Spectral-selective polymer window films: 3M technology in sun protection

The need for rational use of energy has become increasingly significant over the past few decades. This article is devoted to an alternative method of protection against the heat energy of the sun coming through the windows - energy-efficient glazing with optically transparent window films.

')

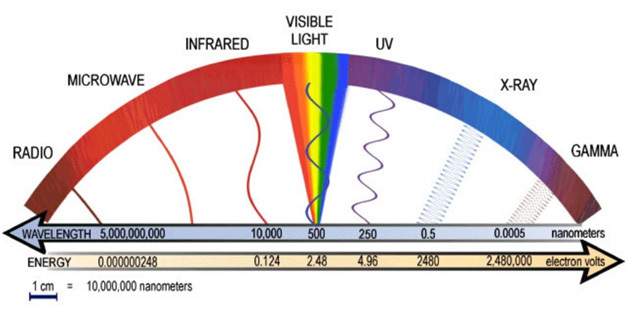

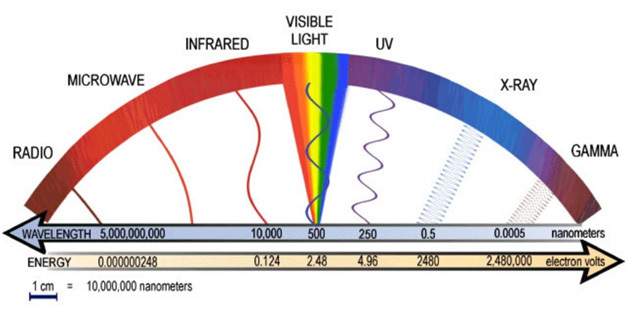

Starting a conversation about sun-optically transparent films, let us recall that white light, ultraviolet (UV) and infrared radiation (IR) are all ranges of the spectrum of electromagnetic radiation, along with Gamma and X-rays.

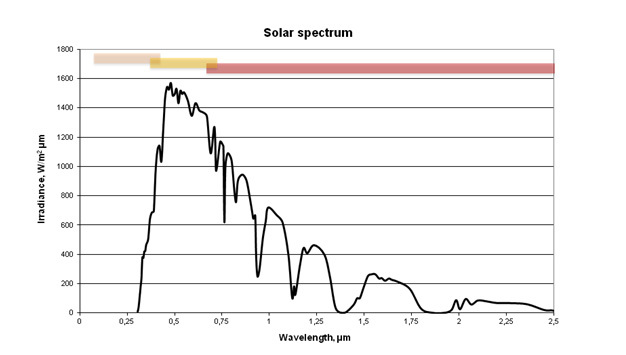

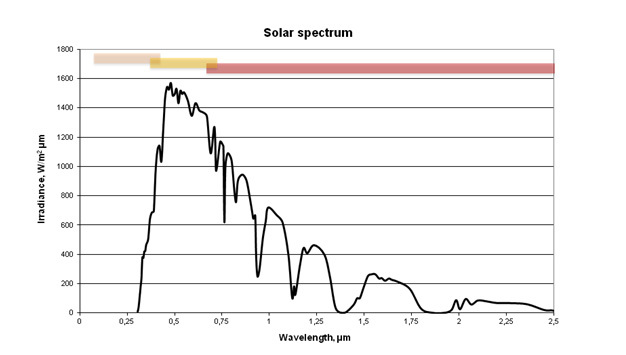

In our article we will talk about the solar spectrum in the range of lengths from 0 to 2.5 Nano Meters (nm), about how Dr. Raghu Padiyat, 3M researcher, made a unique invention of multi-layer optically transparent window films that allow white light to penetrate unhindered in the room and at the same time block UV and IR radiation. There are no sharp transitions between the ranges, but if we consider the length of the solar spectrum, then 3% is ultraviolet, 44% is visible, 53% is infrared.

