Why do engineers in Russia need 3D solutions

When an engineer hears "3D", he usually immediately thinks not about a new shooter, but about designing complex objects like nuclear power plants. I already wrote about the fact that we are recruiting future specialists in 3D-design - and today I want to show you our first 3D-center in Russia.

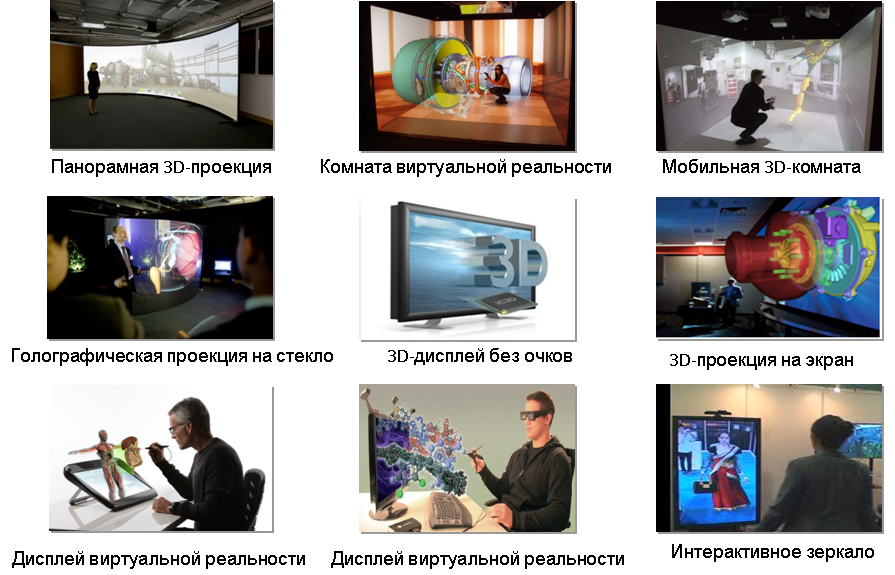

Inside there are the usual three-dimensional projections on screens, holographic projections on glass, a virtual reality room, “glasses-free” 3D displays and other multimedia devices. Only 10 subsystems based on the equipment of the partner EON Reality. All this is compatible with such systems as: Autocad, Inventor, 3Ds Max, Solidworks, NX, Catia, Kompas-3D, Creo.

')

We constantly conduct tours for representatives of large companies. The oil and gas industry is traditionally interested in 3D - for them it is an opportunity to work out a plan of action on the ground without climbing under the ground and without pressing the real “red buttons”. Rostec was also interested in military equipment stores. Of the well-known solutions we know, 3D is used by Boeing, Suzuki, Lexus, BP, Saudi Aramco, Rasgas, and various institutions (medicine, architecture, design).

3D Solution Center

The 3D solution center consists of a school, a demo center and a content development lab. Plus, we do service support for 3D solutions and sometimes take them out to various events for rent. So far, mainly on the exhibition.

At school, 3D-design teach the coolest engineers from the West. A stream of 25 people is studying: a part - our engineers, a part - those whose companies desperately need a specialist with such skills and a few more places - are free, for students whom we recruited just from Habr.

The school is now the only one in Russia that teaches not only creating 3D models, not only programming, but a comprehensive approach to solving a customer’s problem, solving a problem from a model, programming, export optimization in the system to directly configuring and selecting the system itself. We learn to work with specific display systems and optimize content for them, to parallel tasks and work in a team, to interact with “internal customers”. The demand for studying in Russia is very high now (there were more than 100 applications for 15 places for the first year), so we plan to expand the school.

