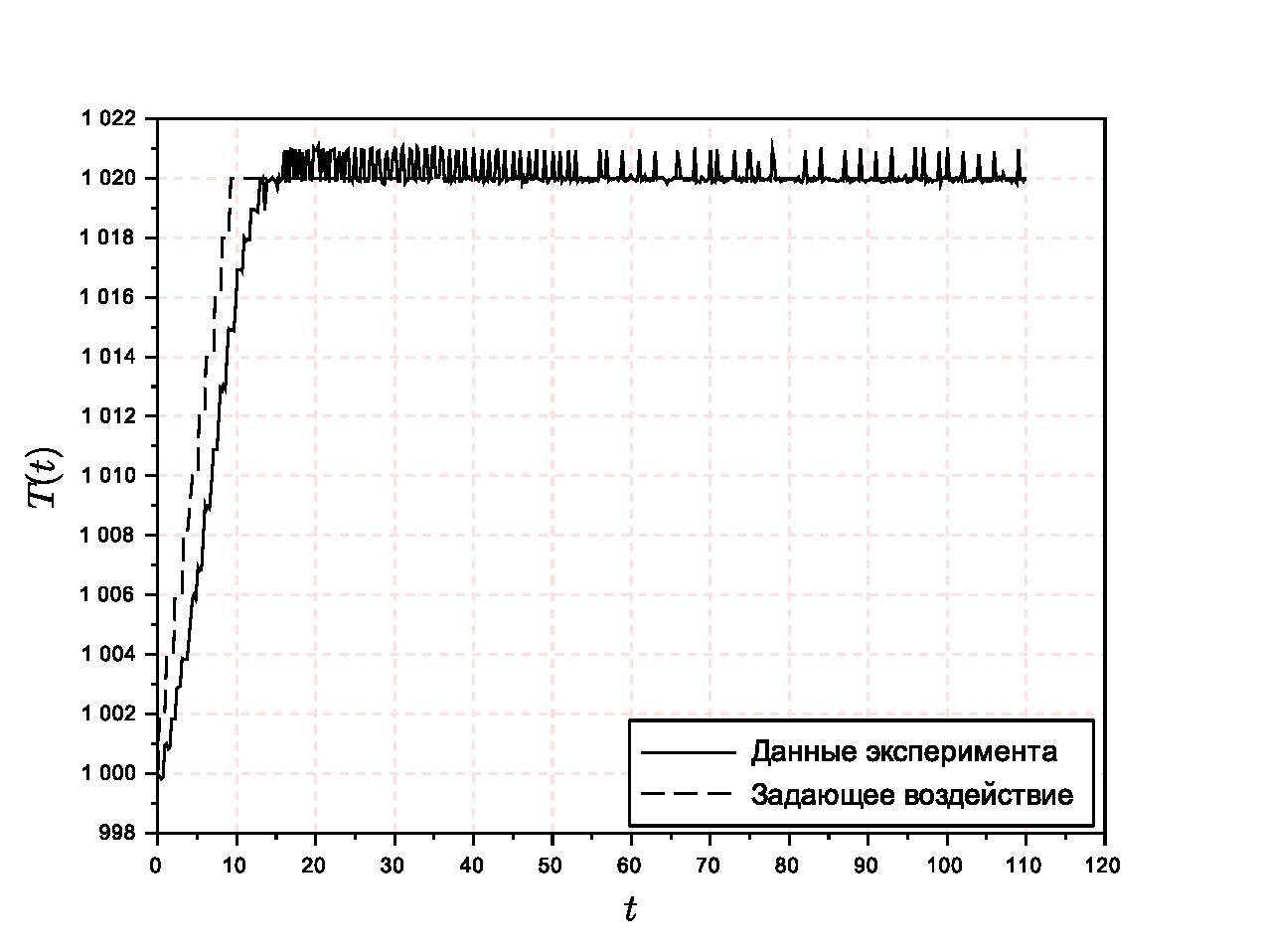

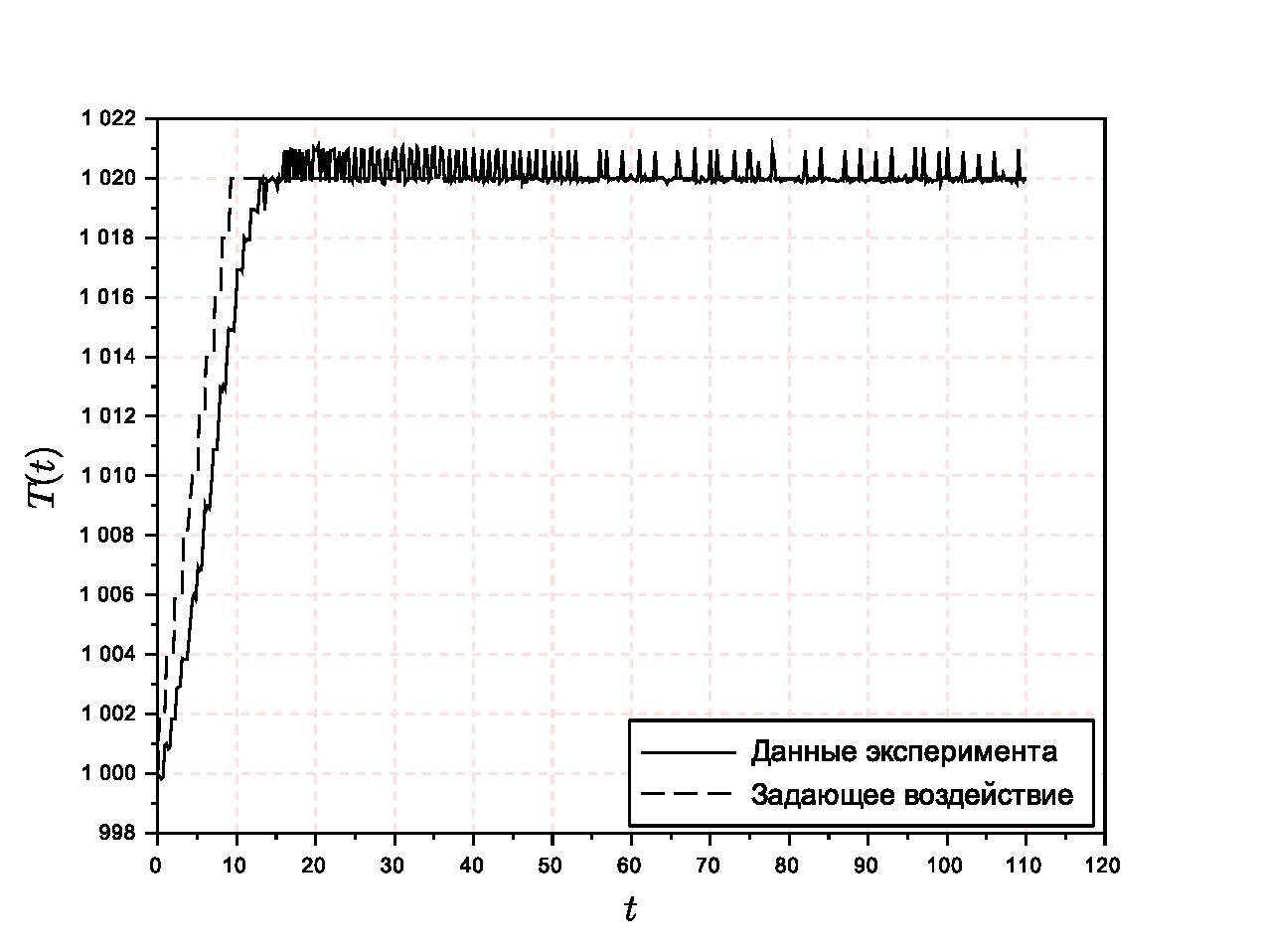

In a real system, the temperature setting occurs smoothly with a linear increase in the driving force, while the growth rate should be limited, since high heating rates provide high currents, which leads to a rapid degradation of graphite. The following is a graph of tracking linearly increasing, with a speed of 2 degrees per second, a driving force. The average steady-state tracking error is 4 degrees. In the steady-state mode, the standard deviation does not exceed 1 degree, the set task can be considered completed.

In principle, the main experimental part of my work is covered here. Again, I would like to thank my colleagues, in particular, the supervisor of Arastas , who helped bring this matter to the end, and Zavarin Evgeny for conducting a large number of experiments and collecting the necessary information.

