Hackathon FabLab: two days and consequences. How it was

A couple of weeks ago in Moscow there was such an interesting event as FabLab Weekend - a hackathon with soldering irons and 3d printers. I participated in this event and was filled with emotions that I want to share with the community.

Attention: inside the composition and photos.

')

Hackathon - popular in recent years, entertainment. The traditional format consists of several stupid speeches with the presentation of ideas, free coffee, pizza, the Internet and bag-chairs. The promoter company receives several hundred young, passionate users, and sometimes several sensible ideas.

The perfect entertainment for a snoring student or freelancer. Another thing is that even something conditionally similar to a product or at least the beginnings of a startup as a result of hakatons is obtained quite rarely.

All the more mysterious, the prospect of the upcoming “hardware hackathon” looked, with 3d-printers and soldering irons right in the workshop: the placement of the equipment and its provision to everyone who wanted it was clearly beyond the scope of the promotion. The threshold for entry into the hardware business is higher, corporations prefer static exhibitions at expo centers, the maximum that can be obtained from them is a cup of coffee and a demos set. Recalling the experience of previous hakatons, we imagined thrash and a crowd of enthusiastic schoolchildren, and with these thoughts we signed up for the event.

In general, doing something iron is more risky than making software products, and therefore unpleasant. Equipment costs money, fails, requires handling skills, and the process of designing devices requires additional knowledge and experience. It was difficult to expect from several groups of enthusiasts success within the framework of the format and even an objective concept.

Friday evening we gathered at Ernst & Young's office, where, according to the program, we had to register participants. Negotiation "Paris", more like a small lecture hall, was filled quite tightly. The presentation template provided by the organizers mostly consisted of parts of a business plan, which looked unusual for a three-minute pitch.

It was necessary to come up with a "serious" product, and we unpacked our student work: our department was engaged in medical electronics, and almost all of the work was related to electrophysiology, so we described the portable cardiograph in the presentation. The calculation was that we will build hardware for the project from the diplomas, put it in a beautiful building, deploy the service on Azure using the developed technology and add integration with social services. Networks - enough to impress the experts.

We sit modestly and make a presentation - half an hour before the performance. Shame on you

At the stage of the presentation, another participant approached us and offered to combine efforts. It was Mikhail Shagiev, who was looking for a team for a startup, which is connected with cardiography. Our team was even more than staffed: we invited as many of our acquaintances as possible to study and work, or just acquaintances. Therefore, at nine zero zero, in McDonalds on Tverskaya. Clear.

Digital Telegraph is similar to other sites located in historical monuments, such as Artplay or Digital October, and is not at all like small anti-cafe basements or office rooms in the buildings of Soviet institutions. In the Telegraph it is very spacious, empty and cold: the brick walls are not covered with finishing at all, and there are gaps in the slopes of the windows. Having seized a strategic resource - furniture and partition-boards, we began to unpack the imported material.

Soon the heroes of the occasion arrived with their hosts - three Picaso Designer and three MakerBot. It all looked like a microscopic exhibition of cats: the owners nervously took care of their pets, and the visitors eagerly looked at them with curiosity with tender eyes. As it turned out, all the devices are provided by various organizations: MakerBot brought Ivan from the 3D Printing Lab, Picaso - Sergey Gerasimov from the Bionic Lab and the guys from the HSE Lab. Most of all I expected to see a compact CNC engraver like Roland MDX, but none of the “masters” were going to take it with me. There were no soldering tools either, and several people went to their offices to correct this oversight.

Printers arrived.

The announced format assumed only one checkpoint for the iron part - at the very end, and for the marketing of events, many were planned. The team was required to conduct a survey of the target audience, draw the landing page of another non-existent product, put together a “business plan”. In addition, strange people went around the site all the time and asked different questions: they asked them to formulate the concept of “two words” or “sell” the device as if it were ready.

The rest of the equipment was brought up: two Lukey stations with a hairdryer, a 100 MHz Rigol Chinese oscilloscope, a bench multimeter, a scattering of soldering irons and a junk box “for components”.

