Smart Transformer Wheelchair

Hi Habr!

I want to tell you about our project to create an all-wheel drive electric wheelchair. In technical terms, this is not just a stroller, but a real robot, I would even say, a transforming robot.

')

The main issue requiring cardinal constructive approaches is, of course, climbing the stairs. A very large number of implementation options were considered, ranging from ordinary large-diameter wheels with a deep tread and ending with a transforming wheel turning into a walking device. Everywhere there were problems: some solutions were not safe, some options fit only one type of ladder (a certain height and depth of the step), etc. The best option was tracked propulsion.

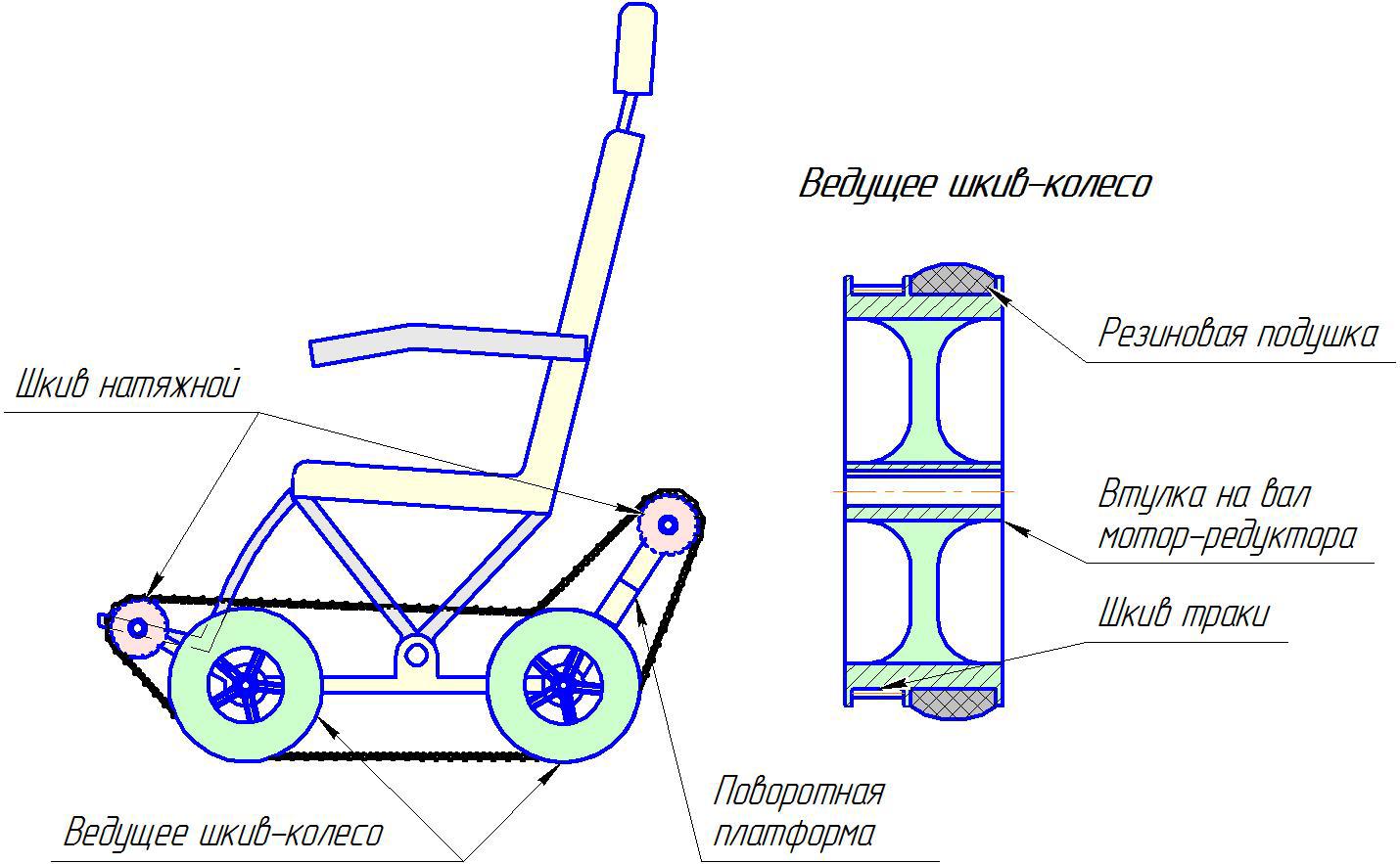

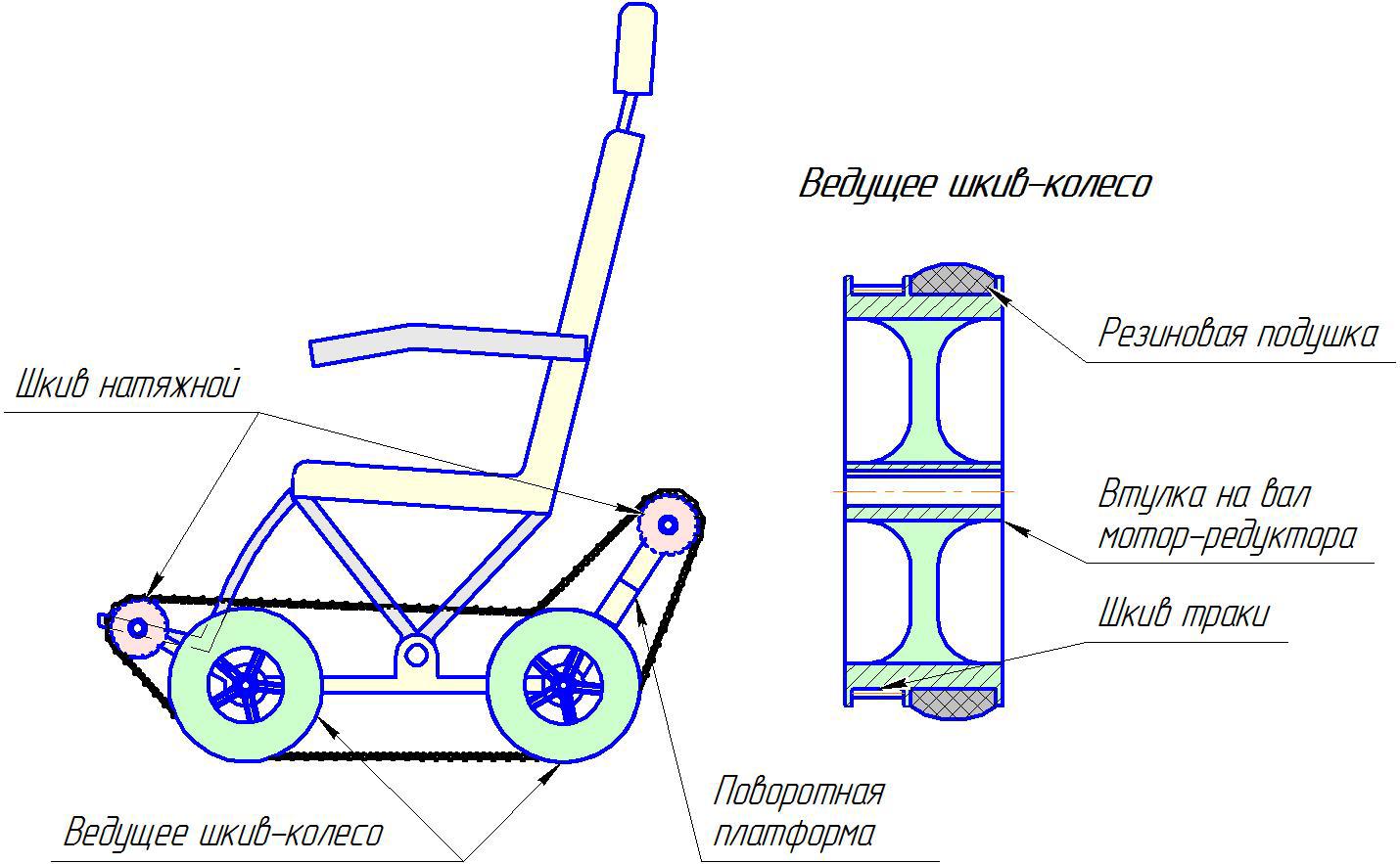

The idea was as follows: 4 gear motor (four-wheel drive), swivel chair, swivel rear platform and 4 pulley wheels with stretched tracks. The key to the pulley wheels is that it doesn’t touch the ground and, therefore, does not create vibrations and additional friction. The stroller rides on rubber cushion pulley wheels. And when hitting an obstacle, such as a ladder, the truck engages with this same obstacle.

