Steel printer

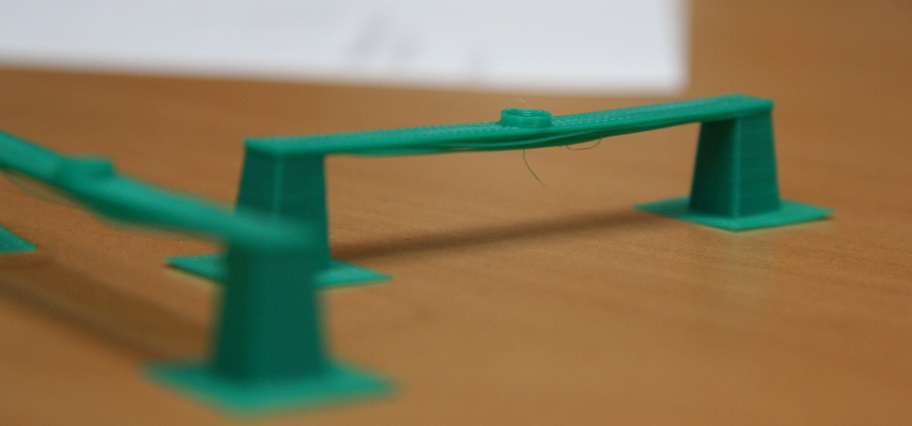

I hasten to share two joyful discoveries - the number of manufacturers of 3d printers in Russia is +1 and you can print horizontal spans without support.

Video: print by air

')

Under the cut, a couple of photos from the assembly shop and a little bit about how to achieve “printing through the air” with the help of a competent organization of blowing.

At the end of the post, a poll was posted on the topic “What kind of printer should I make in Russia in the first place?”

Info

Electronics: Arduino

Firmware: Marlin

• Size of the model building area 260 mm x 170 mm x 170 mm

• The minimum layer height is 0.05 mm (50 microns)

• Accuracy of positioning of the axis X, Y 0.04 mm (40 microns)

• Positioning accuracy of the Z axis 0.02 mm (20 microns)

• Maximum printing speed 25 cm3 per hour

• Maximum movement speed PG 150 mm per second

• The diameter of the nozzle installed in the printer 0.4 mm

• FDM printing technology - layer-by-layer fusing of plastic

• Plastic type for printing 1.75mm ABS, PLA, PVA, HIPS, Nylon-6 and others

• Software Repetier Host, Slic3r

• Connection and peripherals USB 2.0, SD card

• Mains power and power consumption 220V 50Hz, 350 watts.

• Overall dimensions of the printer (W x D x H) 375 mm x 375 mm x 320mm

• Printer weight 12 kg

Firmware: Marlin

• Size of the model building area 260 mm x 170 mm x 170 mm

• The minimum layer height is 0.05 mm (50 microns)

• Accuracy of positioning of the axis X, Y 0.04 mm (40 microns)

• Positioning accuracy of the Z axis 0.02 mm (20 microns)

• Maximum printing speed 25 cm3 per hour

• Maximum movement speed PG 150 mm per second

• The diameter of the nozzle installed in the printer 0.4 mm

• FDM printing technology - layer-by-layer fusing of plastic

• Plastic type for printing 1.75mm ABS, PLA, PVA, HIPS, Nylon-6 and others

• Software Repetier Host, Slic3r

• Connection and peripherals USB 2.0, SD card

• Mains power and power consumption 220V 50Hz, 350 watts.

