Metalworking - 2014, or the story of these robots

While the Artplay continues the Ball of Robots (by the way, there is a MadRobots stand there, you can go and see) at the exhibition center, without an extra pomp, Metalworking-2014 exhibition ended, at which they showed, more interesting robots. As can be determined by name, these were mainly industrial metalworking machines. Of course, they can not communicate with people, and often do only one operation, but how they do it!

I apologize in advance for 800 kilobytes of hyphatism to kata. It will be worse.

Unfortunately, due to lack of time, I visited only one pavilion of 7, but even there was a lot of interesting things.

')

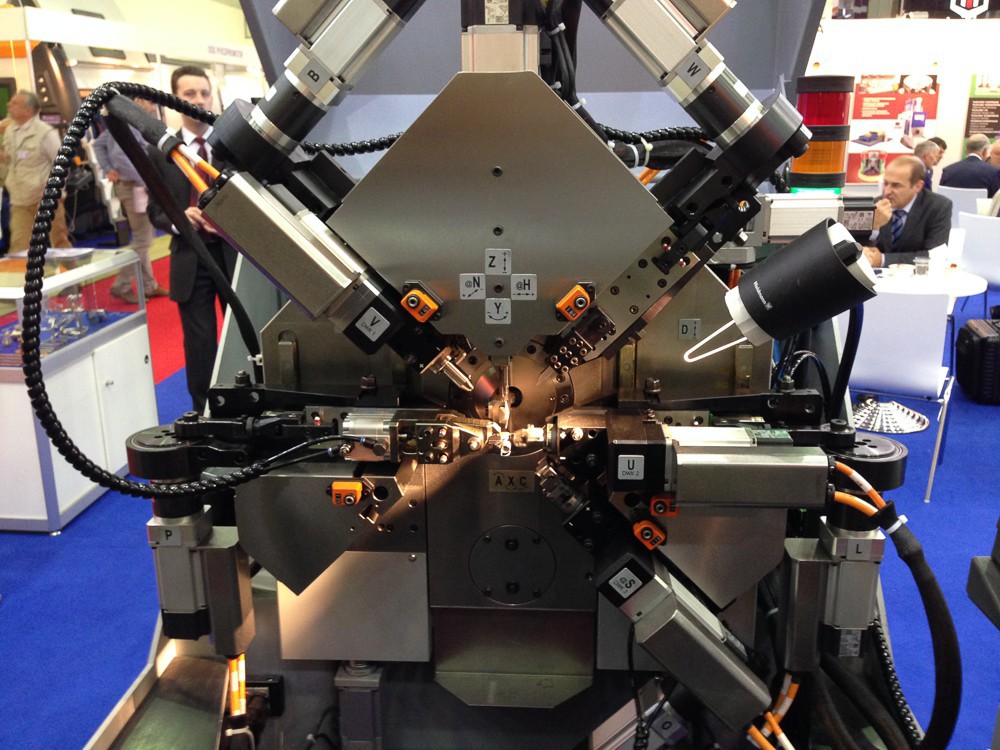

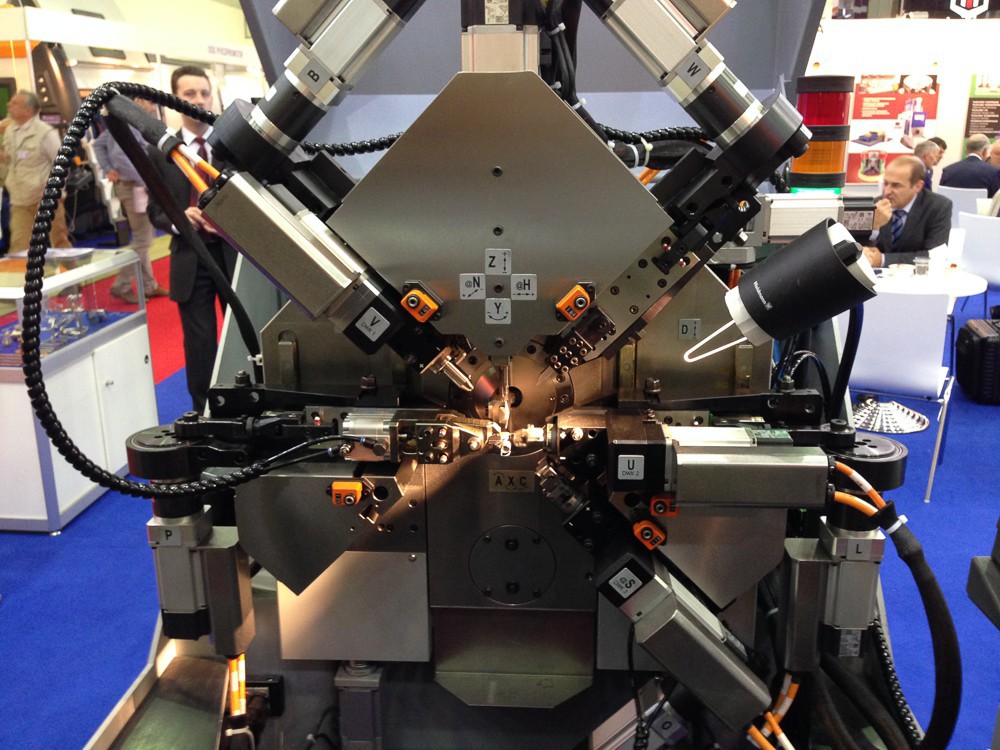

This is how, for example, a wire bending machine with a capital gif looks like:

Can do anything from springs to clips:

Or florets:

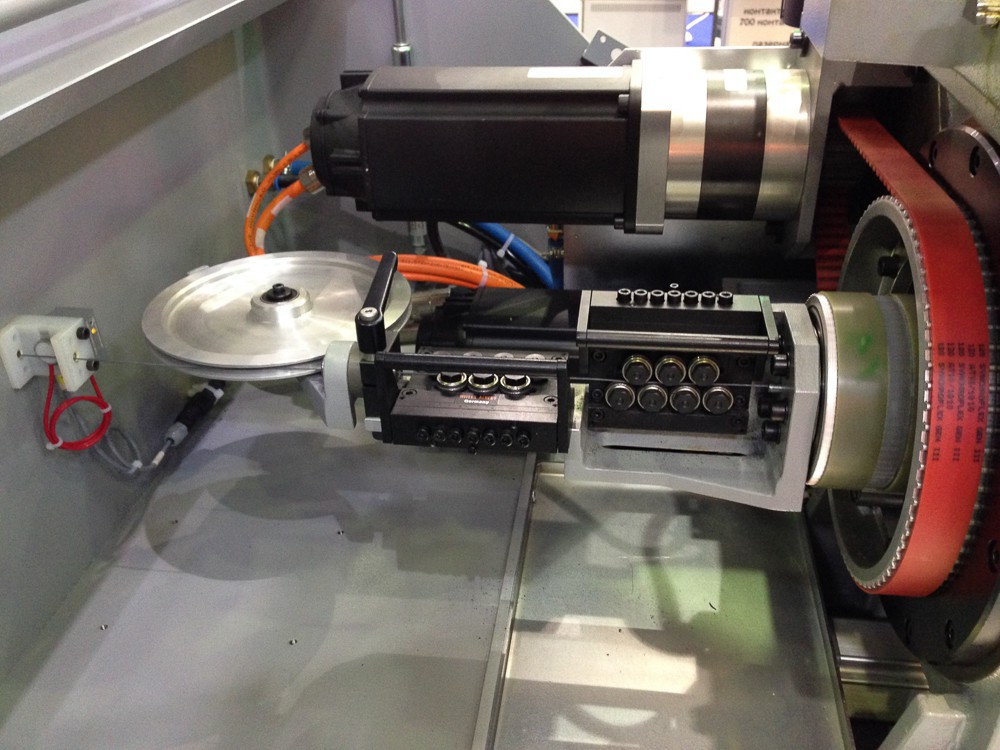

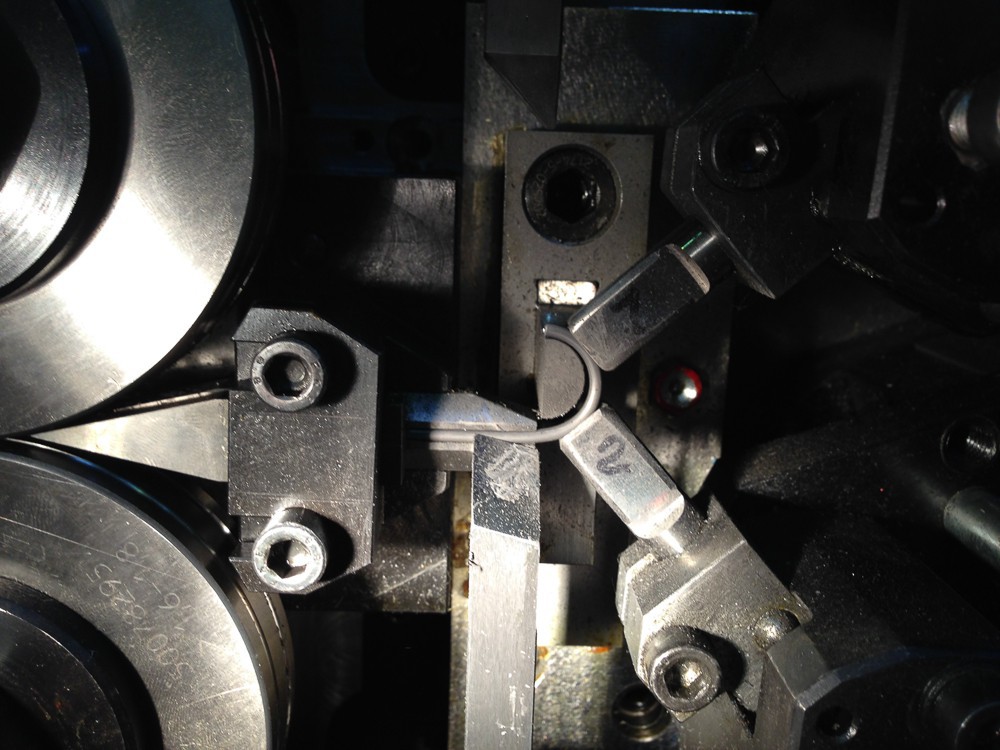

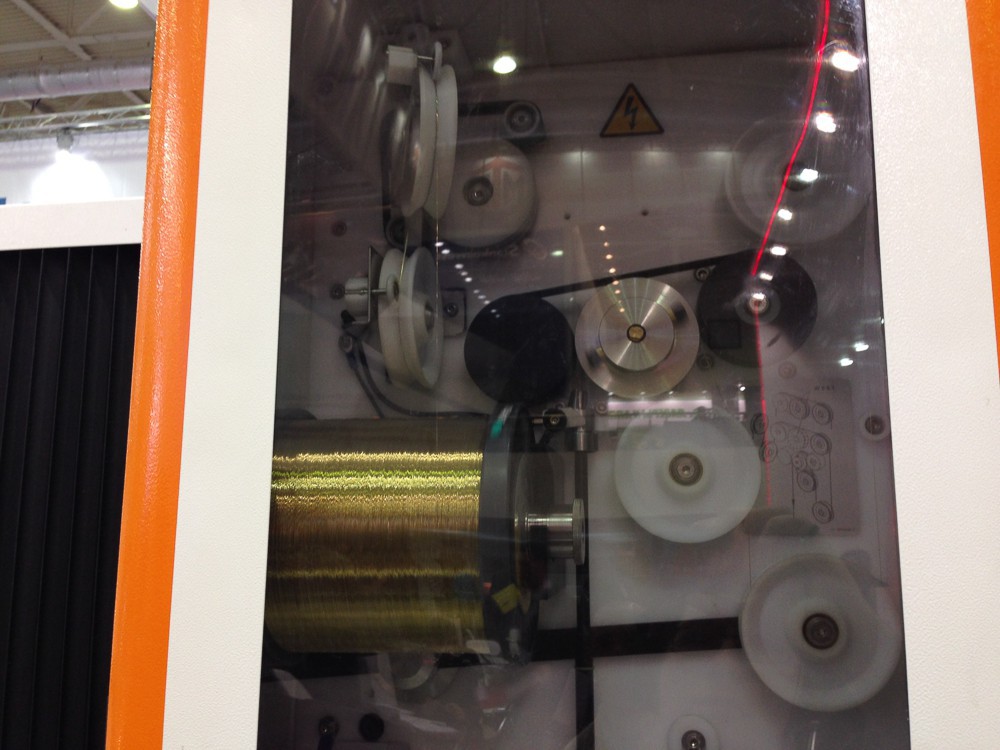

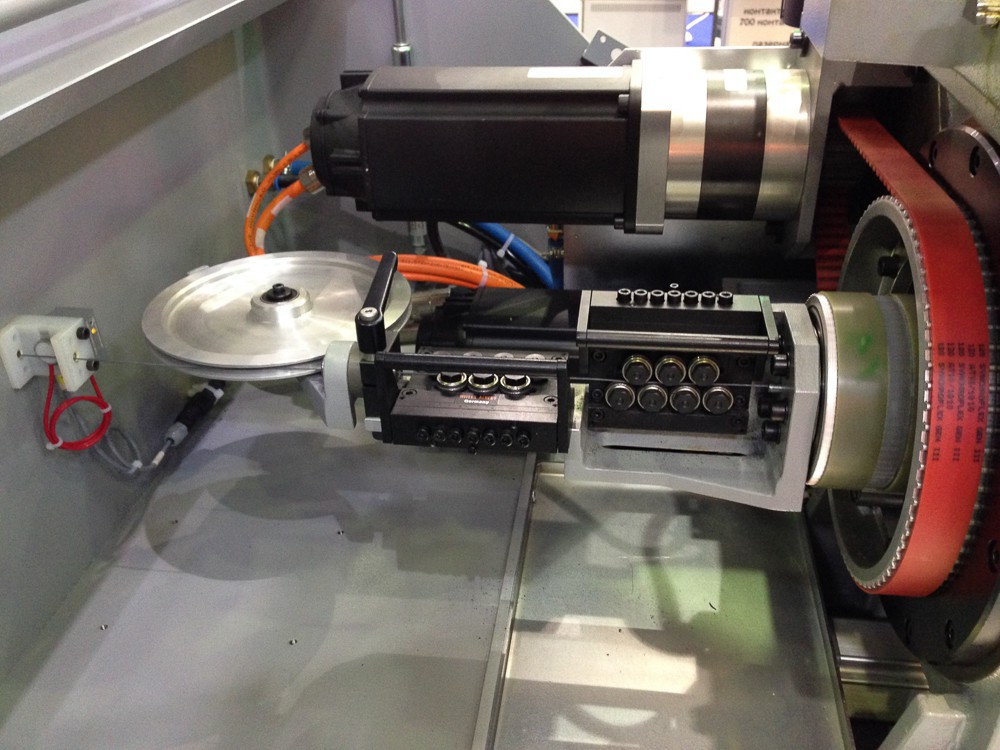

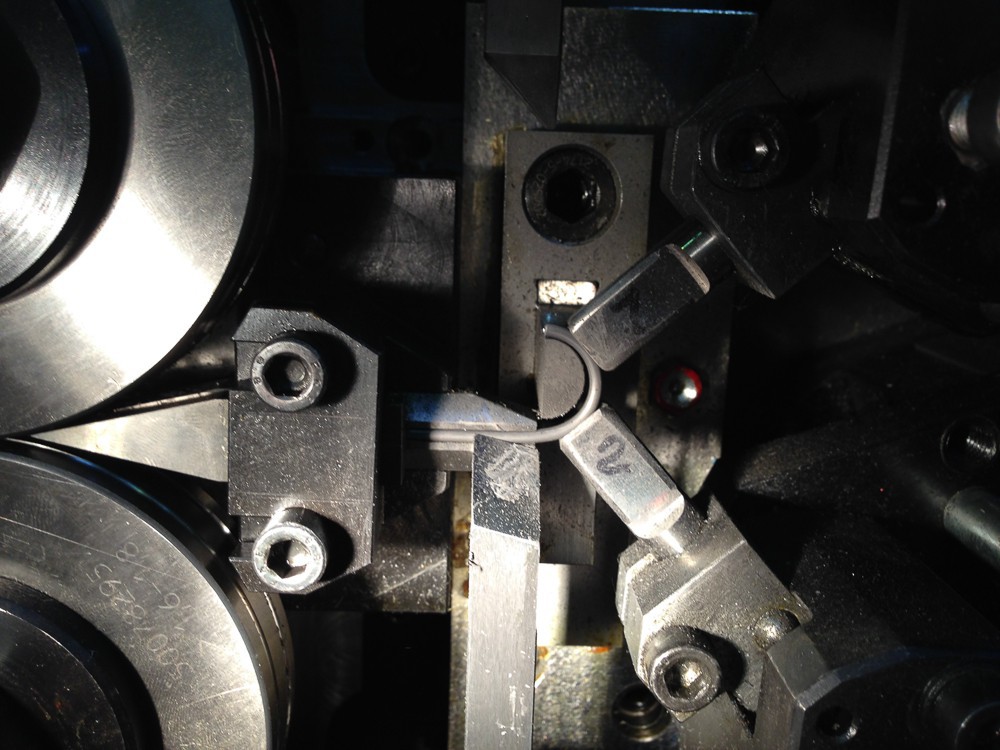

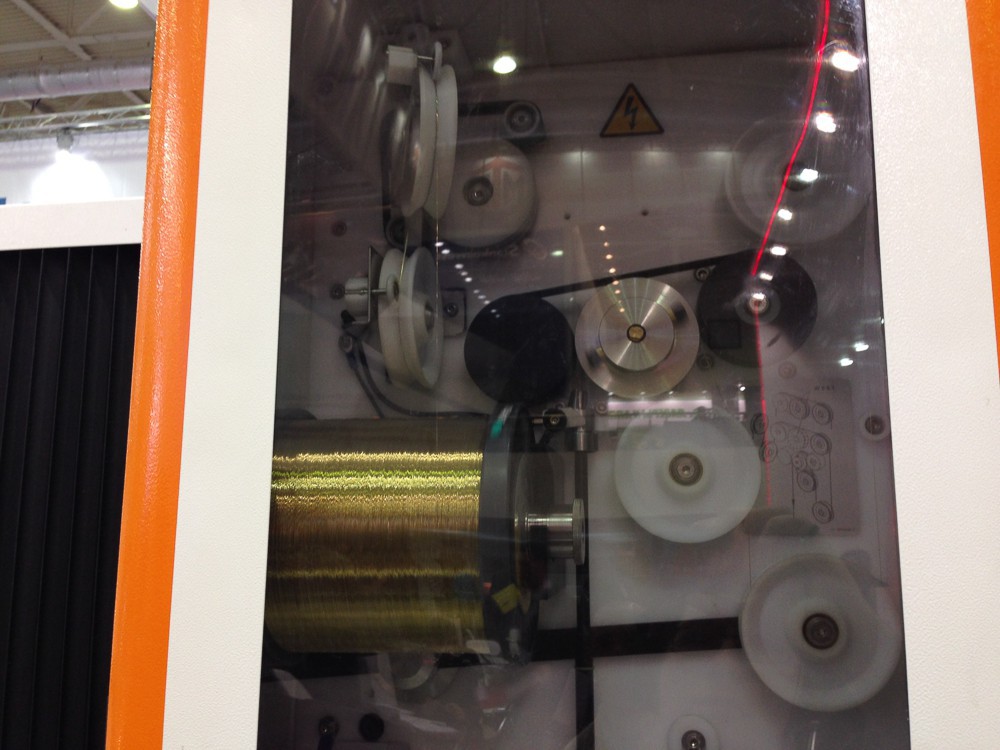

Here is what is located on his other side - rotational drive and wire feed:

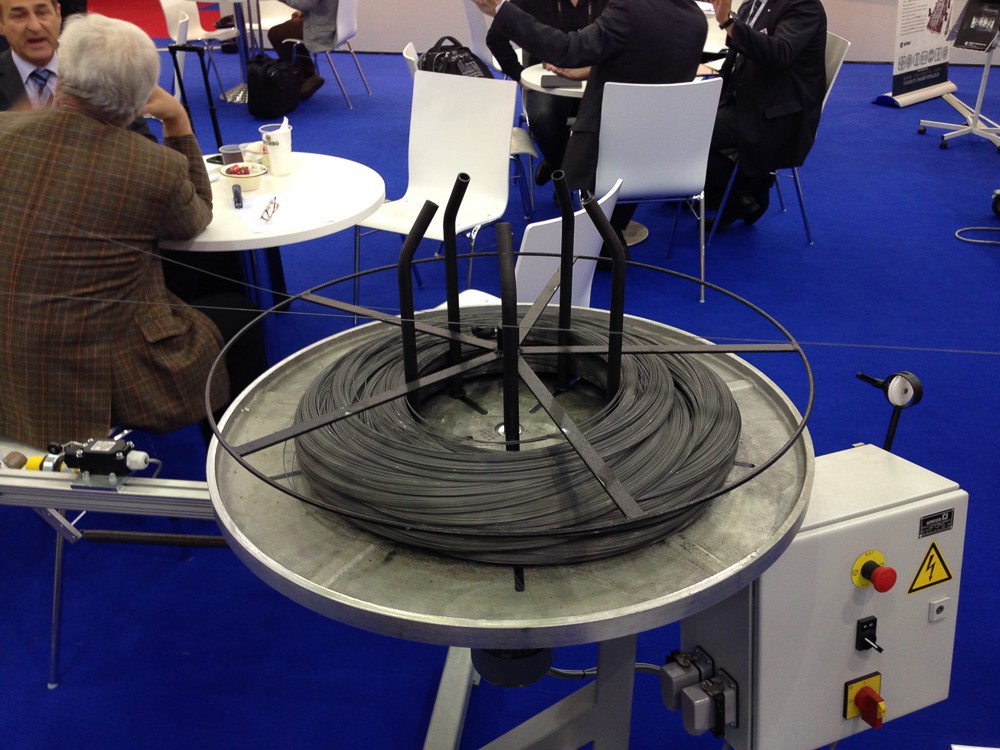

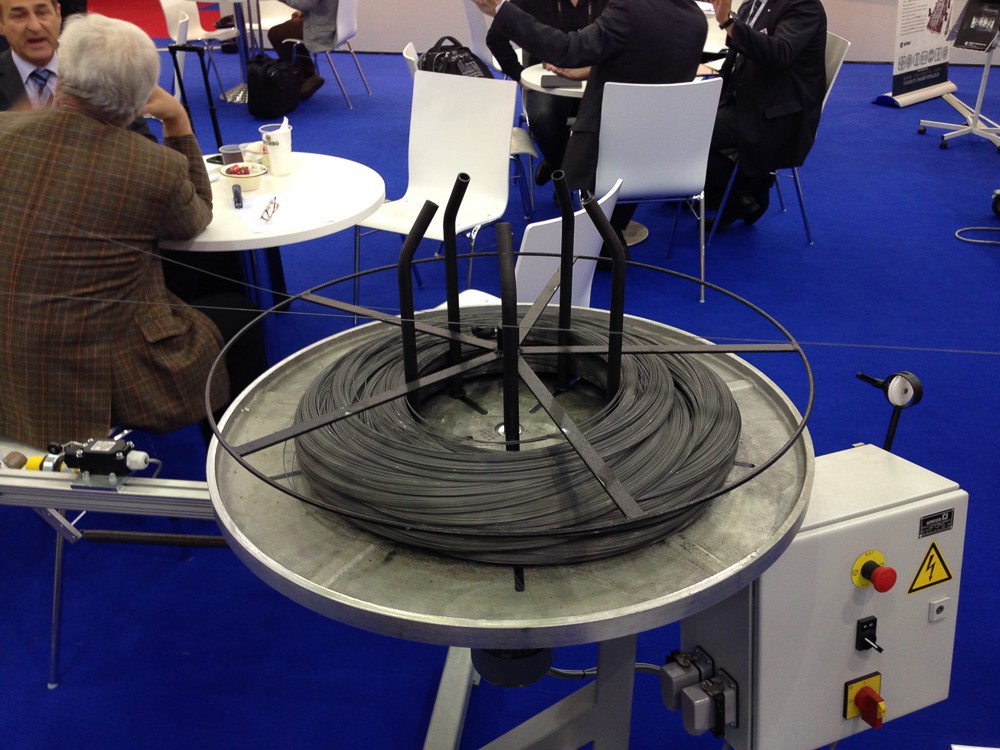

And the wire itself is unwound from such a reel:

Once again the process of working with better quality:

If you want with sound and without acceleration, then you can see here (by the way, subscribe).

Here are a number of similar machine, but more specialized - sharpened under the springs.

The wire is unwound (from the same coil):

And falls into the workspace:

The result of the work are the springs of various configurations:

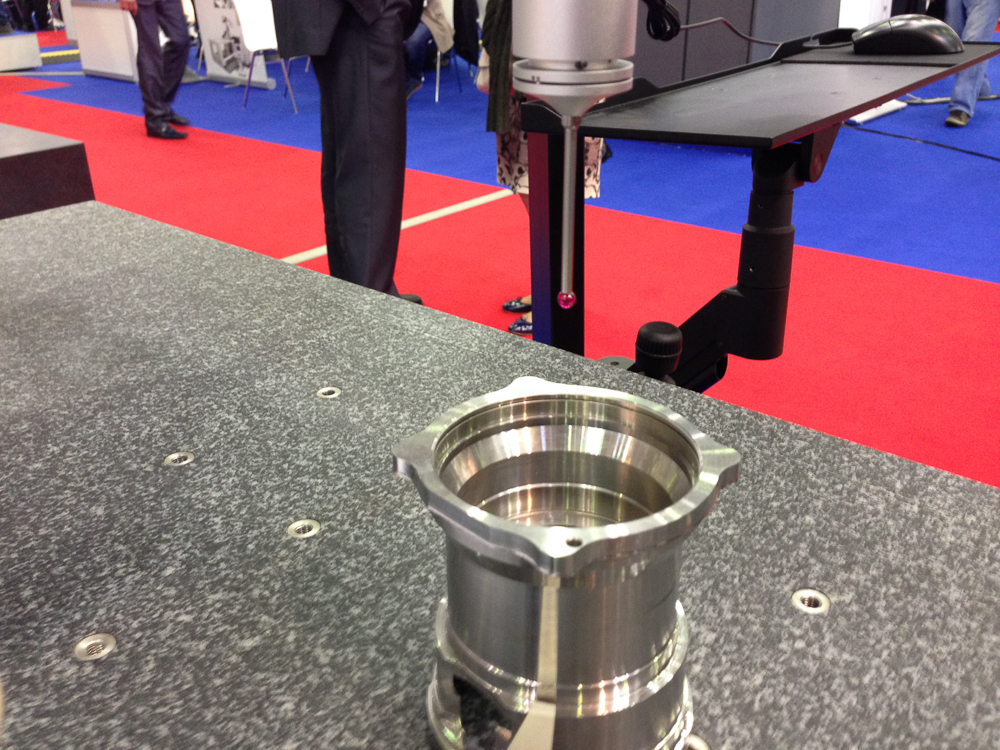

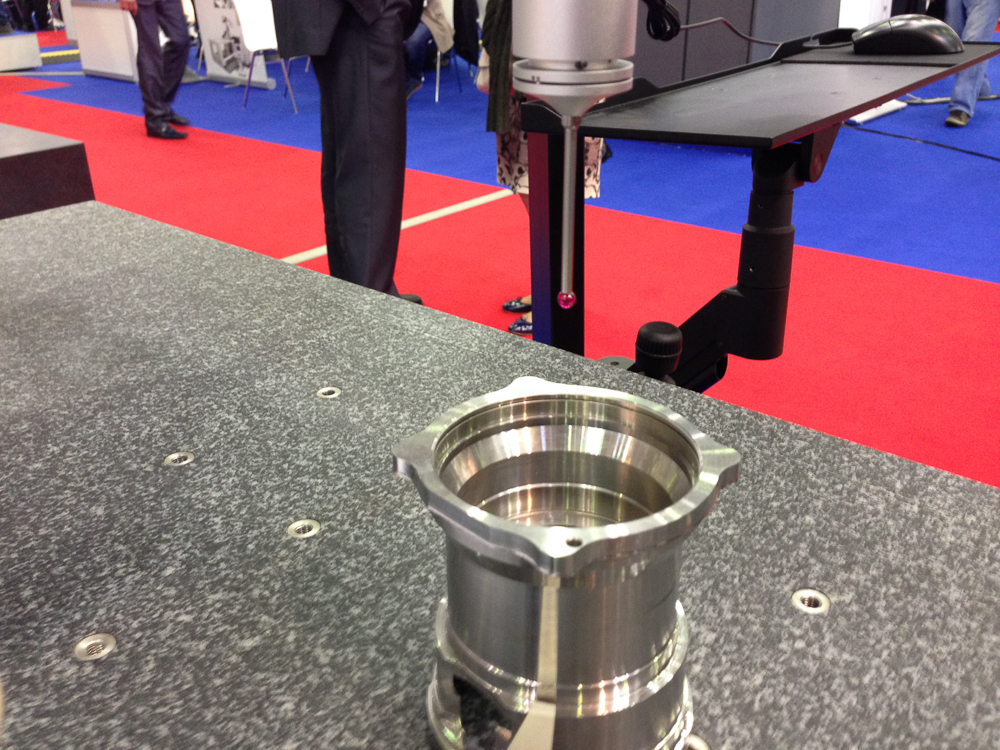

But the coordinate measuring machine.

