Biomass from biomass

Today I will talk about how for four years we, in Tomsk, “immersed” in the biogas topic. In the literal and figurative sense. What has been done and what future prospects for such technology I propose to discuss together.

Today I will talk about how for four years we, in Tomsk, “immersed” in the biogas topic. In the literal and figurative sense. What has been done and what future prospects for such technology I propose to discuss together.Attention! The post contains materials that may not be pleasant to impressionable people!

')

What is biogas?

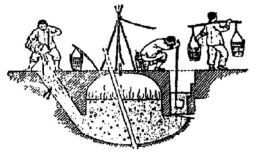

The process of biomass processing into biogas [1] is to place biological waste (manure, wastewater treatment plants, beer bard, etc.) in containers called fermenters. Such a container should be tightly closed to ensure the oxygen-free fermentation of waste, which must be mixed from time to time. The process temperature should be 35-55 gr. A few weeks later, combustible gas will start to be released from the fermenters - a mixture of methane and carbon dioxide with small amounts of hydrogen sulfide. This gas is called biogas . The concentration of methane in it is 50-60%. If biogas is cleaned of impurities and CO2, we get biomethane. Full analogue of natural gas. The process of obtaining biogas has its own characteristics, but in general the technology is quite simple. So it seemed to us at first glance, but the devil lurked in the details ...

Raw materials for biogas process

It turns out that not all raw materials can be immediately used for processing. Chicken droppings and pork drains are very toxic, so you need to add buffer substances such as silage, fresh grass or cow manure. Raw materials should not contain significant impurities of heavy metals, chemicals, surfactants.

In real production, antibiotics are actively used, which are clearly not advertised, but they are used in large quantities. Detergents and disinfectants can also disrupt the process of biogas synthesis. If you do not use disinfectants at all - there is a mold (photo). Additional difficulties include imperfect manure removal systems. Nuts, nails, wires and even bricks are constantly found in raw materials. All this can easily ditch fecal pumps, mixers or clog pipelines. The biogas process does not like seasonal fluctuations in animal feeding. Also requires constant monitoring of the station's operating modes and control of many more factors. And, of course, Russian chance. Historical factor, not predictable. Also in Russia there is a rather cold climate for this technology. Especially beyond the Urals and in Siberia. But this is not all the problems ...

In real production, antibiotics are actively used, which are clearly not advertised, but they are used in large quantities. Detergents and disinfectants can also disrupt the process of biogas synthesis. If you do not use disinfectants at all - there is a mold (photo). Additional difficulties include imperfect manure removal systems. Nuts, nails, wires and even bricks are constantly found in raw materials. All this can easily ditch fecal pumps, mixers or clog pipelines. The biogas process does not like seasonal fluctuations in animal feeding. Also requires constant monitoring of the station's operating modes and control of many more factors. And, of course, Russian chance. Historical factor, not predictable. Also in Russia there is a rather cold climate for this technology. Especially beyond the Urals and in Siberia. But this is not all the problems ...I do not recommend reading this to impressionable people.

Why is all this necessary? For all the time I have been working on this project, hundreds of people have asked me this question. Indeed, biogas technologies are very expensive, profitability is extremely low, there are no specialists and good technologies. All this would seem so. But I would not position biogas technologies as energy ones. Their main trump card is the environmental recycling of waste with the production of bio-fertilizers and the burning of biogas for heat generation. We are a cold country, so the heat will always be relevant. Now our group is focused precisely in these areas. And the problem of waste processing and the environmental situation around large livestock farms in Russia is simply catastrophic. A little help. In the Tomsk region (which is not agrarian, compared to the same Altai Territory) about 2.6 million tons of waste are released annually.  That is about 5.6 thousand tons per day or 120 railway cars. In most cases, this is the so-called non-managed waste, which is poured into the lagoons and formed into piles, producing an unbearable stench within a radius of tens of kilometers. Nobody takes out manure too much and cares little for animals. Sometimes cows stand on their belly in their own fecal fluid for weeks. I am a person, though not very impressionable, but seeing this was just shocked. If there is at least some kind of look behind the dairy cows, then the rejection of livestock and weak animals stand for months in the hope of being quickly hammered into sausage in order to stop their own torment. Some animals rot legs to the bone. I did not insert such photos into the post. Colleagues strongly discouraged. Of course, there are exemplary farms, but they are extremely few.