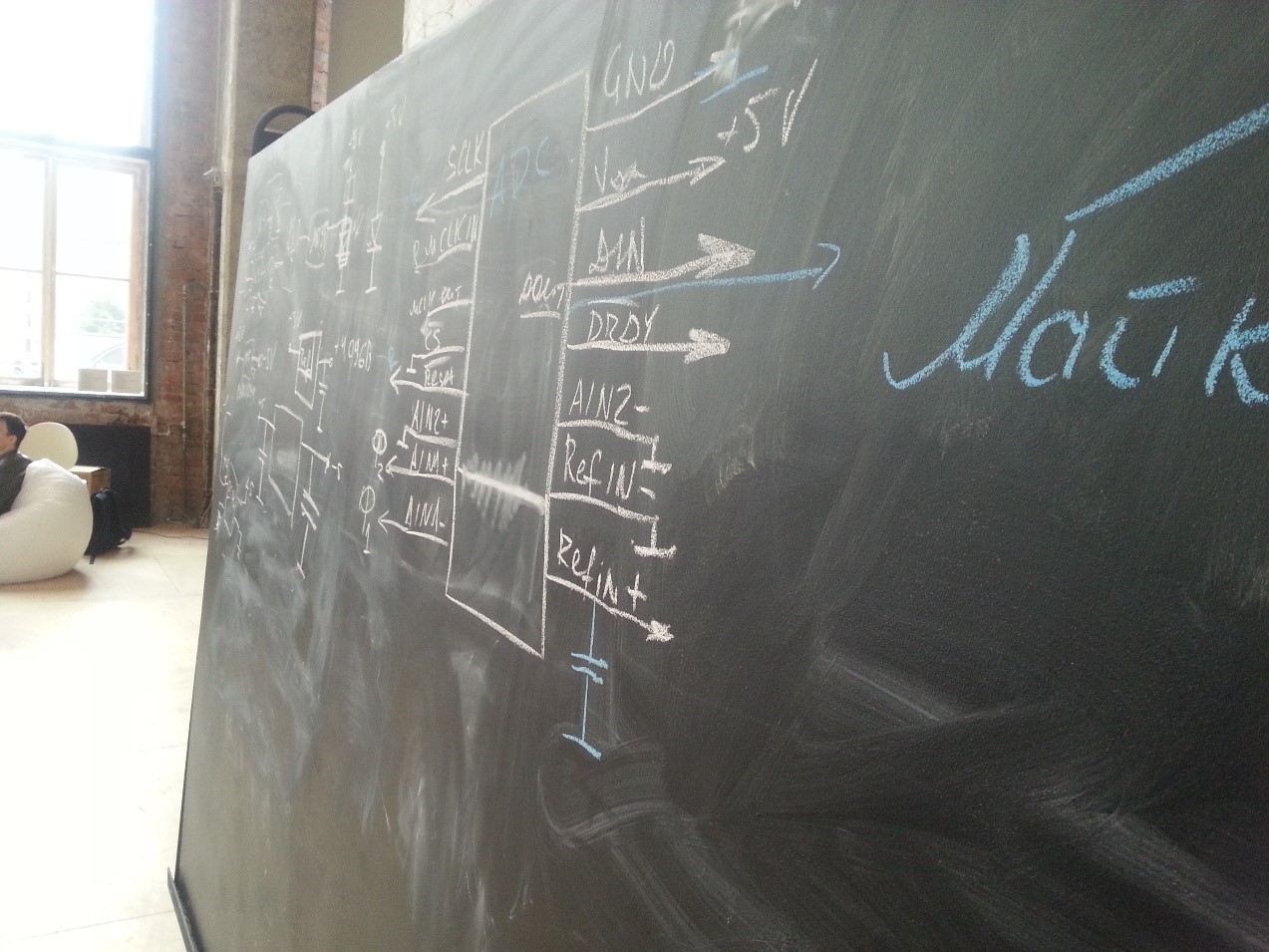

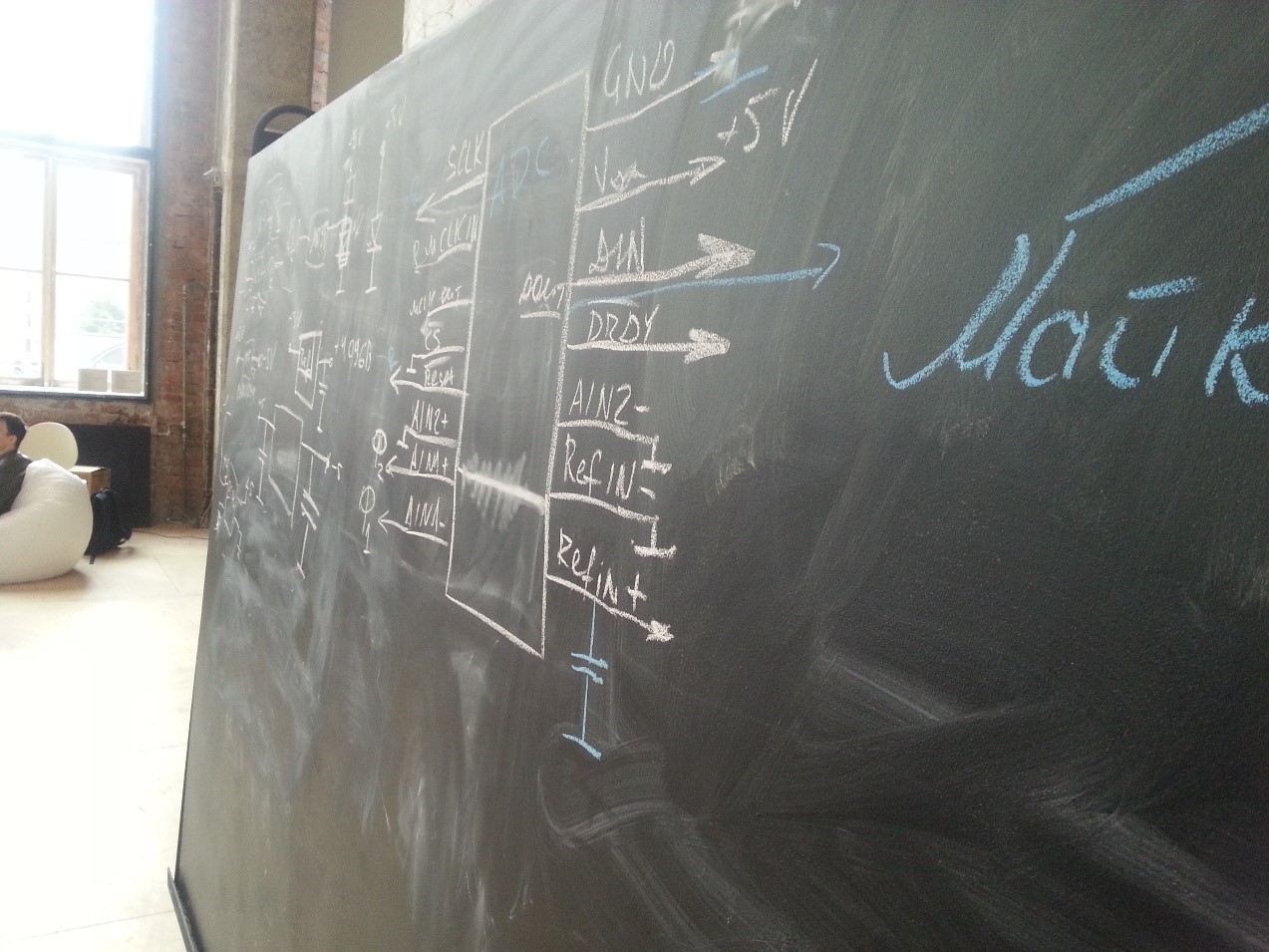

We planned to assemble on a breadboard board a simple circuit for a couple of channels consisting of a balanced amplifier, an active filter, and a sigma-delta ADC. As a "head" was harvested Raspberry Pi with Linux on board. Filters and amplification were counted in the diplomas, the components were purchased according to the lists, it was necessary only to collect all this.

According to the plan, everyone was engaged in his own business:deployed an ASP-service on Azure, orinichev wrote a client for WinRT, simbik turned out a web-face and advertisements for the contest, alexzero collected the scheme, and I set up a "strawberry" environment for data collection and sending.

We were very lucky - the communication on the “sales” part was fully compensated for by the joining participants - Mikhail and Oganes, including the task to interview a few dozen people on the street and to make up the appearance of the target audience.

