BladeRoom enters the US market

BladeRoom introduced a new generation of modular data centers to the US market. The British company has teamed up with Modular Power Solutions to organize the American BladeRoom branch, which will make it possible to produce prefabricated structural elements at a factory in Michigan. This, in turn, will allow to organize the construction of modular data centers at customer sites throughout the United States. In January 2014, the company opened a technology center in Chicago to present its projects.

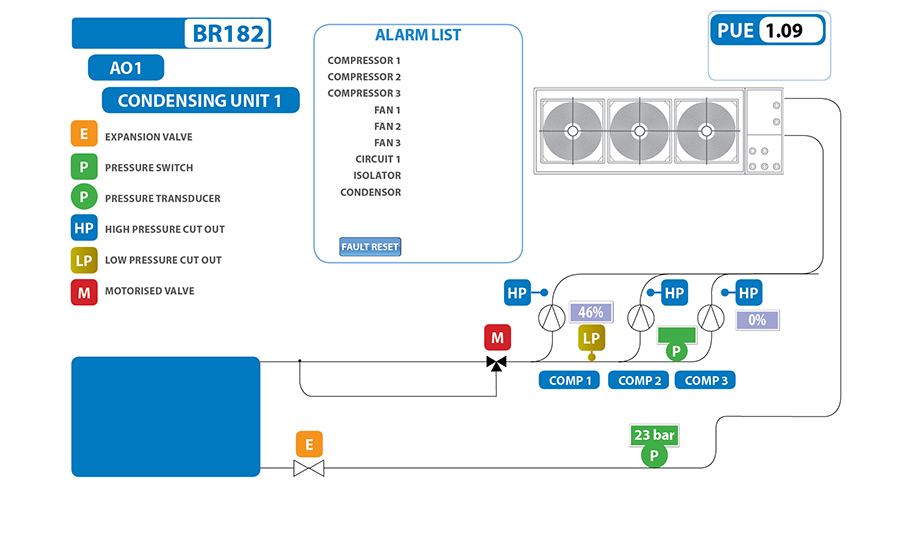

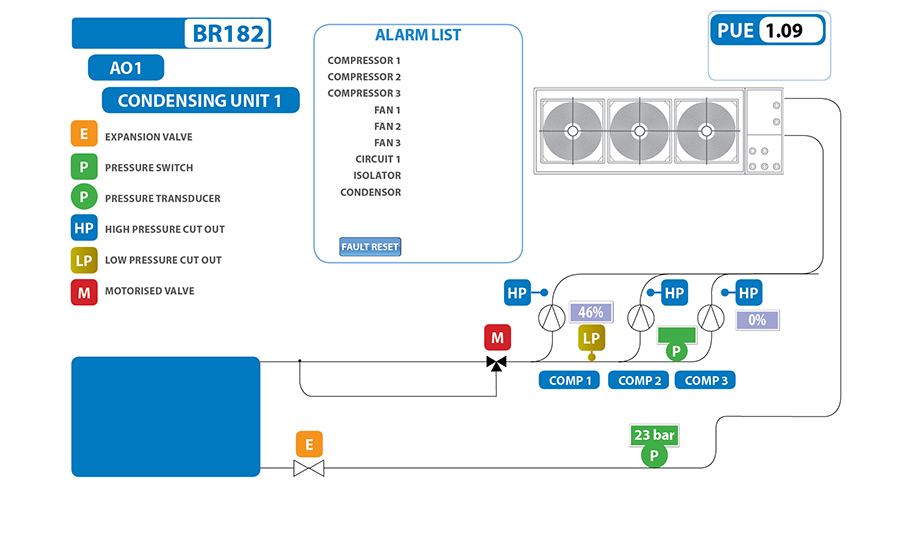

In Europe, Asia and Africa, BladeRoom has built more than 30 data centers using projects that can be implemented in less than 20 weeks. Among them - Merlin, CapGemini data center in the UK, one of the most powerful in the world. BladeRoom reports that such projects, when using free-cooling, can give an indicator of PUE 1.09 - 1.17.