Visible light transmittance with thermal cutoff (LSG), denoted as the ratio of the transmission coefficient of visible light (VLT), and solar thermal gain (SHGC), is often used to determine the effectiveness of a window film. This indicator is suitable for applications in which, in addition to reducing the proportion of passive solar energy flowing through the glazing of buildings, an increased level of internal illumination is also required.

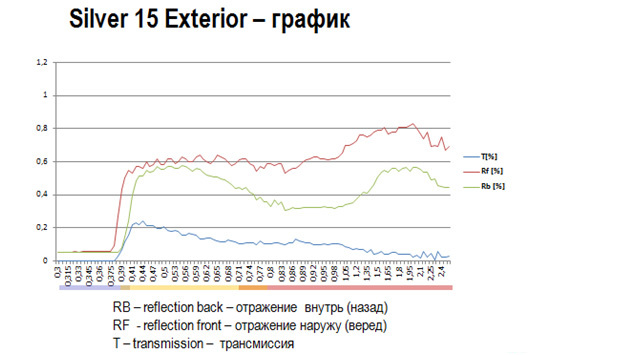

Until now, all high-LSG window films on the market have been manufactured on the basis of a dielectric-silver-dielectric structure [3,4]. In general, these films use up to three layers of silver, which leads to a high reflectance of the infrared rays of the long-wavelength region of the NIR and VLT spectrum of about 70%.

Silver is chosen due to its unique properties [5,6]. One of the drawbacks of using silver is its susceptibility to oxidation. Poor sealing of the edges of the film can cause darkening and corrosion on the perimeter.

The problem of corrosion can be solved by using silver alloys instead of pure silver, as well as careful sealing of the edges of the film. These films also have shielding properties and can interfere with the electronic systems of intra-district communication, GPS, mobile phones, etc.

It is well known that industrial production of films based on silver resonator reflectors is difficult, since very slight variation in the thickness of the silver layer results in a significant color change, especially when viewed in reflected light. In addition, the presence of silver in coatings requires sealing the edges of the applied film.

Another disadvantage of the used window films based on the silver / dielectric deposition technology is that these films have a very low water vapor permeability rate (WVTR). Water is used for mounting films and removing residues between the adhesive layer and the film is extremely important.

The infrared reflective polymer multilayer films were developed by 3M for use in automotive windshields and other applications [7,8].

Anticipating the description of the technology, we offer you a short video illustrating the principle of film operation:

Earlier, Alfrey and others showed that a polymer film comprising hundreds of layers of two materials differing in refractive index can be obtained by coextruding to form a fluorescent film [9]. The use of polymer multilayer films with birefringent optical systems was further developed by 3M [10, 11]. The use of birefringent materials in these constructions leads to the appearance of several unique properties that cannot be obtained using thin-film optics coated with a sputtering method [12].

In these films, the width of the spectrum and the location of the band boundary are determined by the thickness of each pair of layers. The thickness of these layers is chosen in such a way that a single reflection band occurs in the infrared part of the spectrum of electromagnetic waves. With an appropriate choice of the left and right border of the band and precise control of the thickness of a pair of layers, highly efficient infrared rays reflectors of the long-wavelength region of the spectrum with high transmittance of visible light can be created. The optical properties of the infrared reflectors of the long-wavelength region of the spectrum, created from polymeric materials, have an advantage due to low optical absorption, insignificant optical dispersion and optical constants of birefringent systems. These films can have a high transmission of visible light, sharp reflective border bands and low irregularity outside the passband. In a structure with a layer of ABAB simple waves, in which A and B are two polymeric materials with different refractive indices, for constructive reasons limit the reflection band in the range from 800 nm to 1200 nm. A further increase in the width of the spectrum will result in secondary reflection bands, giving color to the film. Since the spectrum of incident solar radiation extends far beyond the limits of 1200 nm, it is necessary to provide means to reduce the proportion of solar energy entering through the glazing and exceeding 1200 nm.

