Overview of manufacturers of consumables for FDM 3D printers

Instead of the preface

Today, the development of 3D printing technology has made possible not only the commercial use of 3d printers, but also the acquisition of them by private individuals for home use. Many Chinese, European and American companies offer a fairly wide range of printers, with prices ranging from a few tens of thousands to millions of rubles. I am sure that not so much time will pass, and 3D printers will appear in almost every home! Today, many people use home 3D-printers to effectively translate their ideas into reality.

Today, there are many technologies of 3D printing, and you can find a printer for any of your purposes, but the most widely spread technology today is the technology of layering molten plastic yarn (FDM). Such printers can be found almost everywhere, where they talk about "3D printing". The method is distinguished by relative simplicity and low cost, both printers and consumables for them. Below we talk about consumables for FDM 3D printers.

Types of materials

Consider what materials we can find today from Russian suppliers:

ABS plastic:

The classic polymer material that you meet every day: Bumper and car interior panels, body of many devices, wear-resistant plastic parts are made of it.

Being a copolymer of styrene (polystyrene), butadiene (rubber) and acrylonitrile (SAN-plastics), it gathered all the advantages of these polymers, virtually without flaws: it is very durable mechanically, resistant to heat, resistant to alkali solutions of acids, alcohols, but easily can be subjected to both mechanical and chemical (treatment with acetone vapors) processing, it is easily glued with acetone, thus forming, in fact, a monolithic structure.

')

PLA plastic:

Being a new material in the trend of “biodegradability”, a material can easily stand on the shelf for several months, or even years, without any signs of decomposition, since it decomposes only at high humidity and high alkalinity, for example, when it enters the soil. Plastic is absolutely safe when absorbed "inside."

Being a polymer of lactic acid, PLA has one very important property: very low shrinkage during printing. It is from PLA plastic that large objects can be printed even on cheap Chinese printers. However, PLA plastic also has a flip side: its low temperature resistance leads to the fact that a model that just heats up in the sun can leak, and low mechanical characteristics (such as strength and impact resistance) make it poorly adapted for any household use other than decorative. High hardness makes machining difficult, and chemical treatment has a detrimental effect: almost all solvents lead to cracking, turbidity and loss of color of the printed part.

HIPS plastic:

High impact polystyrene is the most common plastic that we use every day in the form of parts of handles, housings, electrical insulating materials. Not possessing such high mechanical properties as ABS plastic is still called impact-resistant, since, in comparison with conventional polystyrene, it is clearly superior to this indicator. Fragile. The only thing that is better than ABS plastic is its excellent electrical insulating properties, so if you want to use voltages over 1 kV in your project, HIPS is your material.

PC plastic:

You probably know polycarbonate and every day you have been given as plastic, similar to glass. Used in many advertising structures, very light-resistant, has good mechanical properties. Heat-resistant, but, like the advantage, the heat resistance is also a disadvantage: printing can be made only at a temperature not lower than 280 degrees, at which it already begins to oxidize.

PMMA:

Polymethylmethacrylate, also known as Plexiglass, it’s also known from plexiglass since childhood. Excellent light transmittance makes this material good for printing various decorative items and crafts, but there are several drawbacks: the plastic warps the temperature, and over time its transparency drops, and the color becomes closer to brown.

Nylon:

Nylon is a beautiful, well-proven fabric elastic. Excellent electrical insulation and decent mechanical properties, its characteristic only for nylon, color and texture. Printing with nylon is not easy, however, the models have, besides all the listed advantages, low friction, so it is possible to make even sleeve sleeves from it. But there is one thing: it is very expensive.

Manufacturers

To date, plastic can be purchased directly from three Russian manufacturers:

- Rec ;

- SEM ;

- BestFilament .

I can’t say with absolute certainty that I have mentioned all Russian manufacturers, but these three companies definitely occupy the overwhelming majority of the retail plastic market in Russia.

The two most common Chinese, known in Russia:

- PP3DP ;

- ESUN .

-PP3DP. As a manufacturer of closed printers UP! The company PP3DP, apparently, aims to achieve the highest quality printing on their printers, the flow and heat resistance indicators are chosen so as to achieve maximum quality only on UP printers, and the printers themselves print in one mode: maximum printing quality with PP3DP plastic.

- ESUN. Plastic of the company ESUN is widely distributed in Russia, almost the entire thread under the name of the country of the manufacturer China is sold under the trademark ESUN.

What about quality? With quite attractive prices, plastic (if ordered directly from China) ESUN is not so bad! At first glance, one cannot say that it is “typical China”:

- plastic smells a little bit like “burnt bottle”, but only slightly (there is some probability that the second raw material is used).

- Layers fall quite smoothly, the places of breaking the thread are not common,

- On average, once the nozzle is clogged in a coil with small extraneous inclusions, however, failures caused by “curved hands”, at least for me, happen much more often!

- the thread diameter is stable, within 1.72-1, 77 mm, but I personally threw two almost empty reels (only about 300 grams left), one because of the characteristic non-color, the second because the thread diameter began to beat all records! (up to 2.2 mm!). and scored nozzle.

