3D printer head. Three components and three sources. On the road to excellence

A small overview of the materials used for the manufacture of heads of 3D printers and the heads themselves, to make it clearer why they are doing so, J-Head, Makerbot, Ultimaker.

This is my second article from the epic cycle about printer heads. Joke - but there is still something to say. The first article is here . Like all materials on RepRap - printers refers to open-source, then if you need any details, please contact.

Hot End - The hot part of the head usually consists of three parts:

')

- head itself, nozzle, nozzle;

- thermal barrier, also called nozzle holder, maybe in one bottle with a radiator;

- radiator.

Requirements for the materials of these parts are significantly different. However, I saw people on the Web who made all these parts from aluminum. And they did not succeed. But Pryusha - the same, famous, after which the printer model Prusa is named, made everything from stainless steel. This will also be written.

Prusa Nozzle head

So - the head, the nozzle, it is usually made of brass, sometimes aluminum, heard the mention of bronze and never seen made of copper. Why is that? Probably because in the head, of course, the good thermal conductivity of the material matters, but this value is not too large, the convenience of processing the material is more important.

So, let's look at the values of thermal conductivities for copper, aluminum, brass and bronze:

- copper - 395 W / m K

- aluminum - 220

- brass - 150

- bronze - 58.7 - this is for aluminum bronze, which is noticeably stronger than brass.

Bronze, as you can see, has almost three times less thermal conductivity than brass, which in the case of using a resistor-heater can matter.

Aluminum was abandoned, probably due to excessive softness. Of course, there are sufficiently strong aluminum alloys, but they still need to be found and distinguished ... so ...

Copper is probably difficult to process and is too soft.

For me, an important and useful feature of brass (bronze is the same) is also the fact that it is well soldered with hard silver solder - which is for repairing refrigerators. He is very good, they can solder the bronze to stainless steel and its wettability is simply gorgeous, that is, it flows perfectly along the entire joint, being soldered only at one point. So we smoothly go to the thermal barrier. This is a part that must withstand the mechanical loads of the head and transfer less heat to the device body. The first models of hotnds used for this fluoroplastic - if in Russian, or Teflon, PTFE. In fact, a wonderful material, especially because of its remarkable slipperiness. To him, however, nothing sticks at all and his thermal conductivity is small. However, there is a defect. Strength. Strength is small, and not even this is the worst, the bad thing is that it has fluidity. Fluidity - it means that under load, even with weak heating, it begins to change its shape. Everything. This feature left him only the function of inserts in the head, which reduce the friction of the filament. There he has nowhere to flow. It is propped up from all sides - either by metal or by appropriate plastic.

Let us now look at the properties of materials that we could supply as a thermal barrier. Thermal conductivity is in W / m K (meaning - watt, meter, degree, and which, Kelvin or Celsius - does not matter) and Ultimate tensile strength - in megapascals.

- Teflon 0.25 26

- PEEK 0.29 165

- Stainless Steel grade 304 9.4 580-600

- Stainless Steel 316 9.4 680

- Steel 3, the simplest 55 380

We look, the second line goes PEEK, this is a rather exotic plastic. With an impressive price. Pay attention to the strength, it is only two times lower than Steel 3.

With low thermal conductivity, good slipperiness and good thermal stability, it has become a popular material for nozzle holders.

Classic J-Head Nozzle Mk5 B

There are two minuses and serious ones: - price and heat resistance. 250º - this is the temperature limit, often you want more, thermistors (many) will work up to a temperature of 300º - there is room to grow.