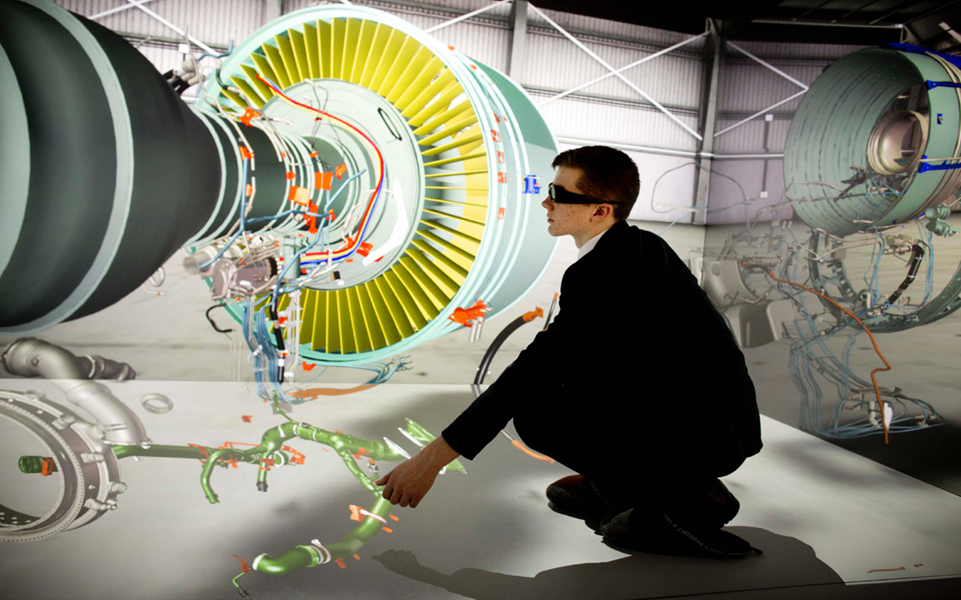

One of the rooms of our center (in the foreground, the EON Ibench mobile system can be used, for example, to refine the process of collecting / parsing complex structures, parts of the parts can be “pulled out” from the screen, viewed from different sides)

Testing evacuation from an oil platform in a 3D-cube.

Why EON Reality?

Because it is a user-friendly interface, good coverage around the world, many ready-made modules for creating content (ready-made libraries, including interactive). A huge number of templates for various 3D-systems, for the most part - with a ready-made detailed code. Export from all major CAD systems, import to all known virtual reality systems.

Submission of information

Why do you need 3D in engineering in principle? After all, without him somehow worked on paper before. Actually, they used to work without computers, but now they are needed. The fact is that there are a number of responsible tasks. For example, exploration of deposits - there the error is very expensive; or designing NPP subsystems — where the error is not measured in money at all. And on these tasks there is a problem with the fact that it is required to process a lot of incoming information. For example, if you receive several hundred letters a day, you will not be able to read each thoughtfully and communicate with each person - there is a chance that you will miss something valuable. We live in a world very rich in information, and these sources of information are becoming more and more. They just surround us and begin to put pressure on us. There are more of them, and they are becoming richer. At the same time, the speed of awareness of information should also increase - but, as you might guess, progress is not very good with this. There are automated systems that help fix the most important - for example, cars can keep valid signs in the corner of the windshield for you to see.

In the field of emergency information at the time, infographics were a real breakthrough. One of the first working infographics appeared a few centuries ago and was a map of the city affected by the epidemic. It was necessary to sort the sources and understand where the disease came from. That is, the critical tasks she solved already.

In parallel, the natural flow of information developed. When we look at the three projections of the object, we need to make an effort to build an image in our consciousness. If the product is complex, then various minor errors are possible. On the other hand, you can submit information as it is. If you are talking about the architecture of the new city block, you need to show it. It is not necessary to draw the layout of the premises and it is not necessary to write high-flown texts about how many trees and bushes will be planted there, how the problem with traffic jams will be solved, and so on. If you tell students about the anatomy of the human eye, for example, the same eye, through which they receive this information, you must show the eye as it is, without any infographics and unnecessary interpretation of this information. If you show a complex technical object, such as an airplane turbine, an aircraft engine, or something else, it becomes very easy to understand their working principle. And if you directly shove your head into a working turbine, you can study the object from the inside and in dynamics. For this, there is a 3D-cube.

As a result, students are passionate about the process and remember the process faster and better. Customers of our customers make purchasing decisions faster due to virtual immersion and Wow effect, etc. Expenses on training, incorrectly assembled products, emergency situations and so on are reduced.

Eye model for medical university

In our center we show such a model with the help of a large holographic 3D system.