')

A company with 20 years of experience has come to this business in its own special way. Initially, BladeRoom was engaged in the construction of modular commercial kitchens, incl. for the Olympic Games, which required knowledge in the field of thermal energy management. It was also built more than 150 modular operating rooms for hospitals, technically complex facilities that required high-quality filtration and ventilation of air to ensure sterility. In 2008, the company was renamed BladeRoom and switched to the construction of modular data centers.

“We started with not very confident positions - building kitchens and operating rooms,” says Barnaby Smith, head of PR department at BladeRoom USA. “We turned the data center into separate engineering parts. Using them, you can create objects of any size and power. ”

Despite a fairly modest start, BladeRoom has serious plans to conquer the American market. “BladeRoom brings progress to the data center construction market in the States because we are the only manufacturers of prefabricated structures for your individual requirements, while maintaining the flexibility and reliability of traditional data centers, ”says Smith,“ Our facilities are commissioned more quickly and are much cheaper than standard data centers due to higher energy efficiency. ”

Modular Power Solutions (MPS) is part of the Rosendin holding (founder of Rosendin Electric) and has already provided more than 60 MW of modular capacity to its customers, including the Digital Realty Trust and Bank of America. The MPS / Rosendin experience in modular structures has become an ideal complement to the BladeRoom experience in IT construction. “We have always followed the US market,” said Smith. “Last year, we contacted Rosendin. They are interested in our system. ”

BladeRoom is now at the forefront of companies developing the production of structural elements for the construction of modular data centers similar to traditional stone construction. Other companies also offer similar new generation projects, including IO, Datapod, Colt and AST Modular. But BladeRoom does not see them as competitors.

“The competition in this area, which we have seen, mainly includes standard solutions and data centers of specifically defined sizes. This is significantly different from what BladeRoom does. We compete with those who choose traditional, unchangeable data centers. Sometimes, of course, we enter into competition with modular projects, but mainly focus on traditional ones. ”

BladeRoom is a neutral IT provider offering any solutions for the location of cabinets and racks, and is able to provide projects of any size and capacity - from 70 KW to 1.5 MW. Optimized for air cooling rooms have an average power from 1 to 20 kW per cabinet, with immediate delivery of cabinets up to 50 kW.

The cooling system is designed so that the air flow uses the least necessary amount of energy and water. BladeRoom has an Air Optimizer multi-chamber cooling system that filters fresh air and cools it with evaporative cooling. The DX system is used as a backup for periods when the outside temperature does not support natural cooling. This system allows you to cool the air that is supplied to the premises, due to the direct contact of the air flow with the evaporators of the cooling system. Each BladeRoom includes control software that automatically adjusts air cooling as IT activities change in machine rooms. The system maintains different densities for data halls within the same object. The design does not use raised floors or air ducts. “This is our secret ingredient,” says Smith.

Rosendin / MPS uses its knowledge and production experience for different climatic zones in all states. “The US is a special market,” says Smith. “He has completely different requirements throughout the country.” There can be no universal approach. Because our system is flexible enough to adapt to the needs of customers in any state. "

There are solutions for seismic zones, wind-resistant structures for regions where hurricanes and tornadoes are a real problem. A significant advantage of BladeRoom, which directly affects sales, is the use of a relatively small number of people in the construction of structures. “One of the advantages of our approach is the accurate calculation of materials and processes,” says Smith. “It allows us to compete on many planes.”

In international business, BladeRoom notes a strong merger of collocation (colocation) and wholesale (wholesale) companies, including Metronode (Australia), Megatron Federal (South Africa) and Ark Continuity (United Kingdom). The same situation can be established in the United States, where service providers were looking for an opportunity to outsource the construction of their facilities. The advantage of this approach is now using Compass Datacenters, using prefabricated structures and building data centers for Windstream, Savvis / CenturyLink and Iron Mountain.

In Europe, Asia and Africa, BladeRoom has built more than 30 data centers using projects that can be implemented in less than 20 weeks. Among them - Merlin, CapGemini data center in the UK, one of the most powerful in the world. BladeRoom reports that such projects, when using free-cooling, can give an indicator of PUE 1.09 - 1.17.

