Hydrointegrator Lukyanova

Computer, but not electric.

Hydraulic integrator - hydraulic calculator:

The water flowing from one glass tube to another allowed solving partial differential equations.

It was during the period of industrialization of the USSR, when the freshly baked engineer Vladimir Lukyanov got into the construction of the railway and was confronted with a problem of low quality concreting (the concrete cracked when it hardened). Lukyanov suggested that this is due to temperature stresses and summarized the existing theoretical developments. The process was described by differential equations requiring long-term calculations, but Lukyanov saw the main thing - the analogy between the equations describing heat transfer and the equations describing the flow of a fluid. Those. the first process could be modeled using the second.

')

A few years later, Lukyanov creates an apparatus for solving this very specific task - analyzing the temperature change in concrete depending on its composition, casting technology and external conditions.

Heat transfer in non-stationary conditions - cooling a multilayer flat wall.

The model is assembled from a series of cylindrical vessels, connected in series with each other by calibrated tubes. Each of the vessels imitates the heat content of the wall layer into which the test fence is divided. The vessels are filled with water to levels corresponding to the initial temperature in each of the layers, after which the taps open and the water from the vessels begins to flow. The change in water levels in the vessels at the same time will be similar to the change in temperature in the corresponding layers of the wall during its cooling.

The following analogies with the thermal parameters of the enclosing structures under investigation were used:

a) the water levels in the vessels in cm correspond to the temperature differences between the layers and the air in degrees;

b) the cross-sectional area of vessels in cm corresponds to the heat capacity of the layers in kcal / degree;

c) the amount of water in the vessels in cm corresponds to the heat content of the layers in kcal;

d) hydraulic resistances of the tubes in min / cm (?) connecting the vessels to each other correspond to the thermal resistances of the layers in degrees-h / kcal;

e) the hydraulic resistance at the outlet tube corresponds to the resistance to heat transfer from the surface of the wall to the air in degrees-h / kcal;

e) water consumption in cm / min corresponds to heat flux in kcal / h.

The time scale, i.e., the ratio of the actual duration of the heat transfer process in hours to the duration of the process on the hydraulic integrator in minutes, is the product of the ratio of the heat capacity to the cross-sectional area of the vessel by the ratio of thermal resistance to hydraulic resistance.

For the possibility of fixing temperatures (water levels in vessels) at certain points in time, the hydraulic integrator had a special device that simultaneously overlapped all the taps between the vessels. At this point, it was necessary to mark on the graph paper, located behind the tubes, the water levels in the piezometers. Then the cranes were opened, and so on until the next measurement. The resulting curve was a solution to the equation.

In other words, the integrator made it possible to replace the process, the direct observation of which is difficult, by a similar, but more visual process. It is important that both processes were described by the same mathematical dependencies.

The thing is, oddly enough, is not over. Engineer V.S. Lukyanov eventually became a doctor of technical sciences and received the Stalin Prize. He designed two-dimensional and three-dimensional hydraulic integrators in the form of standard unified blocks that could be assembled depending on the problem to be solved. Moreover, the hydraulic integrators were launched into mass production. With their help, in particular, they calculated the projects of the Karakum Canal, the Baikal-Amur Mainline, the world's first hydroelectric power station from precast concrete - Saratov. They were used in geology (groundwater movement), metallurgy (cooling of castings), rocket production, and others.