That is about 5.6 thousand tons per day or 120 railway cars. In most cases, this is the so-called non-managed waste, which is poured into the lagoons and formed into piles, producing an unbearable stench within a radius of tens of kilometers. Nobody takes out manure too much and cares little for animals. Sometimes cows stand on their belly in their own fecal fluid for weeks. I am a person, though not very impressionable, but seeing this was just shocked. If there is at least some kind of look behind the dairy cows, then the rejection of livestock and weak animals stand for months in the hope of being quickly hammered into sausage in order to stop their own torment. Some animals rot legs to the bone. I did not insert such photos into the post. Colleagues strongly discouraged. Of course, there are exemplary farms, but they are extremely few.

That is about 5.6 thousand tons per day or 120 railway cars. In most cases, this is the so-called non-managed waste, which is poured into the lagoons and formed into piles, producing an unbearable stench within a radius of tens of kilometers. Nobody takes out manure too much and cares little for animals. Sometimes cows stand on their belly in their own fecal fluid for weeks. I am a person, though not very impressionable, but seeing this was just shocked. If there is at least some kind of look behind the dairy cows, then the rejection of livestock and weak animals stand for months in the hope of being quickly hammered into sausage in order to stop their own torment. Some animals rot legs to the bone. I did not insert such photos into the post. Colleagues strongly discouraged. Of course, there are exemplary farms, but they are extremely few.

That is about 5.6 thousand tons per day or 120 railway cars. In most cases, this is the so-called non-managed waste, which is poured into the lagoons and formed into piles, producing an unbearable stench within a radius of tens of kilometers. Nobody takes out manure too much and cares little for animals. Sometimes cows stand on their belly in their own fecal fluid for weeks. I am a person, though not very impressionable, but seeing this was just shocked. If there is at least some kind of look behind the dairy cows, then the rejection of livestock and weak animals stand for months in the hope of being quickly hammered into sausage in order to stop their own torment. Some animals rot legs to the bone. I did not insert such photos into the post. Colleagues strongly discouraged. Of course, there are exemplary farms, but they are extremely few.Weak points of biogas technology

The weakest point in the biogas process is the low rate of biomass processing and the quality of biogas produced. The process is actually unstable and capricious. Due to the low processing speed, huge fermenters are required. This leads to significant capital expenditures on the construction of waste treatment plants and, as a result, such projects pay off for a long time and require state subsidies. All the leading countries of this industry, such as Germany and most European countries, went the way of state support of biogas producers. The form of such support is implemented in the "green" tariff - i.e. purchasing electricity and heat at inflated prices. This important mechanism of state support stimulated manufacturers at the initial stage, but later led to the stagnation of the industry from a technical point of view, as the biogas equipment manufacturers did not particularly care about the quality and new technologies. And so everyone bought. But times are changing. The crisis of the industry will be enormous as soon as the measures of state support are curtailed, as many European countries have already stated, which has led to the emergence of many lawsuits by investors [2]. Therefore, in the near future, I expect a boom in offers for the sale of obsolete biogas technologies to Russia, where this industry is underdeveloped, and government subsidies will be huge in it. This is a very dangerous trend that should not be allowed. The biogas market in Russia may remain for Russian companies, but these companies must support scientific research in order to get a leading technical reserve in biogas technology. And this, in the first place, is associated with a significant acceleration of the biogas process. Also in Russia there must be a climate-adapted technology that can be used up to Siberia.

Inventing the bicycle again ...

In order to really have significant competitive advantages over existing European technologies in Russia, it is necessary to create a biogas technology that

1. 50% increase in the rate of biomass processing into biogas

2. At least 15% increase in the concentration of methane in biogas directly in the fermenter, regardless of the type and quality of raw materials compared to classical technologies

3. At a minimum, it will not lead to an increase in cost, but as a maximum, it will reduce capital expenditures when scaling up technology to an industrial scale

4. The technology should be resistant to climatic conditions up to the Siberian region

These are the minimum requirements that will reduce the risks of investors and improve the competitiveness and economic efficiency of industrial biogas facilities.