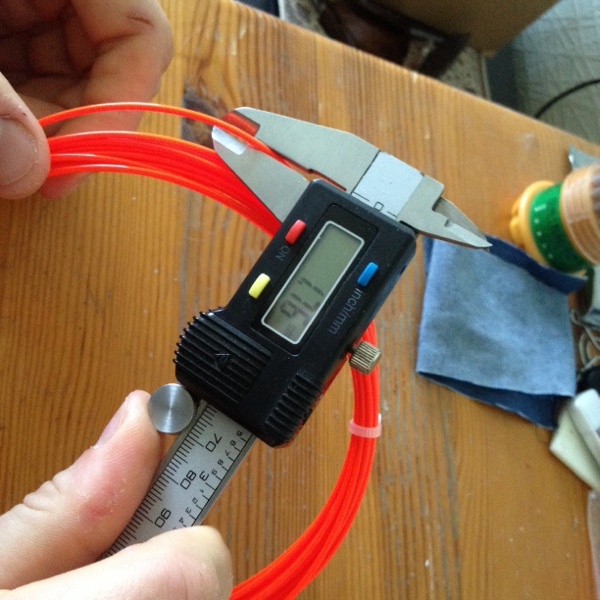

In confirmation of my words, I photographed (sorry, on the iPhone) the procedure for measuring the diameter:

Naturally, it is cheaper to buy plastic directly in China, but it will also go from there accordingly, as well as from Russian suppliers (obviously, almost 2 times more expensive), of which there are a great many today.

And, most importantly, virtually all types of threads can be purchased from ESUN. Not just everything you know, but just everything. Their range is unusually rich, sly Chinese do not sit back and constantly invent new types of plastics, among them fluorescent, luminous, and hips and abs and ... whatever! Plastics for every taste and wallet.

-REC. Having visited the site of REC, you will surely pay attention to how well it is made: you are greeted by a huge logo symbolizing 3D printing, all buttons are highlighted, the abundance of scripts makes navigation through the site convenient and easy. Together with a beautifully designed box, one gets the impression of a large Russian manufacturer of high-quality material, but ... This impression disappears immediately after the first printing, because the only, in fact, lack of plastic destroys all its advantages. I am talking, of course, about the diameter of the thread.

The diameter walks in the range from 1.60 to 1.88 mm, which means that this plastic will not print on anything except the cheapest RepRap printers. In a printer Replicator 2, for example, a bar over 1.82 mm thick will not pass physically, and a bar with a thickness of 1.65 will not be caught by the feed mechanism. The feed mechanism can be improved, but it is exactly the rework of your own printer, jammed bar and uneven layers. What do you expect from a really high-quality bar? I doubt it.

And not to be unfounded:

Otherwise, when a more or less uniform section of the thread comes across, the REC plastic behaves well, although the nozzle clogs more often than ESUN. It does not have a strong smell of burnt plastic, unlike the Chinese product.

Another interesting point that pleases the eye on the site REC - certificate for products and technical conditions. The certificate of the company is a letter, which states that this type of product is not subject to certification. The technical specifications are written by the company itself, which allows it to do anything and sell it as a 3D printing thread.

-SEM. The company's website provides extremely scarce information about its products, however, some interesting information on polymers is presented. Problems with the diameter of the rod, although there are, but the print quality is affected weakly.

So this plastic can be used for printing on fairly expensive machines. Packaging is simple, without frills, the coil is wrapped in stretch film. In general, the packaging gives the "handicrafts", but do we really go after the packaging? The range of materials presented is wide: Polycarbonate, HIPS, TPE plastics, all materials are printed, I did not find any problems with the diameter. The smell when printing is almost invisible.

As for the ABS, plastic with a small amount of foreign inclusions that rarely clog the nozzle. Many different colors are presented. It is most convenient for them to print at temperatures above 250 degrees.

I’ll make a reservation about one thing: all Russian manufacturers use the same coils, but for some reason, the SEM gets a kilogram of it, while REC and BestFilament have 750 grams.

-BestFilament. Last, but not least, plastic manufacturer, which we consider today. Unlike the other two Russian is not in Moscow, plastic is made by the harsh guys from Siberia from the city of Tomsk (the bear in the kit is not attached). The site is represented by a long sheet with goods, which is not very convenient, but quite acceptable. A detailed description of the plastic they do not have, because apparently counting on the familiar audience.

The company sells only ABS and PLA plastics in 750 gram coils. The plastic is pretty well packed, the coil is additionally packed in shrink PVC film. What pleased us is that the plastic has almost no smell, unlike the Chinese one. The diameter is stable: 1.72-1.77, which can also be called the necessary minimum for printing on good printers.

The printing temperature of the ABS plastic is not too high compared to SEM, which allows a slight decrease in heat shrinkage (due to the smaller temperature difference).

In general, for production in Siberia - a very worthy product.

And the traditional photo:

Little about prices

Today, the bar for printing can be purchased, if not at every corner, then at least in several dozens of specialized online stores. The price tag varies widely enough, but, not surprisingly, the manufacturer is cheaper. All three manufacturers sell their plastic at retail through official sites, order from one reel.

As of July 2014, the situation in cents is as follows:

ESUN (Aliexpress) ~ 800 rub / kg;

REC ~ 1000 rub / 750 g (Price from authorized dealers );

BestFilament ~ 750 rub / 750 g (order directly on the website or through Vkontakte );

SEM ~ 1100 rub / 1000 g (order on the website or through Vkontakte ).

Instead of conclusion

The 3D printing market today is one of the fastest growing markets, so let's hope that consumables will become cheaper every day, and their quality will grow exponentially.

Well, we wish good luck to Russian manufacturers, because fighting China is not an easy task.

Source: https://habr.com/ru/post/231299/

All Articles