The job went.

In the evening in the Telegraph it becomes especially cold, and the organizers have not provided any insulation - neither blankets, nor heaters. It was raining outside the window. At the bar, the Jura coffee machine, which looked like the only heat source, not counting soldering irons, materialized very well. Almost the entire population of the hackathon gathered around her like a totem.

“In vain you did not order blankets. On all the hackathons that I was, there were rugs. ”

As usually happens, a carelessly abandoned phrase very quickly developed into a long conversation about the format, goals and fate of the event. The initiative to hold such an atypical competition for Moscow belongs to Dmitry Kirsanov from REAL Inventors , which creates a platform for the start of “zhelebyachnyh” startups. They work closely with Moscow TsMITs, and rely on their equipment, but the prototyping platform’s start-up is not enough: according to Dmitry, engineers, marketers and consumers need to be cooked in the same pan, to ensure that a good idea finds its client, and HSE and Skolkovo. This is the first event of this kind, and the preparation was carried out in a hurry, some of the guests did not come, they expected a very small audience coverage, but it turned out better than they expected.

When Dmitry and other organizers left to sleep, it was time to continue working on the project. The lonely standing oscilloscope was expropriated and the struggle between sleep and debugging began. The spidev driver was the subsystem of interaction with the ADC, python implemented the system logic - it is quite simple and convenient for RPi.

We work at night too.

During periods when sleep and hunger overcame all sorts of productive thoughts, I approached the counter with 3d printers in the hope of finding an idle machine and making myself some souvenir as a souvenir. Finally, I was lucky: most of the participants fell asleep, and two of the three devices blinked in standby mode. Having downloaded several pre-fabricated models from my research and professional activities on the state-owned laptop, I put them on print. Estimation of the printing duration was not very optimistic - the work was supposed to end only by the morning.

Empty in the forest - only the bird sings.

Unfortunately, the data from the ADC was garbage, the readiness line was switched without any order, and it was not even possible to carry out one cycle of reading and writing the register. Questions were caused by the logic of working with the CS line, pre-gating and internal clocking. The most advanced electronics engineer decided that we would fix the last option. There was no suitable quartz around, rPi from the user mode produced only 10 kHz, therefore it was necessary to assemble a generator from the available materials.

It was four in the morning and the dream overcame. With glass eyes, alexzero wrote an assembly blink at 1 MHz and went to check, but someone accidentally pressed the x10 software modifier. Fifty volts from the output of the Arduin sent to the knockout of all: (

In the morning it became clear that nothing would come out of the ADC, and it should be replaced. While the guys were having breakfast, I managed to visit the nearest Chip and Dip. The new microcircuit was configured from the lines and had a good manual work. Having connected and slightly modified the existing code, I saw that the data are quite meaningful.

When the device began to return something intelligible, work began on linking it to the web service. Requests were connected to the python, which sent portions of the signal to the server. On the server, in the meantime, I threw a pulse detector and sent the board to the package in the case.

The printing of my "souvenirs" is over. I experimented with 3d printing for the first time, and for me it became unexpected to fill the holes and bushes with frequent stiffening ribs, layer-by-layer cracks and random displacement of some layers. In principle, I was ready for the low quality of the parts and the result was quite pleasing to me. For comparison, I asked Ivan to make several parts on the MakerBot, and the result was somewhat better: there was no damage when removing parts and filling compartments, but I liked the quality of the external surfaces more on Picaso. Special thanks I want to say Picaso employee Eugene for help in removing parts.

And here is the result.

The trackers from HSE reappeared on the site. This time, the prototype was already interesting for them, and we could even demonstrate something to them. After lunch, a young man of creative appearance arrived at the site, who conducted speech and confidence training on stage. This training, full of choreography and non-standard sounds, contrasted quite strongly with the tired faces of the participants and was very popular.

Anton Lande takes possession.

It soon became clear that there was neither strength nor time anymore. The device was finally packed in a transparent box, connected to the batteries and running. The service worked with a bang, the signal came with a large network noise, but against its background it was possible to somehow distinguish the pulse. The client for the phone turned out to be simple, but rather pretty.