She is committed to poking here such probes:

In different parts. The whole cymes consists in the fact that it can measure the deviation of the surface of the part from the norm up to several microns with a sensor.

And she has a control program adapted for Windows 8!

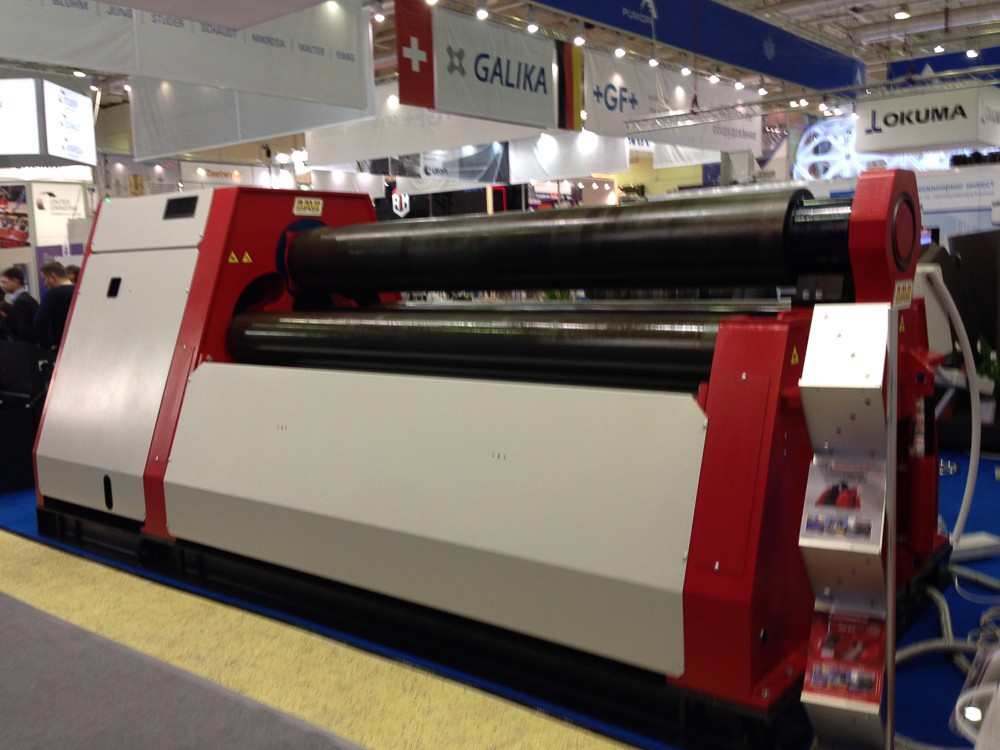

A machine that is hydraulically pressed by the rails. Well, not just the rails, but it will not be difficult for it to bend along a given profile with a piece of metal that is as thick as a rail.

She even turned off makes an impression - a big one, almost as tall as a person, smells of oil and with a flower on the side.

And this is the same company, but for flexible sheets:

But the wire EDM machine:

This is "welding the opposite." Brass wire coming from here:

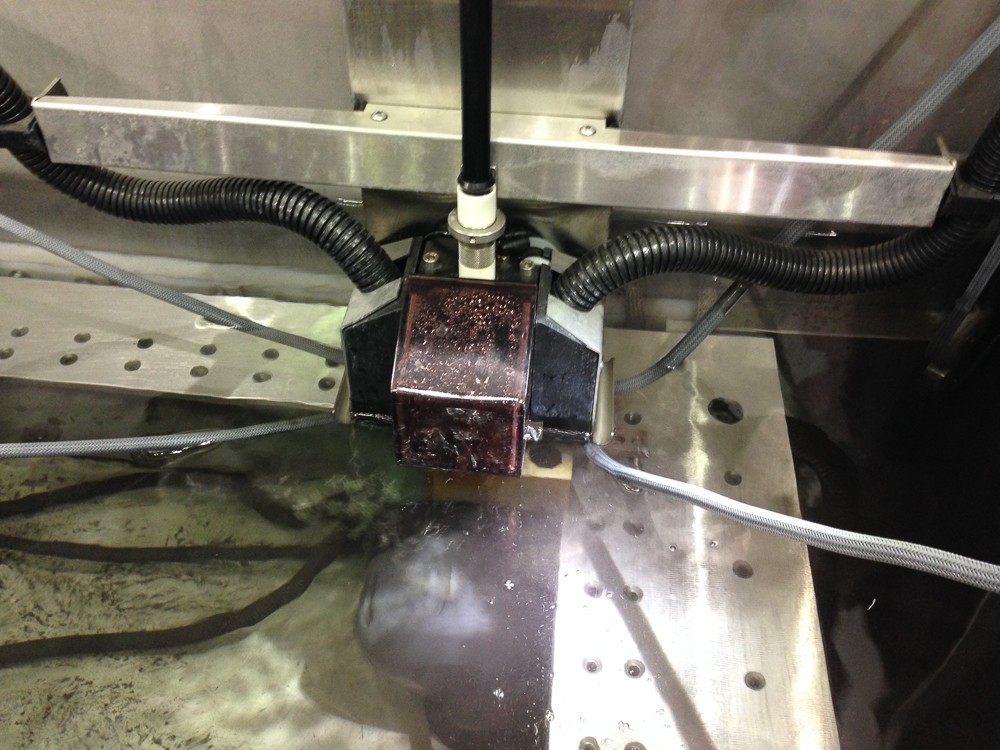

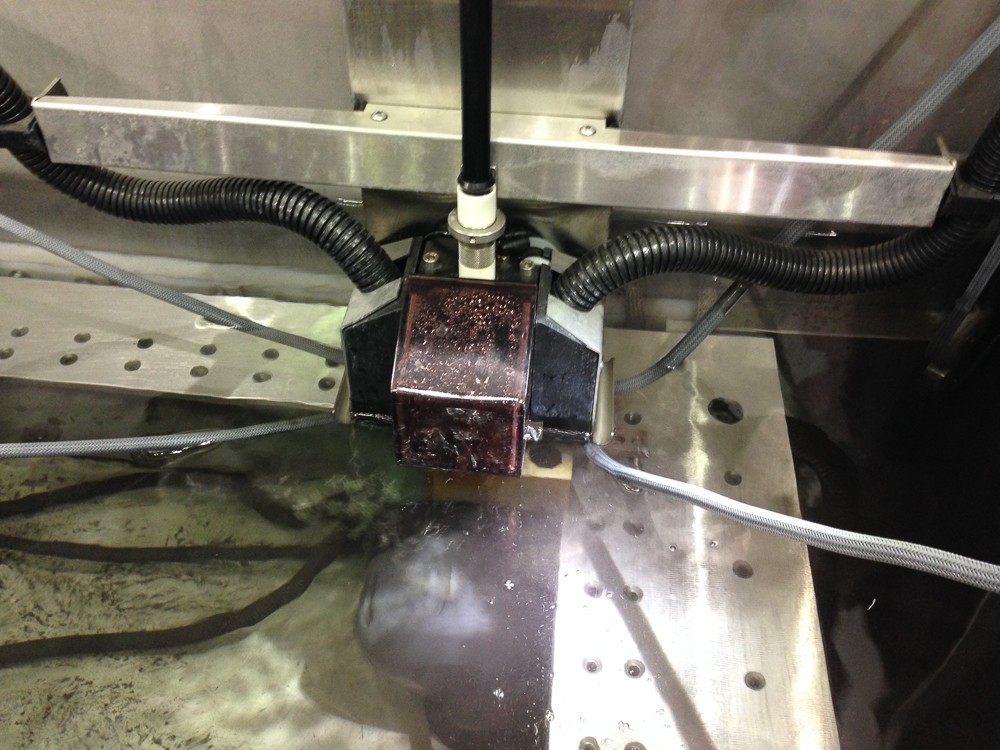

Concerns a part in a liquid dielectric (usually using distilled water):

The generator creates a high-voltage impulse between the wire and the part, as a result of which, a small piece breaks off from the part. This method can very accurately handle any metals without heat and incisors. Only rather slowly.