• Overall dimensions of the printer (W x D x H) 375 mm x 375 mm x 320mm

• Printer weight 12 kg

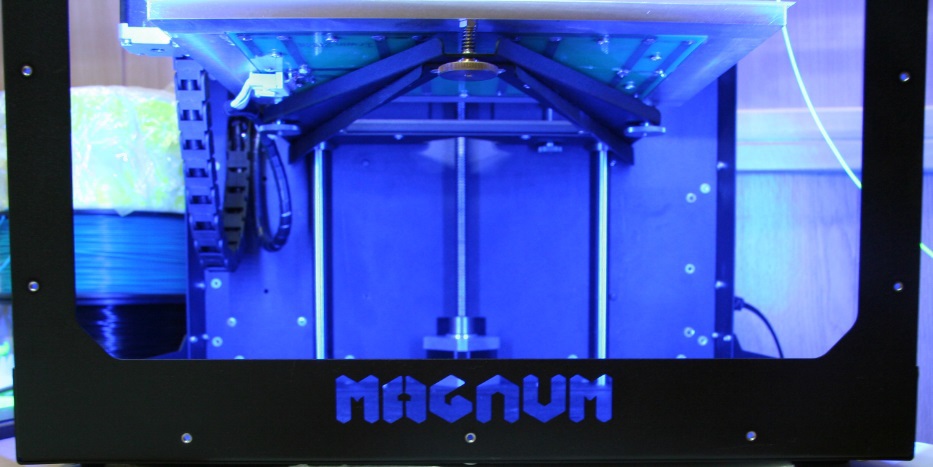

General form:

Front view:

Heated table made of milled aluminum 8mm thick. Calibration with three screws.

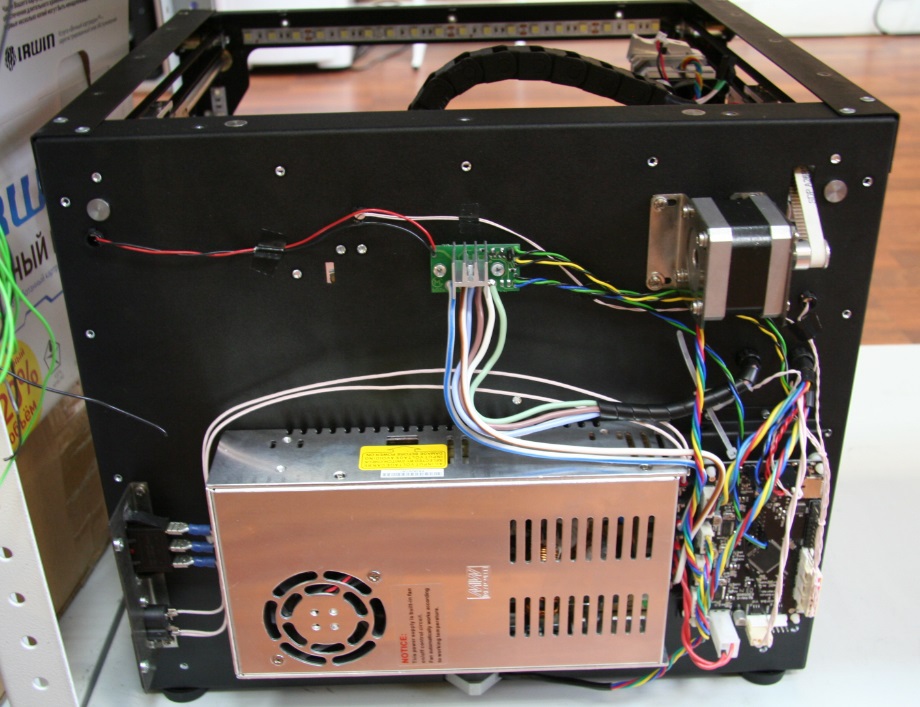

Back view:

Of course, this is all hiding under the cover

Steel enclosures:

The entire printer from the sides, front and back is covered with threaded hardware. They are made so that you can install panels that trap the warm air inside the printer, if anyone needs it. This can help when printing large models of ABS plastic.

Detail:

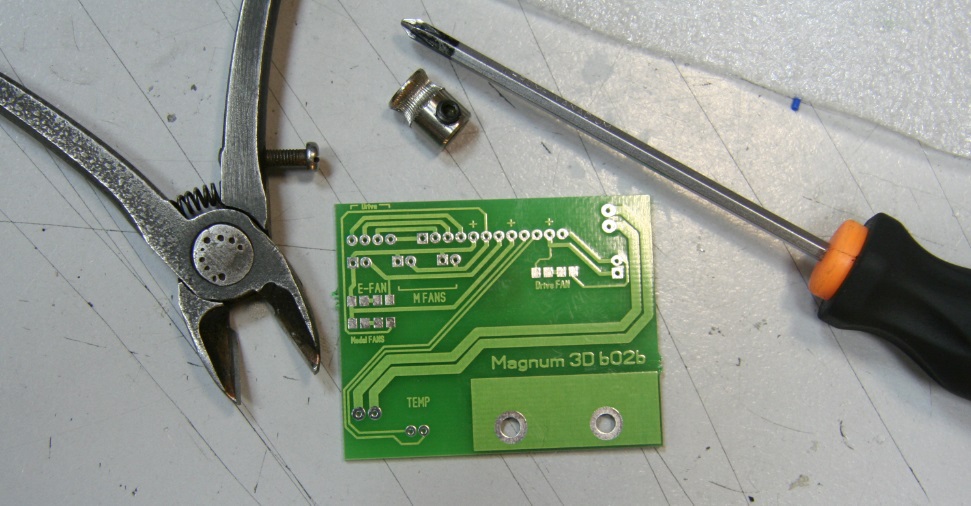

Additional board on which is a powerful power transistor to control the heated table. The power of the table is high so thick wires were needed. Also on this board, additional keys are installed to control the extruder cooling fans (it turns on when the extruder heats over 50 degrees) and the electronics fan (it turns on during printing).

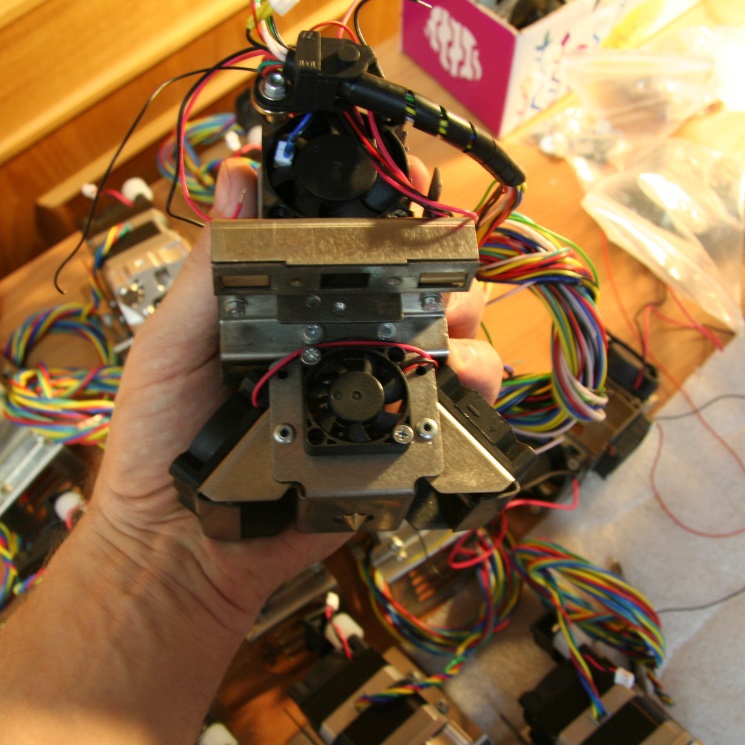

Printhead:

It looks like Ultimaker2, but there are more fans. Completely metal extruder with a working temperature up to 310 ° C.

Patriotism!

Switch of course painfully dear, but made in China.

More patriotism:

Line of radiators:

Extruder Heaters:

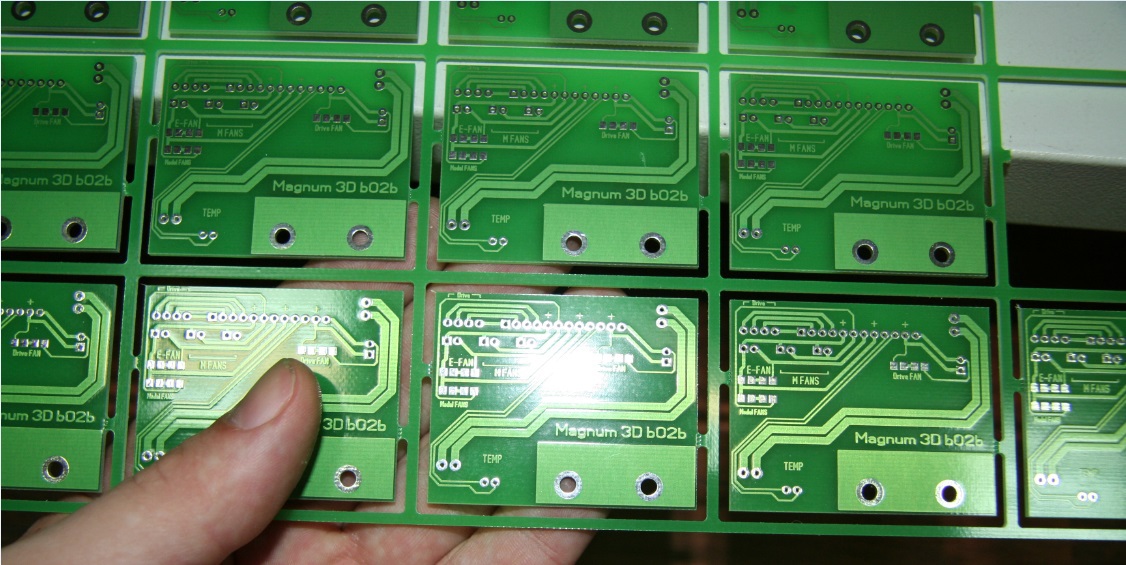

Branded boards - at least use instead of business cards.

Electronics check:

Calibration

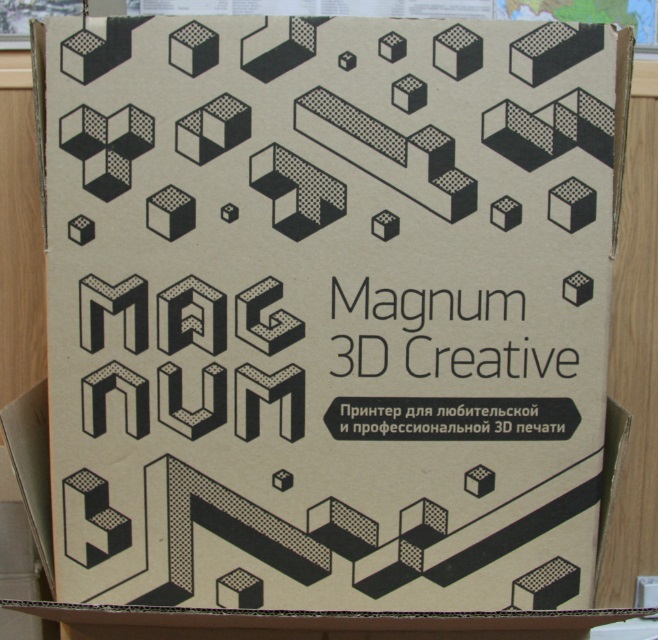

The packaging design was approached conceptually:

The idea of the designer was this: “most likely, Tetris is a three-dimensional game, but it is usually played in a two-dimensional implementation. The transformation from a flat image into 3d takes place in the user's head. The 3d-printer is also associated with the transition from the plane into the volumetric space, but this happens in the real world.

We also all know that Tetris is an invention of our Russian guy, and of course Magnum printers are ours. Whenever possible, use Russian and what can be done or bought in Russia.

All of the above is reflected in the 3-dimensional “Magnum” logo, which is also designed in the form of Tetris cubes.

The guys said that at the last exhibition many such letters were printed, but everyone went somewhere else - visitors dragged almost all exhibition samples from their booth.

In my opinion a trifle, but very cool.

"Anti-stress cube" (shockproof packaging).

Final packaging:

Printing long horizontal spans is obtained due to the viscosity of the plastic. And of course a good blower system helps here.

In general, a good blowing system is relevant not only for ABC plastic, but is also very important for PLA. Good airflow helps to quickly cool the plastic and prevents its spreading. The model turns out better not only at negative angles (sheds) but also in other places. It turns out to be more “sharp”.

It is necessary to use the blowing of course with the mind, especially for ABC plastic, which gives a strong shrinkage and the model can crack with a strong blowing.

Source: https://habr.com/ru/post/226311/

All Articles