Movement along the stairs is as follows:

During the lift, the seat automatically rotates, maintaining its horizontal position. The descent from the stairs is exactly the same way, but in reverse order.

To test the idea, we set about creating a prototype. We decided not to invent the control electronics yet, but to use 2 consoles from other electric wheelchairs (each of which controls 2 engines). The drive of the chair and the rear platform were controlled by three-way toggle switches.

Making a truck is generally a separate story. The basis of the self-made truck is timing belts from the Impreza. Belts are sewn together. As the lugs were cut segments of the V-belt and sewn with screws.

The collective farm methods were used because everything was financed from their own pocket. The cost of manufacturing 4 of these truck according to the drawings (even in China) starts from 70 thousand rubles. (including tooling). As a result, self-made truck was enough for a pram to climb stairs without a passenger. From payload truck broke at the junction.

The creation of the first prototype took about 80 thousand rubles, including the rental of a garage workshop.

According to the test results, it became clear:

The main problem is that for climbing stairs and moving on a flat surface, fundamentally different speeds and moments are needed, which differ by about 10 times. Of course, you can install higher power drives, then when driving on a plane, the load on the engine will be significantly less than nominal, and when you climb stairs, the voltage is lower than nominal (to reduce speed). In this situation, low cost and energy efficiency can be forgotten.

There were several solutions to this problem:

After a close analysis and calculations, it turned out that the last option is the most inexpensive and technically feasible.

On a flat surface, the track bases (lower and rear) are in the uppermost position and do not interfere with the movement of the stroller at all. If it is necessary to overcome obstacles, the lower and rear platforms are lowered, and the stroller gets on the tracks. As a result, due to the mechanical transmission from the motor shaft to the drive pulley and the difference in wheel and pulley diameters, it was possible to achieve a design tenfold difference in speeds and torques.

This time, the prototyping was approached in a more solid way: we ordered the necessary tracks, drives, and electronics from the Celestial Empire. Machining, laser cutting and bending were ordered at Novosibirsk enterprises. Assembly and welding, of course, carried out themselves. All work in a classic startup was carried out in the garage workshop.

The control system consists of a console and an executive module that communicate via bluetooth. The wireless remote control is especially necessary when the disabled person cannot control the joystick himself, and the accompanying person controls the wheelchair. When climbing the stairs, the attendant does not need to reach for the arm of the chair behind the joystick, holding the remote in his hand, he visually controls the movement.

The automatic system for maintaining horizontal position of the chair is based on an accelerometer. Since the system is not highly dynamic, you can do without a gyroscope and reduce mathematical calculations. On the mechanisms of lowering and raising the lower and rear platforms there are feedback sensors. Information about the position of the platforms is transmitted to the console. The system is supplied with 24 V gel batteries (in the next versions we will use lithium-ion).

The tests were carried out on the steps of the high-rise buildings:

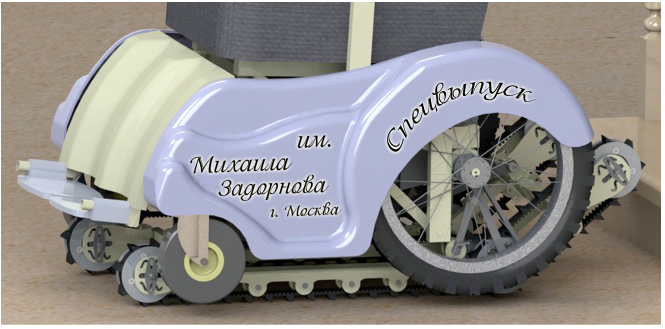

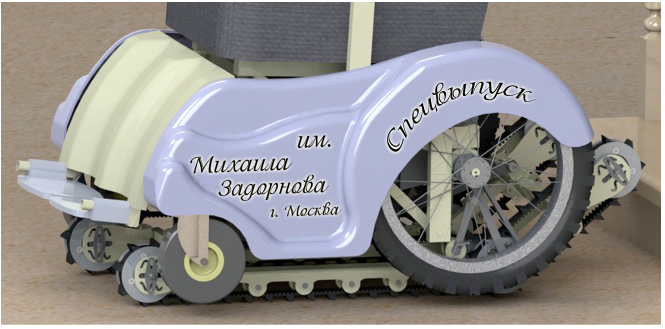

There are still enough problems to solve. But one thing is for sure - it works! An application for a patent has been filed for the development of a wheeled-tracked system with lowered platforms. Our further actions are aimed at improving the electronics, increasing the torque on the tracks, changing the track profile for better engagement and, of course, creating a presentable product appearance.

On the topic of the importance of this development, we shot a video:

Now we can give a disabled person freedom of movement. The staircase at home, the store, the cinema, a couple of staircases on the way to a friend or girlfriend will seem like utter nonsense to them.

I want to tell you about our project to create an all-wheel drive electric wheelchair. In technical terms, this is not just a stroller, but a real robot, I would even say, a transforming robot.

What should this stroller be?

- Most people with disabilities cannot have several electric wheelchairs, so it should be as universal as possible. So that it was possible to move around it both at home, and on the street, and in the forest, and so that you could climb the stairs on your own and climb the curb. This also implies the second point.

- The width of the stroller is not more than 650 mm, so that it is possible to drop in any opening and elevator. Length no more than 1100 mm.

- Safe.

- Cheap. I think there are no comments here.

- Energy efficient, as batteries are expensive.

')

The main issue requiring cardinal constructive approaches is, of course, climbing the stairs. A very large number of implementation options were considered, ranging from ordinary large-diameter wheels with a deep tread and ending with a transforming wheel turning into a walking device. Everywhere there were problems: some solutions were not safe, some options fit only one type of ladder (a certain height and depth of the step), etc. The best option was tracked propulsion.

Our first great idea, doomed to failure

The idea was as follows: 4 gear motor (four-wheel drive), swivel chair, swivel rear platform and 4 pulley wheels with stretched tracks. The key to the pulley wheels is that it doesn’t touch the ground and, therefore, does not create vibrations and additional friction. The stroller rides on rubber cushion pulley wheels. And when hitting an obstacle, such as a ladder, the truck engages with this same obstacle.

