Overview of leading companies in the provision of 3D printing services

I got the impression that there is a stereotype in Russia that you can earn on 3d-printers only in two ways:

I got the impression that there is a stereotype in Russia that you can earn on 3d-printers only in two ways:1) become an international company dealer / create production of your own 3d-printers

2) buy several 3d printers and take orders from architects / doctors / military

This post will be devoted to the fact that there are much more opportunities, the “price of entry” for this market for an individual

Under the cut you will find a brief overview of the three giants of the European and American 3d-printing industry, which do not specialize in producing their own 3d-printers, but develop communities, create a " marketplace ", act as platforms for start-ups, designers and so on. After the review of the "Big Three", an overview of the most interesting projects created around these giants follows.

')

Some projects have comments from Konstantin Ivanov ( consst ), who visited European ( 3DPrintShow ) and American ( Inside 3D Printing ) conferences.

Three giants in the field of 3D printing marketplaces from the USA and Europe

www.shapeways.com

en.wikipedia.org/wiki/Shapeways

The company, organized in 2007 in the Netherlands (came from the Philips business incubator), but is headquartered in New York. The company employs 90 people. At the moment, attracted about $ 40 million investment. It has two full production in the Netherlands and in New York. The number of products ordered has exceeded one million .

Konstantin: “The world leader and leader in the US market, the company Shapeways. She successfully located her head office in Queens, NY, becoming Mecca among the creative people. For a fairly decent history of its existence, Shapeways gathered a huge community of designers, at the end of 2013 - 300,000 people. Of course, the number of active and prolific designers is much smaller, but the total number and products on the marketplace cannot fail to impress.

With each of the active designers, managers of the Shapeways community (they are commonly called community managers, which is rather rare in Russia), work a lot, communicate, help solve any issues: high-quality photography of products, placement on the marketplace, and fixing 3d models. In general, the community is the heart of Shapeways.

The huge knowledge base collected from them on the forum and in the sections of the tutorials on the site allows you to find the answer to almost any question that arises when working with 3d models for printing. A storehouse of knowledge.

A part of immigrants from Shapeways (former community managers, production managers) are already creating their own separate businesses in the field of 3d printing. Shapeways encourages and develops an entrepreneurial culture.

However, competitors are very, very dislike Shapeways for dumping the market. So it is, their prices for 3d-printing from a variety of different materials are almost always lower than competitors from Europe. Can afford, with so many investments attracted)

Shapeways have created and developed an excellent powerful API for developers of various online customizers of 3d models, which can also be made through them. As a result, in addition to the marketplace, they work as a production and API, which is very convenient.

They have completely stopped shipping to Russia since last year, citing problems at customs. By the way, I must say that the experience of ordering 3d printing from them in NY is also not perfect: they threw off the delivery time of the samples, I had to write in support, but the issue was quickly resolved. ”

Some videos and articles in English for more in-depth review.

Video about the company. Keanu Reeves is there too.

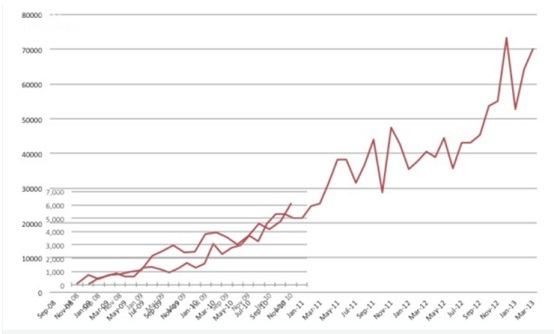

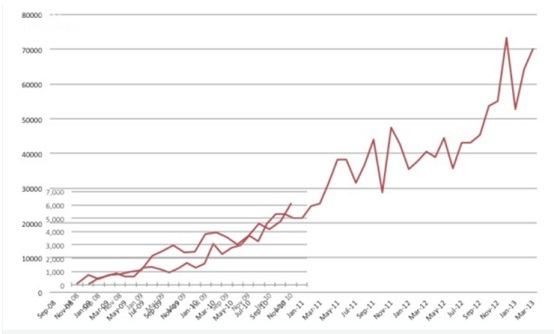

The number of manufactured unique products from 2008 to 2013

Founder Peter Weijmarshausen

Article in Forbes (10/10/2011)

Wired article by Bruce Sterling (03/10/2011)

Article in BusinessInsider (12/19/2012)

Speech by Peter Weijmarshausen on TechCrunch

Another performance by Peter Weijmarshausen

Video about the company. Keanu Reeves is there too.

The number of manufactured unique products from 2008 to 2013

Founder Peter Weijmarshausen

Article in Forbes (10/10/2011)

Wired article by Bruce Sterling (03/10/2011)

Article in BusinessInsider (12/19/2012)

Speech by Peter Weijmarshausen on TechCrunch

Another performance by Peter Weijmarshausen

www.sculpteo.com

en.wikipedia.org/wiki/Sculpteo

French startup launched in 2009. Attracting several million investments, has a small fleet of its equipment

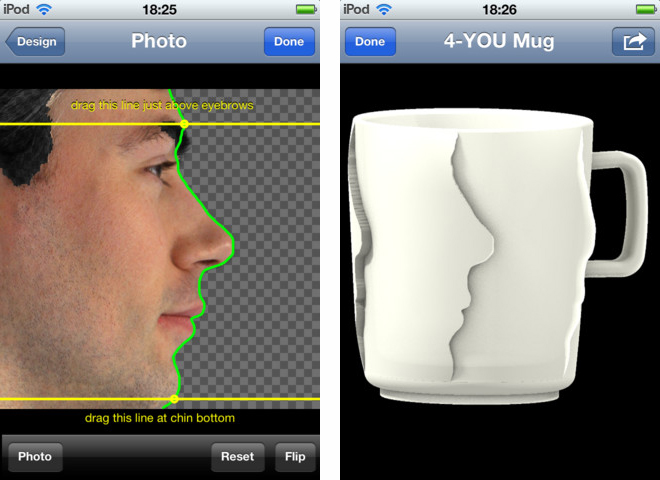

Strengths: a very interesting online service, with the possibilities not only to analyze your model, but also to prepare it for printing online. There is a mobile application 3DPcase

Konstantin: “The guys from France, started after the appearance of Shapeways on the market. A small team, its small production (industrial 3d-printers) in Paris.

