How I used a 3d scanner to forge a key, holding a skull, a heart and a gun in my hands

Hi Habr!

Once again, I looked to visit the professionals in the field of 3d-printing and 3d-scanning.

- Do you have anything interesting?

- That's what we have!

Manual

- Wow, what else?

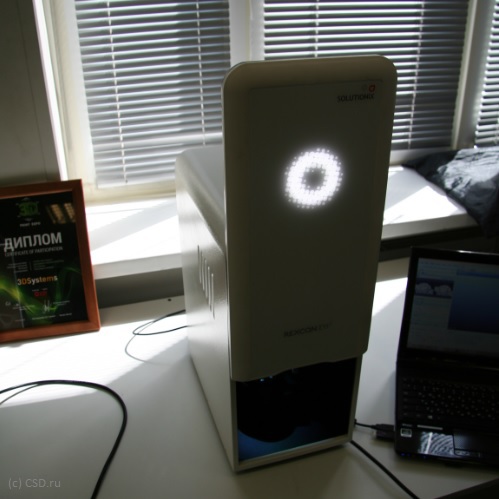

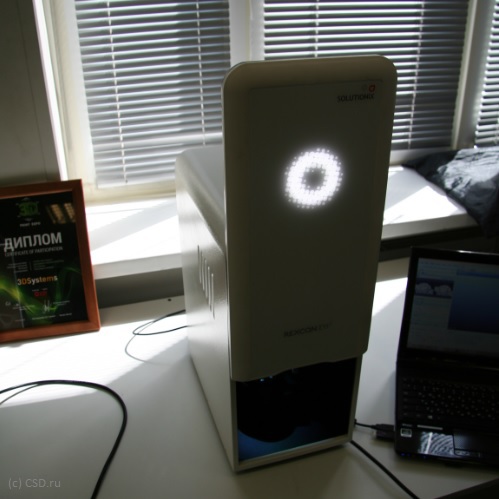

High Precision Industrial Optical Scanner

I decided to test the stationary 3d-scanner, since I had already

- What do they mostly scan?

- Teeth and jewels. There is? Spit it out.

- Eh ... and simpler? Anything closer

- Well, you can scan a bent key, straighten it in a 3d editor, and then print the mold for casting, or immediately recreate it on a metal 3d printer.

- OK, then you just show how the scanning and editing process takes place, and I know how the metal 3d-printer works, and I also did the mold for the casting.

(Caution, a lot of photos)

TTX scanner

Scanning method - Phase shifting optical triangulation

Number of cameras - 2

Scanning volume - 80x60x60 mm

Camera resolution - 1.4 MP

Accuracy ± 0.01 mm

Output Format - STL

google price

Scanning technology

Patent "Phase shifting optical triangulation"

en.wikipedia.org/wiki/Structured_light

en.wikipedia.org/wiki/Structured-light_3D_scanner

The principle of creating a 3d-image of the surface from the interference picture used in 3d-scanners on structured light.

')

Scanning process

The key is mounted on the platform, thanks to a special "chewing gum".

The key is too shiny. First, it must be covered with a matte film.

Spray talc

We place it in the camera for scanning, where it will be twisted, twisted and photographed

The scanned object can move along two axes (oscillation and rotation).

Video scanning process.

Scanning takes about 10 minutes, and in parallel a 3d model appears in the program.

Processing in a 3d editor

Removed the platform (but the "chewing gum" remained)

More serious editor. Allows you to group areas. Clearing the model from the "gum".

Almost ready for modification 3d-model.

While the specialist was processing the model in a 3d editor, I looked around and found something curious

What have i noticed yet

Printing on the basis of light-cured acrylate, one of the most accurate technologies.

Unassembled Liberator

Liberator in assembled form (75% of the original size)

detailing amazing (tree height 2 cm)

City layout

Gypsum

Arm injury splint

They say that it is much more convenient than classical devices, because it is light and personalized

Skull 1

the layout was used in a real neurosurgical operation

Skull 2

3d models are based on x-rays

Heart1

Heart2

Not at all like in anatomy school textbooks.

Teeth

Dental use of 3d printers and 3d scanners is constantly growing.

Micro

3d-printers for metal can work with incredible detail

"See you soon"

P.S.

Thanks to all the employees of the company, for being patiently answering all my questions and taking time for me, sharing their experiences using cool modern devices.

Source: https://habr.com/ru/post/228697/

All Articles