IBM specialists have discovered a new class of durable self-healing polymers

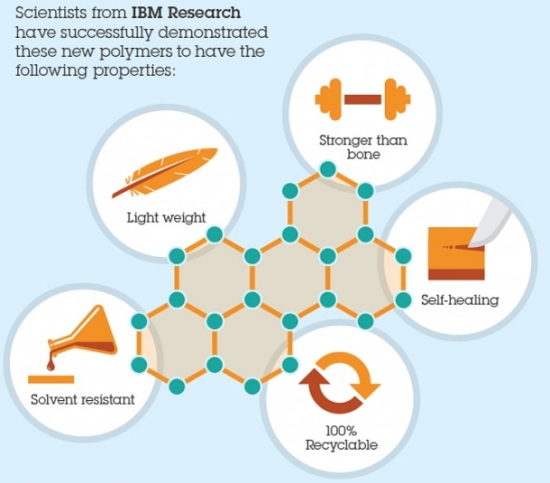

Recently, IBM announced an interesting discovery in the field of industrial polymers: the creation of a new class of polymers that can self-repair, are recyclable and resistant to mechanical damage.

It is worth noting that most of the current industrial polymers (mainly thermosetting polymers) used in electronics are not recyclable. This, of course, creates certain difficulties for the disposal of "waste material", moreover, increases the cost of production.

')

New polymers developed by IBM are devoid of the usual drawbacks - they can be recycled, plus they also have a number of additional benefits, such as the possibility of self-healing. At the same time, a new class of polymers was discovered, one might say, by chance.

Research was conducted in the framework of a new type of material search project, the properties of which could be set in advance.

With the help of IBM computing systems, scientists were able to model the approximate structure and chemical structure of this class of substances, after which the practical stage began, the purpose of which was to create a new class of polymers. Several scientists worked on the task, including Jeannette M. Garcia. Once Jeannette made a mistake in the procedure of mixing the components, and the error turned out to be key - instead of the expected polymer in the flask, a polymer with somewhat different properties was formed. In order to take a sample of the substance obtained, it was necessary to break the flask with a hammer, and the polymer itself could not be damaged, it was so strong.

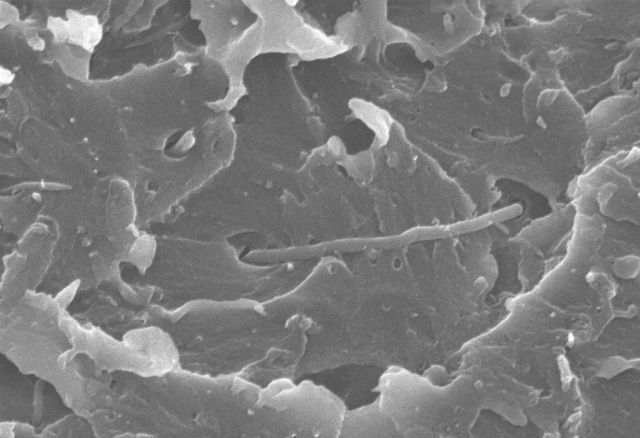

The polymer obtained by Jeannette was examined using a scanning electron microscope, and scientists were able to recognize the structure of the substance. After processing the data on a PC, experts found out that plastic was formed as a result of combining paraformaldehyde and 4,4-oxydianiline through condensation. When exposed to high temperatures of 250 degrees Celsius, a new type of plastic becomes extremely durable due to the formation of covalent bonds and the displacement of the solvent.

It also turned out that when such a polymer is mixed with microscopically small carbon fibers, a composite material is formed that is very durable (strength 60–100 MPa at 20 degrees Celsius) and is capable of self-healing to some extent (if small cracks form).

The second plastic from the same group of polymers was already created not by chance, its structure was calculated on a PC and synthesized. Plastic is an elastic gel at ordinary temperature. At the same time, such plastic, being cut into pieces, which are then folded together, is very quickly restored with preserving the strength of the original material.

According to IBM experts, the second type of plastic can be used as a very durable glue, as well as for transporting certain types of substances.

Both substances got their own names: “Titan” and “Hydro”. By the way, these plastics belong to the group of thermosetting polymers. Plastics from this group of polymers could not be reused, as mentioned earlier. The properties of the materials of the open group of polymers quite allow to process plastics of this group without any problems, using them again and again.

You can use the discovery in areas such as transport, aerospace, electronics. According to experts, discoveries of a similar scale in this area have not been made for 10 years.

The research results were published in an article in the journal Science.

Source: https://habr.com/ru/post/223871/

All Articles