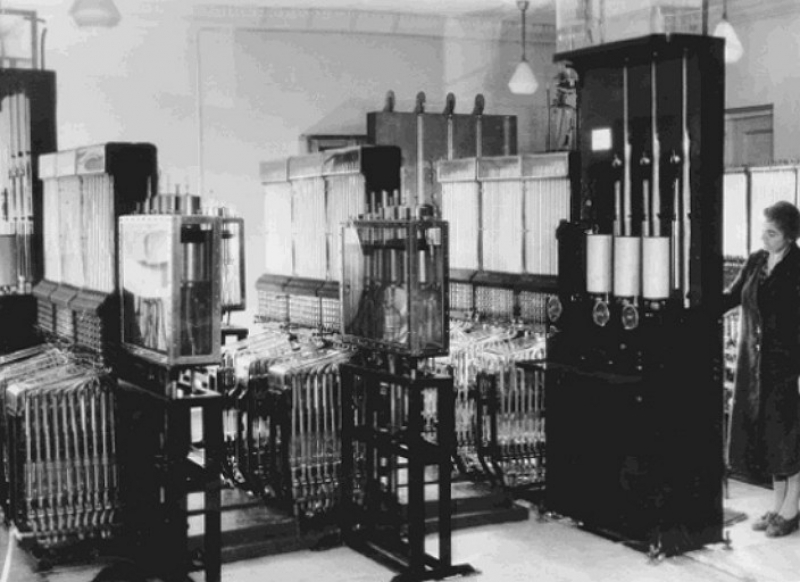

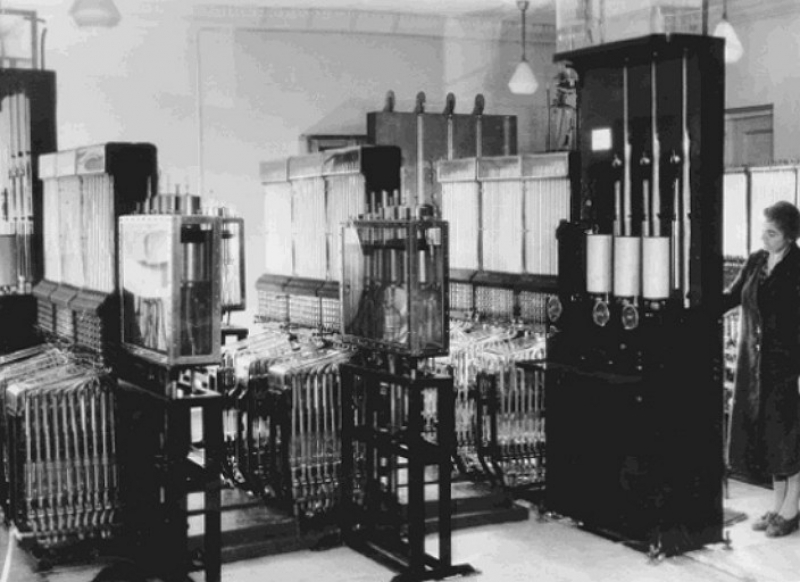

Two hydraulic integrators Lukyanov are represented in the collection of analog machines of the Moscow Polytechnic Museum. One of them:

The photo was taken in the Polytechnic Museum.

1. An article in "Science and Life . "

2. Fokin, K.F. Construction heat engineering of enclosing parts of buildings .

Hydraulic integrator - hydraulic calculator:

The water flowing from one glass tube to another allowed solving partial differential equations.

It was during the period of industrialization of the USSR, when the freshly baked engineer Vladimir Lukyanov got into the construction of the railway and was confronted with a problem of low quality concreting (the concrete cracked when it hardened). Lukyanov suggested that this is due to temperature stresses and summarized the existing theoretical developments. The process was described by differential equations requiring long-term calculations, but Lukyanov saw the main thing - the analogy between the equations describing heat transfer and the equations describing the flow of a fluid. Those. the first process could be modeled using the second.

')

A few years later, Lukyanov creates an apparatus for solving this very specific task - analyzing the temperature change in concrete depending on its composition, casting technology and external conditions.

An example of a solvable problem

Heat transfer in non-stationary conditions - cooling a multilayer flat wall.

The model is assembled from a series of cylindrical vessels, connected in series with each other by calibrated tubes. Each of the vessels imitates the heat content of the wall layer into which the test fence is divided. The vessels are filled with water to levels corresponding to the initial temperature in each of the layers, after which the taps open and the water from the vessels begins to flow. The change in water levels in the vessels at the same time will be similar to the change in temperature in the corresponding layers of the wall during its cooling.

The following analogies with the thermal parameters of the enclosing structures under investigation were used:

a) the water levels in the vessels in cm correspond to the temperature differences between the layers and the air in degrees;

b) the cross-sectional area of vessels in cm corresponds to the heat capacity of the layers in kcal / degree;

c) the amount of water in the vessels in cm corresponds to the heat content of the layers in kcal;

d) hydraulic resistances of the tubes in min / cm (?) connecting the vessels to each other correspond to the thermal resistances of the layers in degrees-h / kcal;

e) the hydraulic resistance at the outlet tube corresponds to the resistance to heat transfer from the surface of the wall to the air in degrees-h / kcal;

e) water consumption in cm / min corresponds to heat flux in kcal / h.

The time scale, i.e., the ratio of the actual duration of the heat transfer process in hours to the duration of the process on the hydraulic integrator in minutes, is the product of the ratio of the heat capacity to the cross-sectional area of the vessel by the ratio of thermal resistance to hydraulic resistance.

For the possibility of fixing temperatures (water levels in vessels) at certain points in time, the hydraulic integrator had a special device that simultaneously overlapped all the taps between the vessels. At this point, it was necessary to mark on the graph paper, located behind the tubes, the water levels in the piezometers. Then the cranes were opened, and so on until the next measurement. The resulting curve was a solution to the equation.

In other words, the integrator made it possible to replace the process, the direct observation of which is difficult, by a similar, but more visual process. It is important that both processes were described by the same mathematical dependencies.

The fate of the project

The thing is, oddly enough, is not over. Engineer V.S. Lukyanov eventually became a doctor of technical sciences and received the Stalin Prize. He designed two-dimensional and three-dimensional hydraulic integrators in the form of standard unified blocks that could be assembled depending on the problem to be solved. Moreover, the hydraulic integrators were launched into mass production. With their help, in particular, they calculated the projects of the Karakum Canal, the Baikal-Amur Mainline, the world's first hydroelectric power station from precast concrete - Saratov. They were used in geology (groundwater movement), metallurgy (cooling of castings), rocket production, and others.

Two hydraulic integrators Lukyanov are represented in the collection of analog machines of the Moscow Polytechnic Museum. One of them:

The photo was taken in the Polytechnic Museum.

1. An article in "Science and Life . "

2. Fokin, K.F. Construction heat engineering of enclosing parts of buildings .

Source: https://habr.com/ru/post/228283/

All Articles