Now look at stainless steels - their thermal conductivity is 5 times lower than ordinary steel! And the strength is almost two times higher! These are popular steel grades in the West corresponding to our 081810 and 0817132. The first is generally a classic stainless steel food, chromium-nickel. True, thermal conductivity is 40 times higher than that of Teflon, but if you take into account the difference in strength, the difference with Teflon will be only 30 percent. PEEK, however, remains an unattainable competitor. But resistance to heat ... and another pleasant opportunity to solder a brass nozzle to a steel tube with silver solder and forget about plastic leakage. Silver solder not only has a melting point of 800 º, but also has excellent strength and solders perfectly - very good fluidity and wettability. 8-12 millimeters of stainless steel tubes are already a sufficient barrier to our needs. This is in the case of a tube with a diameter of 8mm and with 1mm walls. If you use more thin-walled tubes, the effect will be even better. The 0.3 mm tube is strong enough. Here other factors will have the main effect: - heating by radiation from the head, heating by convective currents, which, however, must be blown away by a fan.

The head from Pruša - Prusa Nozzle is made from a single piece of stainless steel, it does have steel of a slightly different composition - with twice the thermal conductivity, grade 303, this is probably a compromise between the requirements for a thermal barrier and a nozzle. A very difficult to manufacture product turned out, and it seems not very successful, although it allowed printing with any kind of plastic. People complain about it. Yes, and buy it now is not easy. The new modification - with an aluminum radiator, and, in my opinion, should not be particularly successful either. Low temperature gradient over thermal barrier.

Classic J-Head Nozzle Mk5 B A good model, especially if it was made without the simplifications and degradations that some Chinese comrades added. The holder is made of plastic PEEK. Prints stably. But not all. The temperature range is limited and it is better not to exceed it - plastic begins to ooze through the junction of the holder and the nozzle. As the heater uses a resistor, the estimated power is about 25 watts. Teflon liner to brass nozzle.

Makerbot MK7 Makerbot - constructively simple, solid metal and judging by the stated parameters, very good. Thermal barrier - stainless steel, not too small section, complex configuration, inside the holder of the fluoroplastic liner no. The large aluminum heating unit is thermally insulated from the air using ceramic tape. Judging by the powerful radiator, a rather large heat flow comes from the head. A short piece of thermal barrier means a high temperature gradient. Why this is good, I will try to show in numbers in the next post.

