FedEx: Part 1. Excursion to the FedEx World Package Sorting Center

Memphis, Tennessee. Signal thunder lights blink, indicating that sorting will start late ...

Caution, a lot of photos!

Blue signal lights do not turn on very often. They blink only when lightning is detected within a radius of 3 miles from Memphis National Airport, and when they turn on, all work stops. Personnel should not be allowed to enter the ladder surrounded by metal structures when a thunderstorm rages around:

')

I sit inside the white FedEx shuttle bus, behind the walls of which there is torrential rain and thunder rumbles. For me, this unexpected delay is just a minor inconvenience, and for thousands of employees of the World FedEx Center (FedEx World Hub) - this is a big problem. Hundreds of thousands of parcels from 140 arriving aircraft must be sorted, but for now the matter is not moving at all.

Boeing 777 awaits unloading.

As part of a CNET road trip, I arrived in the city of Memphis with a population of 655,000 in the southwestern part of the state of Tennessee with the goal of visiting the core of FedEx. The first stop point was the parcel packaging laboratory , and today my goal is the World Sorting Center, the largest distribution center for express shipments, a massive structure that processes from 1.3 to 1.5 million parcels per night.

Finally, the storm subsides and the signal lights go out. Now you can start work. Since the storm began just before the night shift began at 11:00 pm, hundreds of employees who had to move back and forth, moving packages, had to wait for the moment when they could start work. When I entered the secure sector — consider it a simplified version of the airport checkpoint — several hundred FedEx employees stood in line, eagerly waiting for inspection, to finally get to their jobs.

180000 per hour

Meanwhile, the night sorting at the World Center is an impressive operation. 180,000 parcels per hour pass through the sorting center until the latest one is processed.

It works like this: every evening about 140 FedEx airplanes arrive in Memphis from all over the world - the company serves 375 airports from 220 countries - loaded with packages that must be sorted and sent by the same aircraft towards their destination. After unloading, the parcels go through one of the 9 input sectors and then get into the Matrix, where the first line of employees controls that the parcels are correctly placed on the conveyor so that barcode scanners can read any side of the parcel except on which the parcel is on the conveyor.

