To be in 3d or not to be? How I scanned and printed myself on a 3d printer

"From time immemorial, people have sought to reduce what they use" Erlich Bachmann, "Silicon Valley", episode 7

Now, at the junction of 3d-scanning and 3d-printing technology, a service has appeared (the harm began in Japan in 2012) for the production of 3d-figures.

In the cinema, 3d-printers flashed on the “Elementary” series (there the Liberator printed the villain, but the Habré was printed and the liberator was drawn in Photoshop earlier than in the cinema) and in The Big Bang Theory (many didn’t wrote).

In pursuit of the post that it is worth developing various 3d services in Russia , I want to share how the process of creating 3d figures goes on and on.

So, I went to visit the guys on the colored boulevard and the conquest of the 3rd dimension began.

')

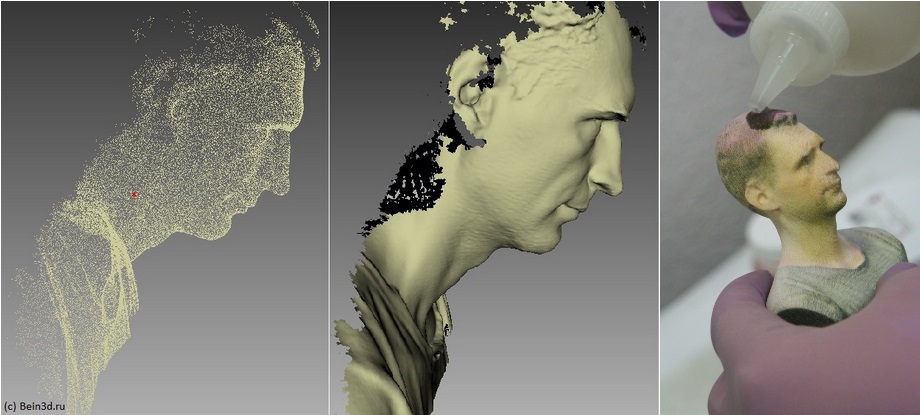

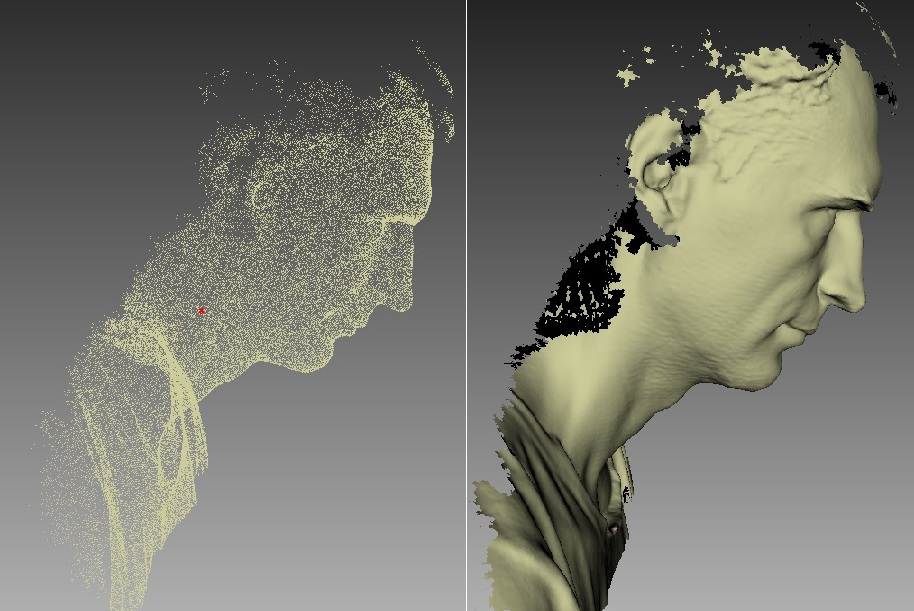

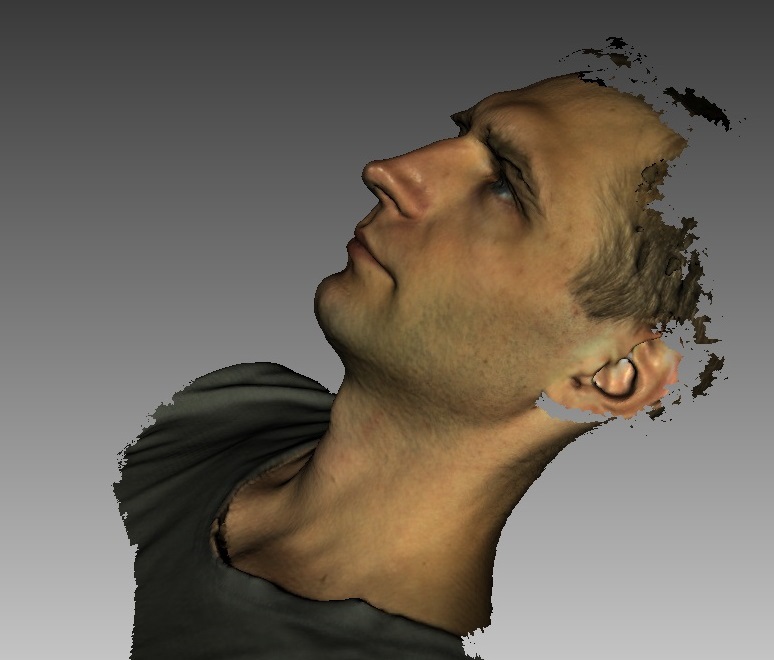

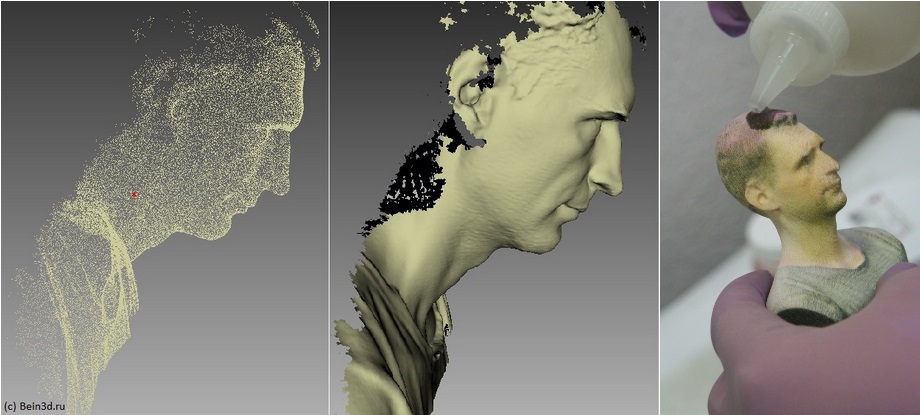

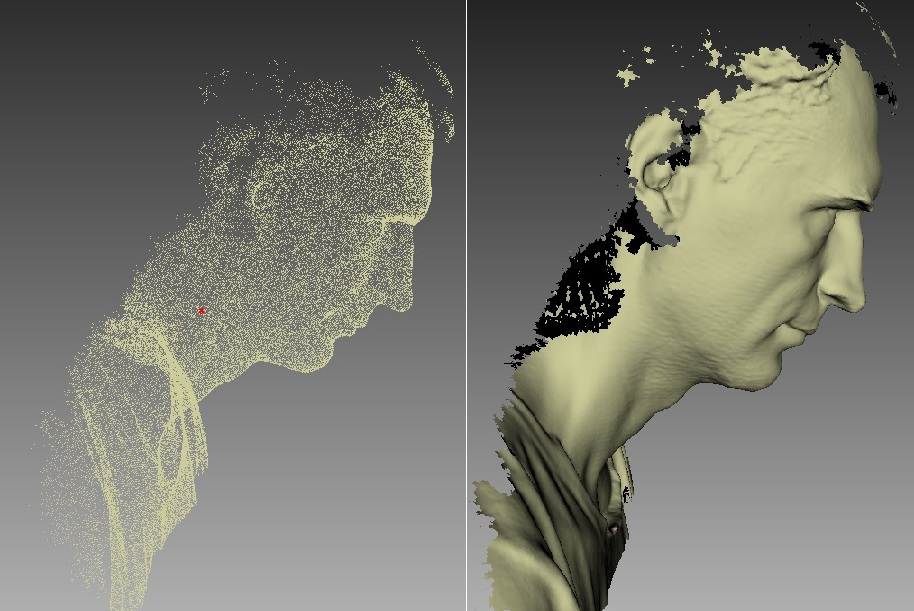

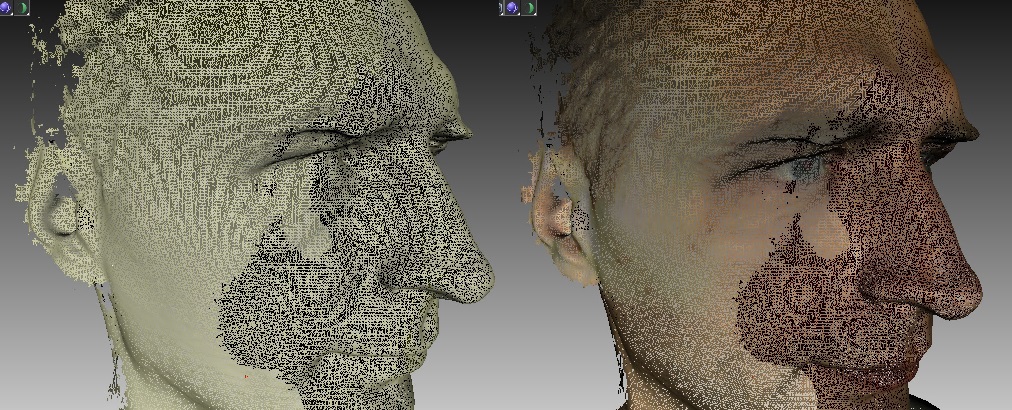

Scanning is done using Artec Eva 3d scanner.

The scanner consists of cameras and backlight, and the 3d image is “generated from photos”

ATTENTION! look under the spoiler is worth mental health:

Scanning takes about 10 minutes.

It usually occurs on a turntable, but it is possible that the operator runs around you.

Scanning looks like a bunch of flashes from a camera (see video at the end of the review)

Editing takes a maximum of an hour if a demanding user asks to “reduce the belly” or “remove the folds” in various places.

An editing program is included with the scanner.