At what stage of the project we come to 3D? In general, virtual reality technologies can be used at all stages of a project, from protecting a business idea to dismantling a complex mechanism. For example, we have a business idea, we need to demonstrate it nicely in order to confirm the budget or the start of a project, we create a layout or visualize the process and thereby clearly demonstrate this to the customer or manager. Next, we perform the design and create a 3D model of the designed object, again visualize and enable the designers to look at the compatibility of all systems if they need to make changes to the project or again demonstrate the virtual object to the customer or manager. Then we can make a virtual instruction for assemblers with step by step assembly and visualize all the nuances. By the way, in parallel with the assembly, we can already start selling the object according to its virtual model, by the way, many companies are already doing (for example, real estate agencies sell apartments and car dealers sell cars). We can make virtual configurators for interior or exterior, configurators for complex products, etc. For the same 3D model, we make instructions for use, maintenance or training to work out abnormal situations. Finally, we can make instructions for dismantling and disposing of complex and dangerous components.

How was this solved before?

For example, for pilots created models 1: 1. They are very difficult to assemble (at a cost - like a half-plane), difficult to transport, the training center cannot be quickly scaled. The staff breaks the simulators, the cost of working off emergency situations is very high, there is no opportunity to quickly modify or detail something.

But, of course, the ability to touch is very important in training pilots. Therefore, the optimal scheme is as follows: dial the required hours on the simulator, and then, when the control is worked out to automaticity, practice emergency situations in virtual reality.

Why did KROK do this?

Because we are 10 years on the first edge of IT in Russia. We accumulate a lot of information, including engineering, which needs to be analyzed and used. We are able to work with information - we have big powerful data centers, good channels and good software. But we are not able to perceive it quickly in the general case, our customers have the same problem. And here we need 3D solutions, similar to those in our 3D center.

You can say that you have already worked with this: 3D TVs and even 3D displays are no longer a rarity. But this is a very rough resemblance to true advanced systems. First, the quality is different. In the phrases “virtual reality” and “augmented reality” the main word will be precisely “reality”. Secondly, in this reality, you can move freely.

How 3D helps businesses in high-risk areas

One of the main tasks here is to increase the speed of decision making in emergency situations. And improving the safety of the facility as a whole. For example, for power engineers, this is a huge savings: to reduce the proportion of wrong actions in an emergency situation. And on the basis of 3D models we can prepare instructions for any complex object being sold, a tool or a node. Understandable and quick to master. Often this is important in commerce, in particular, when presenting complex devices to simple buyers.

Proofs:

1) www.bbc.co.uk/news/technology-15115059 - In 86% of students in a 3D audience, test results improved, the level of attention doubled (92% versus 46%).

2) www.dlp.com/downloads/DLP-CaseStudy-Classroom3.pdf - The number of points scored in the tests increased by 35%

With the help of the possibilities of virtual reality, you can visualize some kind of service incident, an emergency situation, show what will happen with different actions in the interactive and how. In world practice, it saves hundreds of thousands of dollars. If the company employs thousands of people, then this presentation of information can save millions of dollars a year - simply on a substantial reduction in the course of study.

Director of Technology, BP: "Studies have shown that training in the virtual space is absorbed 80% better than training conducted in traditional ways."

NBAA (National Business Aviation Association) when designing the Bombardier 550 reduced the cost of creating layouts and allowed customers to configure the interior at the design stage.

TETRA PAK plans its production in a virtual environment

An example of a situation. We have a model of nuclear power plants. We select "Activate something in the control room." Further, in the framework of the simulation, we call the dispatchers in our control room by walkie-talkie. The model shows the processes from a technical point of view, can show the movement of personnel and so on. If we are in training, the teacher may approach, for example, one of the devices and close the gauge with a palm and ask what should be there.

We are working with data centers. Models can be easily instructed, work out any emergencies and show the infrastructure to the customer.

The founder of EON Reality created the company in 1998 , and before that, he worked as a design engineer on the North Sea for many years. That is why the basic templates always have an interactive oil platform, thought out from the point of view of the needs of engineers.

So, what we do. We do not just sell 3D solutions and make 3D content, we give customers the opportunity to make decisions faster, increase the added value of their products, get qualified personnel faster and cheaper, and avoid unnecessary costs if they are not properly assembled or operating errors occur. If someone has any questions - ask in the comments, write in a personal or email - PPochtennov@croc.ru. There you can also throw applications for “come to see what the center is ”.

Source: https://habr.com/ru/post/221921/

All Articles