Nanofilter absorbing infrared rays have been studied for use in glazing [13,14]. These materials have a fairly high transmission of visible light, as well as a significant absorption in the part of the long-wave infrared region of the spectrum. Such materials can be applied to polymer films that absorb infrared rays to further increase the solar heat gain of the glazing system. Coatings based on tin and antimony oxides (ATO) are particularly interesting, since their absorption band goes beyond the limits of the long-wave infrared region of the spectrum.

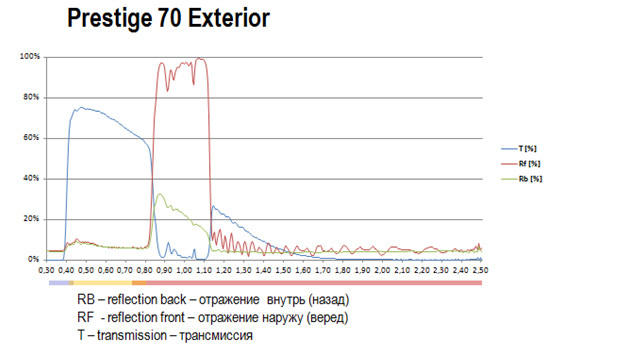

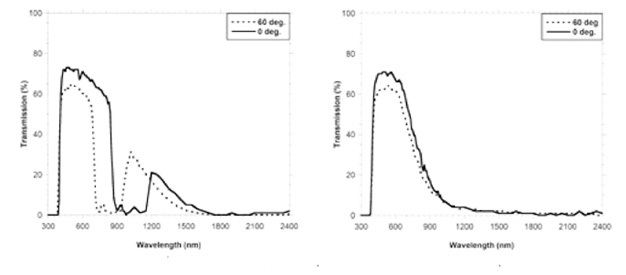

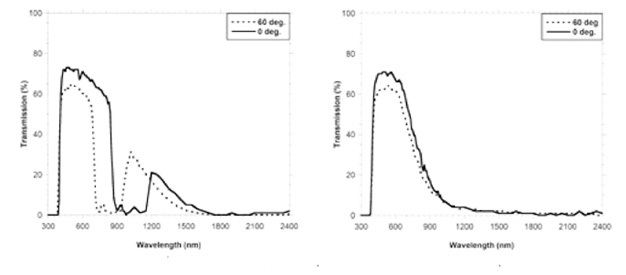

The simulated and measured light transmittance spectra of a multilayer polymer film consisting of 224 layers produced using PET and PMMA are shown in Figure 1a. As can be seen from Figure 1a, almost all light in the range of 850 nm - 1200 nm is reflected in the absence of transmission loss (except for the loss of Fresnel zones) in the visible part of the spectrum and the IR region of the spectrum beyond 1200 nm. When using ATO coating from the inside of this film, transmission in the visible part of the spectrum can be adjusted to about 70%, while almost the entire longwave IR region of the spectrum in the range of 850–2500 nm can be blocked (Figure 1b) while maintaining a high reflectance of the multilayer material. The thickness or amount of ATO in the polymer layer can be increased or decreased as desired to regulate the transmission of visible light. Particles such as carbon black with the ability to absorb in the visible part of the spectrum are used to produce window films with excellent visible light transmission coefficient [15]. In addition, you can turn on these particles to dramatically reduce the transmission coefficient in the visible part of the spectrum without significantly changing the transmission coefficient of infrared radiation or the concentration of ATO in the coating.

Figure 1a and 1b: Simulated and measured light transmission spectra of an uncoated polymeric multilayer film (Figure 1a) and an ATO coated film (Figure 1b).

In contrast to silver / dielectric sprayed films, all reflection bands based on dielectric components have a transition to shorter strip lengths with increasing angle of incidence (far from normal incidence). This angle shift is caused by the dependence of the cosine of the phase angle between the beams reflected from adjacent contact surfaces.

