Restoration of virginity accelerator Cyberstorm MK-III for Amiga computers

Epigraph

AMIGAA !! 11

Instead of the preface

A colleague Easy John gave me to debug a homemade peripheral board his newly acquired A4000 with the well-known in narrow circles accelerator Cyberstorm MK-III. The accelerator is well known not only for the fact that the Cadillac of the 68K - 68060 processor family lives in it, but also for bad problems with the socket of this processor itself. The socket is PGA (pin grid array), and it is soldered on SMD patches, that is, not into the holes of the board, but to the pads on top. Since the board is quite large, and during its installation-removal, as well as adding-removing memory modules, various physical loads are applied to it, in places of such interracial, I would say, the ration sooner or later occurs a phenomenon named after a famous mountain. near Kramatorsk. (Everything, everything, more about Ukraine I will not)

To business

Having worked at least with this setup day and didn’t even know what to do with any more - with glitches, whether in Verilog or paranormal phenomena from the accelerator - I decided to see if the accelerator suffered from disappointment in life in general and in the panel in particular.

')

It seems that the cooler is also attached (almost meaningless thing for 060; the processor heats up significantly less than its older brother in mind 040, and the cooler only makes noise), and the paste is noticeable in some places. Wait a minute, what is it like that?

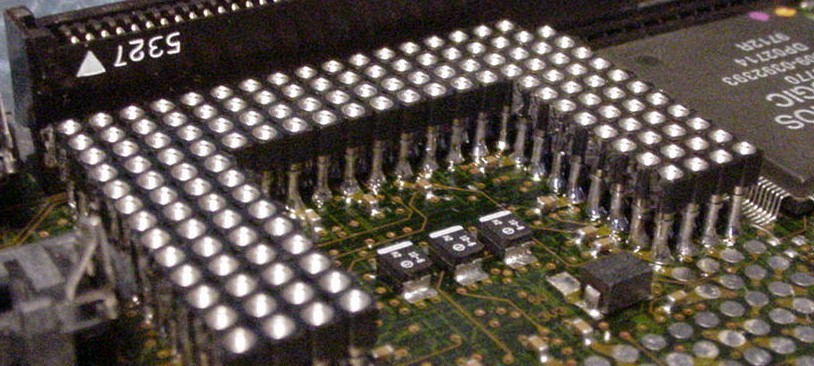

Here it is, the curse of the Baskervilles. In fact, it is known how to treat it: here it is proposed to blow the socket, and instead of it, to load a lot of collet nests, something like this:

But for this feat (266 cozy nests, a soldering iron, uphill and against the wind) I was absolutely not ready. In addition, I didn’t have any nests at hand (and so much money to buy them in the Chip and Dip boutique, all the more), and I wanted to keep the old panel.

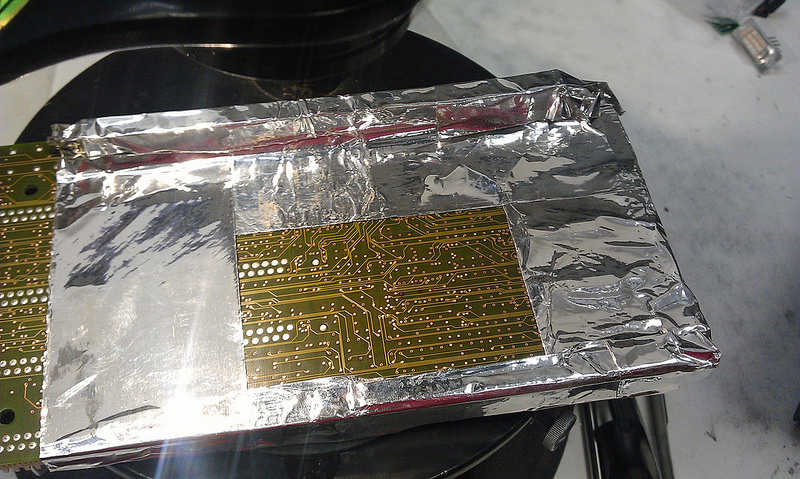

Therefore, the Chinese thermostatic was taken to the light of day, under the socket where it was possibly filled with a wash-free gel flux with the hope that when heated it would spread and dampen everything, including the rest of the socket, and the delicate parts of the board were sealed with aluminum sticky tape. (As you know, you can repair almost everything with silver tape - and what cannot be fixed with silver tape can not be fixed at all. But this is not about that now.)