Like many other players in the market, part of their production capacity is outsourced. This is quite logical, as to keep under control a huge production, including from metals, ceramics, etc. - pretty false story.

Quite often you can meet them at exhibitions. The last time, talking with them at 3DPrintShow in London and Inside3DPrinting in New York, the guys shared their opinions about the market development rates in Europe and the USA and a little more about competition in Europe, where Shapeways is also actively going.

The main focus of Sculpteo's development is applications, their own online software for calculating, correcting and even preparing 3D models for printing. This is very impressive, none of the competitors do this. For comparison, Shapeways uses its software only half, the second part - software companies Netfabb.

Sculpteo is great for those who are already in many ways professionally able to work with 3d-models and use 3d-printing for prototyping.

The team also develops its API. They do the delivery to Russia, according to the Clement’s director, but this is not possible in fact. ”

more about Sculpteo

Founder of Éric Carreel

en.wikipedia.org/wiki/Eric_Carreel

Speech by Éric Carreel on TED in French

www.technobuffalo.com/2012/04/01/want-to-print-in-3d-just-grab-your-ios-device-and-the-sculpteo-app

en.wikipedia.org/wiki/Eric_Carreel

Speech by Éric Carreel on TED in French

www.technobuffalo.com/2012/04/01/want-to-print-in-3d-just-grab-your-ios-device-and-the-sculpteo-app

i.materialise.com

en.wikipedia.org/wiki/Materialise_NV

Belgian company, established in 1990 (sic!) Year.

The makers of the “mammoth-like stereolithography machine” (print area 2 meters x 0.7 meters x 0.8 meters)

Once they kept their blog on Habré, with some quite useful articles, for example, the translation of the article about the "Industrial Revolution" 1 , 2 , 3 , 4 , 5 .

Konstantin: “The parent company Materialize has been established for quite some time, it has an office both in Belgium and, for example, in Ukraine. The main activity is the prototyping of industrial, engineering, medical, aviation, etc. products.

However, the company has its own consumer direction, which was called i.Materialise. Also develop marketplace and community. If you look closely, it is very much taking an example from American colleagues, right up to copying interface elements, which is quite logical - usability in Shapeways is really very good.

Not so long ago launched the so-called Boutiques, separate stores for select designers. Continue to move to the consumer segment.

A number of important advantages: its large production with the most experienced staff and a large number of different technologies, printers and post-processing. Completely your software that works well with models (but not better than Sculpteo does). And, of course, API, which they actively develop and connect new and new partners to it.

I also offer the white label option for companies who want their customers not to know exactly where their goods are manufactured. ”

A little video about projects Materialize

TED Video (in English)

How the biggest stereolithography machine works

Printing clothes

How the biggest stereolithography machine works

Printing clothes

How to make money on 3d printing without having a 3d printer

Aggregators:

3DHubs.com - allow owners to register their 3d-printer in the database. Thus, it is possible for any person to find either the nearest 3d printer, or the one that is needed (worldwide).

Plus, they can collect useful statistics and publish monthly reports on trends . Take a commission of 15-20%

Konstantin: “One of the investors from the London fund, who also invested in the company, introduced me to the founders of a fairly fresh start-up 3dhubs. Brian and Bram have invented and made an excellent international history, which in reality makes life easier for those who need to print something “close to home”.

The service works worldwide and even a little in Russia. The guys are attentive to the client service inside, help each client if there are problems with printing from one of the hub owners. Very comfortably.

Coming to each new city or exhibition, they make the so-called unlock of the city and open new hubs with printers there. So it was at an exhibition in London last year. "

makeXYZ.com

The project of Texas entrepreneurs. Let you search for 3d printers and 3d designers. Got an investment from Intel.

Standing on the shoulders of giants

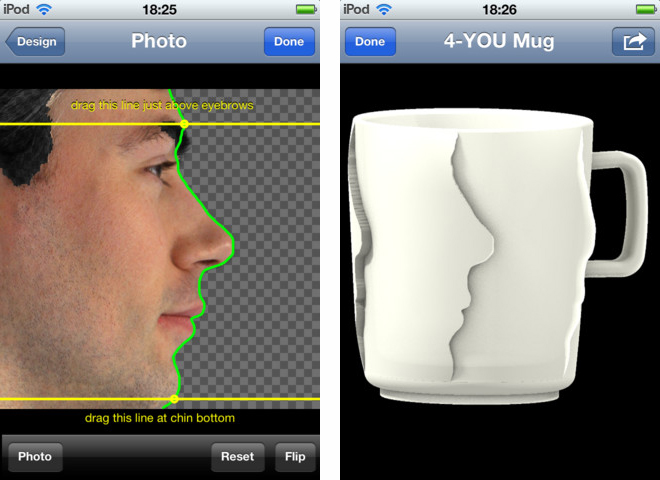

www.sols.co

Allows you to create personalized insoles.

Konstantin: “A great example of how Sols - Kegan Schouwenburg, developing inside a small startup company, became infected with an entrepreneurial spirit and began its project to produce customized orthopedic insoles made with 3d printing!

Kegan was one of those who made the production of Shapeways from scratch, and this is truly a great job.

Now her company has already attracted about $ 8 million in investments, from the same investors that have invested in Shapeways and are actively developing their business. At the same time for the manufacture of bases for insoles uses polyamide (nylon) and makes all the samples using Shapeways. Proper collaboration and collaboration. ”

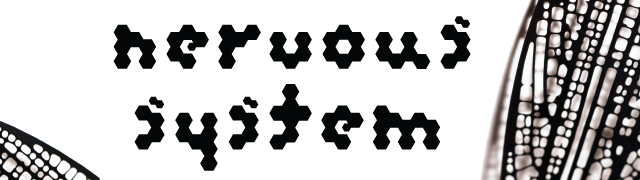

mixeelabs.com

The online application allows you to create figures ($ 25), molecules , key chains for dogs , cufflinks and wallets for cards .