Due to the increase in the angle of incidence, the centers of the reflection bands with polarization perpendicular to the plane of incidence of the beam, and with polarization parallel to the plane of incidence of the beam, go to shorter wavelengths, taking into account the effective phase thickness of the layers. A polymer with a high birefringence ability can be used to create dielectric reflectors that maintain or increase their reflectance as the angle of incidence increases. In addition, for non-normal incidence, polarization effects in isotropic materials limit the steepness of the boundary of the band of natural light, which can have a significant effect on color purity.

Birefringent polymers can be used to create a reflector that has a matched border of a short wavelength band at all angles for both polarized light parallel to the plane of incidence of the beam and polarized light perpendicular to the plane of incidence of the beam, eliminating these difficulties.

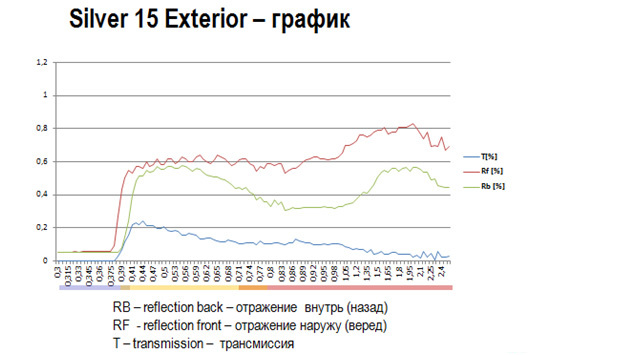

Since the reflection band of a multilayer polymer reflector shifts to shorter wavelengths containing more solar energy (Figure 3a), there is a rapid decrease in the solar heat gain at large angles of incidence. As can be seen from Figure 2a and 2b, this transition is significantly higher in multilayer polymeric structures compared to window films based on a dielectric / silver structure. The optical properties of these two types of film when falling along the normal and at 60 from the normal (given as 0 in the table and in the figures) are presented in Table 1.

It should be noted that there are no standards for off-axis performance. Industrial standard methods (see the Council on the Assessment of Translucent Constructions, www.nfrc.org ) and software (Window 5, available for download from windows.lbl.gov/software/window/window.html ) are designed to perform calculations outside the center taking into account the type of materials, based on the algorithm described by Furler [15], these calculations lead to insufficient approximation for birefringent materials. As a result, the calculations of the annual energy demand represent an approximate prediction of the savings achieved using multilayer polymer window films. In addition, since the incident solar energy varies from place to place and depends on a large number of factors, including water vapor, capable of condensing and precipitating, ground surface albedo, recharge and concentration of atmospheric pollutants among other things, solar heat gain factors vary depending on the shape spectrum of incident solar radiation.

Figure 2a and 2b: Transfer ratio of a multi-layer ATO-coated polymer film (Figure 2a) and a 7-layer ITO / Ag / ITO film (Figure 2b) for normal incidence and 60 for normal incidence.

The infrared reflective polymer multilayer films were coated with ATO nanoparticles that absorb infrared radiation to create window films for aftermarket application with a high coefficient of light transmission and a high coefficient of heat removal. It was shown that these films have a higher coefficient of heat at increased angles of the sun. Since these films do not contain any sprayed layers, they have high water vapor permeability rates and are easier to install. A comparison of these films and sprayed films with a silver / dielectric structure is presented.

UPD: Friends, thanks for the comments and your feedback!

We want to offer some more articles on this topic:

Publications of Dr. Raghu Padiyath, inventor of optically transparent films

Energy efficient IGUs with polymeric nearinfrared reflecting films

Spectrally Selective Window Films

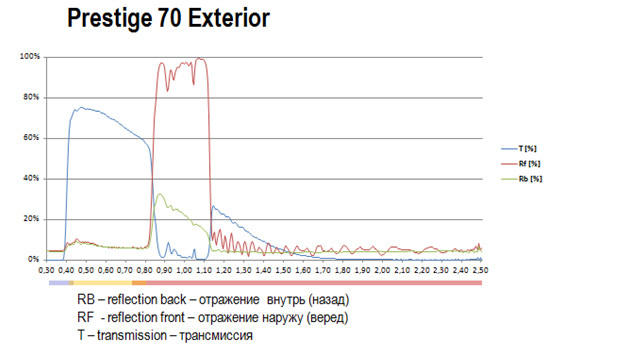

Also, the results of testing the laboratory "Composite" of our films: http://www.svetoplast.su/prestige.html