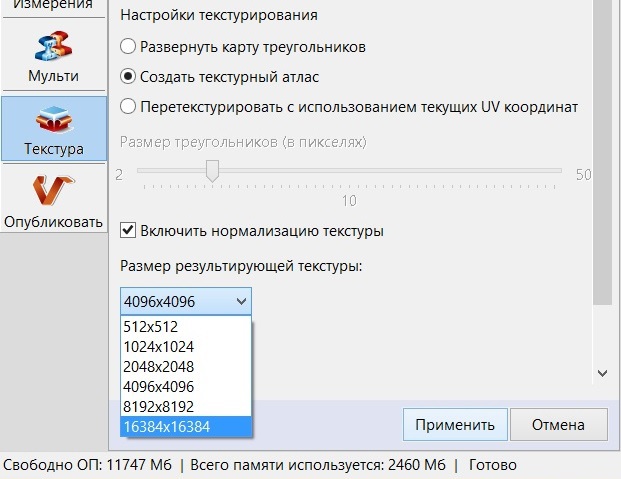

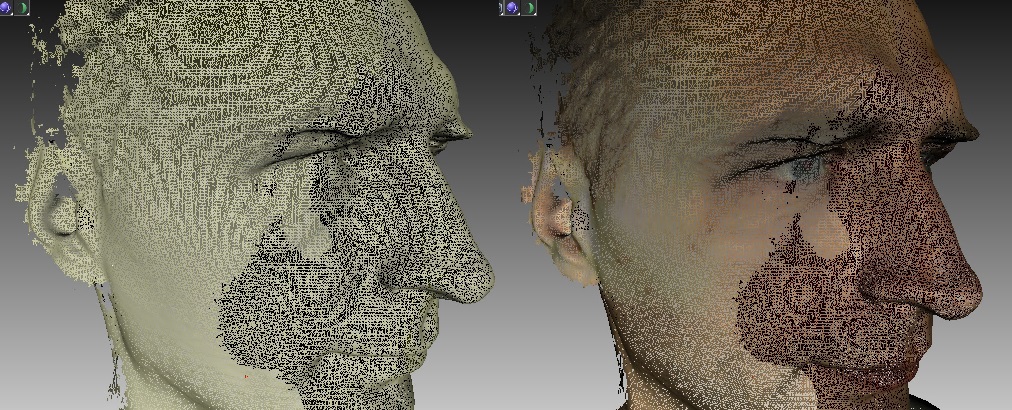

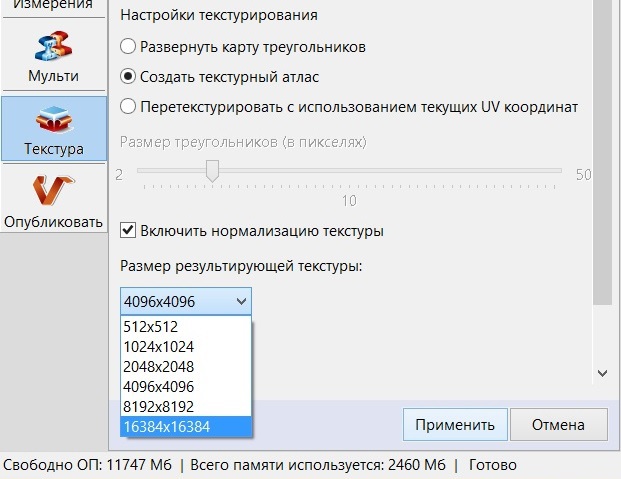

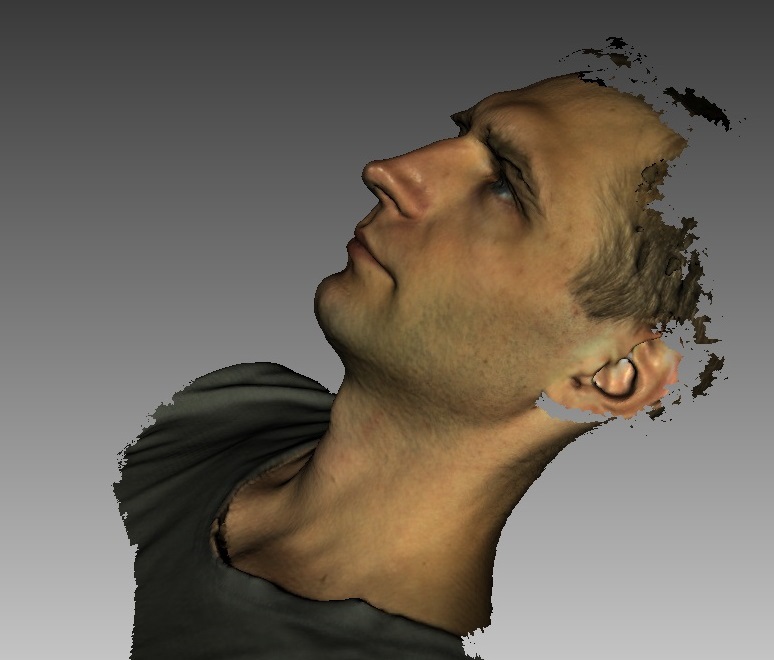

Remarkably, texture processing is possible with a space resolution:

RAM is required a lot.

My first impression, a printer, is a mixture of a giant jet, a bread machine, and a vacuum cleaner.

The printer weighs 340 kg, and lives its own life, sometimes it switches itself on and performs cleaning.

The printer requires constant inclusion in the network.

Layer thickness - 89-102 microns

Print speed 2-4 layers per minute

For scale - a live girl:

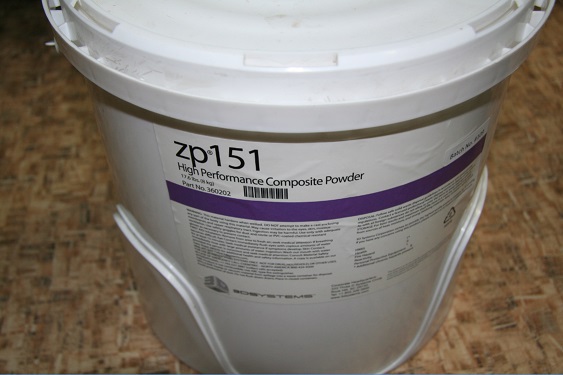

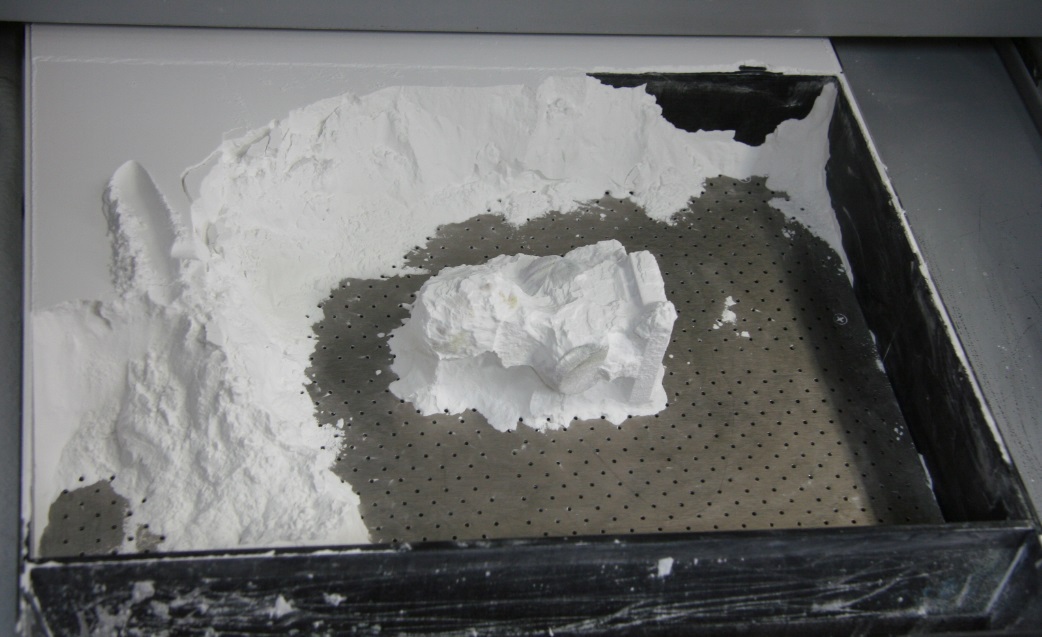

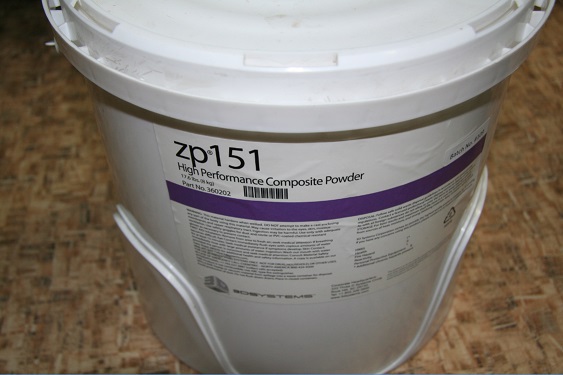

Consumable - gypsum from which the model is printed:

