How to assemble a 3D printer in Russia and why I went to do it in China

Home 3D printers are the first thing that, if it does not bring the new industrial revolution closer, then at least it provides opportunities for the realization of ideas that are useful to the world.

But why 3D-printers in Russia are so expensive, while in the west there are already devices for $ 300? I would like to tell the community about my experience in creating a 3D printer.

Everyone already knows about the benefits of 3D printing. Maximum efficiency from it is achieved in research and training, the development of new devices, and I believe that 3D printing should be available to every technical student, engineer, and generally everyone whose work is connected with creative or engineering design.

3D printer for everyone?

My goal is the development of 3D printing in Russia. There are many talented people who do not have such a wonderful tool. Therefore, my main problem was to find such 3D printers that were easy to use and accessible to everyone.

About my attempts to assemble a 3D printer in Russia

Why in Russia is such a weak development of home 3D printing?

Suppose you decide to build a 3D printer yourself .

')

Briefly about what you need for self-assembly of a 3D printer

- Printer frame This is his design, on which guides and drives with carriages are fastened, as well as electronics.

- Engines and power transmission from them to move the carriages (engines, gears, belts, threaded rods, bearings for belts)

- Carriage moving systems. This is what allows the carriages to move smoothly and not dangle (linear guides, linear bearings)

- Pusher, melter and plastic extruder. (usually a printed extruder with gears, a pushing bolt and a bar clamping system for this bolt, hotnd)

- Plane for printing (heating table)

- Electronics control. In RepRap printers, this is a card or a sandwich from 2 boards that is connected via USB to a computer.

The most important thing in the printer is the frame.

The frame of the printer RepRap is directly dependent on the design of the printer - it can be made of

threaded rods connected by plastic parts (Reprap Prusa, Original Mendel and others)

sheet material connected by ends with screws (Ultimaker)

sheet material connected by threaded rods (RepRap Prusa Air2)

aluminum profile connected by plastic parts (MendelMax, Kessel)

other combinations of the above materials

Thus, to assemble any printer you need to have sets of materials that make up the frame. Since The principle of RepRap movement is self-replication, then be prepared for the fact that for any printer you have to buy printed plastic parts. Their share is a large percentage in printers on a hairpin design, the percentage is smaller in printers with the use of sheet material (Prusa Air, Prusa i3) and the smallest or even even zero in devices completely twisted, for example, from plywood.

In addition to sets of parts, do not forget about fasteners for them to assemble the frame. In the hairpin constructions there are about a hundred nuts and washers for the M8, in the others it is smaller, mostly, most likely, the screws and nuts of the M3. In general, the amount of fasteners can reach up to 1000 rubles.

Search for accessories in our country - quest. Price tags are sometimes surprising, and many parts in Russia are simply not produced - you have to order literally at random from China and wait for the parcel for a month or more. Ordering the manufacture of some parts in Russia — also a thankless job — is either refused due to too small an order, the deadlines are delayed for many weeks, or the price tag is obtained beyond reason.

Because of all this, the gap in this area from Europe and America is 2 years. There, prices for parts and production are less, so homemade people and enthusiasts live easier.

The first printers (almost 3 years ago) my colleagues and I did the whole thing ourselves - we sharpened nozzles, weighed boards, we made parts. We bought only stepper motors.

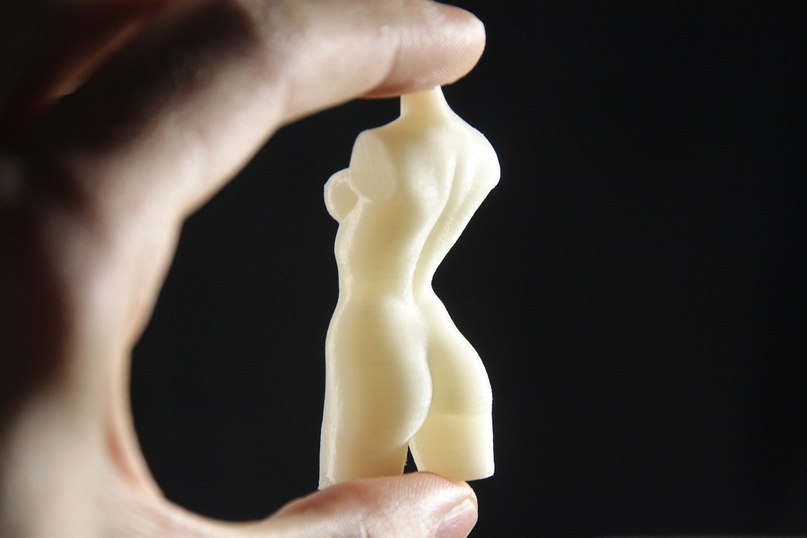

I must say that the results of the painstaking adjustment of our self-made Reprap were very good:

But it soon became clear that homemade printers are a very “fancier” product.

And what if you just buy ready?

You can buy a printer from well-known American companies that cost 90-150 thousand rubles from local dealers, or you can try to buy it yourself, which can cause problems with customs .

Many immediately have the idea to buy a ready-made Chinese-made printer, thousands for 40 rubles. Many do just that - they buy directly from the Chinese with delivery by Russian Post. But, I must upset you - it’s usually morally obsolete for a year and a half printers, whose print quality is very sad. And what can we say about the complexity of their settings and finishing files before the first print.

Road to china

It was here that the thought was ripe to see how the Americans manage to make printers of 300 bucks. And where to do it? Naturally, in China!

7584 kilometers is just over 9 hours of flight - and here we have a world production center.

Finally, I felt a freedom of action - all the components available in the stores within walking distance, milling and turning work are without exaggeration at every corner! The Chinese master simply takes the drawing from you, looks at it for 5 seconds, and the detail begins to be milled out of the blank. From the right material, right now. And this is despite the language barrier and, sometimes, communication in sign language!

A little bit about China.

We made the printer in the city of Shenzhen - the center of world electronics. In its industrial area.

All the first floors of almost all buildings are garages in which there is either production, or shops, or restaurants.

Here is the street:

For example, stainless steel products are made here.

And this is a rubber shop. Need a belt or seal? Here you can find anything:

Or, for example, look into the garages of metal processing. Everywhere there are powerful machines:

These are the products:

Immediately make and molds:

If we talk about the center of the city, it is, of course, different:

What did we get

The results are amazing - in a week we (there were only two of us) did a job that would take a month or two in Russia. We conducted experiments with different designs, constantly reworked the details - all adjustments were made instantly. And in the end they achieved what they wanted.

Why we could not do this in Russia?

It's simple: when on production they start to order only in a month, then this greatly misleads the plan of action. The smaller the order in volume, the less priority it is - the time is delayed even more. And when you realize that you need to make about 5 more minor adjustments to the final result, and it will take several months, then the mood deteriorates completely. But this is only a prototype.

Upon my return to Russia, I had the parts for the assembly of four 3D printers. And one fully assembled prototype.

Of course, I could not meet the cherished $ 300 for a finished 3D printer. This is only possible with mass production and large quantities. But significantly reduce the cost relative to the existing analogues turned out!

The print volume is 18 x 16 cm and about 15 cm in height. Layer thickness - from 0.1 mm, materials for printing - ABS, PLA, PC and others, even “rubber” plastic.

My printers cost me 50 thousand apiece and I will try to make them even cheaper and more convenient to manufacture.

Question for habrovchan in the attached poll.

UPD: now developing my project for the largest 3D printer: tsar3d.ru

Source: https://habr.com/ru/post/223123/

All Articles