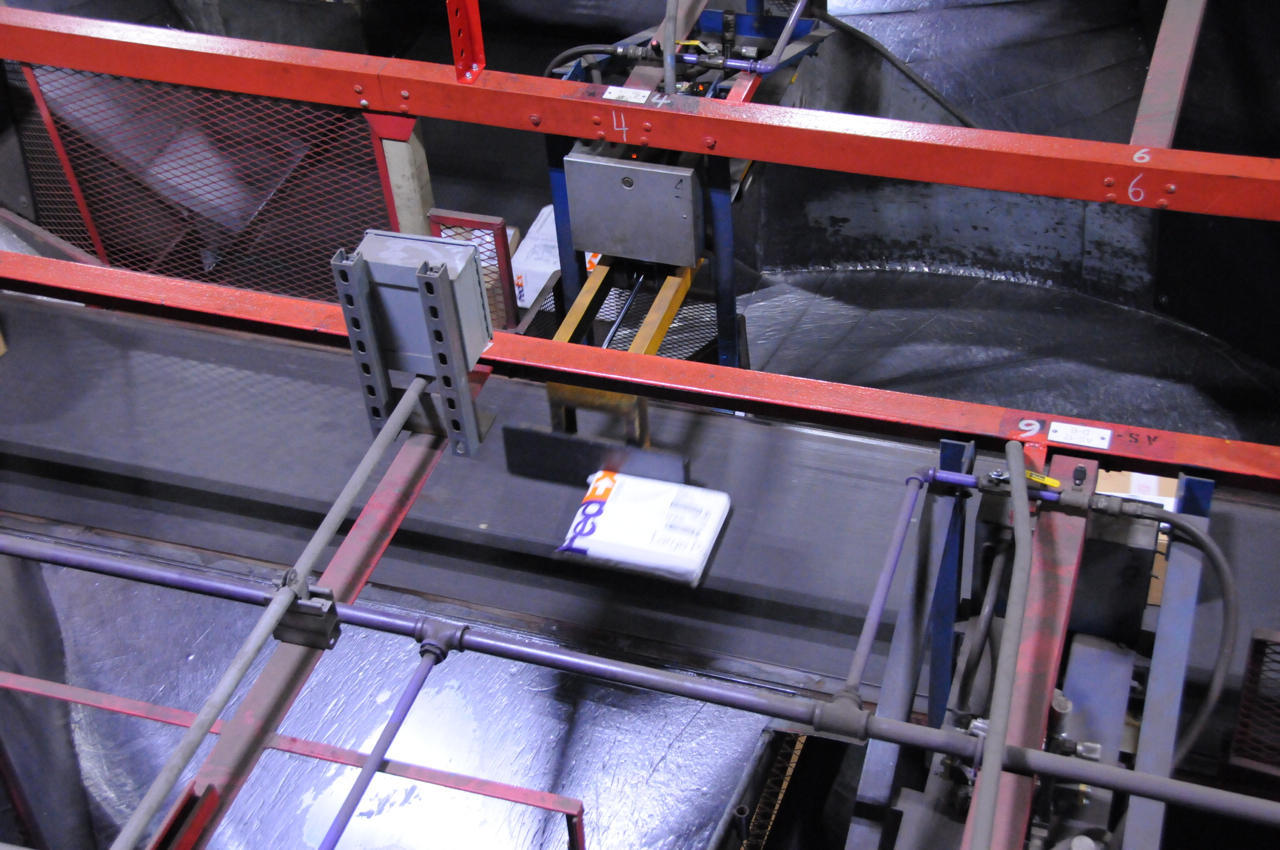

After entering the "Matrix", the parcels are moved along the conveyor further into the structure, first passing the scanner, which reads the parcel barcode. Depending on this information, the parcels go into one of the 19 automatic distributors, after which they are sent to the secondary sorting sector, and then to the “Exit”, where they are repacked in containers and again get on the plane.

"140 arrived, 140 flew away"

FedEx World Center in Memphis is the largest of the 12 centers that perform night sorting of packages and letters in the company's global network. The rest are scattered around the country and around the world in places like Indianapolis, Dallas, Miami, Toronto, Oakland (California) and Tokyo.

In total, FedEx handles about 4 million express (air) shipments per night, and 10 million shipments in total, including ground. But the World Center is the heart of the whole operation, and FedEx claims it is the largest sorting station in the world.

Every night, 7,000 employees go to work to sort out 1.3–1.5 million express shipments per shift. The day shift, consisting of 3,500 employees, processes only about 650,000 parcels with a delivery time of 2 and 3 days.

Commercial flights to Memphis stop landing at 9:30 pm, and from that point onwards only FedEx aircraft land. On a good night, when the lights do not turn on due to a thunderstorm, FedEx planes lined up for landing from 22:30 and continue to land one after the other until about 1:00 AM:

The goal is for the latest parcel to reach the entrance to the sorting area by 2:07. By 2:30, the first outgoing aircraft begin to leave the exit of the sorting zone, and by 4:30 am, all aircraft leave Memphis. As the World Center Coordinator Rick Armstrong says, "140 arrived, 140 flew away."

Separate teams are appointed responsible for unloading each liner. They work quickly: they take metal containers that have a shape that fits perfectly into the contours of the interior of the aircraft, unload them and carefully lower them to the ground:

Their goal is to unload the largest ship in the FedEx fleet - the Boeing 777 - in 1 hour and 7 minutes. Unloading the next-sized liner - McDonnell Douglas MD-11 - takes from 35 to 40 minutes:

Unloaded containers are placed on loaders and delivered to the entrance area:

The FedEx World Center has 9 entrance zones where the “Matrices” are located. Five of them are for domestic mailings, and the remaining four are for shipments from abroad, as well as dangerous, heavy or mini-shipments. Dangerous goods may contain caustic, explosive or radioactive substances, weapons, as well as, among other things, batteries and accumulators. FedEx is the largest supplier of dangerous goods in the world, Armstrong says. The list of dangerous goods allowed for transportation is quite large, about the size of a telephone book.

Parcel Flow

As soon as the parcels enter the input sector, they are placed on one of the three conveyors, upper, middle or lower. Most parcels weigh less than 75 pounds ( about 34 kg - approx. Transl. ) And falls on the average conveyor, heading to the "Matrix":

Heavier parcels or parcels of irregular shapes, such as skis or golf clubs, fall on the lower conveyor. The upper conveyor is designed for small parcels and documents that are sent to the Small Package Sorting System (SPSS) distribution center.

As soon as the parcels from the input sector fall into the Matrix, a “flow” is created in the literal sense of the word. If you watched a video tsunami in Japan in 2011, when villages were washed away by raging rivers, thousands of packages heading to the Matrix look much the same, only without such terrifying overtones:

Parcels run in groups - each container unloaded from an airplane contains approximately 235 parcels. It would seem that such a flow should overwhelm the workers who are in the Matrix. It’s good that FedEx Packaging Labs is working with customers to ensure that the packages are securely packed, because the packages in the Matrix jump, fall and fight against each other at high speed until they fall into a sea of cardboard. Matrix workers sort tens of thousands of parcels per hour:

Next, the parcels are sent by conveyors through the first of 12 scanners on the way to the 19 distributors and ultimately to the aircraft, which will send them further in the direction of the destination:

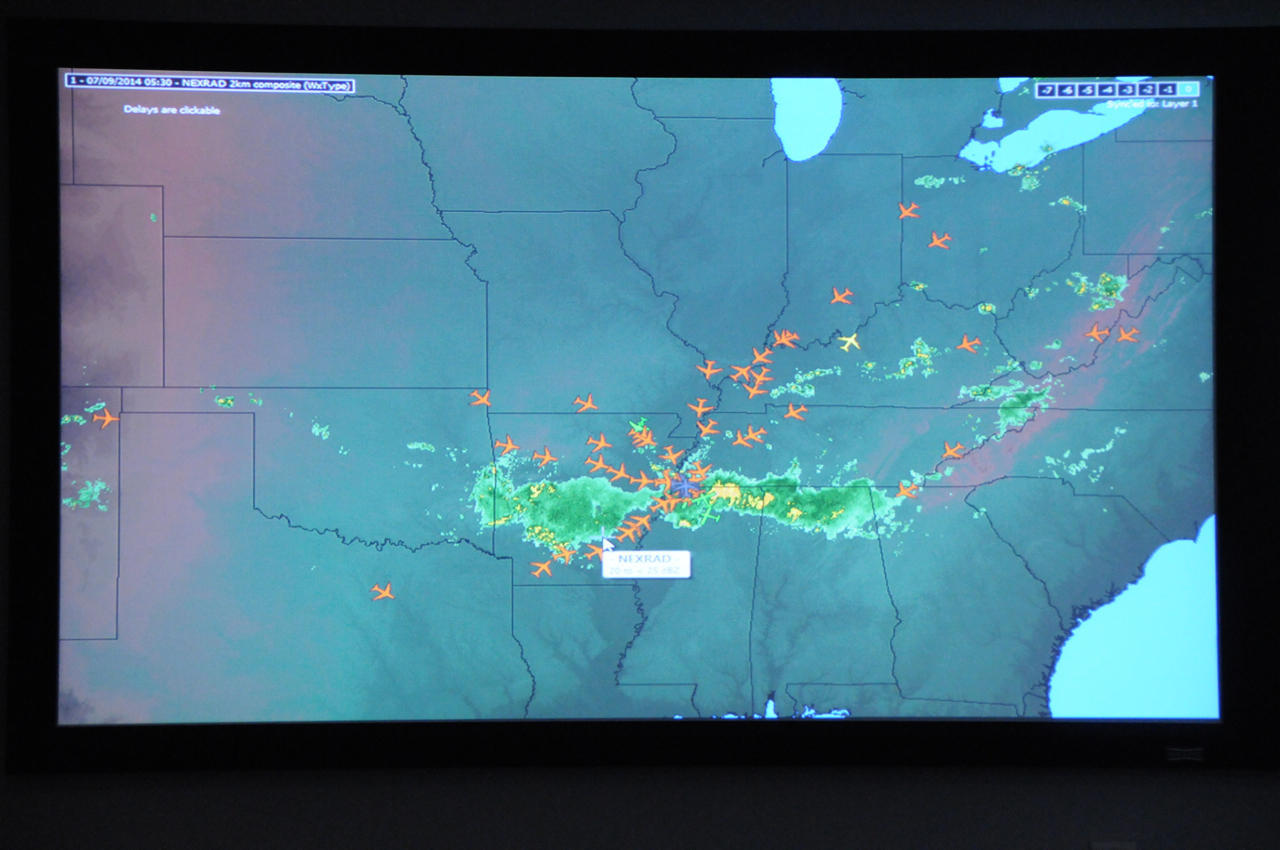

On the global monitoring screen, FedEx employees can track the location of each FedEx aircraft at any time. The screen displays the status of dozens of aircraft over the past few days:

Small Parcel Distribution System

Perhaps the most exciting part of the action in addition to the flow of packages moving towards the Matrix is the sorting system for small packages. Here, in a separate building, the teams sort from 760 to 860 thousand small shipments - for the most part of documents - per night. According to Armstrong, they are sorted with an accuracy of 99.97%.

When these small parcels pass through the input sector, they are placed on the conveyor and scanned. But instead of sorting, as it does with larger shipments - they move around the building until they fall into one of 1500 packages corresponding to their destination. When the package is filled, the system automatically generates a tag and the employee signs it.

The sorting system of small parcels is fascinating, especially if you digress from it and concentrate on dozens of conveyors, each moving in its own direction and carrying letters and small parcels, which ultimately slip into the package:

In the most difficult part, the FedEx parcel processing center is a giant mechanism with thousands of moving parts, each of which must be lubricated in time for the entire system to operate smoothly. But apart from this, the process is incredibly simple: bring hundreds of thousands of parcels every night, sort them by size and destination, load them into planes and send them further. It looks incredible. And almost always the FedEx package arrives on time. As Armstrong emphasized, “Our accuracy is 99%. And we will repeat this result tomorrow. ”

PS Continuation of the article: FedEx: part 2. We drop parcels for money: FedEx packaging laboratory .

Source: https://habr.com/ru/post/229847/

All Articles