Makerbot Stepstruder MK7 Head

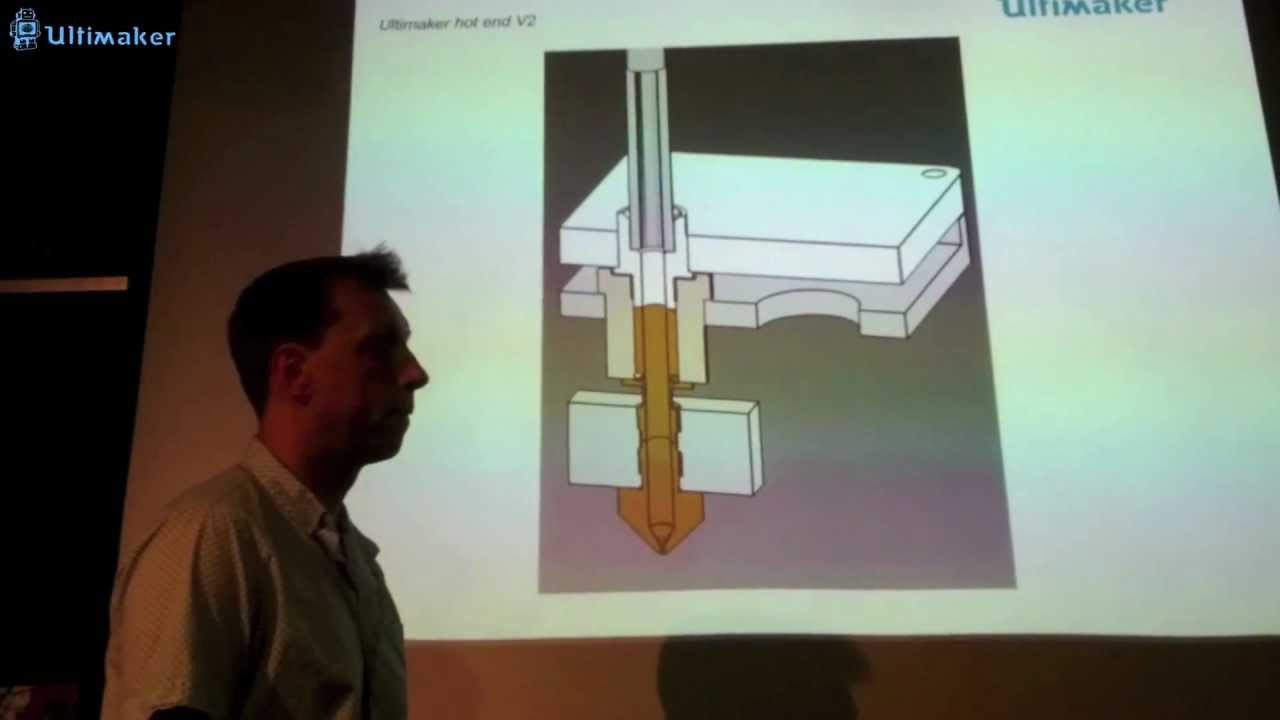

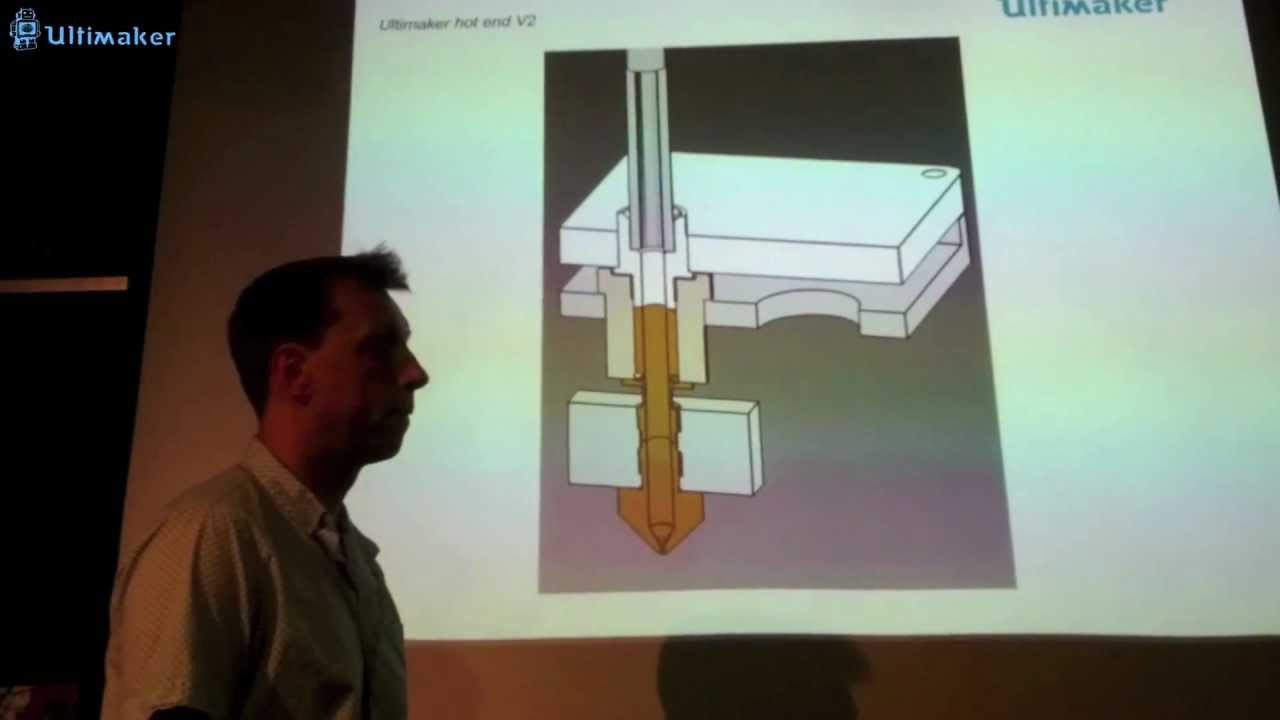

And Ultimaker HotEnd v2 uses a PEEK thermal barrier. So nothing surprising in the temperature range, do not wait. Uses heating cartridge, 40W. Just like the Stepstruder MK7. The design is interesting. Teflon is competently used. Very large length of the melting part. Apparently from here the record speed of printing. For detailed analysis there are no drawings and descriptions.

What I found on Ultimaker, and he is Open source.

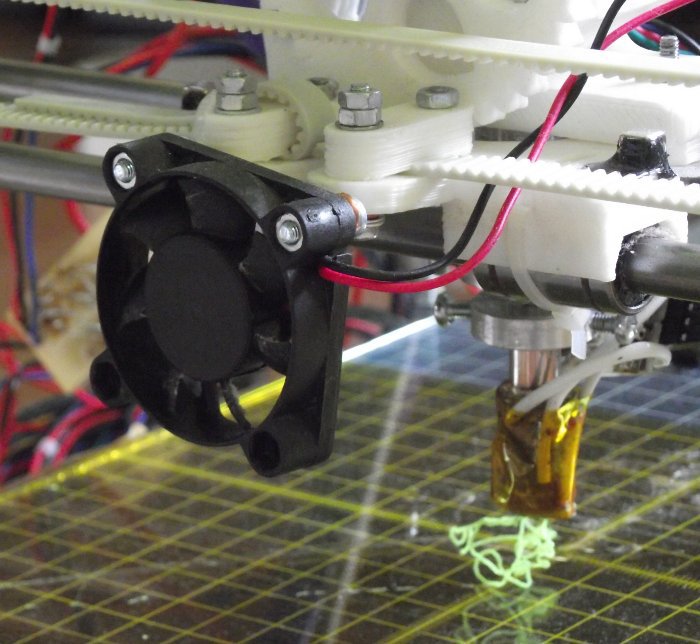