The presentations of the projects were completely calm. The guys really collected workable prototypes. The most disastrous aspect of the performance was the length of the pitch, in which no one could fit. The long-term setup of the audience by the atmosphere of a startup incubator led to the fact that talk about product positioning crowded out both the idea and progress over the weekend, but I wanted to explain everything.

On stage - Misha Shagiev and orinichev .

In the end, we were measured in second place and the audience award, so we consider ourselves winners - we have two nominations here only here. Here is a drop of disappointment: there were no material prizes. A few days later, however, a letter came to confirm the free monthly access to the three CMITs - modestly, but wonderful for initial communication with the CMITs themselves.

Wow.

In some ways, hackathons are a bit like a village brides fair in front of a gentleman, in some ways an advertising party, like the Red Bull festival, and in some ways a deadly corporate conference with curtsies and lousy coffee. Something different happened here: there was nothing to advertise to the organizers, the invited guests looked like “cherry on the cake”, there was no master, no one was able to do curtsy. And it turned out quite interesting!

On the other hand, the lack of an advertising initiative led to organizational failures associated with a lack of funding. The corporation can afford, of course, much more.

In general, it is not clear to me why CMITs lack an audience, because rudely these are single inventors, start-ups, students and children, and all of them potentially have their own activity and are looking for opportunities to implement their ideas. There is some kind of conceptual gap between the development of money for equipment and its use, and the “hardware hackathon” - one scored pile in building this bridge.

The success of the pilot event shows that the "threshold of entry" has fallen, and even a group of enthusiastic schoolchildren can demonstrate a prototype in hardware in two days. Nevertheless, experienced electronics engineers and designers among the participants have significantly raised the overall level of the event (this is an invitation to electronics people in Habré!).

Dmitry promised that such hackathons will be held once every two months, which means the next one in September. Will wait.

As for us, after two days of work, we began to receive offers of resellers. Such an unusual return for us and the efforts of Michael are, of course, the reason for opening a startup, and we are already slowly working on a prototype and are communicating with start-up investors. Follow the news!

Most of the photos belong to the organizers, and I tell them many thanks for them.

Attention: inside the composition and photos.

')

Hackathon - popular in recent years, entertainment. The traditional format consists of several stupid speeches with the presentation of ideas, free coffee, pizza, the Internet and bag-chairs. The promoter company receives several hundred young, passionate users, and sometimes several sensible ideas.

The perfect entertainment for a snoring student or freelancer. Another thing is that even something conditionally similar to a product or at least the beginnings of a startup as a result of hakatons is obtained quite rarely.

All the more mysterious, the prospect of the upcoming “hardware hackathon” looked, with 3d-printers and soldering irons right in the workshop: the placement of the equipment and its provision to everyone who wanted it was clearly beyond the scope of the promotion. The threshold for entry into the hardware business is higher, corporations prefer static exhibitions at expo centers, the maximum that can be obtained from them is a cup of coffee and a demos set. Recalling the experience of previous hakatons, we imagined thrash and a crowd of enthusiastic schoolchildren, and with these thoughts we signed up for the event.

In general, doing something iron is more risky than making software products, and therefore unpleasant. Equipment costs money, fails, requires handling skills, and the process of designing devices requires additional knowledge and experience. It was difficult to expect from several groups of enthusiasts success within the framework of the format and even an objective concept.

Friday

Friday evening we gathered at Ernst & Young's office, where, according to the program, we had to register participants. Negotiation "Paris", more like a small lecture hall, was filled quite tightly. The presentation template provided by the organizers mostly consisted of parts of a business plan, which looked unusual for a three-minute pitch.

It was necessary to come up with a "serious" product, and we unpacked our student work: our department was engaged in medical electronics, and almost all of the work was related to electrophysiology, so we described the portable cardiograph in the presentation. The calculation was that we will build hardware for the project from the diplomas, put it in a beautiful building, deploy the service on Azure using the developed technology and add integration with social services. Networks - enough to impress the experts.

We sit modestly and make a presentation - half an hour before the performance. Shame on you

At the stage of the presentation, another participant approached us and offered to combine efforts. It was Mikhail Shagiev, who was looking for a team for a startup, which is connected with cardiography. Our team was even more than staffed: we invited as many of our acquaintances as possible to study and work, or just acquaintances. Therefore, at nine zero zero, in McDonalds on Tverskaya. Clear.