')

Terminology

Some terms in the format of abbreviations we give to simplify the perception of the material:

• Light-to-solar-gain (LSG) ratio - The transmittance of visible light with a cut-off of thermal energy

• Visible light transmission (VLT) - Visible light transmission ratio

• Solar heat gain coefficient (SHGC) Solar heat gain coefficient

• Near infrared rejection (NIR) Longwave region of the spectrum

• Water vapor transmission rates (WVTR) - Water vapor transmission coefficient

• Metal-free solar reflecting films (SRF) - Metal-free sunscreen films

• Antimony tin oxide (ATO) - Antimony and Tin Oxide

• Indium tin oxide (ITO), indium oxide and tin

• Multilayer optical film (MOF) Multi-layer optical film

• Light-to-solar-gain (LSG) ratio - The transmittance of visible light with a cut-off of thermal energy

• Visible light transmission (VLT) - Visible light transmission ratio

• Solar heat gain coefficient (SHGC) Solar heat gain coefficient

• Near infrared rejection (NIR) Longwave region of the spectrum

• Water vapor transmission rates (WVTR) - Water vapor transmission coefficient

• Metal-free solar reflecting films (SRF) - Metal-free sunscreen films

• Antimony tin oxide (ATO) - Antimony and Tin Oxide

• Indium tin oxide (ITO), indium oxide and tin

• Multilayer optical film (MOF) Multi-layer optical film

Starting a conversation about sun-optically transparent films, let us recall that white light, ultraviolet (UV) and infrared radiation (IR) are all ranges of the spectrum of electromagnetic radiation, along with Gamma and X-rays.

In our article we will talk about the solar spectrum in the range of lengths from 0 to 2.5 Nano Meters (nm), about how Dr. Raghu Padiyat, 3M researcher, made a unique invention of multi-layer optically transparent window films that allow white light to penetrate unhindered in the room and at the same time block UV and IR radiation. There are no sharp transitions between the ranges, but if we consider the length of the solar spectrum, then 3% is ultraviolet, 44% is visible, 53% is infrared.

Visible light transmittance with thermal cutoff (LSG), denoted as the ratio of the transmission coefficient of visible light (VLT), and solar thermal gain (SHGC), is often used to determine the effectiveness of a window film. This indicator is suitable for applications in which, in addition to reducing the proportion of passive solar energy flowing through the glazing of buildings, an increased level of internal illumination is also required.

Until now, all high-LSG window films on the market have been manufactured on the basis of a dielectric-silver-dielectric structure [3,4]. In general, these films use up to three layers of silver, which leads to a high reflectance of the infrared rays of the long-wavelength region of the NIR and VLT spectrum of about 70%.

Silver is chosen due to its unique properties [5,6]. One of the drawbacks of using silver is its susceptibility to oxidation. Poor sealing of the edges of the film can cause darkening and corrosion on the perimeter.

The problem of corrosion can be solved by using silver alloys instead of pure silver, as well as careful sealing of the edges of the film. These films also have shielding properties and can interfere with the electronic systems of intra-district communication, GPS, mobile phones, etc.

It is well known that industrial production of films based on silver resonator reflectors is difficult, since very slight variation in the thickness of the silver layer results in a significant color change, especially when viewed in reflected light. In addition, the presence of silver in coatings requires sealing the edges of the applied film.

Another disadvantage of the used window films based on the silver / dielectric deposition technology is that these films have a very low water vapor permeability rate (WVTR). Water is used for mounting films and removing residues between the adhesive layer and the film is extremely important.

Polymer films reflecting infrared rays

The infrared reflective polymer multilayer films were developed by 3M for use in automotive windshields and other applications [7,8].