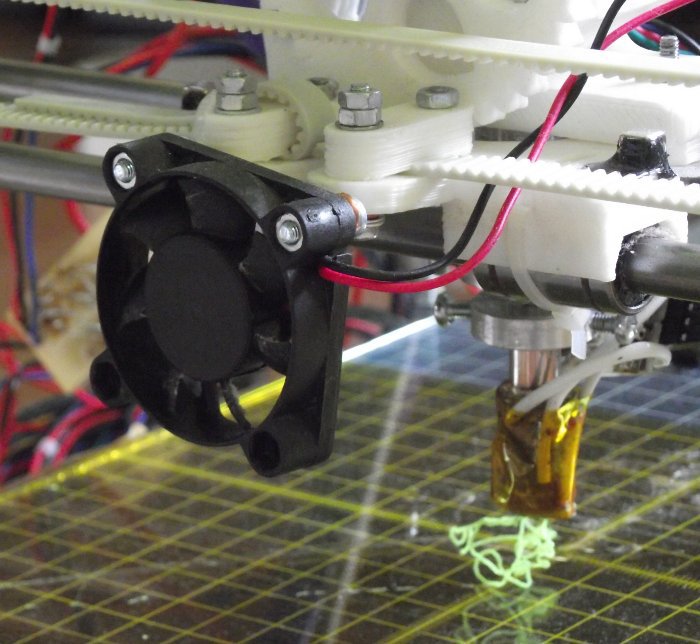

Homemade - BASS - prints well and quickly. 140 mm / sec when printing with a nylon / trim line. Tedious to manufacture. One winding of the heater is worth something. Thermal barrier made of stainless steel tube 304. Turning work - good. Silver brazing is used. Because of the wound radiator - good heating uniformity, low weight and high reliability. Before the brass nozzle, a Teflon liner is used, the last 5 millimeters of which is replaced with a stainless steel ring to reduce the load. Power - the same, about 40 watts.