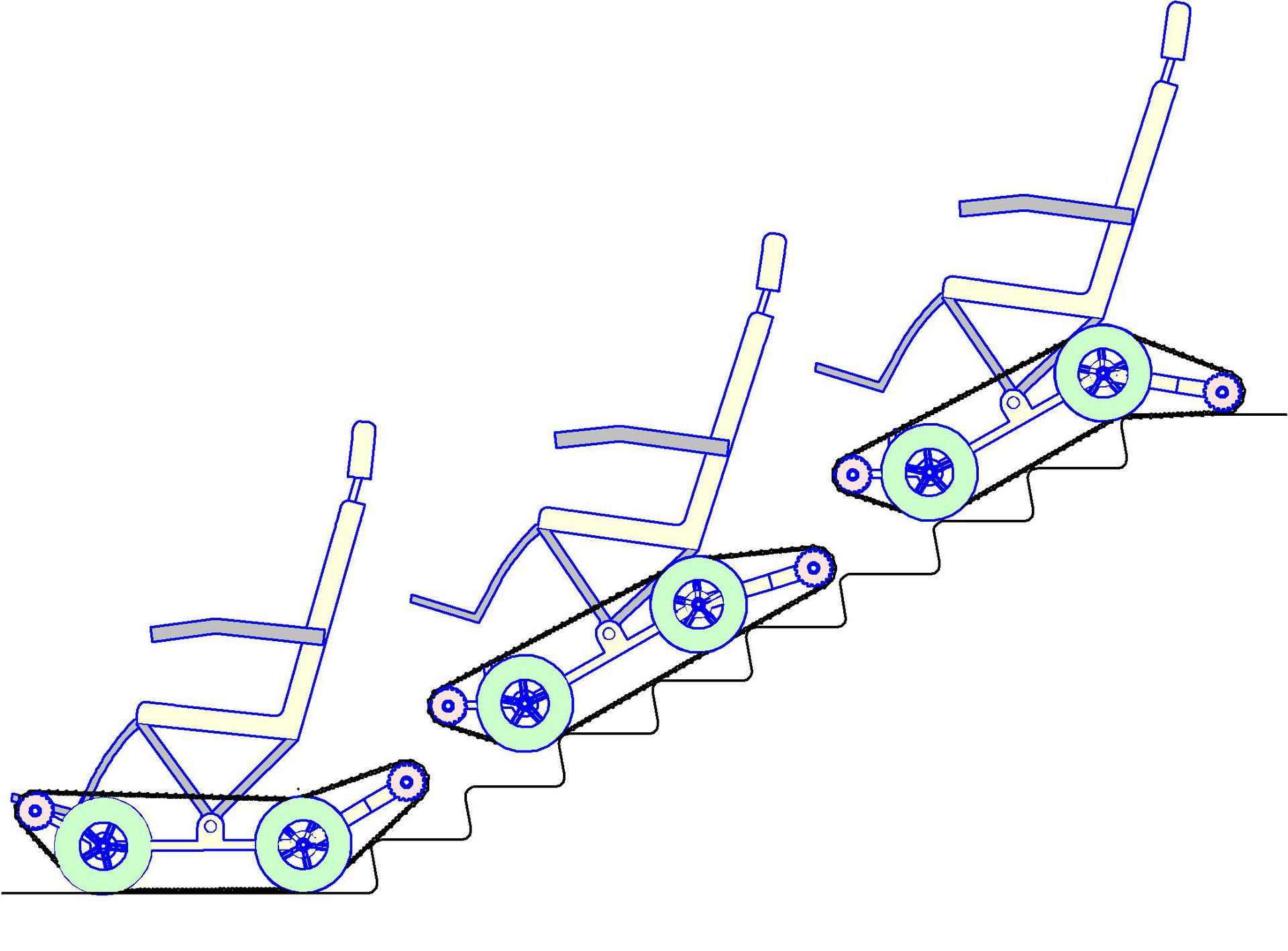

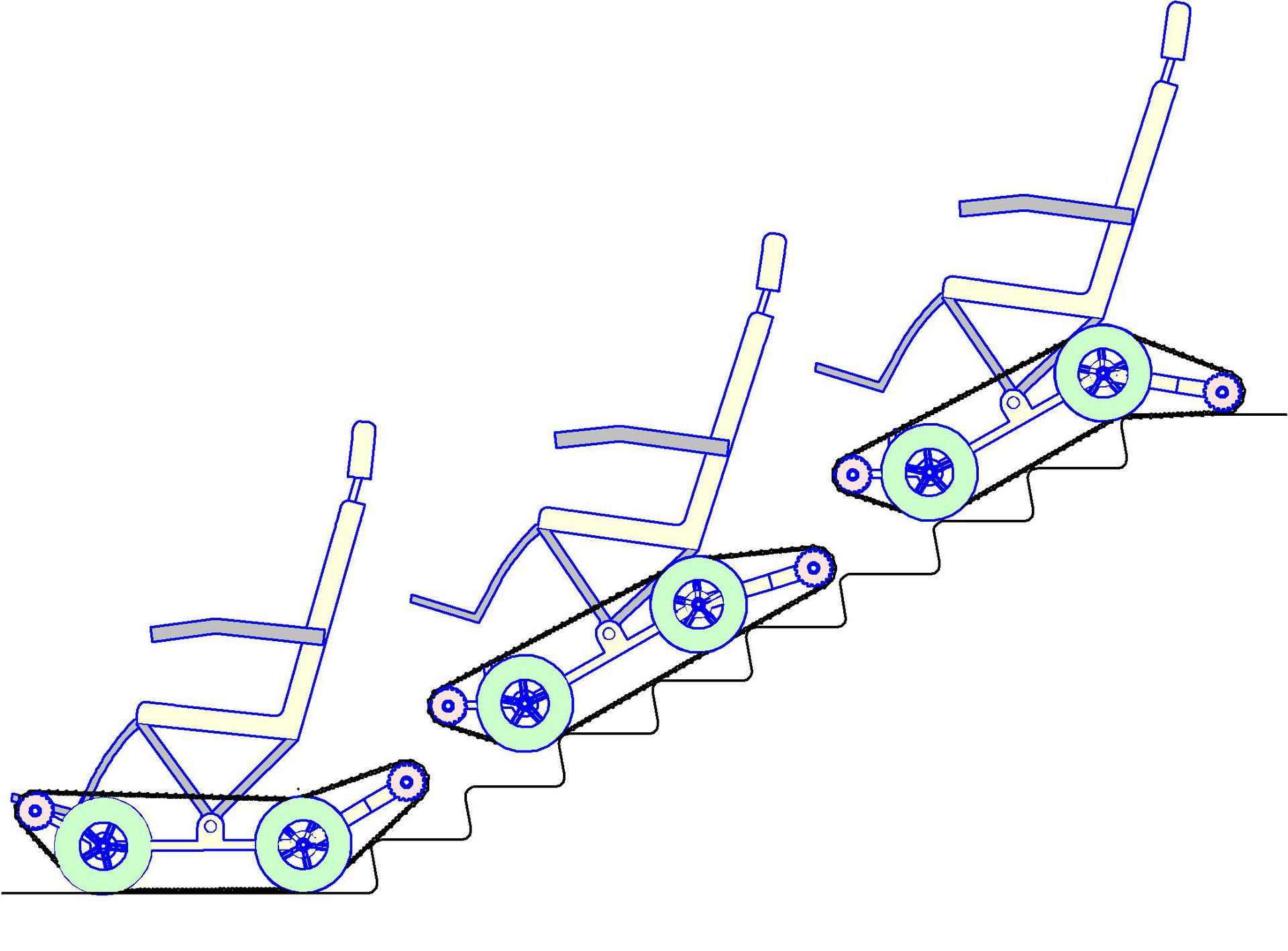

Movement along the stairs is as follows:

- The turntable is lowered for easy access to the stairs.

- After arrival, the rear platform is lowered in line with the main platform. Thus, the total length of the track base provides good grip and safety from a coup.

- At the exit of the stairs, the rear platform goes down to prevent a sharp fall.

During the lift, the seat automatically rotates, maintaining its horizontal position. The descent from the stairs is exactly the same way, but in reverse order.

Creation of the first prototype

To test the idea, we set about creating a prototype. We decided not to invent the control electronics yet, but to use 2 consoles from other electric wheelchairs (each of which controls 2 engines). The drive of the chair and the rear platform were controlled by three-way toggle switches.

Making a truck is generally a separate story. The basis of the self-made truck is timing belts from the Impreza. Belts are sewn together. As the lugs were cut segments of the V-belt and sewn with screws.

The collective farm methods were used because everything was financed from their own pocket. The cost of manufacturing 4 of these truck according to the drawings (even in China) starts from 70 thousand rubles. (including tooling). As a result, self-made truck was enough for a pram to climb stairs without a passenger. From payload truck broke at the junction.

The creation of the first prototype took about 80 thousand rubles, including the rental of a garage workshop.

According to the test results, it became clear:

- On the track with the lugs, you can climb the stairs. Even if the steps are of different sizes and chipped.

- The idea with a swivel rear platform works.

- The pulley wheel scheme is doomed to failure.

The main problem is that for climbing stairs and moving on a flat surface, fundamentally different speeds and moments are needed, which differ by about 10 times. Of course, you can install higher power drives, then when driving on a plane, the load on the engine will be significantly less than nominal, and when you climb stairs, the voltage is lower than nominal (to reduce speed). In this situation, low cost and energy efficiency can be forgotten.

Electric wheelchair - transformer.