')

A company with 20 years of experience has come to this business in its own special way. Initially, BladeRoom was engaged in the construction of modular commercial kitchens, incl. for the Olympic Games, which required knowledge in the field of thermal energy management. It was also built more than 150 modular operating rooms for hospitals, technically complex facilities that required high-quality filtration and ventilation of air to ensure sterility. In 2008, the company was renamed BladeRoom and switched to the construction of modular data centers.

Weak origins - global ambitions

“We started with not very confident positions - building kitchens and operating rooms,” says Barnaby Smith, head of PR department at BladeRoom USA. “We turned the data center into separate engineering parts. Using them, you can create objects of any size and power. ”

Despite a fairly modest start, BladeRoom has serious plans to conquer the American market. “BladeRoom brings progress to the data center construction market in the States because we are the only manufacturers of prefabricated structures for your individual requirements, while maintaining the flexibility and reliability of traditional data centers, ”says Smith,“ Our facilities are commissioned more quickly and are much cheaper than standard data centers due to higher energy efficiency. ”

Modular Power Solutions (MPS) is part of the Rosendin holding (founder of Rosendin Electric) and has already provided more than 60 MW of modular capacity to its customers, including the Digital Realty Trust and Bank of America. The MPS / Rosendin experience in modular structures has become an ideal complement to the BladeRoom experience in IT construction. “We have always followed the US market,” said Smith. “Last year, we contacted Rosendin. They are interested in our system. ”

Flexibility in modular design

BladeRoom is now at the forefront of companies developing the production of structural elements for the construction of modular data centers similar to traditional stone construction. Other companies also offer similar new generation projects, including IO, Datapod, Colt and AST Modular. But BladeRoom does not see them as competitors.

“The competition in this area, which we have seen, mainly includes standard solutions and data centers of specifically defined sizes. This is significantly different from what BladeRoom does. We compete with those who choose traditional, unchangeable data centers. Sometimes, of course, we enter into competition with modular projects, but mainly focus on traditional ones. ”

BladeRoom is a neutral IT provider offering any solutions for the location of cabinets and racks, and is able to provide projects of any size and capacity - from 70 KW to 1.5 MW. Optimized for air cooling rooms have an average power from 1 to 20 kW per cabinet, with immediate delivery of cabinets up to 50 kW.

The cooling system is designed so that the air flow uses the least necessary amount of energy and water. BladeRoom has an Air Optimizer multi-chamber cooling system that filters fresh air and cools it with evaporative cooling. The DX system is used as a backup for periods when the outside temperature does not support natural cooling. This system allows you to cool the air that is supplied to the premises, due to the direct contact of the air flow with the evaporators of the cooling system. Each BladeRoom includes control software that automatically adjusts air cooling as IT activities change in machine rooms. The system maintains different densities for data halls within the same object. The design does not use raised floors or air ducts. “This is our secret ingredient,” says Smith.

More diverse requirements in the USA

Rosendin / MPS uses its knowledge and production experience for different climatic zones in all states. “The US is a special market,” says Smith. “He has completely different requirements throughout the country.” There can be no universal approach. Because our system is flexible enough to adapt to the needs of customers in any state. "

There are solutions for seismic zones, wind-resistant structures for regions where hurricanes and tornadoes are a real problem. A significant advantage of BladeRoom, which directly affects sales, is the use of a relatively small number of people in the construction of structures. “One of the advantages of our approach is the accurate calculation of materials and processes,” says Smith. “It allows us to compete on many planes.”

In international business, BladeRoom notes a strong merger of collocation (colocation) and wholesale (wholesale) companies, including Metronode (Australia), Megatron Federal (South Africa) and Ark Continuity (United Kingdom). The same situation can be established in the United States, where service providers were looking for an opportunity to outsource the construction of their facilities. The advantage of this approach is now using Compass Datacenters, using prefabricated structures and building data centers for Windstream, Savvis / CenturyLink and Iron Mountain.

Source: https://habr.com/ru/post/231635/

All Articles