In the mount, the heat is not strong, the fan copes weakly.

We can say that the first period of development of FDM-printers ends, well-working heads are no longer a rarity. Although it does not leave me feeling that the principles of their design are not yet clearly defined. In the next post I want to talk about the thermal calculations of the printer head, why they are doing this and how to avoid the formation of traffic jams. I even had the impression that I could now consciously choose the dimensions, radiators, thermal barriers and so on. I would be glad if the community takes part in the search for possible errors and errors. Thanks to all.

This is my second article from the epic cycle about printer heads. Joke - but there is still something to say. The first article is here . Like all materials on RepRap - printers refers to open-source, then if you need any details, please contact.

Hot End - The hot part of the head usually consists of three parts:

')

- head itself, nozzle, nozzle;

- thermal barrier, also called nozzle holder, maybe in one bottle with a radiator;

- radiator.

Requirements for the materials of these parts are significantly different. However, I saw people on the Web who made all these parts from aluminum. And they did not succeed. But Pryusha - the same, famous, after which the printer model Prusa is named, made everything from stainless steel. This will also be written.

Prusa Nozzle head

So - the head, the nozzle, it is usually made of brass, sometimes aluminum, heard the mention of bronze and never seen made of copper. Why is that? Probably because in the head, of course, the good thermal conductivity of the material matters, but this value is not too large, the convenience of processing the material is more important.

So, let's look at the values of thermal conductivities for copper, aluminum, brass and bronze:

- copper - 395 W / m K

- aluminum - 220

- brass - 150

- bronze - 58.7 - this is for aluminum bronze, which is noticeably stronger than brass.

Bronze, as you can see, has almost three times less thermal conductivity than brass, which in the case of using a resistor-heater can matter.

Aluminum was abandoned, probably due to excessive softness. Of course, there are sufficiently strong aluminum alloys, but they still need to be found and distinguished ... so ...

Copper is probably difficult to process and is too soft.

For me, an important and useful feature of brass (bronze is the same) is also the fact that it is well soldered with hard silver solder - which is for repairing refrigerators. He is very good, they can solder the bronze to stainless steel and its wettability is simply gorgeous, that is, it flows perfectly along the entire joint, being soldered only at one point. So we smoothly go to the thermal barrier. This is a part that must withstand the mechanical loads of the head and transfer less heat to the device body. The first models of hotnds used for this fluoroplastic - if in Russian, or Teflon, PTFE. In fact, a wonderful material, especially because of its remarkable slipperiness. To him, however, nothing sticks at all and his thermal conductivity is small. However, there is a defect. Strength. Strength is small, and not even this is the worst, the bad thing is that it has fluidity. Fluidity - it means that under load, even with weak heating, it begins to change its shape. Everything. This feature left him only the function of inserts in the head, which reduce the friction of the filament. There he has nowhere to flow. It is propped up from all sides - either by metal or by appropriate plastic.

Let us now look at the properties of materials that we could supply as a thermal barrier. Thermal conductivity is in W / m K (meaning - watt, meter, degree, and which, Kelvin or Celsius - does not matter) and Ultimate tensile strength - in megapascals.

- Teflon 0.25 26

- PEEK 0.29 165

- Stainless Steel grade 304 9.4 580-600

- Stainless Steel 316 9.4 680

- Steel 3, the simplest 55 380

We look, the second line goes PEEK, this is a rather exotic plastic. With an impressive price. Pay attention to the strength, it is only two times lower than Steel 3.

With low thermal conductivity, good slipperiness and good thermal stability, it has become a popular material for nozzle holders.

Classic J-Head Nozzle Mk5 B

There are two minuses and serious ones: - price and heat resistance. 250º - this is the temperature limit, often you want more, thermistors (many) will work up to a temperature of 300º - there is room to grow.