Anticipating the description of the technology, we offer you a short video illustrating the principle of film operation:

Earlier, Alfrey and others showed that a polymer film comprising hundreds of layers of two materials differing in refractive index can be obtained by coextruding to form a fluorescent film [9]. The use of polymer multilayer films with birefringent optical systems was further developed by 3M [10, 11]. The use of birefringent materials in these constructions leads to the appearance of several unique properties that cannot be obtained using thin-film optics coated with a sputtering method [12].

In these films, the width of the spectrum and the location of the band boundary are determined by the thickness of each pair of layers. The thickness of these layers is chosen in such a way that a single reflection band occurs in the infrared part of the spectrum of electromagnetic waves. With an appropriate choice of the left and right border of the band and precise control of the thickness of a pair of layers, highly efficient infrared rays reflectors of the long-wavelength region of the spectrum with high transmittance of visible light can be created. The optical properties of the infrared reflectors of the long-wavelength region of the spectrum, created from polymeric materials, have an advantage due to low optical absorption, insignificant optical dispersion and optical constants of birefringent systems. These films can have a high transmission of visible light, sharp reflective border bands and low irregularity outside the passband. In a structure with a layer of ABAB simple waves, in which A and B are two polymeric materials with different refractive indices, for constructive reasons limit the reflection band in the range from 800 nm to 1200 nm. A further increase in the width of the spectrum will result in secondary reflection bands, giving color to the film. Since the spectrum of incident solar radiation extends far beyond the limits of 1200 nm, it is necessary to provide means to reduce the proportion of solar energy entering through the glazing and exceeding 1200 nm.

Nanofilter absorbing infrared rays have been studied for use in glazing [13,14]. These materials have a fairly high transmission of visible light, as well as a significant absorption in the part of the long-wave infrared region of the spectrum. Such materials can be applied to polymer films that absorb infrared rays to further increase the solar heat gain of the glazing system. Coatings based on tin and antimony oxides (ATO) are particularly interesting, since their absorption band goes beyond the limits of the long-wave infrared region of the spectrum.

RESULTS AND DISCUSSION

The simulated and measured light transmittance spectra of a multilayer polymer film consisting of 224 layers produced using PET and PMMA are shown in Figure 1a. As can be seen from Figure 1a, almost all light in the range of 850 nm - 1200 nm is reflected in the absence of transmission loss (except for the loss of Fresnel zones) in the visible part of the spectrum and the IR region of the spectrum beyond 1200 nm. When using ATO coating from the inside of this film, transmission in the visible part of the spectrum can be adjusted to about 70%, while almost the entire longwave IR region of the spectrum in the range of 850–2500 nm can be blocked (Figure 1b) while maintaining a high reflectance of the multilayer material. The thickness or amount of ATO in the polymer layer can be increased or decreased as desired to regulate the transmission of visible light. Particles such as carbon black with the ability to absorb in the visible part of the spectrum are used to produce window films with excellent visible light transmission coefficient [15]. In addition, you can turn on these particles to dramatically reduce the transmission coefficient in the visible part of the spectrum without significantly changing the transmission coefficient of infrared radiation or the concentration of ATO in the coating.

Figure 1a and 1b: Simulated and measured light transmission spectra of an uncoated polymeric multilayer film (Figure 1a) and an ATO coated film (Figure 1b).

In contrast to silver / dielectric sprayed films, all reflection bands based on dielectric components have a transition to shorter strip lengths with increasing angle of incidence (far from normal incidence). This angle shift is caused by the dependence of the cosine of the phase angle between the beams reflected from adjacent contact surfaces.

Due to the increase in the angle of incidence, the centers of the reflection bands with polarization perpendicular to the plane of incidence of the beam, and with polarization parallel to the plane of incidence of the beam, go to shorter wavelengths, taking into account the effective phase thickness of the layers. A polymer with a high birefringence ability can be used to create dielectric reflectors that maintain or increase their reflectance as the angle of incidence increases. In addition, for non-normal incidence, polarization effects in isotropic materials limit the steepness of the boundary of the band of natural light, which can have a significant effect on color purity.