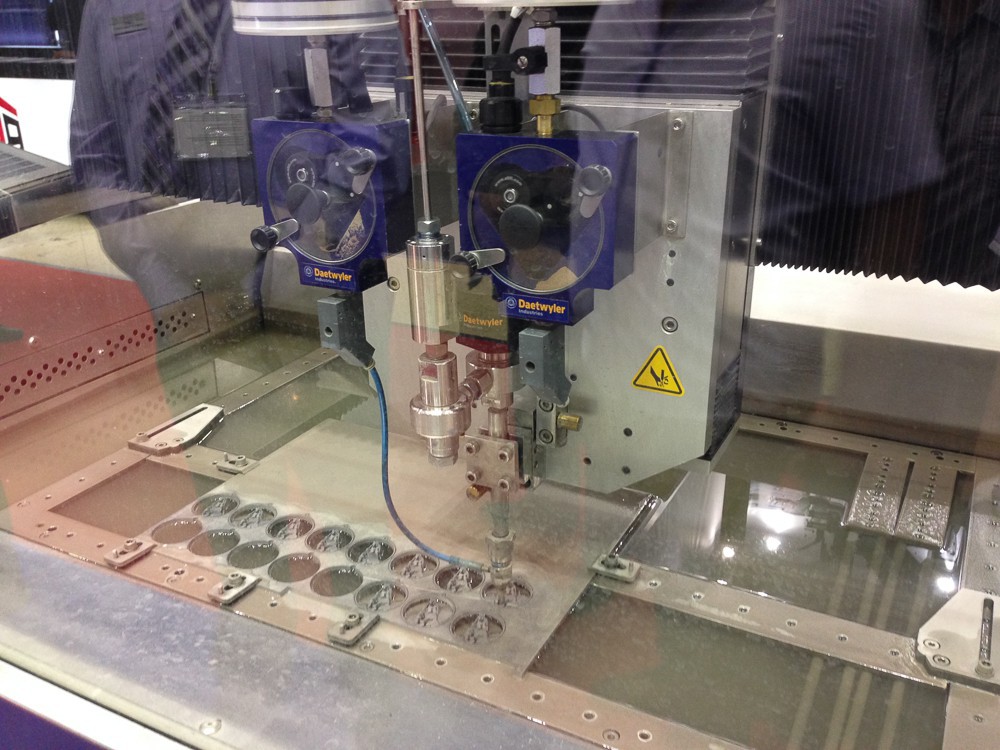

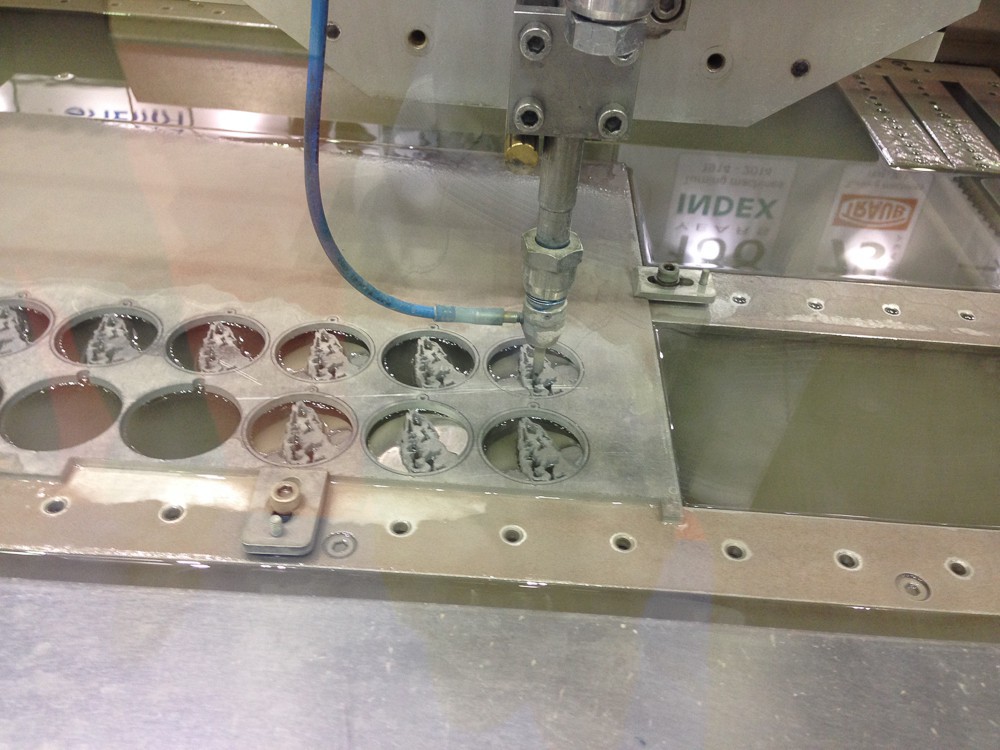

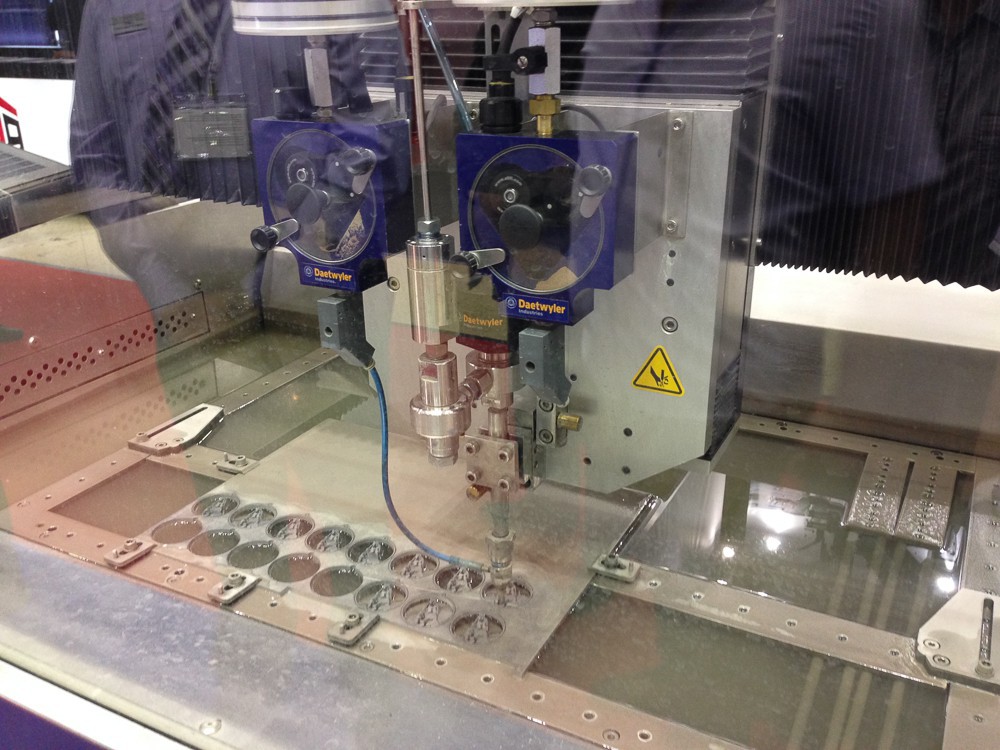

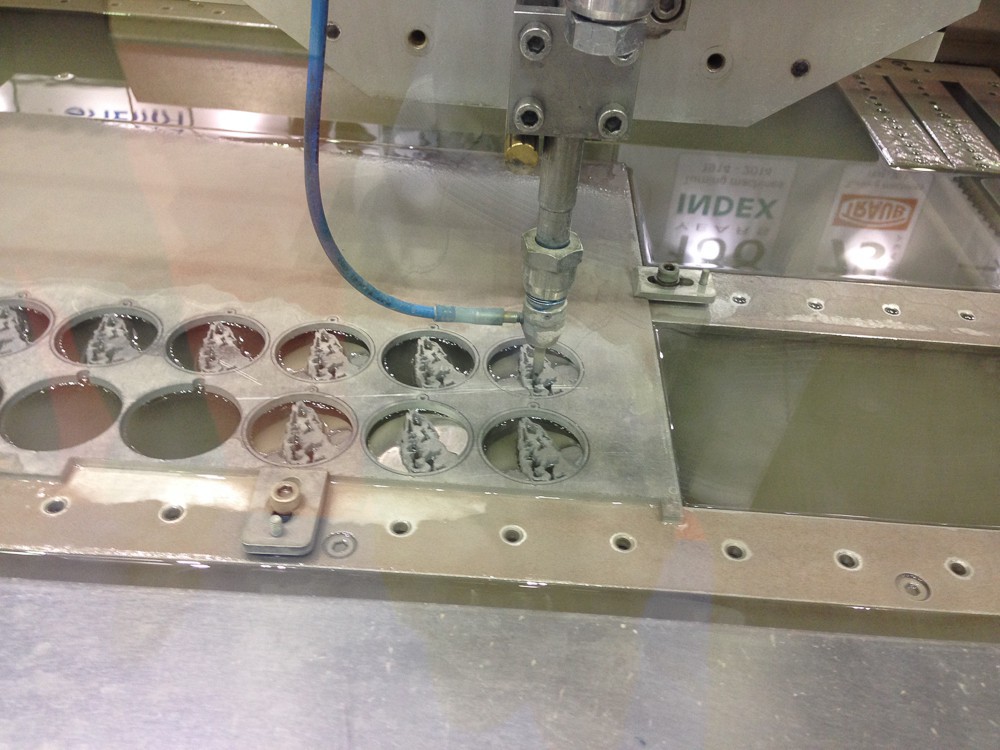

However, metals can be processed in many ways, for example, waterjet cutting :

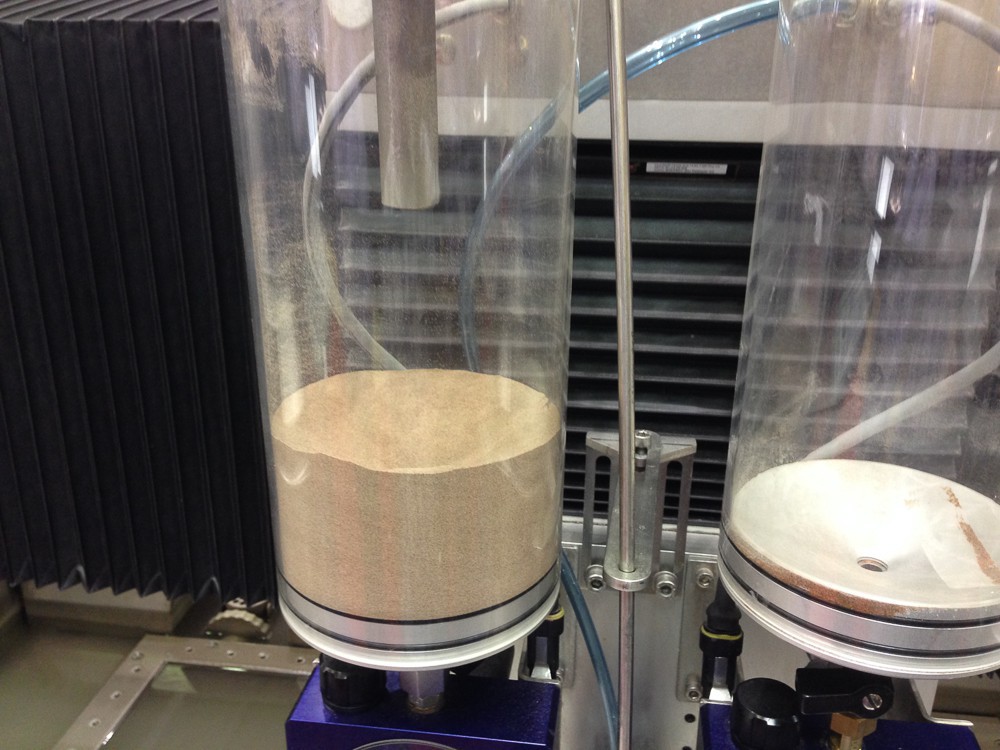

This machine cuts metal, feeding under ultrahigh pressure (4000 atmospheres) and speed with a stream of water with an abrasive - fine garnet sand:

Cutting out any complicated contour in the blank:

Accuracy - 2.5 microns, cutting speed - up to 40 cm per minute, with increasing material thickness, the speed decreases.

It weighs 8 tons, eats from the network 22 kilowatts.

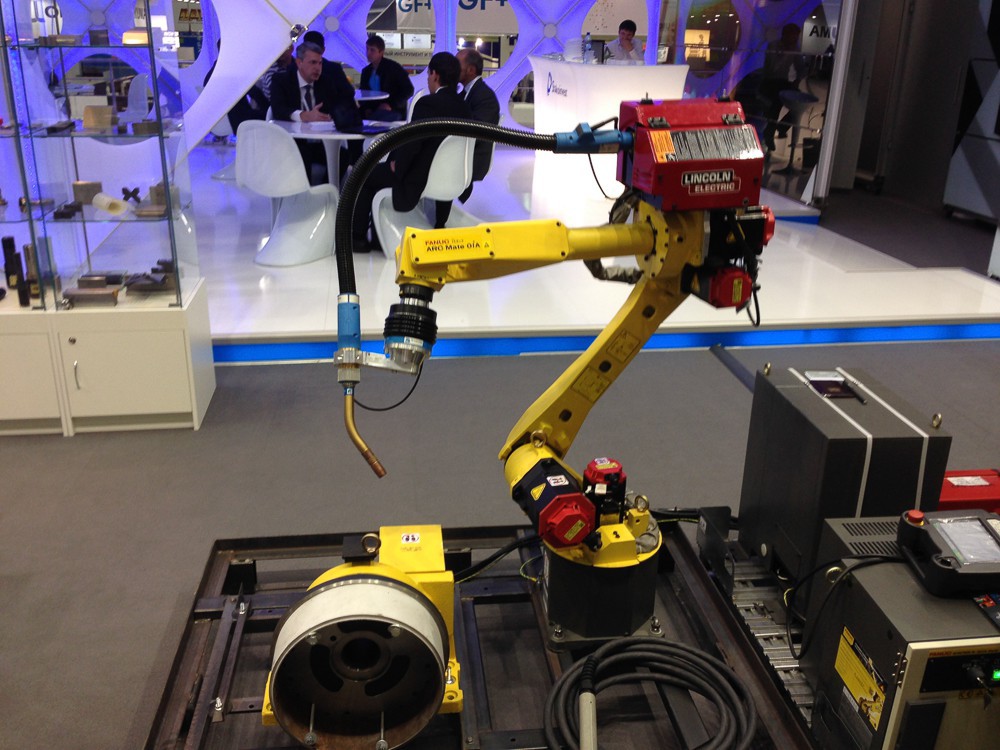

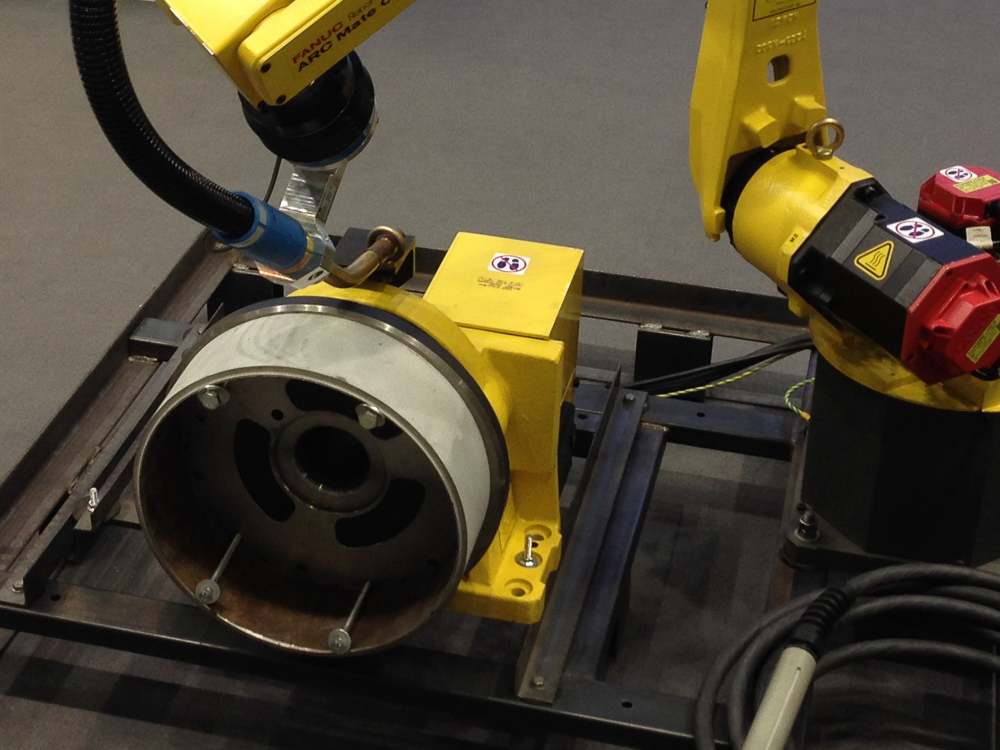

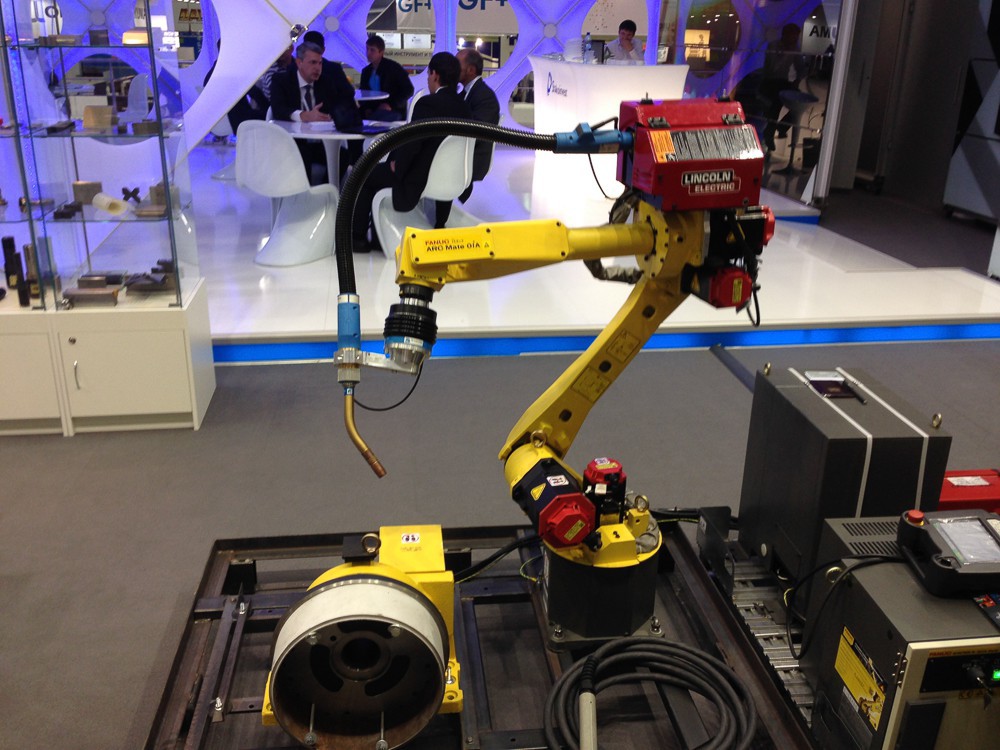

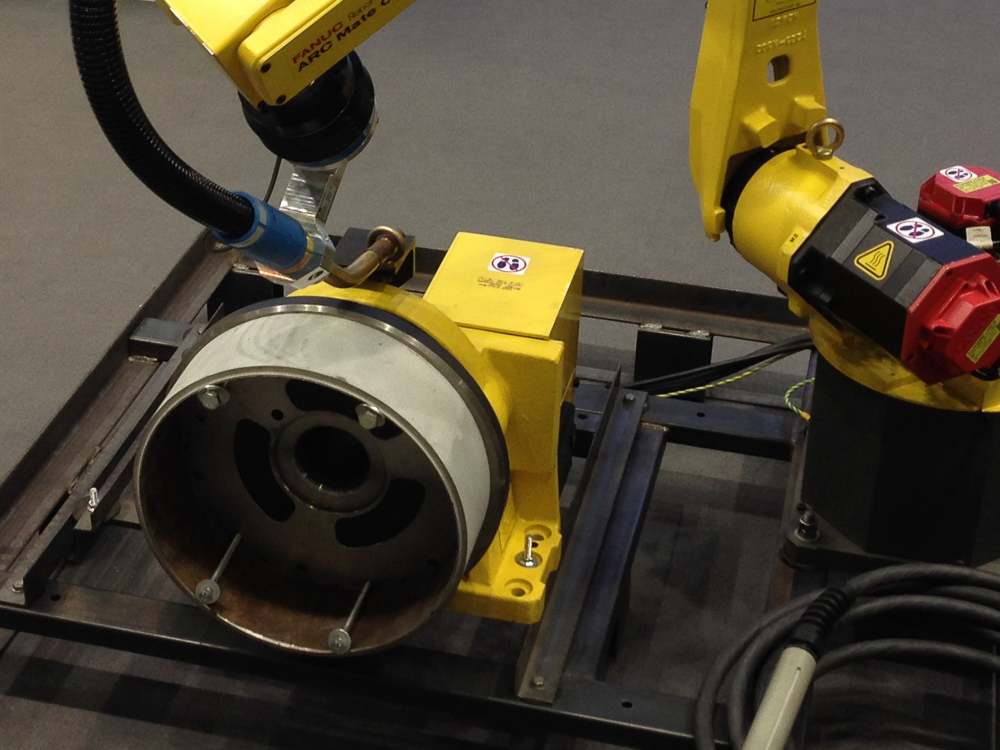

And metals can be welded. If you manually make it lazy, then you can take just such a hand, combined with welding and a turntable (below):

She can crawl through this hole and cook something inside.