Now look at stainless steels - their thermal conductivity is 5 times lower than ordinary steel! And the strength is almost two times higher! These are popular steel grades in the West corresponding to our 081810 and 0817132. The first is generally a classic stainless steel food, chromium-nickel. True, thermal conductivity is 40 times higher than that of Teflon, but if you take into account the difference in strength, the difference with Teflon will be only 30 percent. PEEK, however, remains an unattainable competitor. But resistance to heat ... and another pleasant opportunity to solder a brass nozzle to a steel tube with silver solder and forget about plastic leakage. Silver solder not only has a melting point of 800 º, but also has excellent strength and solders perfectly - very good fluidity and wettability. 8-12 millimeters of stainless steel tubes are already a sufficient barrier to our needs. This is in the case of a tube with a diameter of 8mm and with 1mm walls. If you use more thin-walled tubes, the effect will be even better. The 0.3 mm tube is strong enough. Here other factors will have the main effect: - heating by radiation from the head, heating by convective currents, which, however, must be blown away by a fan.

The head from Pruša - Prusa Nozzle is made from a single piece of stainless steel, it does have steel of a slightly different composition - with twice the thermal conductivity, grade 303, this is probably a compromise between the requirements for a thermal barrier and a nozzle. A very difficult to manufacture product turned out, and it seems not very successful, although it allowed printing with any kind of plastic. People complain about it. Yes, and buy it now is not easy. The new modification - with an aluminum radiator, and, in my opinion, should not be particularly successful either. Low temperature gradient over thermal barrier.

Classic J-Head Nozzle Mk5 B A good model, especially if it was made without the simplifications and degradations that some Chinese comrades added. The holder is made of plastic PEEK. Prints stably. But not all. The temperature range is limited and it is better not to exceed it - plastic begins to ooze through the junction of the holder and the nozzle. As the heater uses a resistor, the estimated power is about 25 watts. Teflon liner to brass nozzle.

Makerbot MK7 Makerbot - constructively simple, solid metal and judging by the stated parameters, very good. Thermal barrier - stainless steel, not too small section, complex configuration, inside the holder of the fluoroplastic liner no. The large aluminum heating unit is thermally insulated from the air using ceramic tape. Judging by the powerful radiator, a rather large heat flow comes from the head. A short piece of thermal barrier means a high temperature gradient. Why this is good, I will try to show in numbers in the next post.

Makerbot Stepstruder MK7 Head

And Ultimaker HotEnd v2 uses a PEEK thermal barrier. So nothing surprising in the temperature range, do not wait. Uses heating cartridge, 40W. Just like the Stepstruder MK7. The design is interesting. Teflon is competently used. Very large length of the melting part. Apparently from here the record speed of printing. For detailed analysis there are no drawings and descriptions.

What I found on Ultimaker, and he is Open source.

Homemade - BASS - prints well and quickly. 140 mm / sec when printing with a nylon / trim line. Tedious to manufacture. One winding of the heater is worth something. Thermal barrier made of stainless steel tube 304. Turning work - good. Silver brazing is used. Because of the wound radiator - good heating uniformity, low weight and high reliability. Before the brass nozzle, a Teflon liner is used, the last 5 millimeters of which is replaced with a stainless steel ring to reduce the load. Power - the same, about 40 watts.

In the mount, the heat is not strong, the fan copes weakly.

We can say that the first period of development of FDM-printers ends, well-working heads are no longer a rarity. Although it does not leave me feeling that the principles of their design are not yet clearly defined. In the next post I want to talk about the thermal calculations of the printer head, why they are doing this and how to avoid the formation of traffic jams. I even had the impression that I could now consciously choose the dimensions, radiators, thermal barriers and so on. I would be glad if the community takes part in the search for possible errors and errors. Thanks to all.

Source: https://habr.com/ru/post/225485/

All Articles