Birefringent polymers can be used to create a reflector that has a matched border of a short wavelength band at all angles for both polarized light parallel to the plane of incidence of the beam and polarized light perpendicular to the plane of incidence of the beam, eliminating these difficulties.

Since the reflection band of a multilayer polymer reflector shifts to shorter wavelengths containing more solar energy (Figure 3a), there is a rapid decrease in the solar heat gain at large angles of incidence. As can be seen from Figure 2a and 2b, this transition is significantly higher in multilayer polymeric structures compared to window films based on a dielectric / silver structure. The optical properties of these two types of film when falling along the normal and at 60 from the normal (given as 0 in the table and in the figures) are presented in Table 1.

It should be noted that there are no standards for off-axis performance. Industrial standard methods (see the Council on the Assessment of Translucent Constructions, www.nfrc.org ) and software (Window 5, available for download from windows.lbl.gov/software/window/window.html ) are designed to perform calculations outside the center taking into account the type of materials, based on the algorithm described by Furler [15], these calculations lead to insufficient approximation for birefringent materials. As a result, the calculations of the annual energy demand represent an approximate prediction of the savings achieved using multilayer polymer window films. In addition, since the incident solar energy varies from place to place and depends on a large number of factors, including water vapor, capable of condensing and precipitating, ground surface albedo, recharge and concentration of atmospheric pollutants among other things, solar heat gain factors vary depending on the shape spectrum of incident solar radiation.

Table 1: Solar energy transmission properties of a polymer window film for after-sales application and a dielectric / silver window film.

| Type of | VLT (%) | VLR (%) | SHGC | Reflection of UV rays (%) | |||

| 0 | 60 | 0 | 60 | 0 | 60 | ||

| Polymer Multilayer with ATO | 69 | 60 | 8.5 | 13 | 0.51 | 0.42 | 99.9 |

| 7-layer ITO / Ag | 69 | 62 | 8.0 | 12 | 0.47 | 0.44 | 99.9 |

Figure 2a and 2b: Transfer ratio of a multi-layer ATO-coated polymer film (Figure 2a) and a 7-layer ITO / Ag / ITO film (Figure 2b) for normal incidence and 60 for normal incidence.

CONCLUSION

The infrared reflective polymer multilayer films were coated with ATO nanoparticles that absorb infrared radiation to create window films for aftermarket application with a high coefficient of light transmission and a high coefficient of heat removal. It was shown that these films have a higher coefficient of heat at increased angles of the sun. Since these films do not contain any sprayed layers, they have high water vapor permeability rates and are easier to install. A comparison of these films and sprayed films with a silver / dielectric structure is presented.

Literature

1. www.v-kool-usa.com

2. www.vista-films.com

3. PH Berning and AF Turner, “Forced Transmission in Absorbing Films Used in the Design of a Bandpass Filter”, 47 (3), 230, J. Opt. Soc. Am., 1957

4. PH Berning, Principles of Architectural Tiling Design, 22 (24), 4127, Appl. Opt., 1983

5. J. Boettcher, M. Scott, B. Koster and M. Kominami, “Reflective Sunlight and Metal-Free Film as a Result Provides Multi-Layer Execution”, p. 513, Glass Processing Days Conference, June 2001

6. J. Boettcher, M. Kominami and M. Scott, “The results of multi-layer performance using a metal-free and neutral color reflective sun-ray film,” p. 538, Glass Processing Days Conference, 2003.