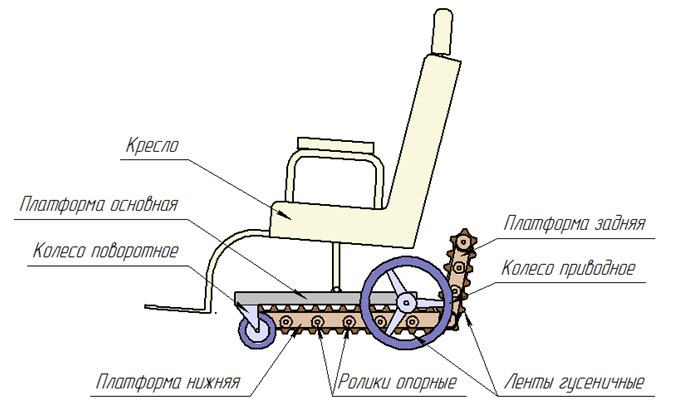

There were several solutions to this problem:

- Make a gearbox with switching speeds. More precisely, 4 gearboxes or at least 2 (on the left and right sides).

- Caterpillars and wheels rotate from different drives.

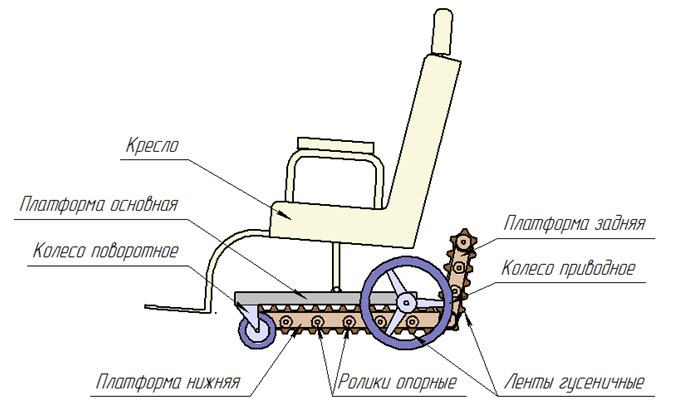

- Separate wheeled and tracked base. In this case, the wheel and the truck will be driven by one drive with reduction to the truck.

After a close analysis and calculations, it turned out that the last option is the most inexpensive and technically feasible.

On a flat surface, the track bases (lower and rear) are in the uppermost position and do not interfere with the movement of the stroller at all. If it is necessary to overcome obstacles, the lower and rear platforms are lowered, and the stroller gets on the tracks. As a result, due to the mechanical transmission from the motor shaft to the drive pulley and the difference in wheel and pulley diameters, it was possible to achieve a design tenfold difference in speeds and torques.

The implementation of ideas in the gland

This time, the prototyping was approached in a more solid way: we ordered the necessary tracks, drives, and electronics from the Celestial Empire. Machining, laser cutting and bending were ordered at Novosibirsk enterprises. Assembly and welding, of course, carried out themselves. All work in a classic startup was carried out in the garage workshop.

The control system consists of a console and an executive module that communicate via bluetooth. The wireless remote control is especially necessary when the disabled person cannot control the joystick himself, and the accompanying person controls the wheelchair. When climbing the stairs, the attendant does not need to reach for the arm of the chair behind the joystick, holding the remote in his hand, he visually controls the movement.

The automatic system for maintaining horizontal position of the chair is based on an accelerometer. Since the system is not highly dynamic, you can do without a gyroscope and reduce mathematical calculations. On the mechanisms of lowering and raising the lower and rear platforms there are feedback sensors. Information about the position of the platforms is transmitted to the console. The system is supplied with 24 V gel batteries (in the next versions we will use lithium-ion).

The tests were carried out on the steps of the high-rise buildings:

There are still enough problems to solve. But one thing is for sure - it works! An application for a patent has been filed for the development of a wheeled-tracked system with lowered platforms. Our further actions are aimed at improving the electronics, increasing the torque on the tracks, changing the track profile for better engagement and, of course, creating a presentable product appearance.

On the topic of the importance of this development, we shot a video:

Now we can give a disabled person freedom of movement. The staircase at home, the store, the cinema, a couple of staircases on the way to a friend or girlfriend will seem like utter nonsense to them.

Source: https://habr.com/ru/post/222645/

All Articles