The installation is a high-temperature water-cooled chamber in which elements of organometallic compounds are deposited on sapphire substrates. Growth is performed at temperatures from 550 to 1000 degrees Celsius and atmospheric pressure. The semiconductors obtained in this way are reliable and highly efficient, which allows them to be used in space technologies.

The entire installation is controlled by the computer on which Windows is installed with TwinCAT. All the main electrical components manufactured by Beckhoff, therefore the installation is controlled by the above software. By the way, in the midst of the summer heat, it turned out that their electronics are very sensitive to room temperature, and the signal starts to make a lot of noise.

')

One of the main elements of the control circuit is a high-frequency generator with an inductive element.

Inside, this tube is hollow and coated with silver so as not to be oxidized by passing coolant. We transmit the control signal directly to the generator connected to the inductor circuit. In a tricky way, the generator adjusts the parameters of the inductor circuit and the frequency of the signal, minimizing the current in the inductive element, maximizing the Foucault currents on the receiver side.

The receiver is a graphite substrate holder, in which there are three holes for sapphire substrates for growing semiconductors. Sapphire is necessary for the grown material to adopt a similar lattice structure. This allows you to get the material with the necessary structure, but if growth occurs at varying temperatures, the structure is uneven, which reduces the service life. Also, with significant fluctuations in temperature, destruction of graphite occurs. The photograph clearly shows the traces of long-term operation of the substrate holder.

The temperature is measured with an optical pyrometer in increments of 1 degree, the noise of the analog-to-digital converter is 0.2 degrees. Accordingly, the task was formulated: ensuring the highest possible accuracy of temperature maintenance, for this installation, in a steady state with a modulus of amplitude deviation equal to 1 degree. The secondary task was to minimize the time of the transition process and overshoot when reaching the operating temperature.

To begin with, a mathematical description of the temperature model of the reactor was obtained, after which its parameters were identified. The differential equation describing the process at the measuring point is as follows:

where T is the measured temperature, P is the control power of the inductor, B is the coefficient at the control action, A1 is the coefficient characterizing the radiant energy distribution, A2 is the coefficient characterizing convection, C is the heating rate of the measuring point from the environment. The experiments revealed that the coefficient A1 depends mainly on the type of material the receiver is made of (substrate holder), A2 increases with increasing temperature and speed of blowing chemicals through the liner (quartz casing, which localizes the chemical reaction zone). It turns out that for the qualitative result of the identification of parameters A1 and C, it is necessary to measure the gas temperature at the reactor inlet and outlet, and it would not hurt to know the temperature of the liner. But it still remains in the plans for the future.

Then two mathematical models were obtained for the extreme modes. The parameters identified by the least squares method in the last post had to be corrected by minimizing the prediction error; we got two sets of parameters for the minimum and maximum temperatures of the working range.

For 550 degrees: | For 1000 degrees: |

All changes in parameter values are of a physical nature. In particular, with increasing graphite temperature, its electromagnetic characteristics change. We see a decrease in the efficiency of converting electromagnetic energy into heat by 17%. The remaining coefficients themselves are dependent on temperature.

To the model obtained, a PI regulator was added and a closed system was obtained; for this case, there is evidence of stability, which is detailed in the text of the thesis .

The control system was run-in at extreme temperatures of the operating range, in order to make sure that the regulator was working with a significant change in the object's parameters.

The following are some results of work for 550 and 1000 degrees Celsius. A stepped effect with an amplitude of 20 degrees was applied as a control.

It is worth noting that the proportional coefficient of the regulator is too high, since an overshoot of 2 degrees can be seen in the hold mode of 550 degrees. Mathematical modeling and experimental data have the following residual graph for the 1000 degree mode. It looks very good, although it is difficult to talk about the quality of the model of a closed system.

In a real system, the temperature setting occurs smoothly with a linear increase in the driving force, while the growth rate should be limited, since high heating rates provide high currents, which leads to a rapid degradation of graphite. The following is a graph of tracking linearly increasing, with a speed of 2 degrees per second, a driving force. The average steady-state tracking error is 4 degrees. In the steady-state mode, the standard deviation does not exceed 1 degree, the set task can be considered completed.

In principle, the main experimental part of my work is covered here. Again, I would like to thank my colleagues, in particular, the supervisor of Arastas , who helped bring this matter to the end, and Zavarin Evgeny for conducting a large number of experiments and collecting the necessary information.

Source: https://habr.com/ru/post/232339/

All Articles