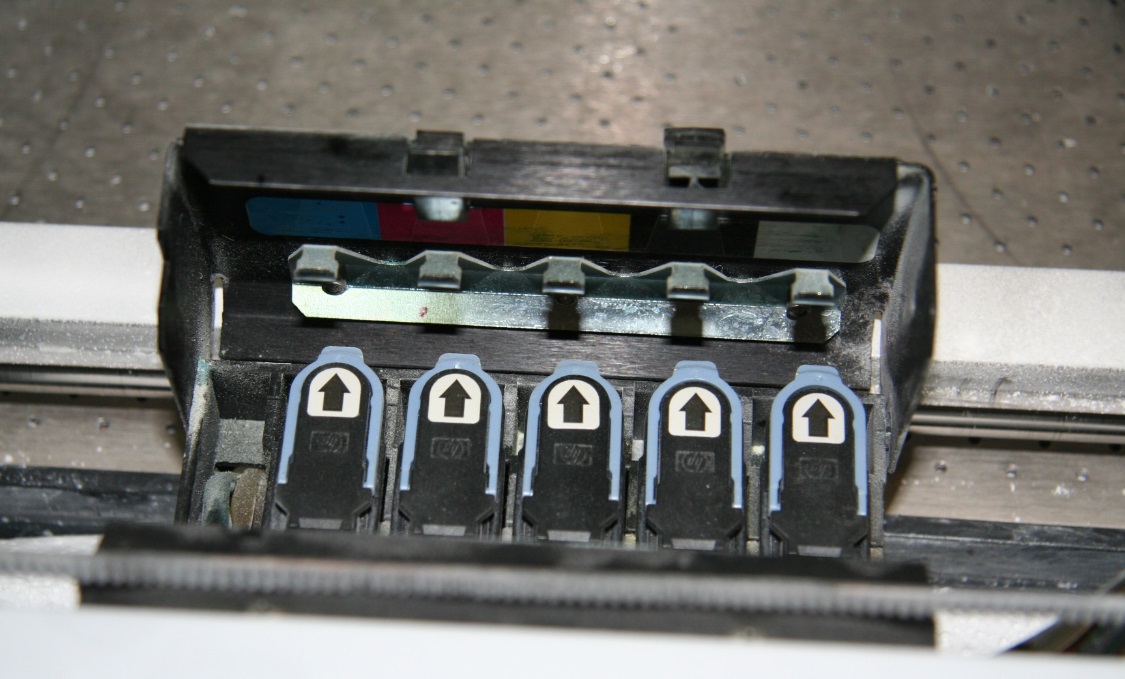

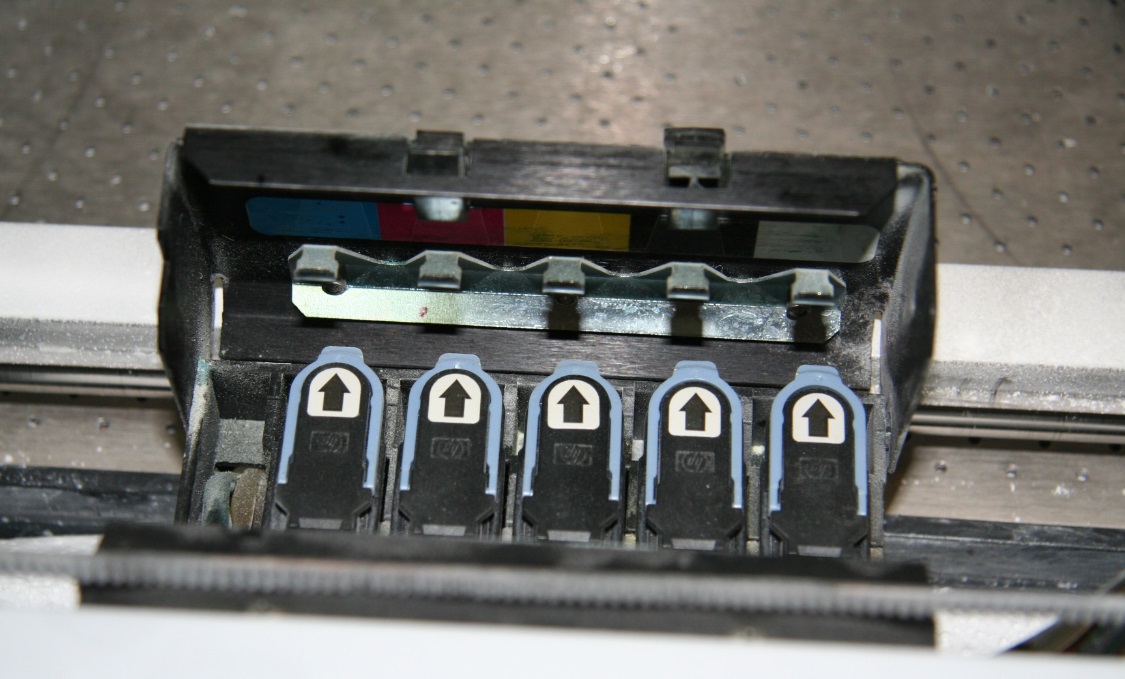

Printhead ("noggin"):

Ink cartridge:

Ink delivery to the printhead:

ATTENTION! Look under the spoiler is worth mental health:

Print

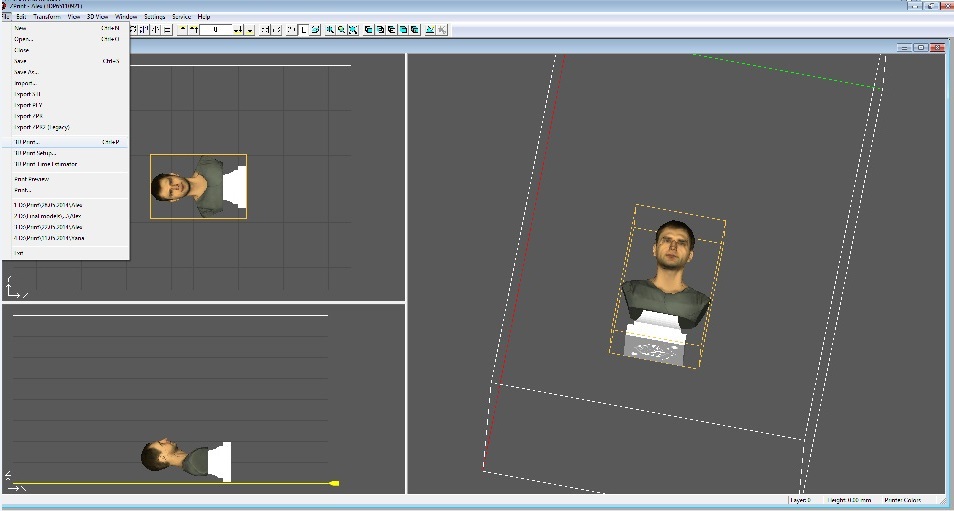

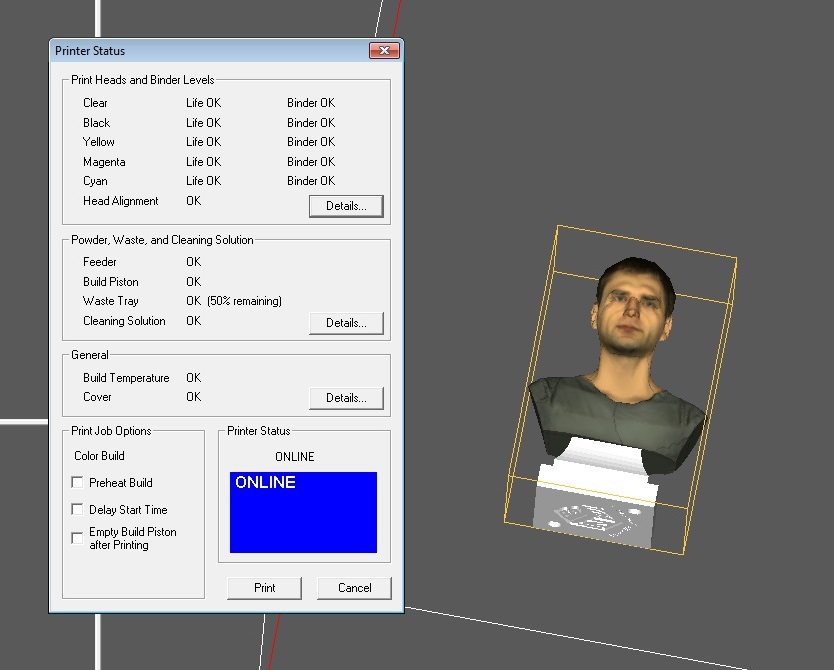

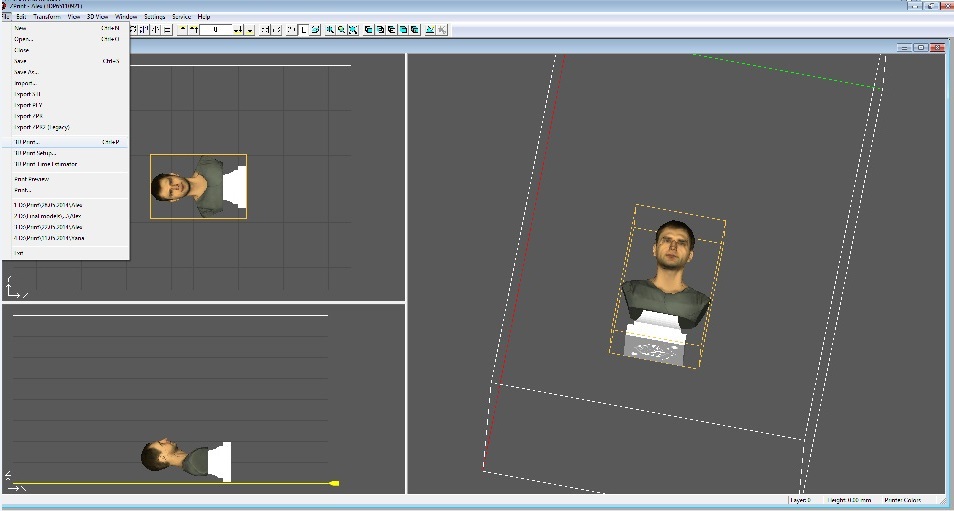

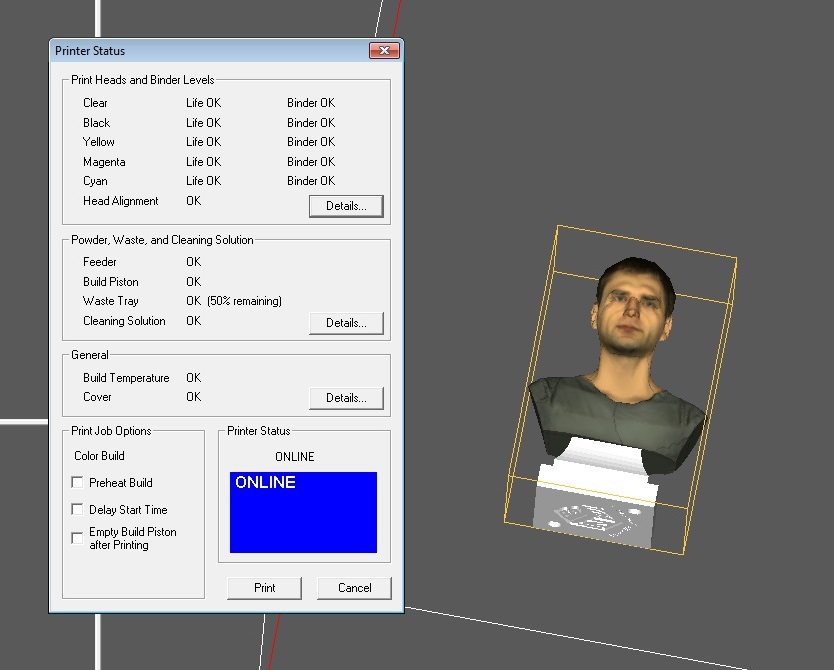

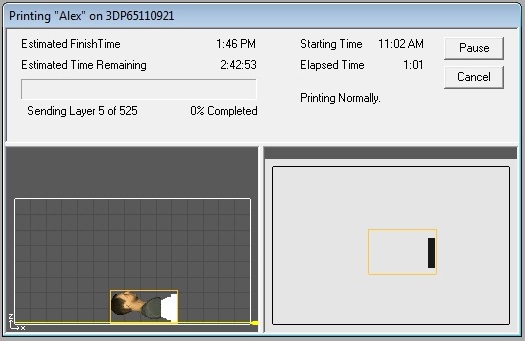

Management Program and Preview

Preview in several projections.