7. T. Alfrey Jr., EF Gurnee and WJ Schrenk, “Physical Optics of a Fluorescent Multilayer Plastic Film”, 9 (6), 400, Poly. Eng. Sci, 1969

8. JM Jonza, MF Weber, AJ Ouderkirk and CA Sover, Optical Film, US Patent 5,882,774, March 16, 1999

9. JA Wheatley, MF Weber, AJ Ouderkirk, “Optical Film with a Sharp Border Strip”, US Patent 6,157,490, December 5, 2000

10. MF Weber, CA Stover, LR Gilbert, TJ Nevitt, and AJ Ouderkirk, “Large birefringent optics in multilayer polymer reflectors”, Science, 287, 2451, 2000

11. S. Schlem and GB Smith, “Weak LaB6 Nanoparticles in Polymers as Optimized Sun Glazing”, 82 (24), 4346, Appl. Phys. Lett., 2003

12. GB Smith, MJ Ford, C. Masens and J. Muir, “Energy-saving Coatings in the NanohouseTM Project”, 4, 381, Current Applied Physics, 2004

14. DJ McGurran, RL Brott, JA Olson, US Patent No. 6,811,867, November 2, 2007

15. RA Furler, Angular Dependence of the Optical Properties of Homogeneous Glasses, 97 (2), 1129, ASHRAE Trans., 1991

2. www.vista-films.com

3. PH Berning and AF Turner, “Forced Transmission in Absorbing Films Used in the Design of a Bandpass Filter”, 47 (3), 230, J. Opt. Soc. Am., 1957

4. PH Berning, Principles of Architectural Tiling Design, 22 (24), 4127, Appl. Opt., 1983

5. J. Boettcher, M. Scott, B. Koster and M. Kominami, “Reflective Sunlight and Metal-Free Film as a Result Provides Multi-Layer Execution”, p. 513, Glass Processing Days Conference, June 2001

6. J. Boettcher, M. Kominami and M. Scott, “The results of multi-layer performance using a metal-free and neutral color reflective sun-ray film,” p. 538, Glass Processing Days Conference, 2003.

7. T. Alfrey Jr., EF Gurnee and WJ Schrenk, “Physical Optics of a Fluorescent Multilayer Plastic Film”, 9 (6), 400, Poly. Eng. Sci, 1969

8. JM Jonza, MF Weber, AJ Ouderkirk and CA Sover, Optical Film, US Patent 5,882,774, March 16, 1999

9. JA Wheatley, MF Weber, AJ Ouderkirk, “Optical Film with a Sharp Border Strip”, US Patent 6,157,490, December 5, 2000

10. MF Weber, CA Stover, LR Gilbert, TJ Nevitt, and AJ Ouderkirk, “Large birefringent optics in multilayer polymer reflectors”, Science, 287, 2451, 2000

11. S. Schlem and GB Smith, “Weak LaB6 Nanoparticles in Polymers as Optimized Sun Glazing”, 82 (24), 4346, Appl. Phys. Lett., 2003

12. GB Smith, MJ Ford, C. Masens and J. Muir, “Energy-saving Coatings in the NanohouseTM Project”, 4, 381, Current Applied Physics, 2004

14. DJ McGurran, RL Brott, JA Olson, US Patent No. 6,811,867, November 2, 2007

15. RA Furler, Angular Dependence of the Optical Properties of Homogeneous Glasses, 97 (2), 1129, ASHRAE Trans., 1991

Today 3M films are available for everyone to find comfort

We suggest you to visit the website www.3mrussia.ru/okna for more detailed information.

And we also offer a 15% discount on the film to all Habrahabr readers. For more information, please contact the 3M specialized partners for the distribution and installation of 3M window films.

And we also offer a 15% discount on the film to all Habrahabr readers. For more information, please contact the 3M specialized partners for the distribution and installation of 3M window films.

Where can I buy?

Call us at the multichannel phone +7 495 784 7474.

Ask questions in the comments, we will try to answer all!

Ask questions in the comments, we will try to answer all!

UPD: Friends, thanks for the comments and your feedback!

We want to offer some more articles on this topic:

Publications of Dr. Raghu Padiyath, inventor of optically transparent films

Energy efficient IGUs with polymeric nearinfrared reflecting films

Spectrally Selective Window Films

Also, the results of testing the laboratory "Composite" of our films: http://www.svetoplast.su/prestige.html

Source: https://habr.com/ru/post/223005/

All Articles