Saturday

Digital Telegraph is similar to other sites located in historical monuments, such as Artplay or Digital October, and is not at all like small anti-cafe basements or office rooms in the buildings of Soviet institutions. In the Telegraph it is very spacious, empty and cold: the brick walls are not covered with finishing at all, and there are gaps in the slopes of the windows. Having seized a strategic resource - furniture and partition-boards, we began to unpack the imported material.

Soon the heroes of the occasion arrived with their hosts - three Picaso Designer and three MakerBot. It all looked like a microscopic exhibition of cats: the owners nervously took care of their pets, and the visitors eagerly looked at them with curiosity with tender eyes. As it turned out, all the devices are provided by various organizations: MakerBot brought Ivan from the 3D Printing Lab, Picaso - Sergey Gerasimov from the Bionic Lab and the guys from the HSE Lab. Most of all I expected to see a compact CNC engraver like Roland MDX, but none of the “masters” were going to take it with me. There were no soldering tools either, and several people went to their offices to correct this oversight.

Printers arrived.

The announced format assumed only one checkpoint for the iron part - at the very end, and for the marketing of events, many were planned. The team was required to conduct a survey of the target audience, draw the landing page of another non-existent product, put together a “business plan”. In addition, strange people went around the site all the time and asked different questions: they asked them to formulate the concept of “two words” or “sell” the device as if it were ready.

The rest of the equipment was brought up: two Lukey stations with a hairdryer, a 100 MHz Rigol Chinese oscilloscope, a bench multimeter, a scattering of soldering irons and a junk box “for components”.

We planned to assemble on a breadboard board a simple circuit for a couple of channels consisting of a balanced amplifier, an active filter, and a sigma-delta ADC. As a "head" was harvested Raspberry Pi with Linux on board. Filters and amplification were counted in the diplomas, the components were purchased according to the lists, it was necessary only to collect all this.

According to the plan, everyone was engaged in his own business:

We were very lucky - the communication on the “sales” part was fully compensated for by the joining participants - Mikhail and Oganes, including the task to interview a few dozen people on the street and to make up the appearance of the target audience.

The job went.

Night

In the evening in the Telegraph it becomes especially cold, and the organizers have not provided any insulation - neither blankets, nor heaters. It was raining outside the window. At the bar, the Jura coffee machine, which looked like the only heat source, not counting soldering irons, materialized very well. Almost the entire population of the hackathon gathered around her like a totem.

“In vain you did not order blankets. On all the hackathons that I was, there were rugs. ”

As usually happens, a carelessly abandoned phrase very quickly developed into a long conversation about the format, goals and fate of the event. The initiative to hold such an atypical competition for Moscow belongs to Dmitry Kirsanov from REAL Inventors , which creates a platform for the start of “zhelebyachnyh” startups. They work closely with Moscow TsMITs, and rely on their equipment, but the prototyping platform’s start-up is not enough: according to Dmitry, engineers, marketers and consumers need to be cooked in the same pan, to ensure that a good idea finds its client, and HSE and Skolkovo. This is the first event of this kind, and the preparation was carried out in a hurry, some of the guests did not come, they expected a very small audience coverage, but it turned out better than they expected.

When Dmitry and other organizers left to sleep, it was time to continue working on the project. The lonely standing oscilloscope was expropriated and the struggle between sleep and debugging began. The spidev driver was the subsystem of interaction with the ADC, python implemented the system logic - it is quite simple and convenient for RPi.

We work at night too.

During periods when sleep and hunger overcame all sorts of productive thoughts, I approached the counter with 3d printers in the hope of finding an idle machine and making myself some souvenir as a souvenir. Finally, I was lucky: most of the participants fell asleep, and two of the three devices blinked in standby mode. Having downloaded several pre-fabricated models from my research and professional activities on the state-owned laptop, I put them on print. Estimation of the printing duration was not very optimistic - the work was supposed to end only by the morning.

Empty in the forest - only the bird sings.

Unfortunately, the data from the ADC was garbage, the readiness line was switched without any order, and it was not even possible to carry out one cycle of reading and writing the register. Questions were caused by the logic of working with the CS line, pre-gating and internal clocking. The most advanced electronics engineer decided that we would fix the last option. There was no suitable quartz around, rPi from the user mode produced only 10 kHz, therefore it was necessary to assemble a generator from the available materials.