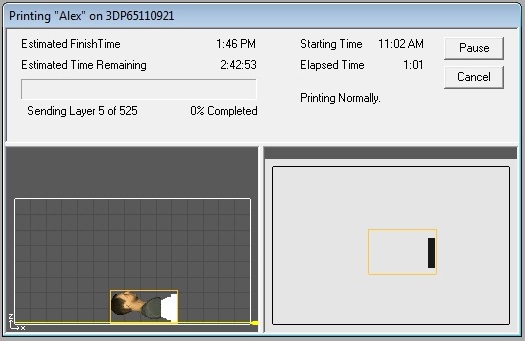

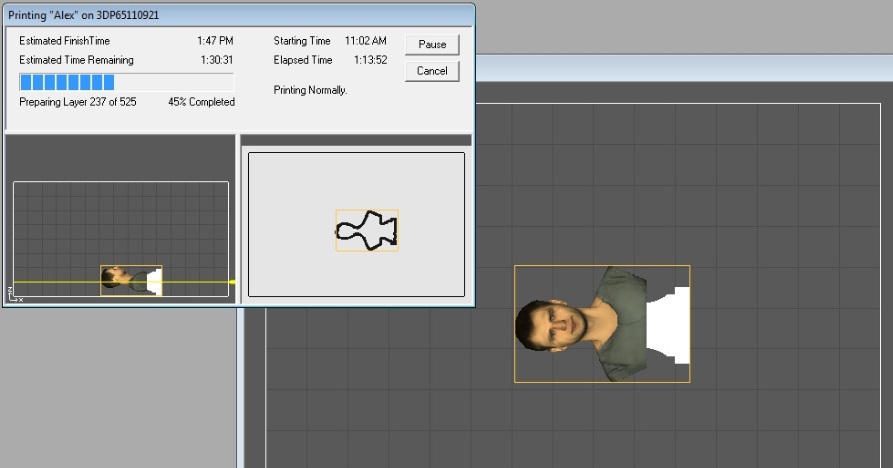

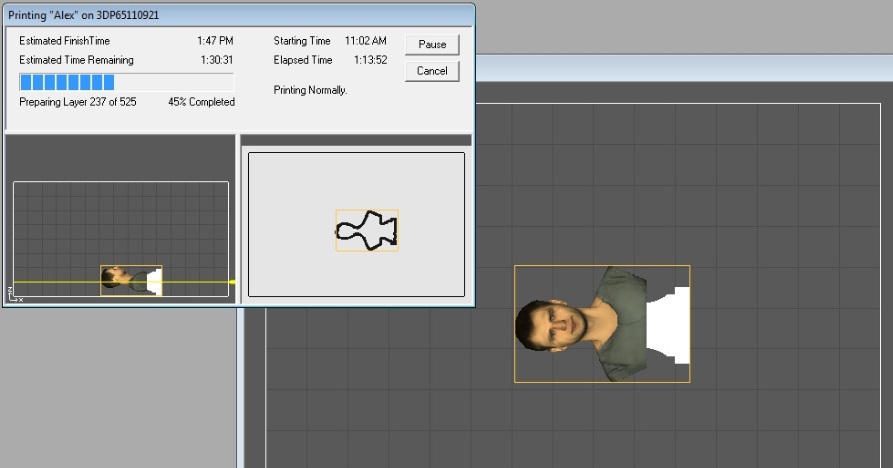

Estimated print time and display of the current print layer.

First, a thin layer of gypsum powder is applied to the base. After that, the print head applies a special resin, gluing the plaster in the right places, and ordinary ink. Then the next layer of gypsum is applied, etc.