Turn on thermostatic and go to drink tea. Thermostatic though Chinese, but has a Baltic temperament: its heating rate is good if 1 degree in 2 seconds. This is so that the boards and parts get warm evenly, without haste, without twisting and other deformations there. Previously, I practiced on a pair of old dead boards, experimentally taking out from there knowledge about 300 degrees of useful temperature at the surface and 280 degrees

When everything is well warmed up and the flux began to evaporate intensively, we gently help from above with a heat gun (without fanaticism!).

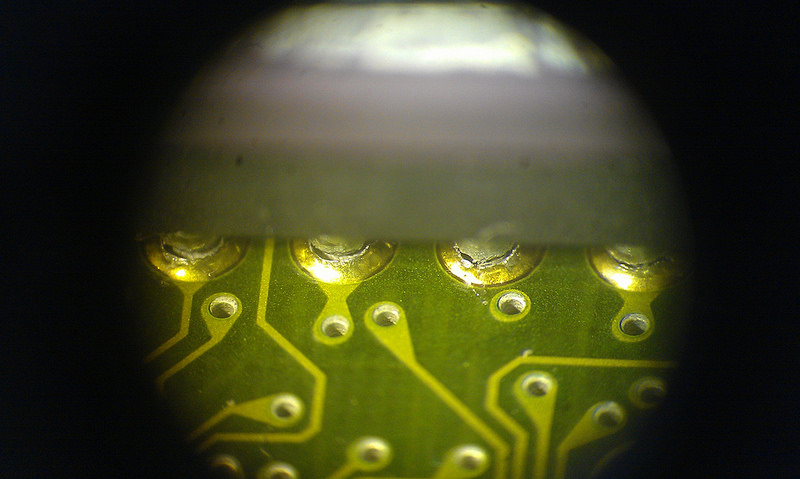

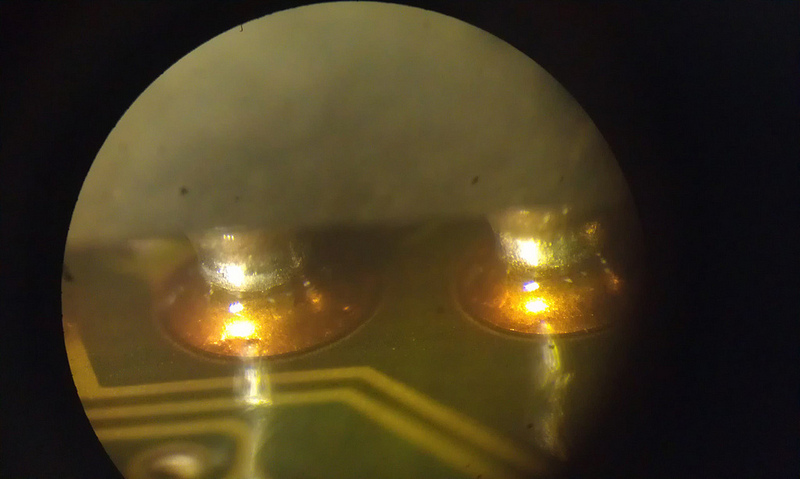

Done, let the board cool down and rest down on the microscope eyepieces (MBS-1 biological stereo microscope, around the end of the sixties of the last century, a smart thing if you replace it with an LED light):

Well, well:

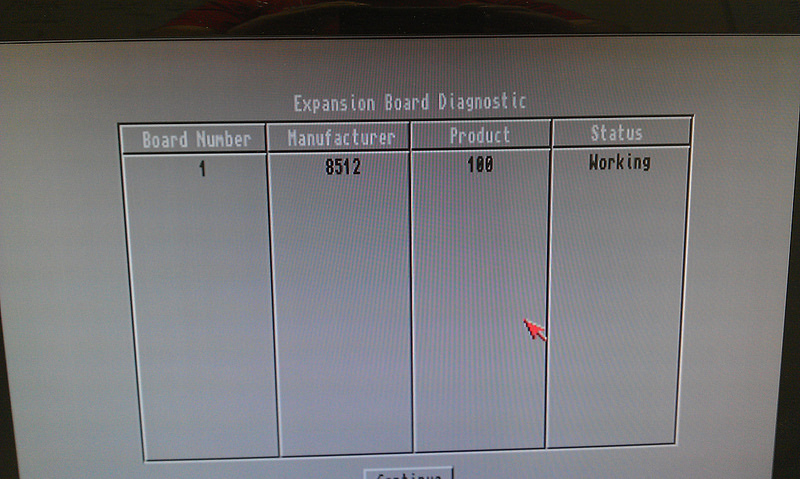

It looks convincing. We put a fee on combat duty and see if there is any smoke coming from somewhere. The smoke did not go, everyone is alive and well.

And there is peace on earth, and in man favor, as St. Luke said on another, by the way, occasion.

Source: https://habr.com/ru/post/223025/

All Articles