It was four in the morning and the dream overcame. With glass eyes, alexzero wrote an assembly blink at 1 MHz and went to check, but someone accidentally pressed the x10 software modifier. Fifty volts from the output of the Arduin sent to the knockout of all: (

Sunday

In the morning it became clear that nothing would come out of the ADC, and it should be replaced. While the guys were having breakfast, I managed to visit the nearest Chip and Dip. The new microcircuit was configured from the lines and had a good manual work. Having connected and slightly modified the existing code, I saw that the data are quite meaningful.

When the device began to return something intelligible, work began on linking it to the web service. Requests were connected to the python, which sent portions of the signal to the server. On the server, in the meantime, I threw a pulse detector and sent the board to the package in the case.

The printing of my "souvenirs" is over. I experimented with 3d printing for the first time, and for me it became unexpected to fill the holes and bushes with frequent stiffening ribs, layer-by-layer cracks and random displacement of some layers. In principle, I was ready for the low quality of the parts and the result was quite pleasing to me. For comparison, I asked Ivan to make several parts on the MakerBot, and the result was somewhat better: there was no damage when removing parts and filling compartments, but I liked the quality of the external surfaces more on Picaso. Special thanks I want to say Picaso employee Eugene for help in removing parts.

And here is the result.

The trackers from HSE reappeared on the site. This time, the prototype was already interesting for them, and we could even demonstrate something to them. After lunch, a young man of creative appearance arrived at the site, who conducted speech and confidence training on stage. This training, full of choreography and non-standard sounds, contrasted quite strongly with the tired faces of the participants and was very popular.

Anton Lande takes possession.

It soon became clear that there was neither strength nor time anymore. The device was finally packed in a transparent box, connected to the batteries and running. The service worked with a bang, the signal came with a large network noise, but against its background it was possible to somehow distinguish the pulse. The client for the phone turned out to be simple, but rather pretty.

The presentations of the projects were completely calm. The guys really collected workable prototypes. The most disastrous aspect of the performance was the length of the pitch, in which no one could fit. The long-term setup of the audience by the atmosphere of a startup incubator led to the fact that talk about product positioning crowded out both the idea and progress over the weekend, but I wanted to explain everything.

On stage - Misha Shagiev and orinichev .

In the end, we were measured in second place and the audience award, so we consider ourselves winners - we have two nominations here only here. Here is a drop of disappointment: there were no material prizes. A few days later, however, a letter came to confirm the free monthly access to the three CMITs - modestly, but wonderful for initial communication with the CMITs themselves.

Wow.

Aftertaste

In some ways, hackathons are a bit like a village brides fair in front of a gentleman, in some ways an advertising party, like the Red Bull festival, and in some ways a deadly corporate conference with curtsies and lousy coffee. Something different happened here: there was nothing to advertise to the organizers, the invited guests looked like “cherry on the cake”, there was no master, no one was able to do curtsy. And it turned out quite interesting!

On the other hand, the lack of an advertising initiative led to organizational failures associated with a lack of funding. The corporation can afford, of course, much more.

In general, it is not clear to me why CMITs lack an audience, because rudely these are single inventors, start-ups, students and children, and all of them potentially have their own activity and are looking for opportunities to implement their ideas. There is some kind of conceptual gap between the development of money for equipment and its use, and the “hardware hackathon” - one scored pile in building this bridge.

The success of the pilot event shows that the "threshold of entry" has fallen, and even a group of enthusiastic schoolchildren can demonstrate a prototype in hardware in two days. Nevertheless, experienced electronics engineers and designers among the participants have significantly raised the overall level of the event (this is an invitation to electronics people in Habré!).

Dmitry promised that such hackathons will be held once every two months, which means the next one in September. Will wait.

As for us, after two days of work, we began to receive offers of resellers. Such an unusual return for us and the efforts of Michael are, of course, the reason for opening a startup, and we are already slowly working on a prototype and are communicating with start-up investors. Follow the news!

Most of the photos belong to the organizers, and I tell them many thanks for them.

Source: https://habr.com/ru/post/230415/

All Articles