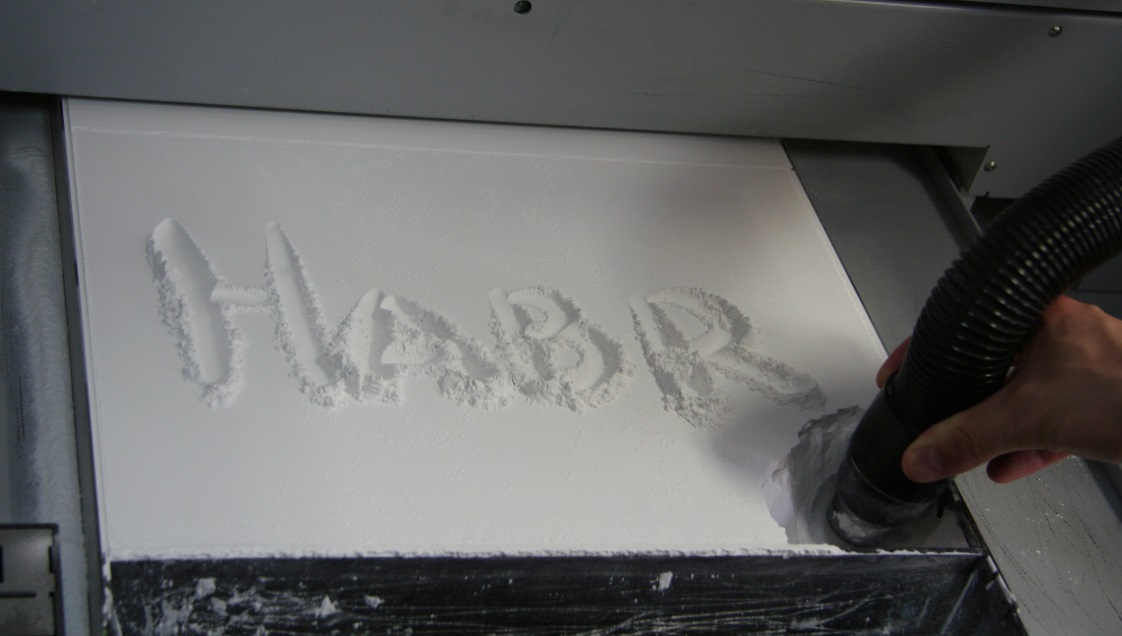

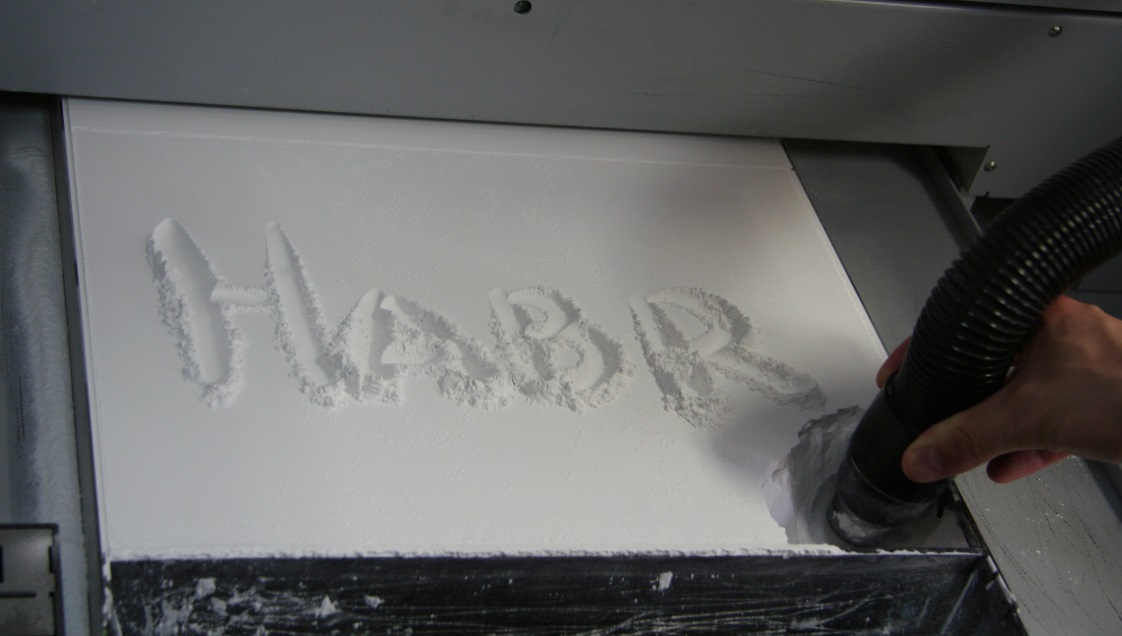

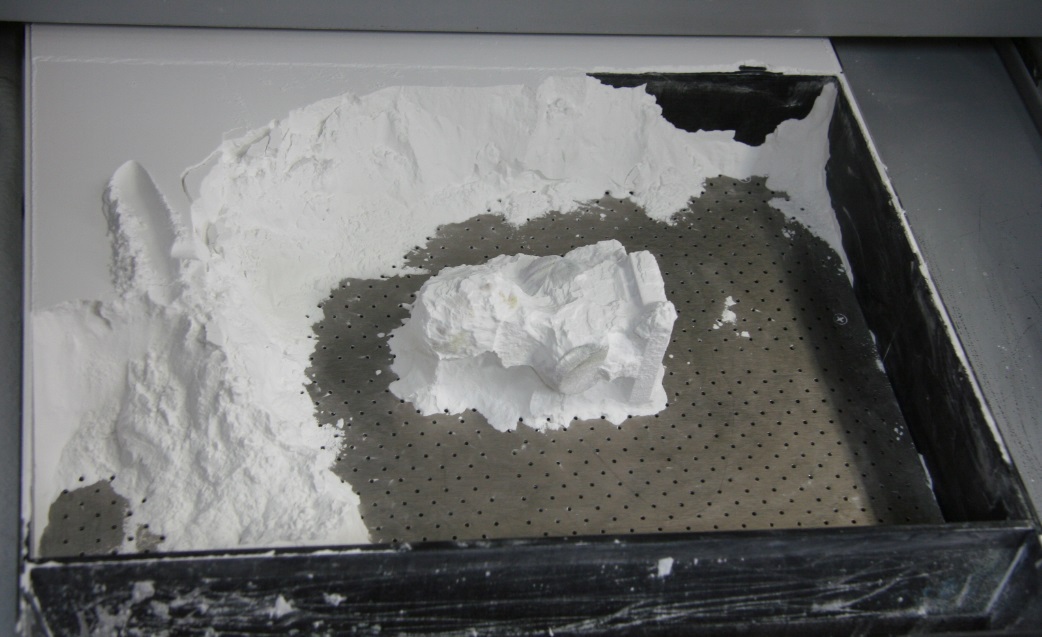

After printing, the excess gypsum is removed with a special vacuum cleaner, and from hard-to-reach places with compressed air.

237 (out of 525) print layer as the program displays:

237 layer in reality:

After the printer has fully printed the model - it takes some time to dry.

It took 1.5 hours, now we will "pull out of the stove":

Remove excess gypsum using the “suction” method:

Gypsum is re-cleaned / filtered and goes into action.

Now remove the excess by the method of "blowing":

From the bottom there are 2 holes - one also blows a plaster out of them - the figure is hollow inside

Cover me with cyanoacrylate ("fixer"):

Half an hour to dry up - and in the hall of fame:

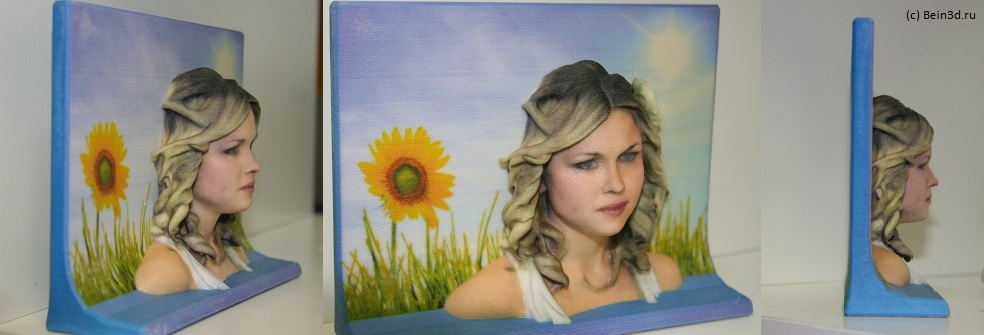

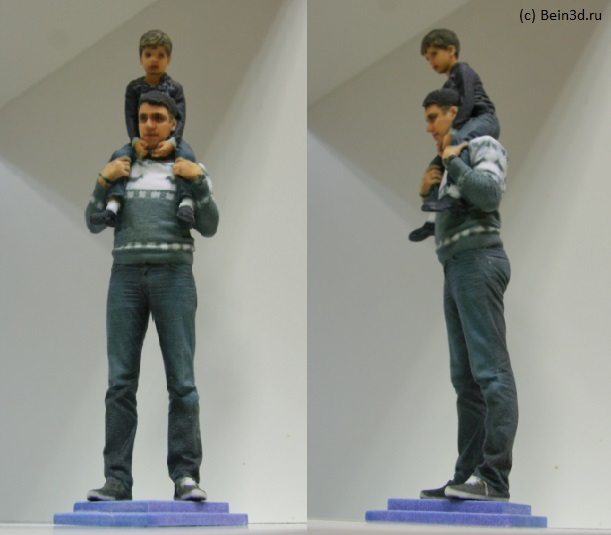

Capture a memorable moment, a memorable form.

You can experiment with the design.

In my opinion, the most original figure.

Quality allows you to print even small patterns of clothing.

Conclusion

While still playing Quake2, I wanted to make a skin with my face.

The stage is not far off when, along with photo albums, there will be 3d albums .

So far, the figures cause a wow effect, than you can use and make a cool gift.

PS

Now, at the junction of 3d-scanning and 3d-printing technology, a service has appeared (the harm began in Japan in 2012) for the production of 3d-figures.

In the cinema, 3d-printers flashed on the “Elementary” series (there the Liberator printed the villain, but the Habré was printed and the liberator was drawn in Photoshop earlier than in the cinema) and in The Big Bang Theory (many didn’t wrote).

In pursuit of the post that it is worth developing various 3d services in Russia , I want to share how the process of creating 3d figures goes on and on.