Konstantin: “The second success story in the business of 3d printing is also from a girl, a former employee of Shapeways. Nancy Yi Liang - the founder of the customizer of various products Mixeelabs earns on his brainchild and lives in New York.

At our last meeting with her, she told how well things are going with selling her products from the site (80% of sales), a little worse from the Shapeaways marketplace (20% of sales), but at the same time, the very same viral effect was given to her by the very Sad Keanu which she invented and perfectly spread everywhere.

Her project is a great example of how to come up with an interesting and rather viral thing, you can earn on it in the long run. ”

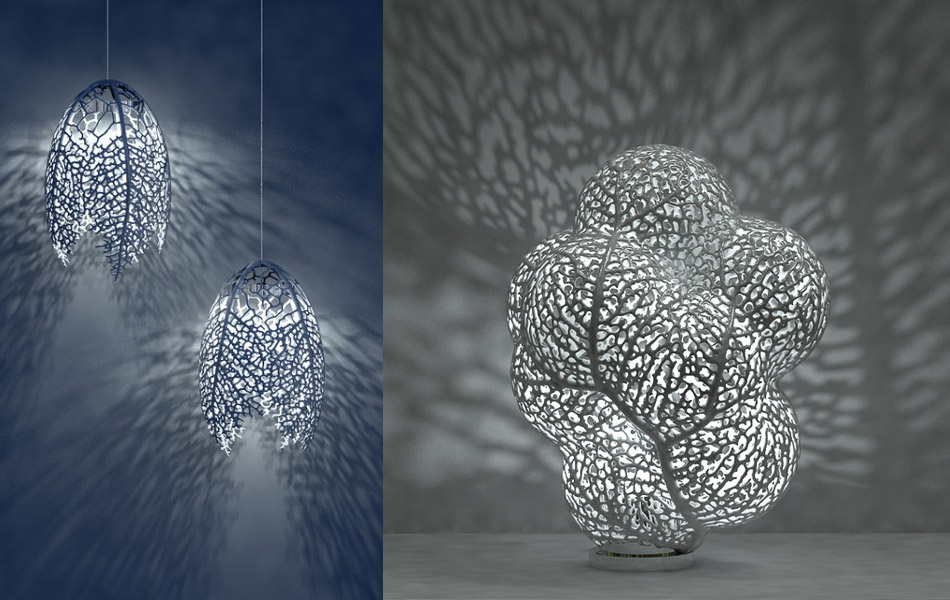

joshharker.com

Joshua Harker - Artist, sculptor, musician, digital adventurer, imagination architect, troublemaker

Konstantin: “Joshua Harker is a vivid example of how an offline sculptor began to apply digital technologies in his work, 3d-modeling and later engaged in entrepreneurship, opened his company, developed his uniform and recognizable style (which many others later copied ) and showed how to effectively apply new approaches in design to 3d printing. ”

Speech by Joshua Harker on TED

His KickStarter project (in collaboration with Shapeways)

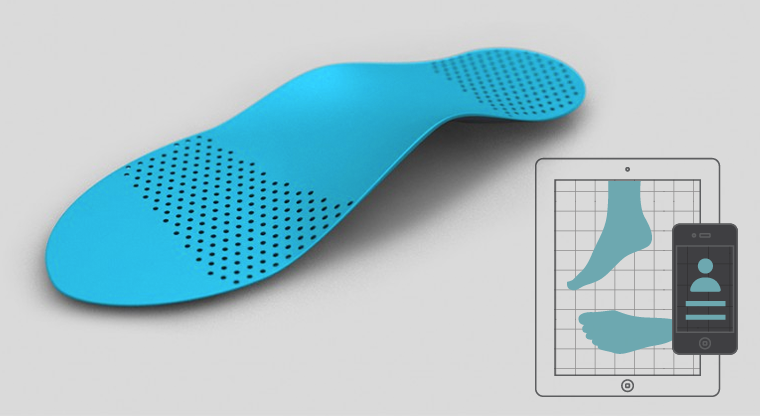

Mathematician's dice

KickStarter Project (in collaboration with Shapeways)

Independent projects

www.mymo.is

Konstantin: Just a wonderful and simple online service for those who want to create, for example, a personalized metal pendant. Everything is very simple: enter the letters you need, see what your product looks like, choose metal, order.

I could not resist and decided that with what we are worse, we would do this too. Here is the result:

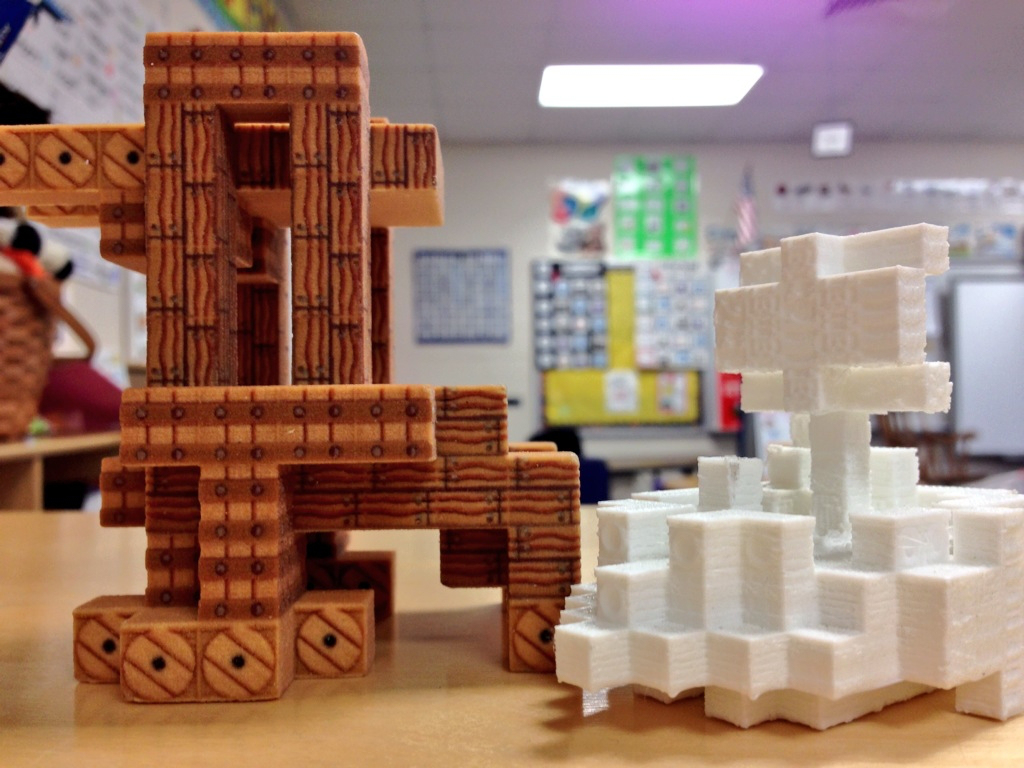

www.minetoys.com

For all Minecraft fans. Prints your character from the game.

www.twikit.com

The service allows you to customize gifts and decorations from plastic and metal.

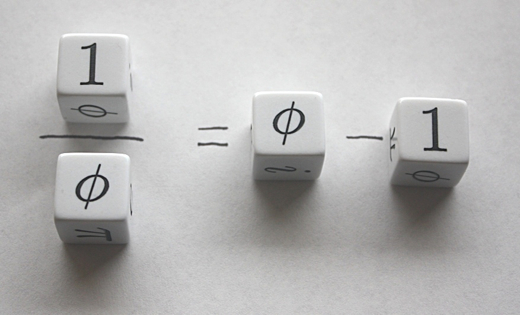

nervous.com

Konstantin: “The company Nervous is practically the gods in the design of things for 3d printing, they come up with new forms and structures and constantly amaze.

In addition to the beautiful futuristic design, they came up with an incredible online thing , which creates stunning kinetic structures right in the browser, right before your eyes. All this is flexible and allows you to actually make wearable objects made using 3d printing.

Photos of works from the Nervous System

Blokify.com

A mobile application that makes it very easy to create a 3d model and send it to print. Convenient to work with children.