I lost the video, so I dragged off Dru4 with similar hands:

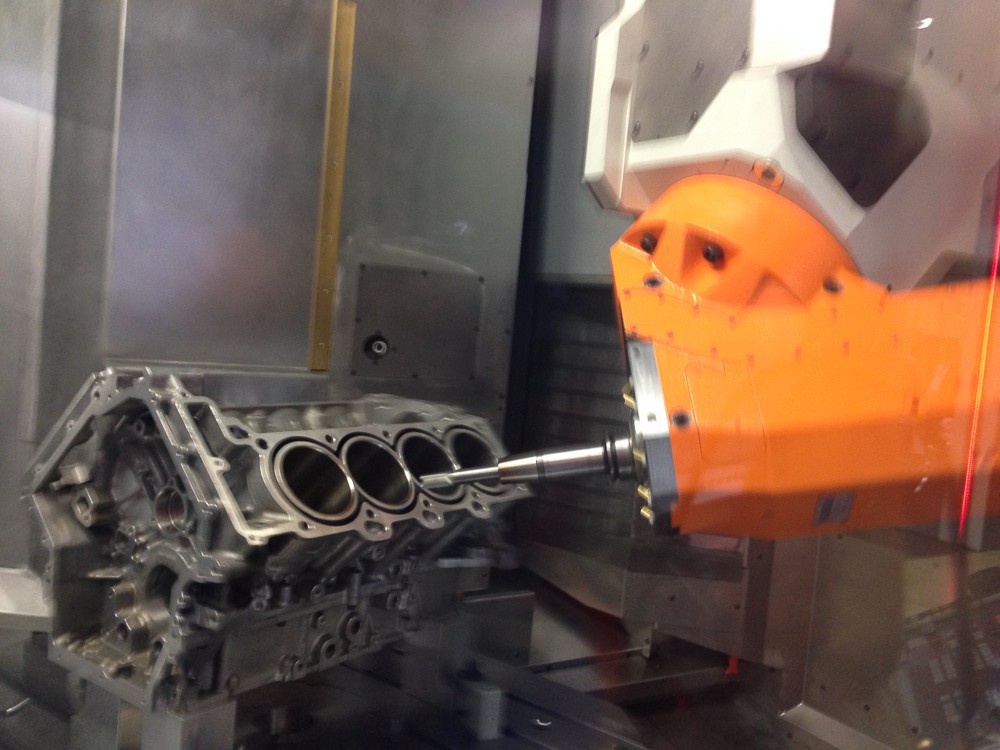

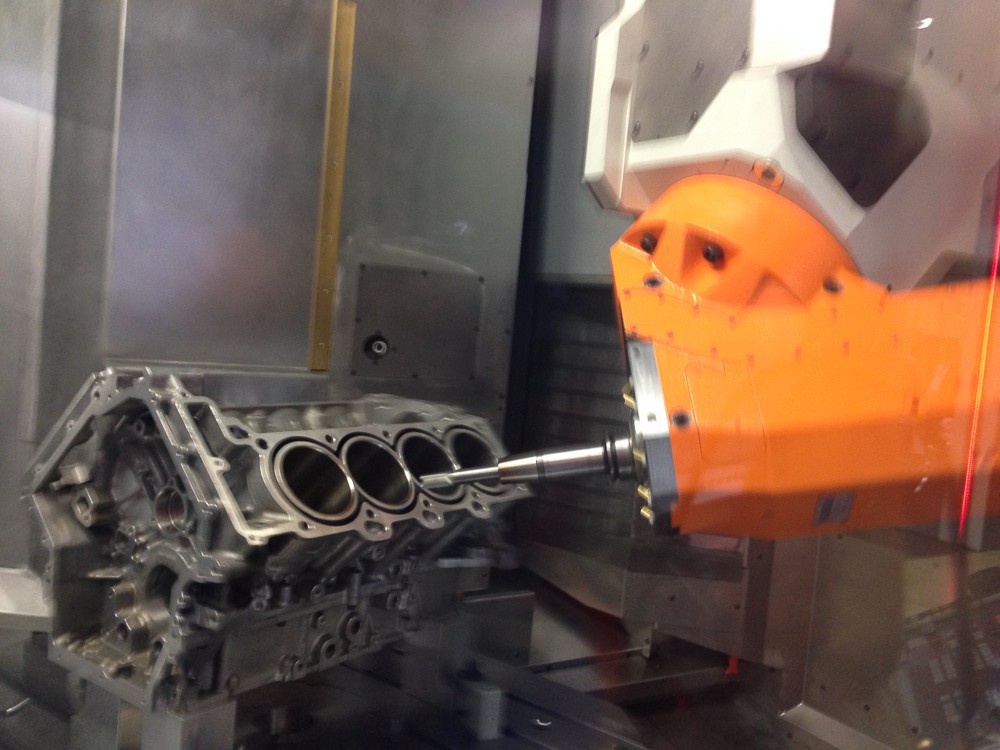

There were also a variety of CNC coordinate machines. I didn’t see such cool ones as on this legendary video, but there were many other, less complex ones. But similar:

This orange fool, despite the large volume and surely the weight, moved so fast that I could not take a picture of it normally.

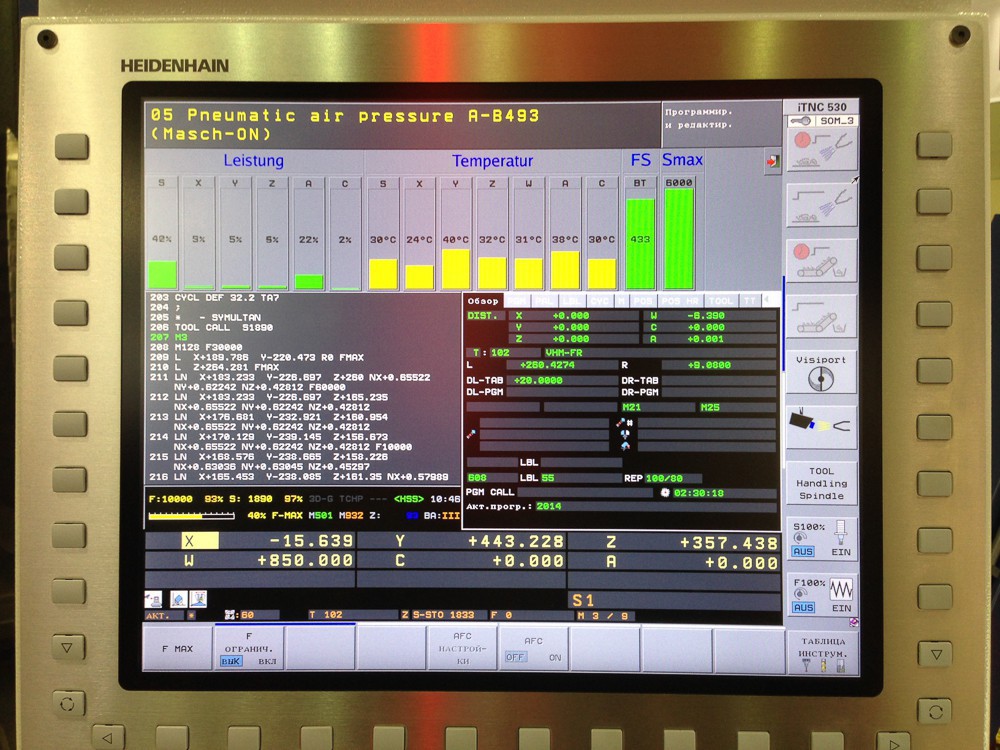

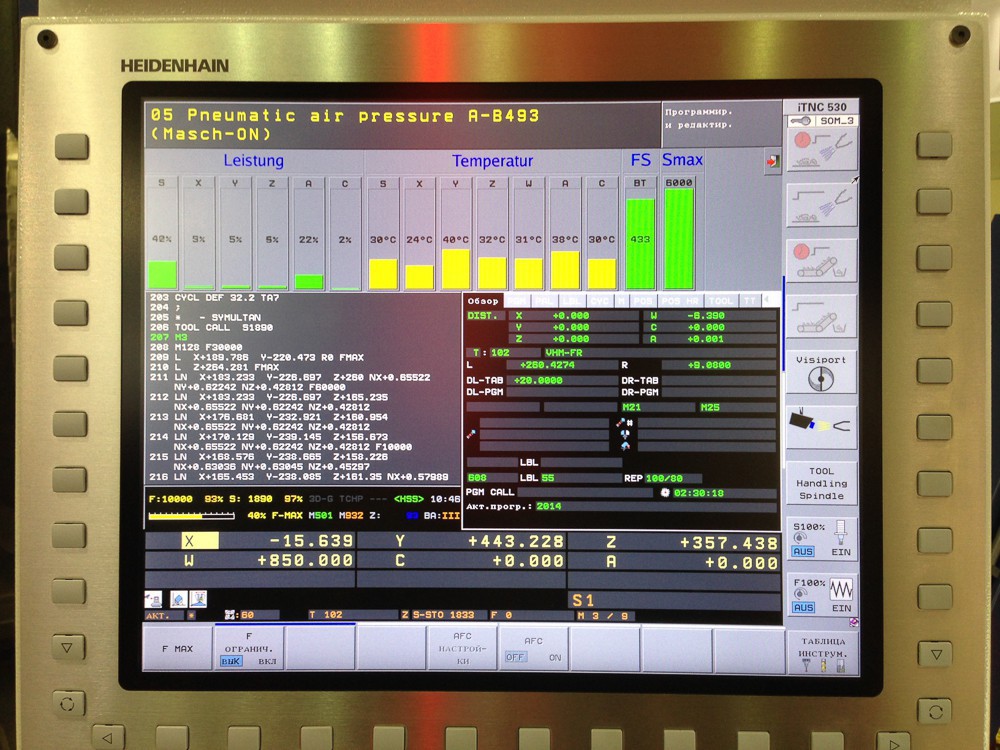

But I could take a picture of the control panel:

Screen closer:

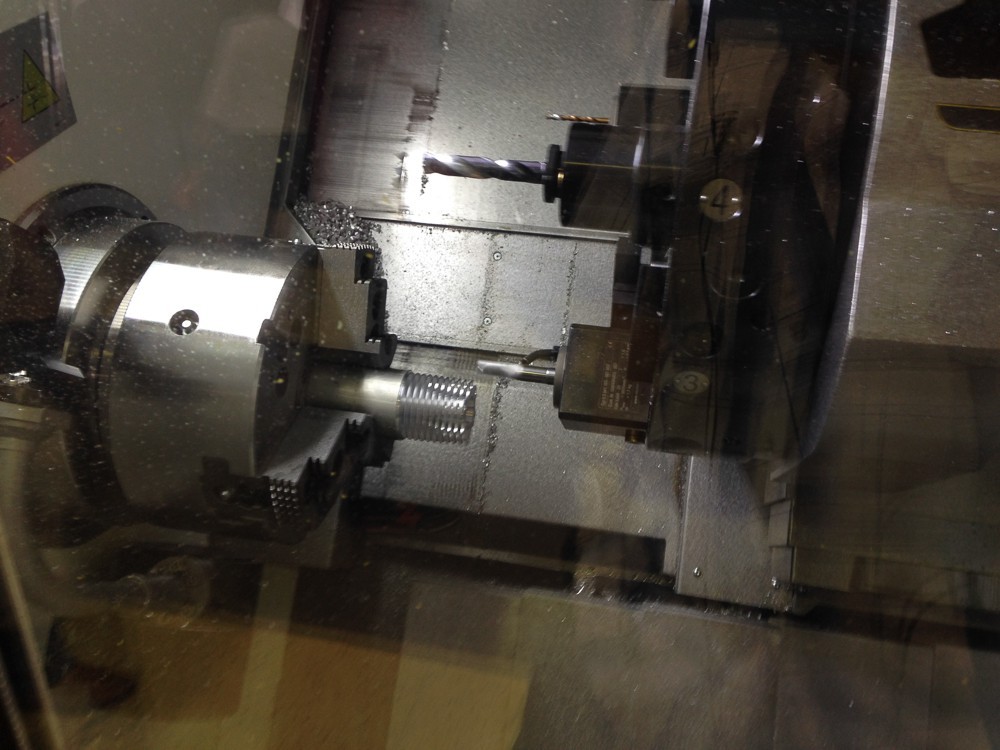

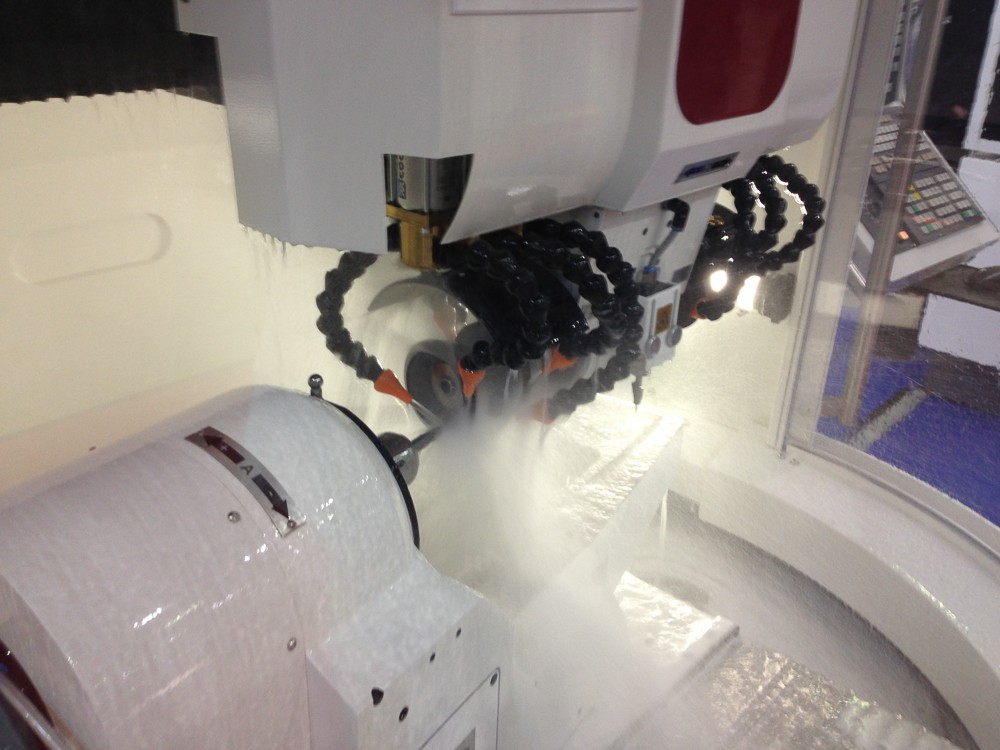

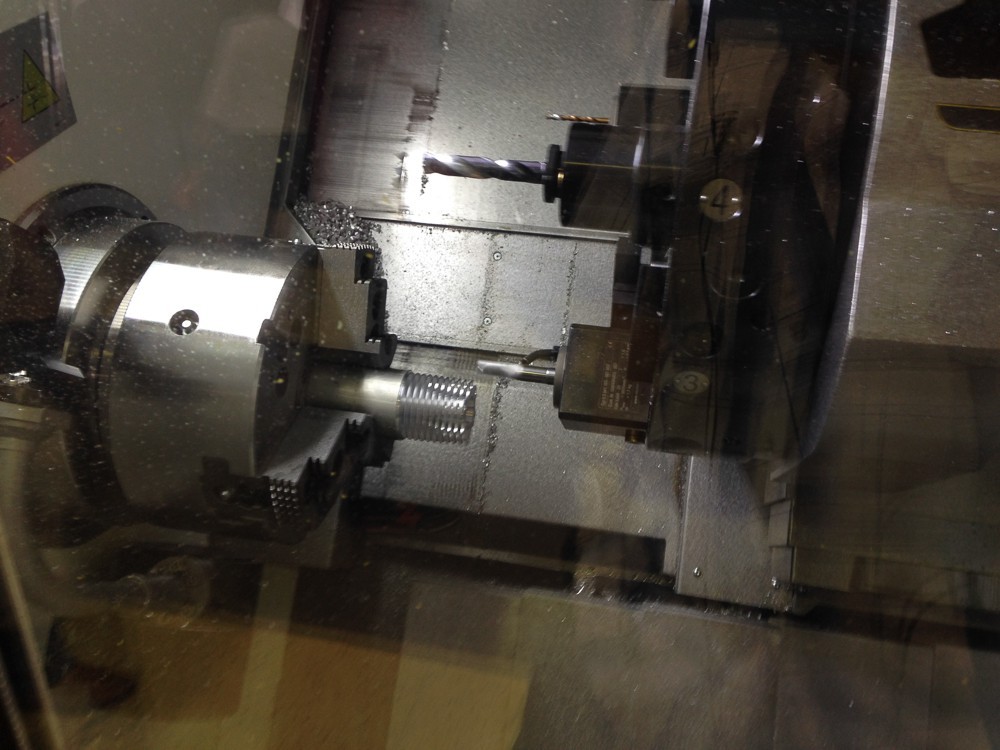

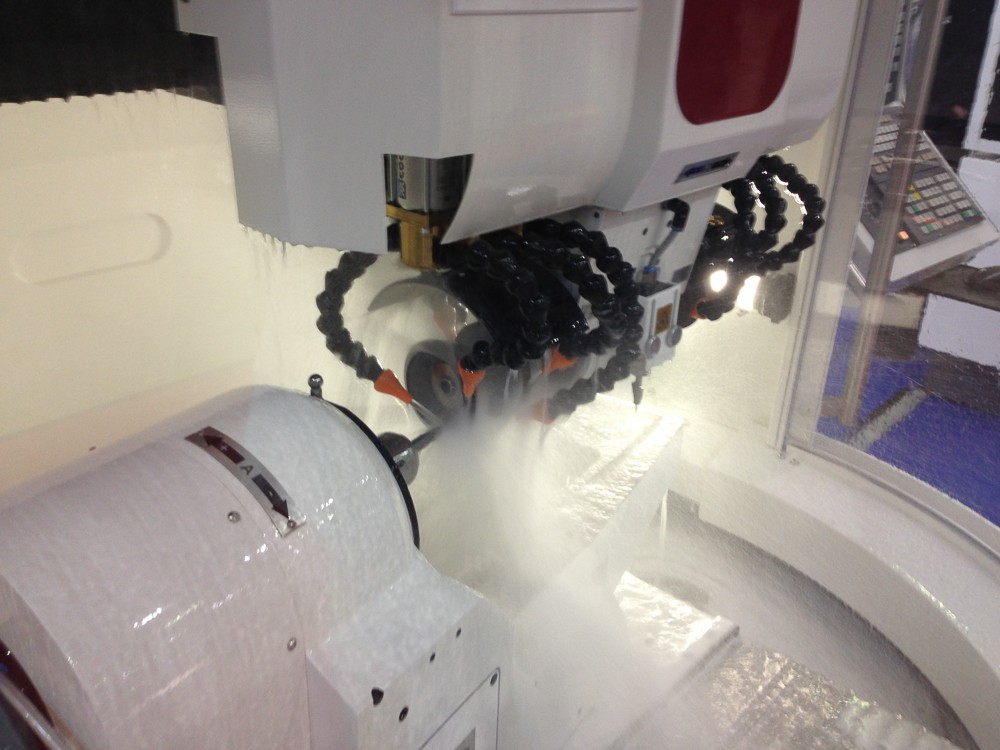

True, she was in demo mode (= moving fast, not cutting anything). But here is this lathe really cut the detail:

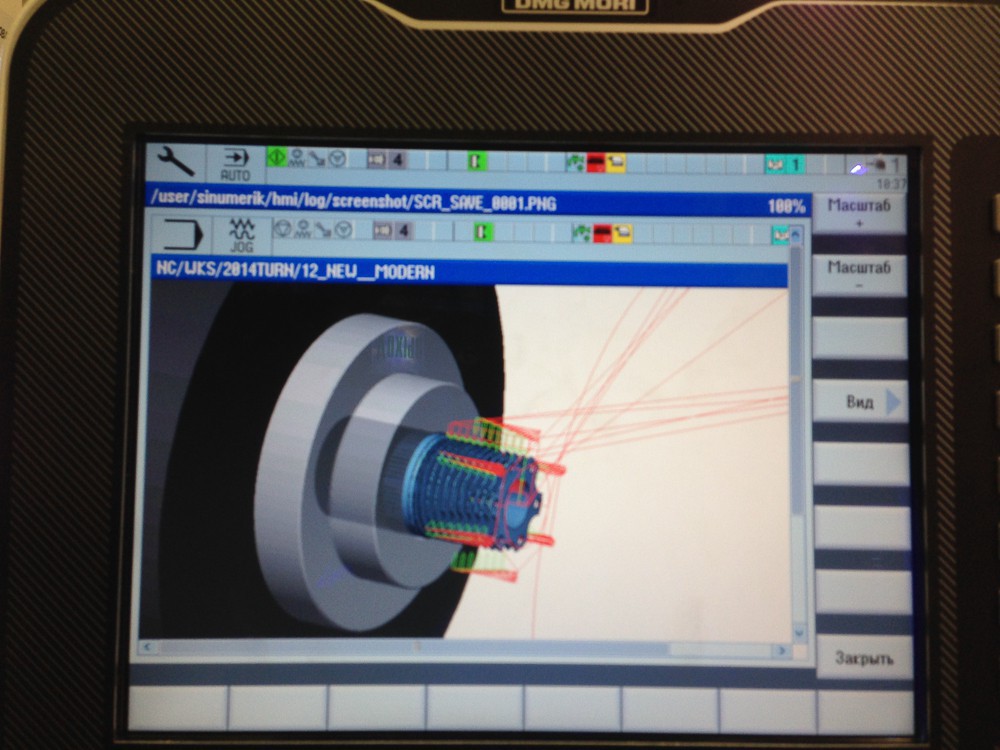

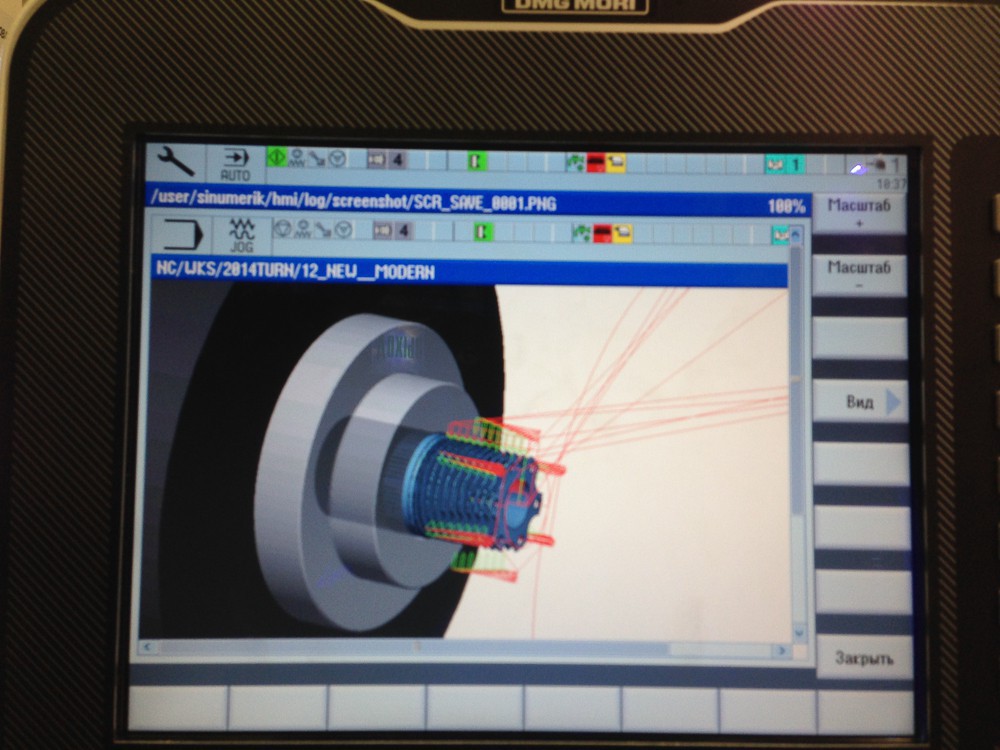

Here the control panel is already more glamorous:

And on the small screen you can see the trajectory of the head:

Such a machine is worth about 5 million rubles.

And this machine looks like a shower:

Because he is part of it:

To facilitate the cut and reduce the temperature of the cutter and parts during the processing of them generous stream pours grease. Generously - because it is reused, the pump below collects the cleaned lubricant and feeds it again to the nozzles.

Another metal can be cut with a laser!

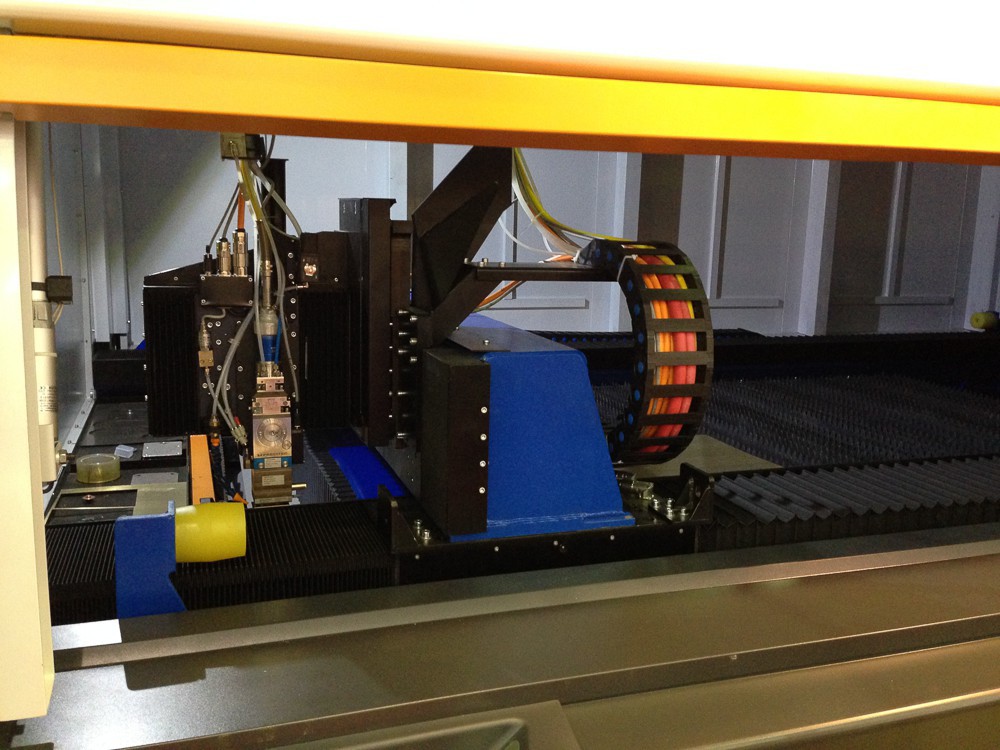

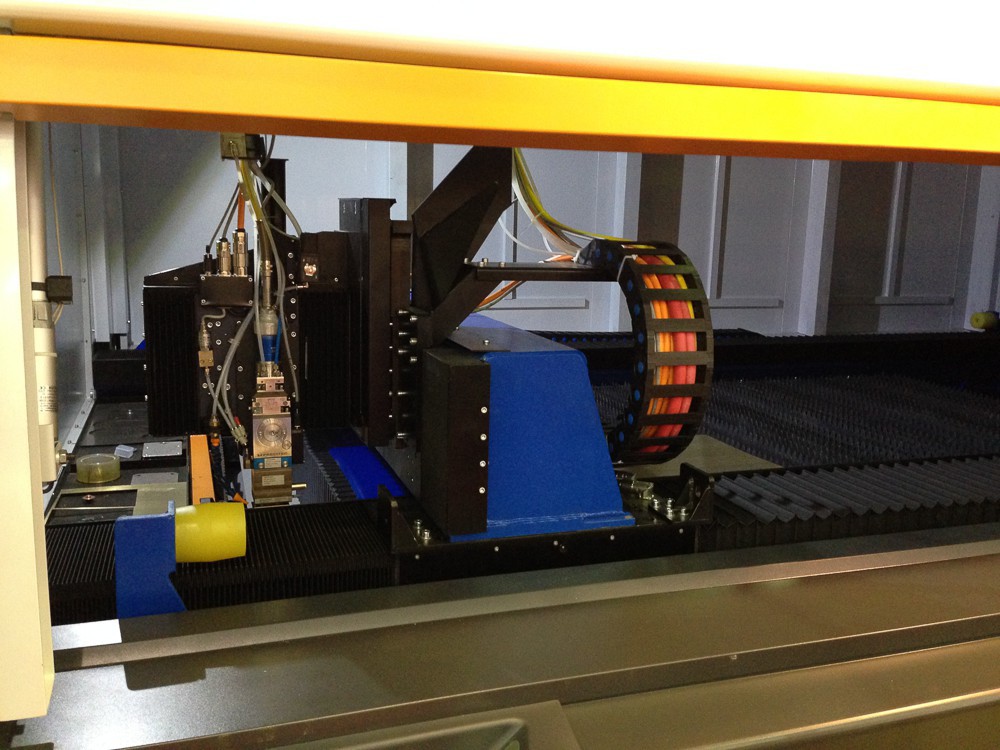

Unfortunately, the cutting process could not be photographed properly, it was dark and there were some flashes. Here are the insides:

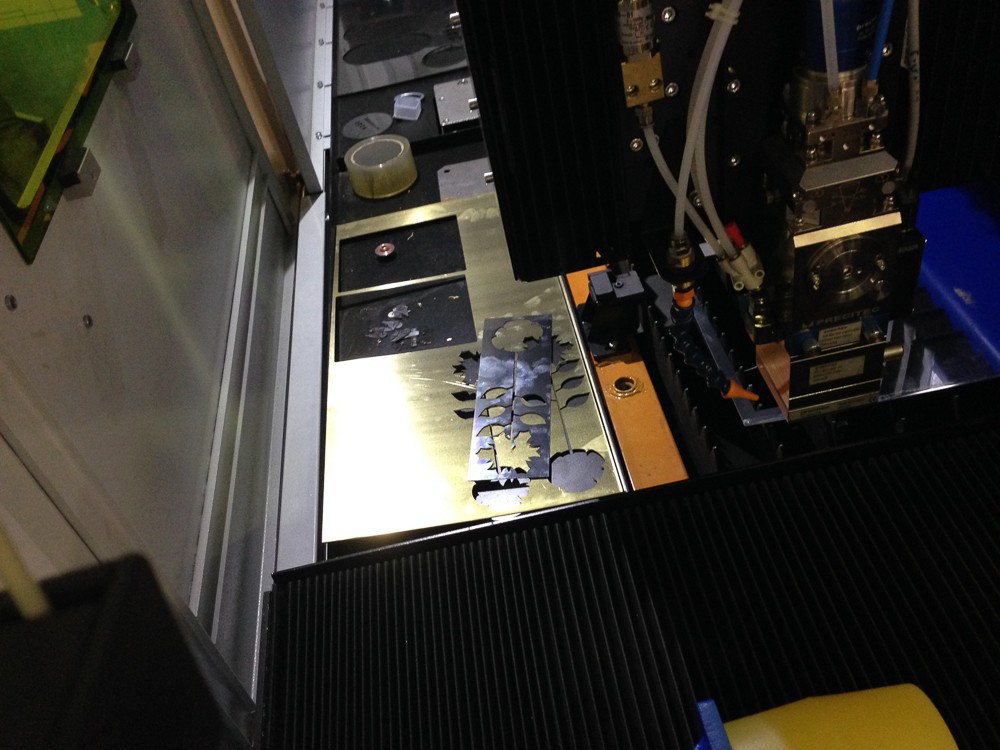

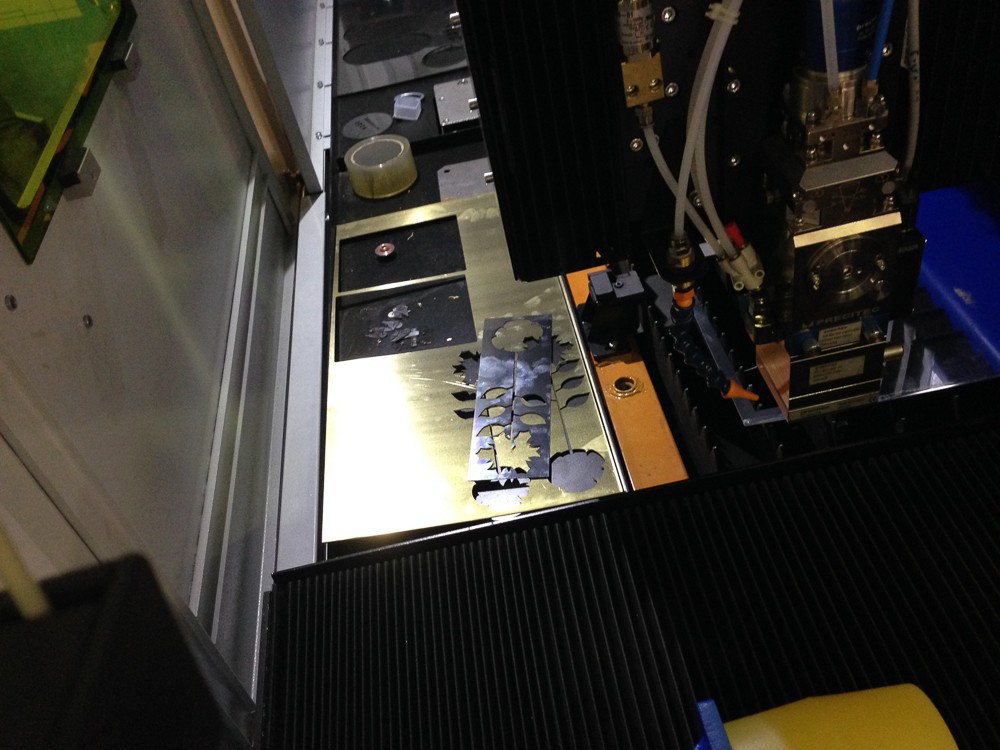

On the side, the thing to which all the tubes converge - this is the laser head. And here are the results of cutting:

And so:

In my opinion, it will be a figure, like this:

Only not from plywood, but from brass.

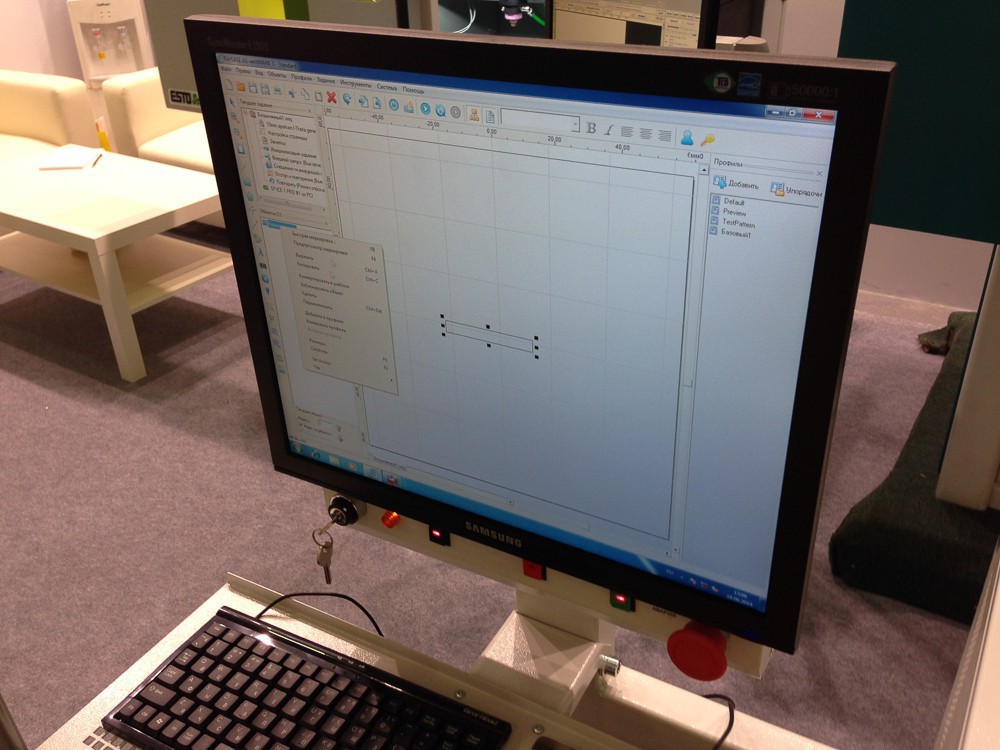

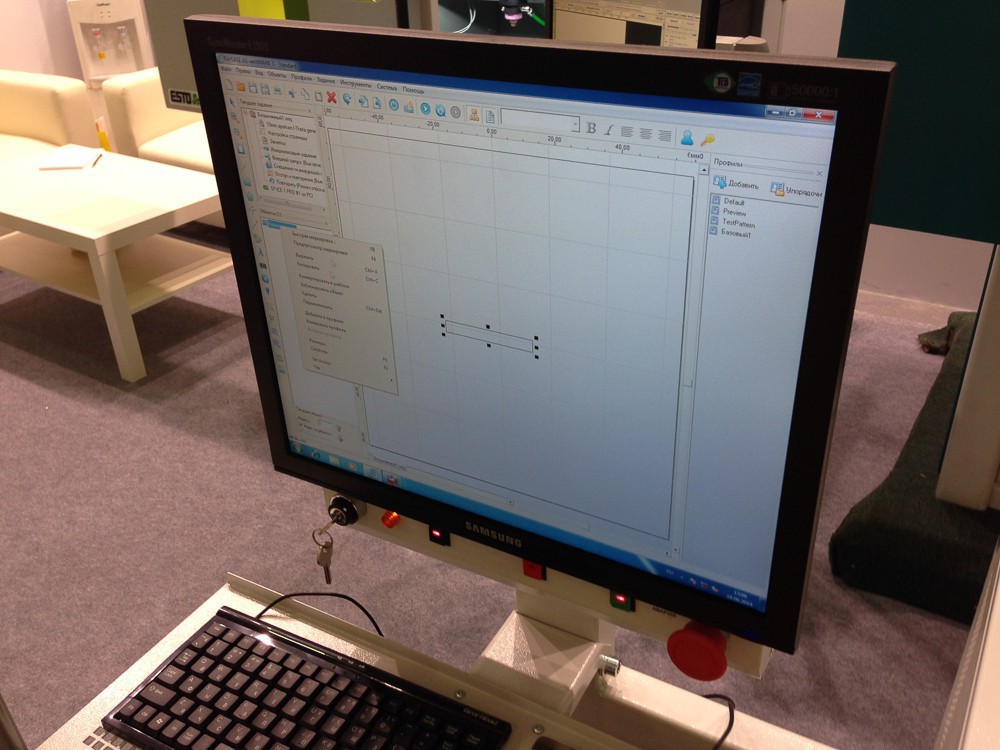

The control panel is a regular computer. Only the keyboard is covered with a metal lining (probably, it was cut on it),

And the USB is closed with a lid:

And metals can be labeled.

But only metals. From metal materials, I found only a carbine and a voice recorder (I forgot about the aluminum laptop. Maybe fortunately)

We put there titanium snap:

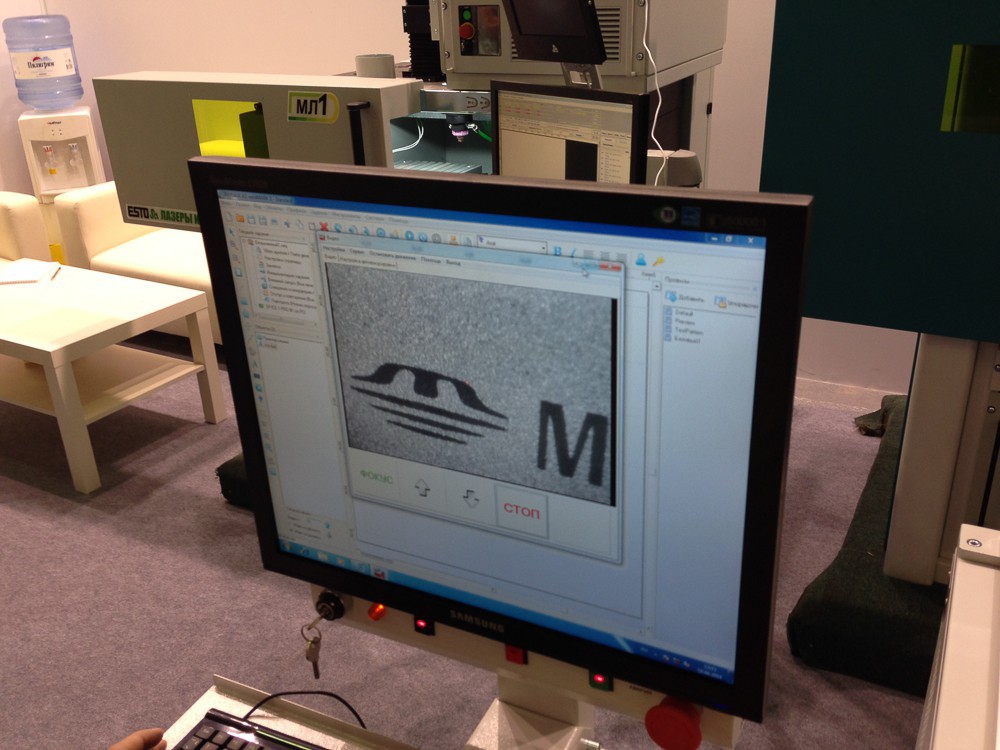

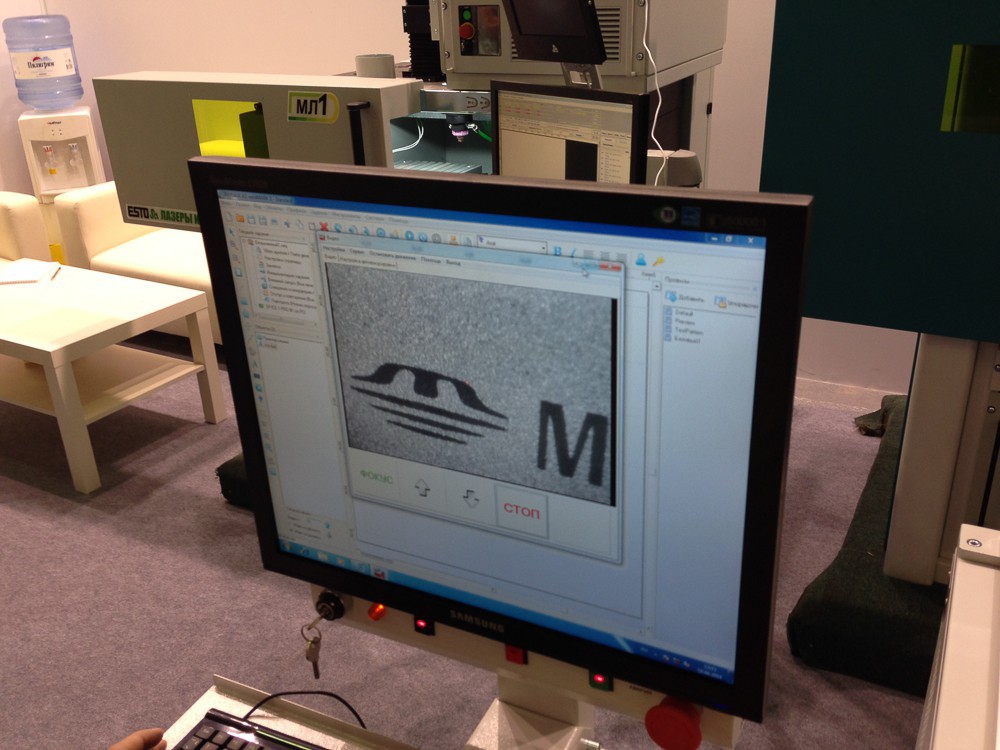

Hover, focus, expose the workspace:

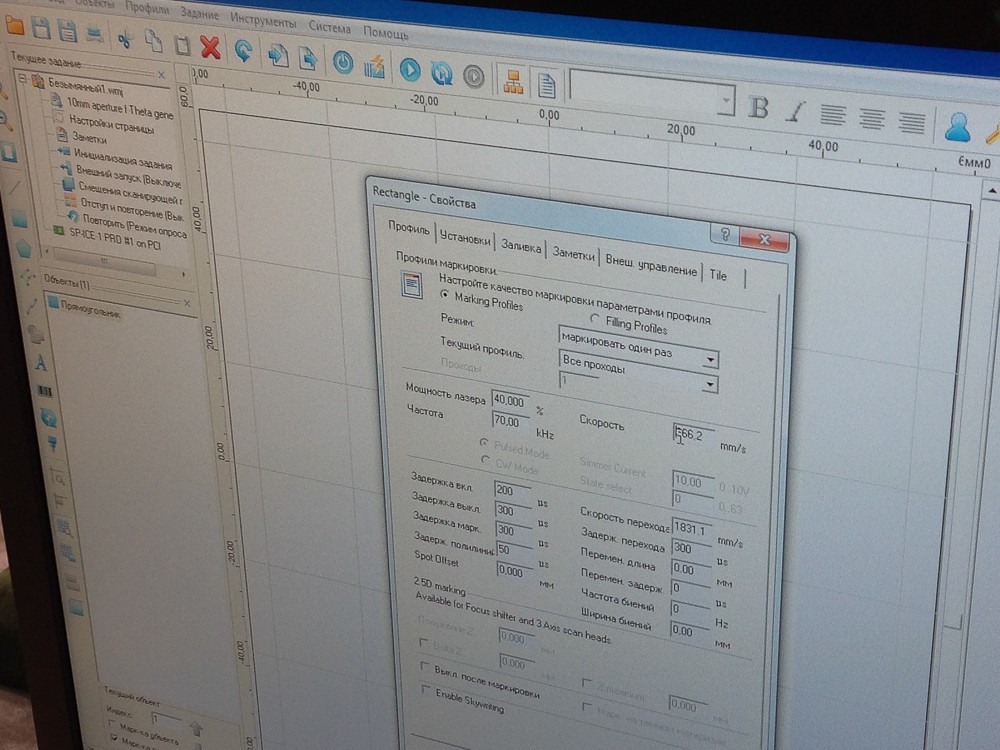

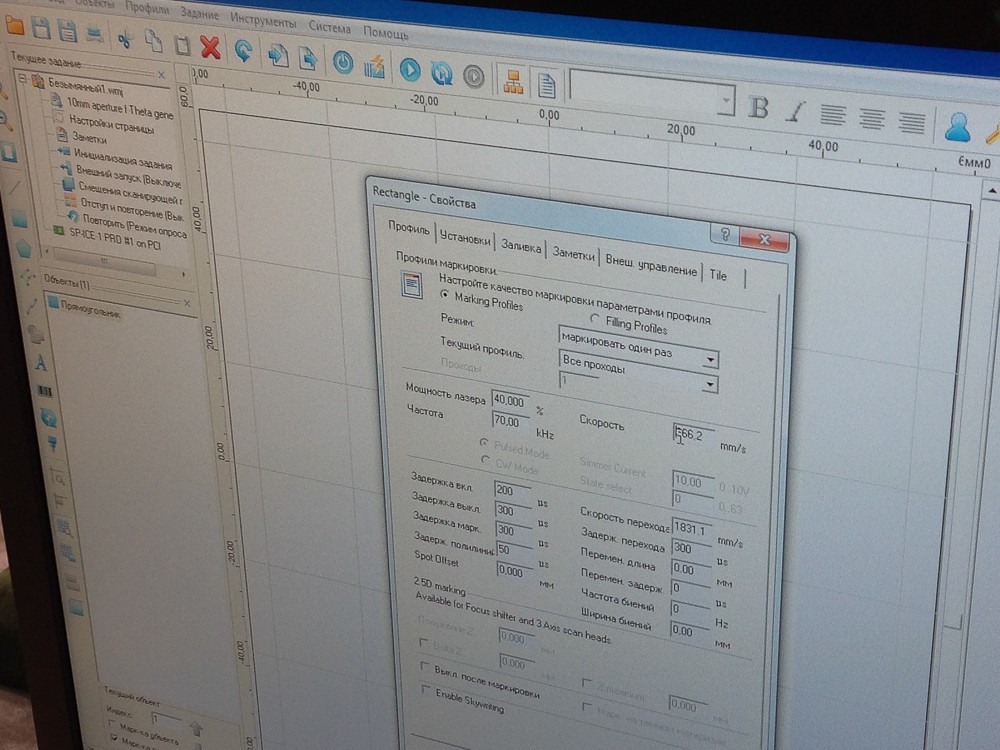

Adjust the laser parameters:

And once!

"Cut" the inscription. In fact - deepened to the level of the inscription. Two - and cut over another inscription:

Put the recorder:

Focusing on:

Run:

We get just such an inscription (but a little oblique, not very smoothly laid)

White inscription because aluminum itself without an oxide film is very light.

I apologize in advance for 800 kilobytes of hyphatism to kata. It will be worse.

Unfortunately, due to lack of time, I visited only one pavilion of 7, but even there was a lot of interesting things.

')

This is how, for example, a wire bending machine with a capital gif looks like:

Can do anything from springs to clips:

Or florets:

Here is what is located on his other side - rotational drive and wire feed:

And the wire itself is unwound from such a reel:

Once again the process of working with better quality:

If you want with sound and without acceleration, then you can see here (by the way, subscribe).

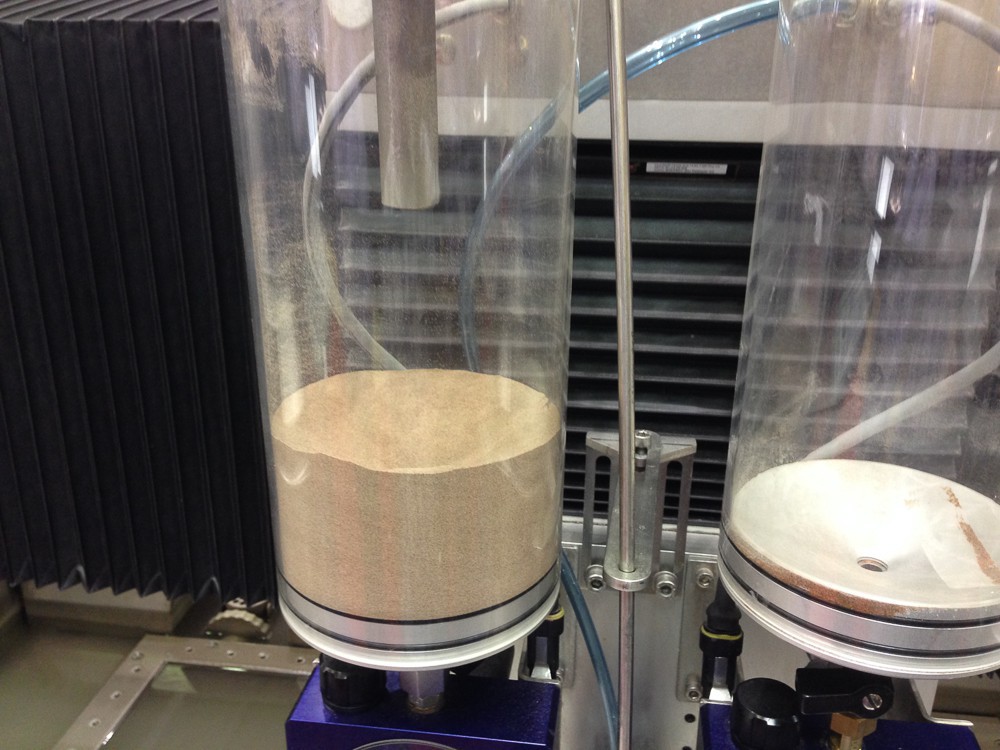

Here are a number of similar machine, but more specialized - sharpened under the springs.

The wire is unwound (from the same coil):

And falls into the workspace:

The result of the work are the springs of various configurations:

But the coordinate measuring machine.

She is committed to poking here such probes:

In different parts. The whole cymes consists in the fact that it can measure the deviation of the surface of the part from the norm up to several microns with a sensor.

And she has a control program adapted for Windows 8!

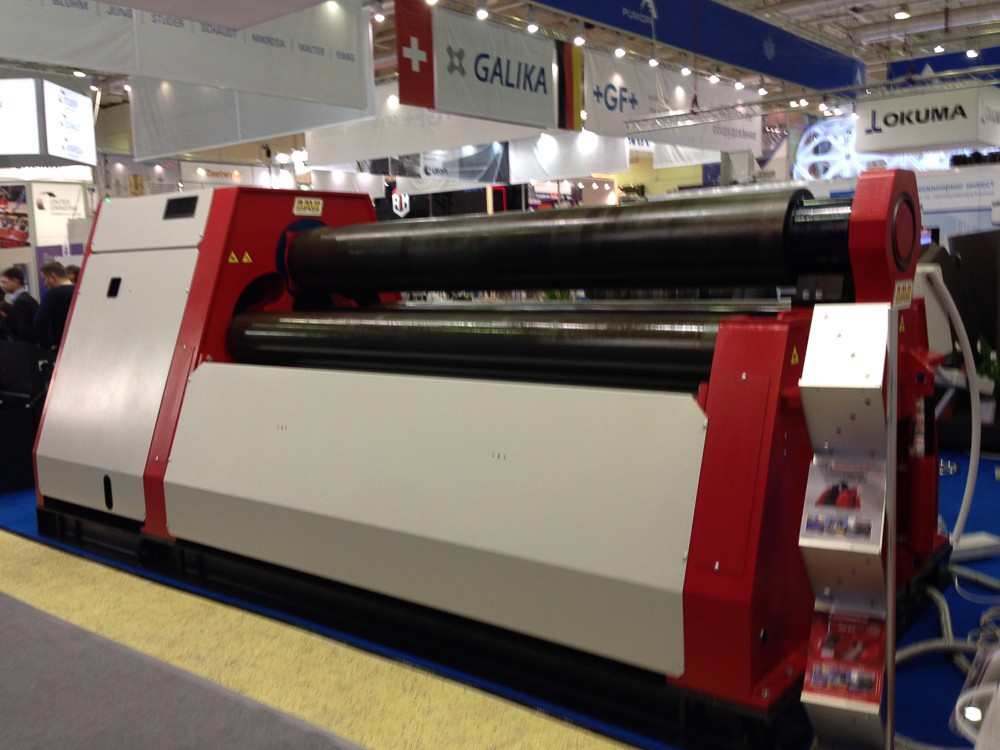

A machine that is hydraulically pressed by the rails. Well, not just the rails, but it will not be difficult for it to bend along a given profile with a piece of metal that is as thick as a rail.

She even turned off makes an impression - a big one, almost as tall as a person, smells of oil and with a flower on the side.

And this is the same company, but for flexible sheets:

But the wire EDM machine:

This is "welding the opposite." Brass wire coming from here:

Concerns a part in a liquid dielectric (usually using distilled water):

The generator creates a high-voltage impulse between the wire and the part, as a result of which, a small piece breaks off from the part. This method can very accurately handle any metals without heat and incisors. Only rather slowly.

However, metals can be processed in many ways, for example, waterjet cutting :

This machine cuts metal, feeding under ultrahigh pressure (4000 atmospheres) and speed with a stream of water with an abrasive - fine garnet sand:

Cutting out any complicated contour in the blank:

Accuracy - 2.5 microns, cutting speed - up to 40 cm per minute, with increasing material thickness, the speed decreases.

It weighs 8 tons, eats from the network 22 kilowatts.

And metals can be welded. If you manually make it lazy, then you can take just such a hand, combined with welding and a turntable (below):

She can crawl through this hole and cook something inside.

I lost the video, so I dragged off Dru4 with similar hands:

There were also a variety of CNC coordinate machines. I didn’t see such cool ones as on this legendary video, but there were many other, less complex ones. But similar:

This orange fool, despite the large volume and surely the weight, moved so fast that I could not take a picture of it normally.

But I could take a picture of the control panel:

Screen closer:

True, she was in demo mode (= moving fast, not cutting anything). But here is this lathe really cut the detail:

Here the control panel is already more glamorous:

And on the small screen you can see the trajectory of the head:

Such a machine is worth about 5 million rubles.

And this machine looks like a shower:

Because he is part of it:

To facilitate the cut and reduce the temperature of the cutter and parts during the processing of them generous stream pours grease. Generously - because it is reused, the pump below collects the cleaned lubricant and feeds it again to the nozzles.

Another metal can be cut with a laser!

Unfortunately, the cutting process could not be photographed properly, it was dark and there were some flashes. Here are the insides:

On the side, the thing to which all the tubes converge - this is the laser head. And here are the results of cutting:

And so:

In my opinion, it will be a figure, like this:

Only not from plywood, but from brass.

The control panel is a regular computer. Only the keyboard is covered with a metal lining (probably, it was cut on it),

And the USB is closed with a lid:

And metals can be labeled.

But only metals. From metal materials, I found only a carbine and a voice recorder (I forgot about the aluminum laptop. Maybe fortunately)

We put there titanium snap:

Hover, focus, expose the workspace:

Adjust the laser parameters:

And once!

"Cut" the inscription. In fact - deepened to the level of the inscription. Two - and cut over another inscription:

Put the recorder:

Focusing on:

Run:

We get just such an inscription (but a little oblique, not very smoothly laid)

White inscription because aluminum itself without an oxide film is very light.

Source: https://habr.com/ru/post/227081/

All Articles