Scientific approach to the problem

In Russia, there are a number of research groups working to improve biogas technologies and adapt them to Russian conditions. Such activities are carried out, in particular, by specialists of the Belgorod Institute of Alternative Energy [3]. This is perhaps the most successful example of the approach to work on solving problems in the field of renewable energy (RES). However, such examples and scientific groups should be more and they should be united in a kind of scientific community, which sets standards and offers advanced technologies, taking into account international experience and domestic developments. At the same time, efficient biogas technology must be accompanied by

1. Sample preparation of raw materials (transfer systems, ultrasonic disinfection, sterilization, etc.)

2. Process control (industrial controllers adapted to such tasks, SCADA systems, etc.)

3. Systems and technologies for monitoring the composition of biogas (modern gas analyzers, sensors, sensors)

4. Systems and technologies for utilization of low-calorie biogas (efficient gas boilers, boilers, electricity generators)

5. Environmental Monitoring Systems

6. Biogas purification systems to biomethane

7. Research and technologies for the use of biogas fertilizer for agriculture

the list goes on ...

In our opinion, the creation of hybrid approaches is very promising for the Russian conditions, i.e. projects containing not only biogas reactors, but also wind-solar systems and (or) installations that take away some of the heat from the earth (heat pumps). This approach requires the creation of additional technologies for the control of solar insolation, wind characteristics and specialized software. Thus, renewable energy is quite capable of becoming the driver of many sectors of the economy and business, because in Russia there are practically no technologies accompanying this industry. At the same time, the market for renewable energy in Russia is huge. Proof of this is an example of an assessment of the potential of renewable energy sources, which I wrote about in my last article . At the same time, the real scale of the potential of this market has not yet been estimated, which is also one of the interesting problems. The training of biogas industry specialists, technologists, engineers in universities and vocational schools and vocational

Our modest contribution ...

For the last four years, we have been researching biogas technologies in order to obtain high-speed technology for processing biomass into biogas. At the same time, unexpectedly quickly, we obtained very decent results, which were highly appreciated by independent German experts from the Fraunhofer scientific community. But this is probably a topic for future posts, and now I invite you to our laboratory for a 5-minute tour (video is not very good, we save traffic))).

In spite of the seeming simplicity of the installations in our laboratory, which are made by hand from the materials at hand, hundreds of experiments were made on them to study biogas processes. Actual data on microbiology, gas concentrations, controlling, logging were obtained on the most modern equipment, for example, using TFR gas analysis. We are ready to openly share our results and we hope that this unique experience will be useful for specialized specialists and experts.

I also want to share a collection of articles, books, analytics, which has accumulated over the years. Mainly in English archive 100 MB

What is biogas in Russia? Coldly!

Firstly, in Russia it is not so cold everywhere. In most southern areas of the European part of Russia, biogas technology will be sustainable. At the same time, we also believe that biogas stations can also be built in Siberian conditions, but using activation biogas approaches, modern insulating materials, and additions to regional feedstocks of regional energy crops, for example, for the Tomsk region clover silo, which is well grown in northern areas of the region. Also, such objects can be in a hybrid version and have a backup heat source in case of extremely cold weather. Yes, simple solid fuel boilers for wood or coal, just in case. There is nothing shameful in this, besides the peak of cold weather and anomalies in the weather should be accompanied by the transition of the installations to the energy saving mode by controlling systems, which should be connected with the systems of operational meteorological observations. The biggest problem (in our opinion) is to utilize biogas in the summer, when heat is not needed, as in winter, and a huge amount of gas. There is also room for technology development, in particular, the production of "cold" in the summer for the storage of agricultural products, freezing berries, mushrooms, wild plants, etc. Or vice versa - to set up a business of cooking semi-finished products, baking bread, drying wood and so on. The scope for business thinking is huge.

Used links

[1] Biomass as an energy source . MIR Publishing House, 1985

[2] About the problems of "Green tariff"

[3] Belgorod Institute of Alternative Energy www.altenergo-nii.ru/science

[4] Minutes of the meeting of the Presidium of the Presidential Council

Source: https://habr.com/ru/post/226953/

All Articles