So, I went to visit the guys on the colored boulevard and the conquest of the 3rd dimension began.

')

Scanner

Scanning is done using Artec Eva 3d scanner.

The scanner consists of cameras and backlight, and the 3d image is “generated from photos”

Specs

The ability to read textures is

3D resolution - 0.5 mm

3D degree of accuracy - 0.1 mm

3D degree of accuracy at a distance of up to –0.15% per 100 mm

Texture resolution - 1.3 MP

Color - 24 bits

Parallel processing - yes

Performance - 40,000,000 polygons per 1GB of RAM

Output Format OBJ, STL, WRML, ASCII, AOP, CSV, PTX

Calibration less than 1 min, does not require special equipment

Data acquisition rate, up to 288,000 points / s

Exposure time - 0.0002 sec.

Video shooting frequency, up to 16 frames / sec.

Working distance 0.4 - 1 m

Light source - lamp flash (not laser)

Other:

Dimensions, HxDxSH - 261.5 x 158.2 x 63.7 mm

Weight - 0.85 kg

Power consumption - 12V, 48W

Minimum system requirements

IntelCore 2 duo, 2Gb RAM, NVIDIA Quadro / GeForce 9000

3D resolution - 0.5 mm

3D degree of accuracy - 0.1 mm

3D degree of accuracy at a distance of up to –0.15% per 100 mm

Texture resolution - 1.3 MP

Color - 24 bits

Parallel processing - yes

Performance - 40,000,000 polygons per 1GB of RAM

Output Format OBJ, STL, WRML, ASCII, AOP, CSV, PTX

Calibration less than 1 min, does not require special equipment

Data acquisition rate, up to 288,000 points / s

Exposure time - 0.0002 sec.

Video shooting frequency, up to 16 frames / sec.

Working distance 0.4 - 1 m

Light source - lamp flash (not laser)

Other:

Dimensions, HxDxSH - 261.5 x 158.2 x 63.7 mm

Weight - 0.85 kg

Power consumption - 12V, 48W

Minimum system requirements

IntelCore 2 duo, 2Gb RAM, NVIDIA Quadro / GeForce 9000

ATTENTION! look under the spoiler is worth mental health:

Price

Scanning

Scanning takes about 10 minutes.

It usually occurs on a turntable, but it is possible that the operator runs around you.

Scanning looks like a bunch of flashes from a camera (see video at the end of the review)

Editing takes a maximum of an hour if a demanding user asks to “reduce the belly” or “remove the folds” in various places.

An editing program is included with the scanner.

Remarkably, texture processing is possible with a space resolution:

RAM is required a lot.

Printer

My first impression, a printer, is a mixture of a giant jet, a bread machine, and a vacuum cleaner.

The printer weighs 340 kg, and lives its own life, sometimes it switches itself on and performs cleaning.

The printer requires constant inclusion in the network.

Layer thickness - 89-102 microns

Print speed 2-4 layers per minute

For scale - a live girl:

Consumable - gypsum from which the model is printed:

Printhead ("noggin"):

Ink cartridge:

Ink delivery to the printhead:

ATTENTION! Look under the spoiler is worth mental health:

Price

Some video

Management Program and Preview

Preview in several projections.

Estimated print time and display of the current print layer.

First, a thin layer of gypsum powder is applied to the base. After that, the print head applies a special resin, gluing the plaster in the right places, and ordinary ink. Then the next layer of gypsum is applied, etc.

After printing, the excess gypsum is removed with a special vacuum cleaner, and from hard-to-reach places with compressed air.

237 (out of 525) print layer as the program displays:

237 layer in reality:

After the printer has fully printed the model - it takes some time to dry.

It took 1.5 hours, now we will "pull out of the stove":

Remove excess gypsum using the “suction” method:

Gypsum is re-cleaned / filtered and goes into action.

Now remove the excess by the method of "blowing":

From the bottom there are 2 holes - one also blows a plaster out of them - the figure is hollow inside

Cover me with cyanoacrylate ("fixer"):

Half an hour to dry up - and in the hall of fame:

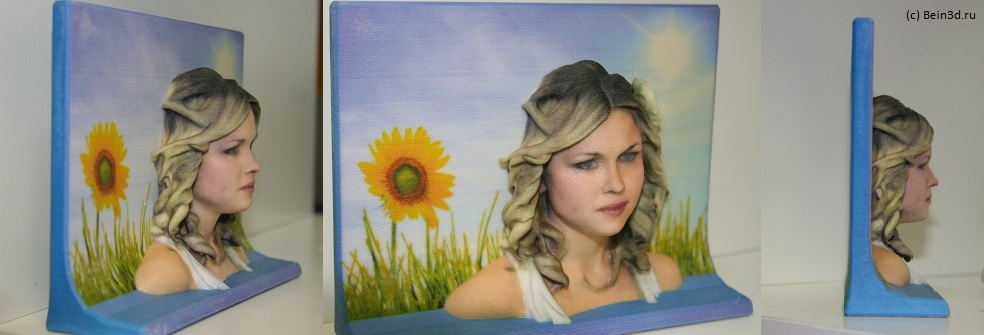

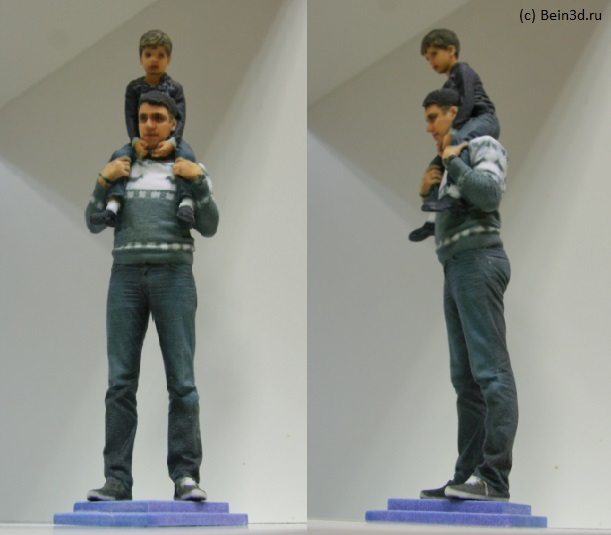

Work examples

Capture a memorable moment, a memorable form.

You can experiment with the design.

In my opinion, the most original figure.

Quality allows you to print even small patterns of clothing.

Conclusion

While still playing Quake2, I wanted to make a skin with my face.

The stage is not far off when, along with photo albums, there will be 3d albums .

So far, the figures cause a wow effect, than you can use and make a cool gift.

PS

Source: https://habr.com/ru/post/224775/

All Articles