Video and a couple of pictures

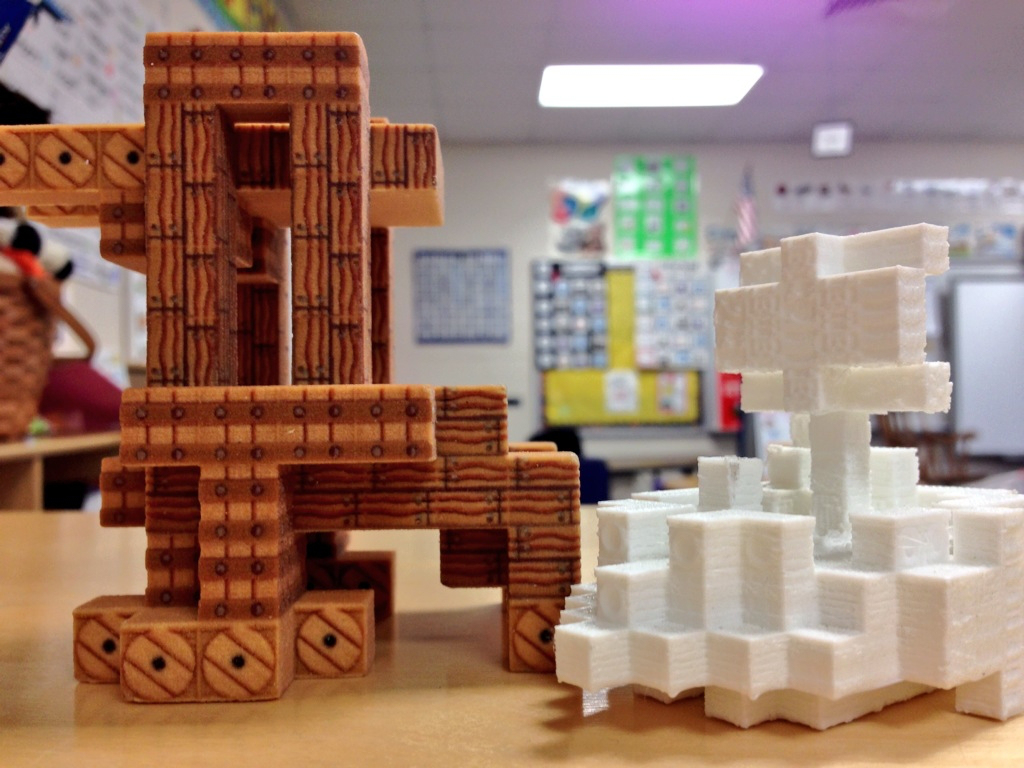

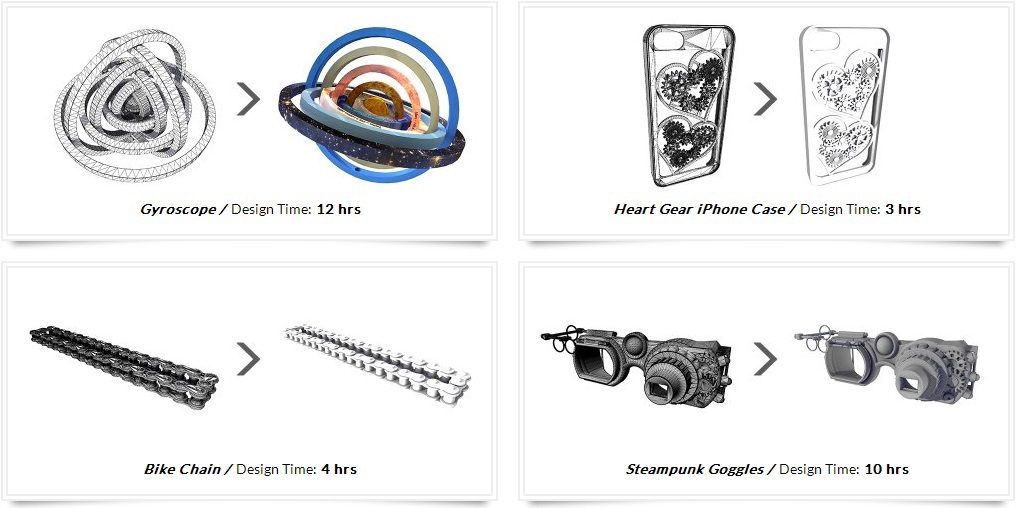

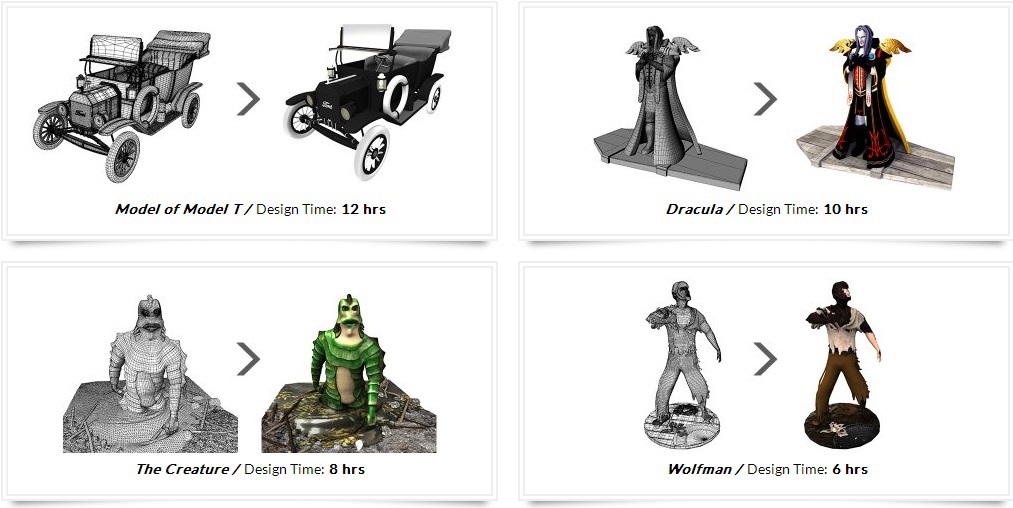

we draw

materialize

we draw

materialize

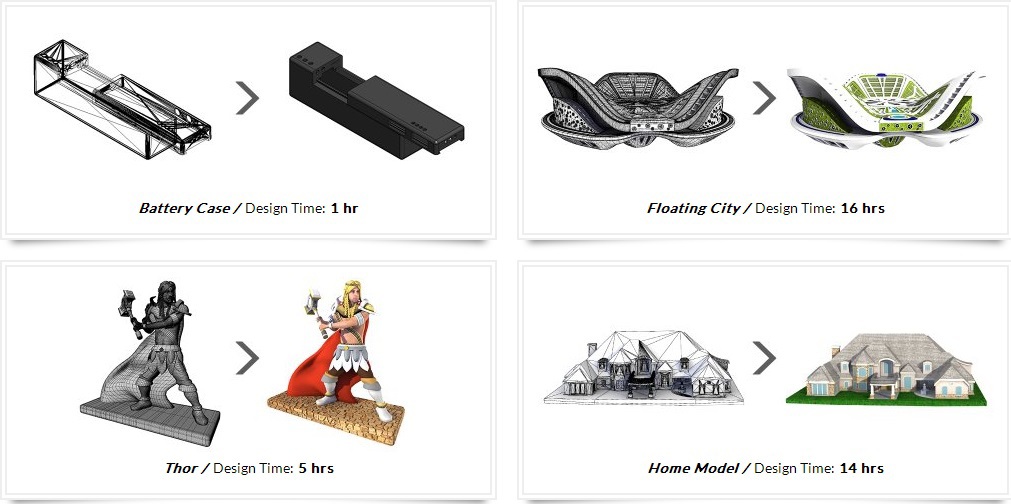

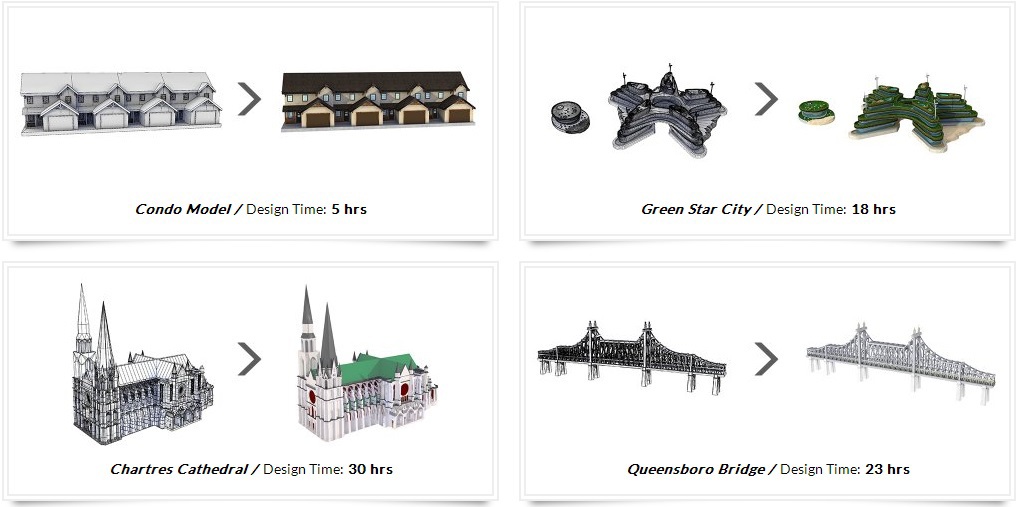

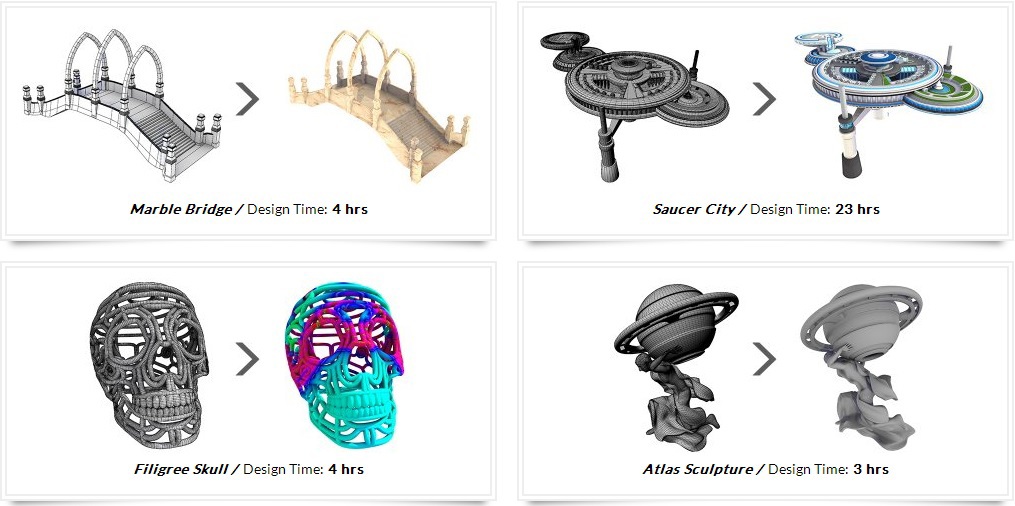

WhiteClouds.com

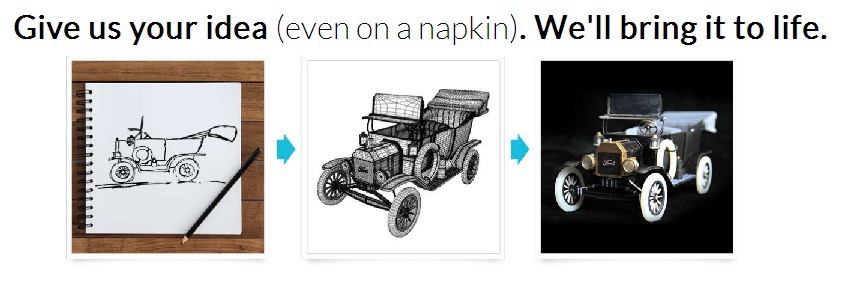

»Send your ideas (even on a napkin). We will bring them to life. "

The company does not require its customers to be able to handle a computer: you can send a simple sketch, made by hand, and the company's specialists will turn it into a digital three-dimensional model, print it on a 3D printer, and send the finished product to the customer. Once they even sent a cardboard model to the company, asking them to print a copy on a 3d printer, and the order was completed.

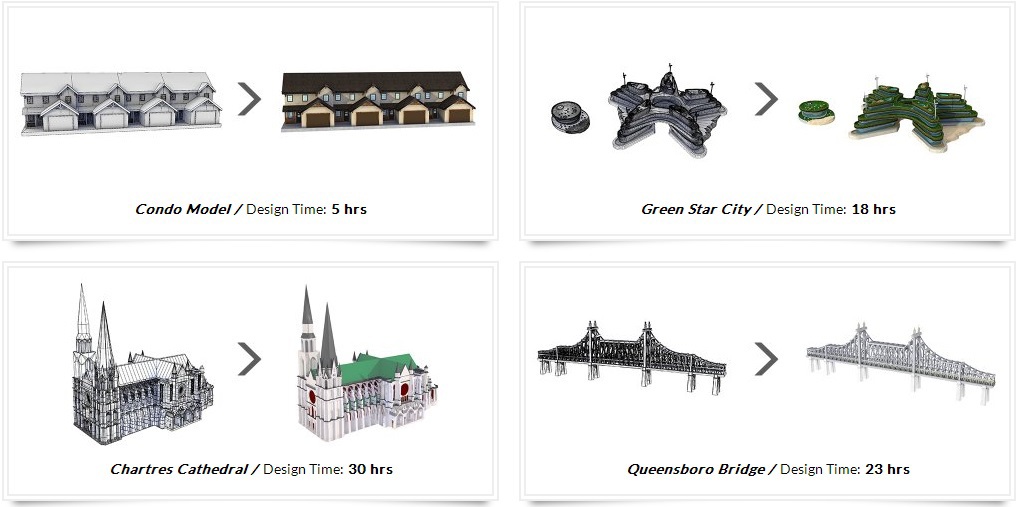

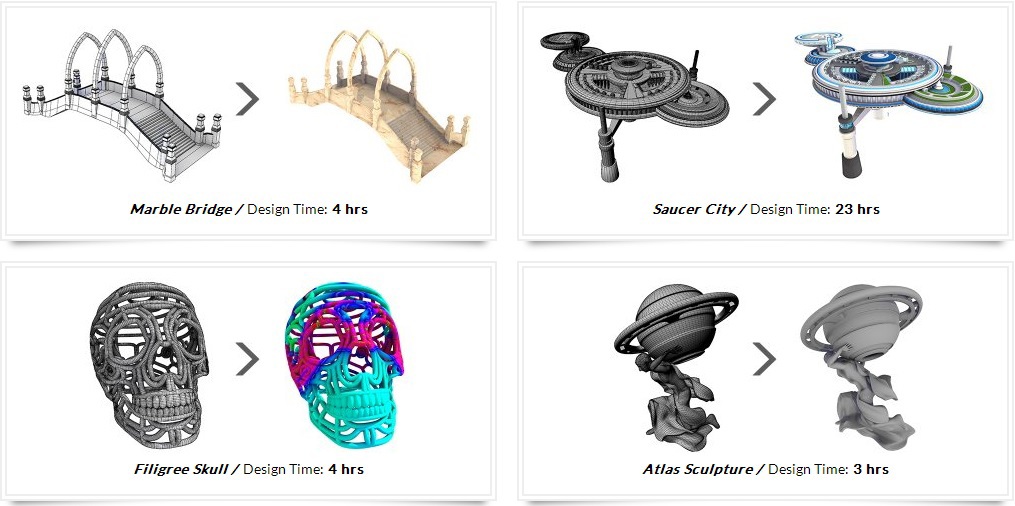

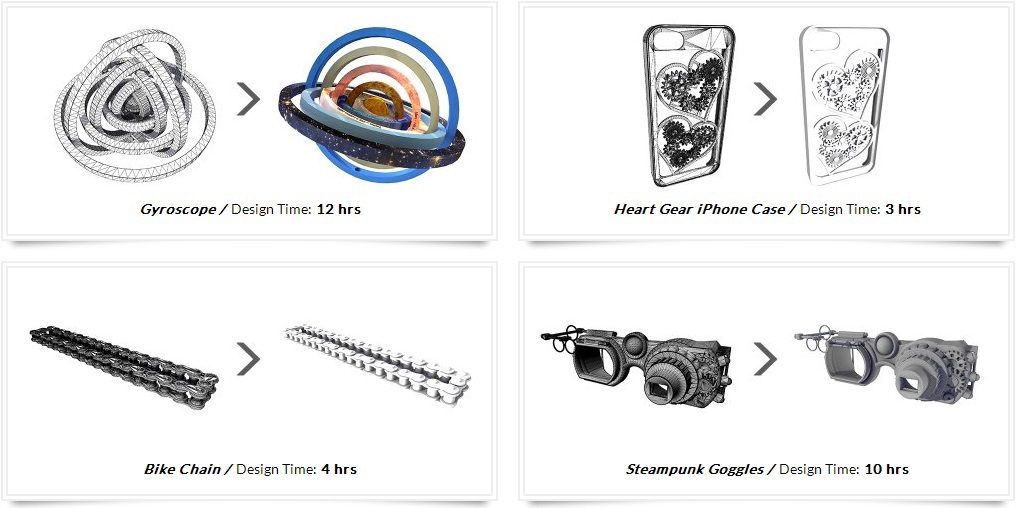

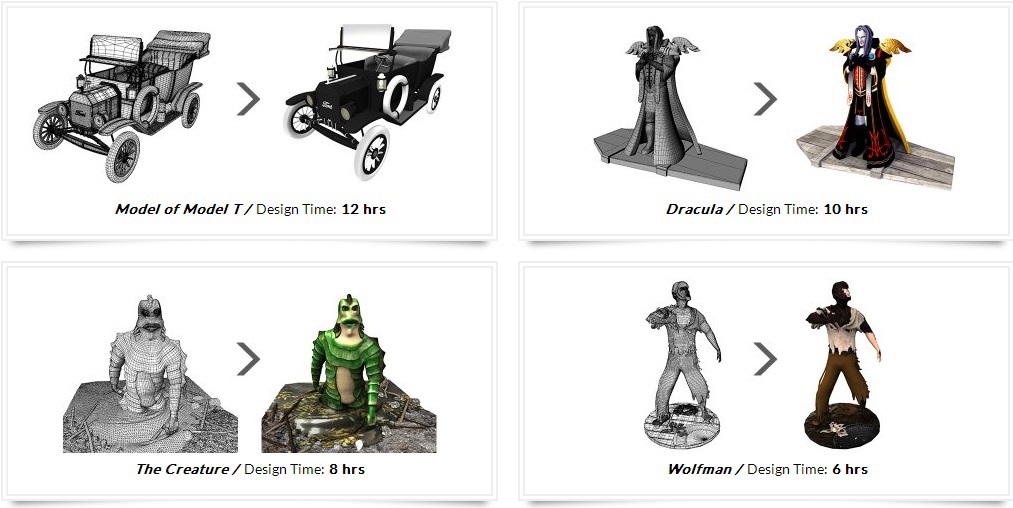

Portfolio under the spoiler

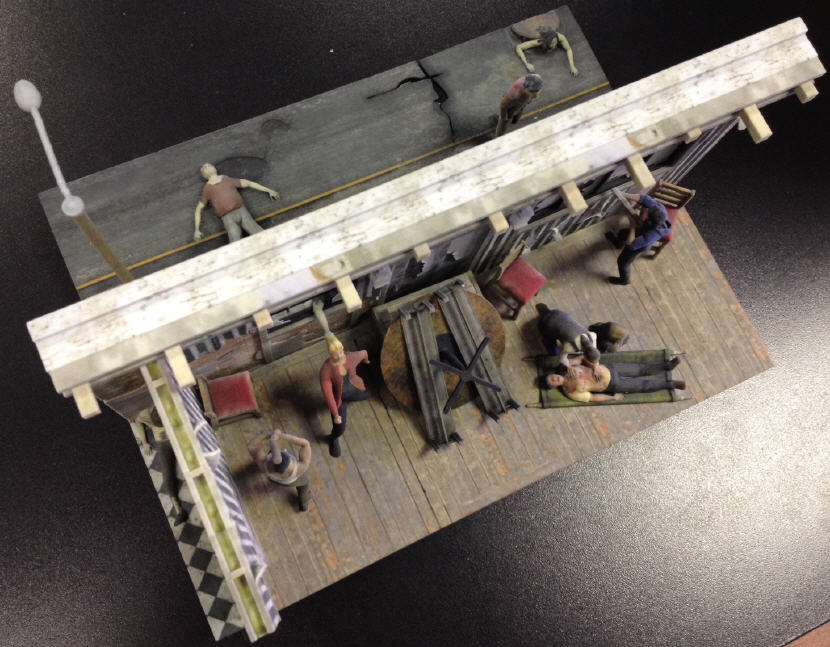

Little zombies:

Little zombies:

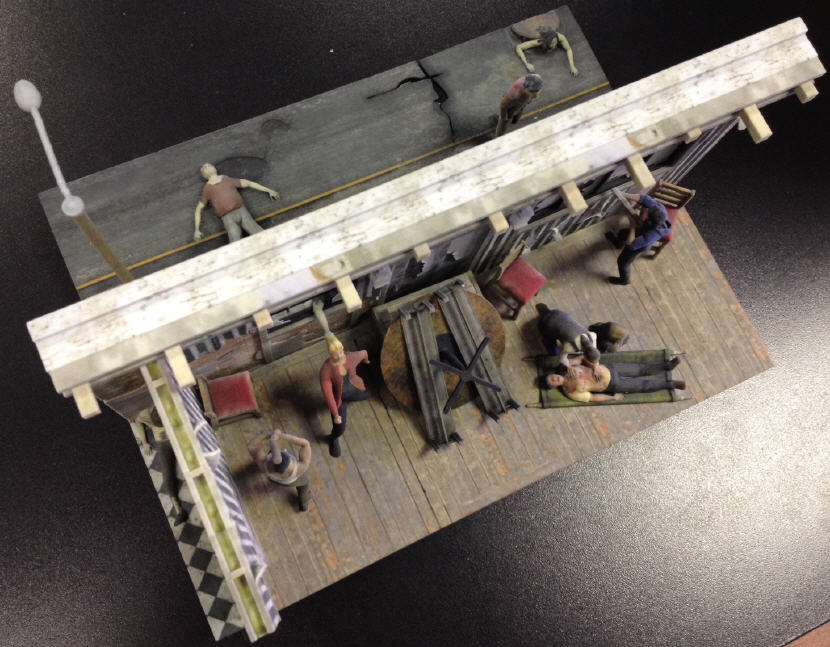

Russian projects

The following picture speaks eloquently about the state of affairs in Russia:

3D Printing Map of the World

parable on the topic

One company once sent a shoe seller to an African city.

Shortly after arriving in Africa, he wrote to the office:

“You can take me back. Everyone goes barefoot here. ”

They returned him to his homeland.

Sweat they sent another shoe seller.

Almost immediately upon arrival, he sends an urgent telegram to the office:

“Send all the shoes you have. Everyone goes barefoot here! ”

Shortly after arriving in Africa, he wrote to the office:

“You can take me back. Everyone goes barefoot here. ”

They returned him to his homeland.

Sweat they sent another shoe seller.

Almost immediately upon arrival, he sends an urgent telegram to the office:

“Send all the shoes you have. Everyone goes barefoot here! ”

zdravprint.ru

Service to create individual clamps that are printed on a 3D-printer and are designed to replace the gypsum at certain stages of recovery.

Konstantin: “My good friend Fedor Aptekarev on the last Yandex Startup Camp launched a project to create a gypsum using a 3d printing. With such a plaster, the fracture can be transferred a little easier. ”

What awaits us in the future

Me : Konstantin, collecting materials for this post, I came across some skeptical remarks by highly respected people (for example, Epson director) about the future of 3d printing, and you, in turn, have been actively developing this industry in Russia for a year now, you are training seminars, developing a community, holding contests for designers, planning to launch an API for your project, what is the basis for your confidence in what it is worth doing?

Konstantin: Glad you asked. Let's clarify exactly what the Epson head said. Something like this: “Home plastic 3D printing has no big future. We will only make commercial 3d printers. ” He talks about creating an industrial design printer. Epson itself is going to develop industrial printers. And I completely agree with them.

My opinion is that it is industrial 3d-printing technologies that we use that can really bring 3d printing to a new consumer level. Here it is necessary to immediately say that the head of Epson speaks about home printing, but only implies FDM technology (melting of plastic thread), as the most popular technology of home 3d printing. At the same time, we should not forget that after the end of the patent for the SLA technology ( stereolithography ), for example, the Formlabs 1 “home” printer appeared quite to itself, which gives a very acceptable quality. Yes, of course, it can not be compared with industrial.

I'm talking about the fact that rather there is no future not for home 3d-printing, but for FDM-technology. She will become obsolete. It is suitable for too narrow application and the quality is very, very low.

I am sure that what we are doing now will create (and is already creating it abroad) a new market and new opportunities for consumers and designers, speed up the solution of many tasks and, of course, will become more accessible. Confidence is fully confirmed by the facts, the results of communication with colleagues from abroad and in Russia and, of course, numbers that are constantly growing.

I: Konstantin, after talking with the CEO of world leading companies and “having been in the future for a while”, share what the world is waiting for in the coming years?

Konstantin: In the very near future, I can say with full confidence that we are waiting for the following:

- the widespread integration of the "print on 3d-printer" button into all imaginable and inconceivable applications, programs, games, and so on. We will print both in 3d-printing services and among enthusiasts on home 3d-printers.

- the end of patents for the main industrial technologies of 3d printing (SLA (already), SLS, 3DP, DMLS) will lead to a more serious development of smaller and less expensive printers, respectively, the growth of industrial technologies and quality will also increase greatly

- Google, which is actively introducing 3d-scanners into its phones, will also contribute to the growth of the market, since many people will have the most important thing for the market - a model for printing. And to create it you only need a phone.

- Finally, the alliance of 3D Systems and Google in the Ara project will give a significant leap in the development of 3d printing speed and we will probably see how with the help of 3d printing a whole conveyor of custom goods production will be made. This is what is called mass customization.

P.S.

Base models:

Thingiverse.com (free models, MakerBot project, more than 100,000 models downloaded, 21 million downloaded)

Threeding.com (paid and free models, a project from Bulgaria, plan to release an application for Apple iOS and Android, commission 8.5%)

3DPrintWise.com ()

CGtrader.com (paid models, received investments from Intel. 35,000 3d designers placed more than 45,000 3d models)

P.P.S.

Who wants to participate in the API test for 3d printing service - write to me magisterludi or Konstantin consst

Source: https://habr.com/ru/post/222991/

All Articles