Graphene nano engine

This week was fruitful for news related to applied applications of graphene and other nano-materials. At first there was an ultrathin transistor , now in the same journal Nano Letters published an article on the development of a molecular nano-motor, in which the graphene layer plays a key role. This engine consists of a highly elastic membrane, which plays the role of a piston, and ClF 3 molecules, which are the working fluid. The volume of a working body changes under the influence of the laser. The nano-engine develops pressure up to 10 6 Pa and withstands more than 10,000 cycles.

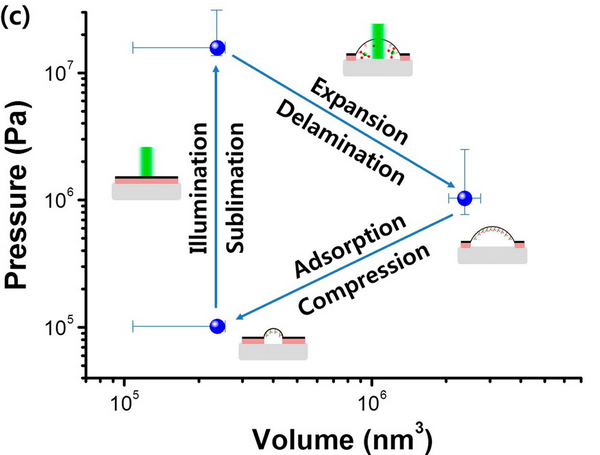

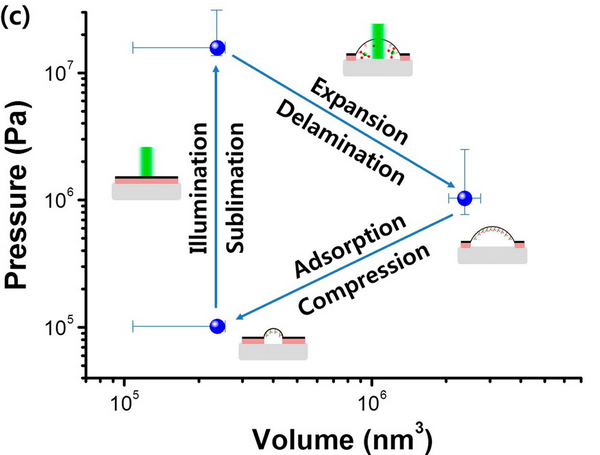

The engine consists of graphene particles with ClF 3 inclusions. Between carbon atoms and ClF 3 molecules, CF chemical bonds arise, which can easily dissociate. In particular, these bonds are destroyed when irradiated with a laser with a wavelength of 532 nm. Destruction of bonds leads to the fact that the molecules are trying to "move away" from carbon atoms. As a result, the pressure under the graphene layer increases, graphene separates from the substrate, and a blister (bubble) is formed. When the laser is turned off, graphene quickly returns to its original flat state, because the reactivity of ClF 3 is very high, and it forms bonds with carbon atoms again. The rapid increase in volume under a layer of graphene is equivalent to the expansion of the working fluid and the movement of the piston in an internal combustion engine. The key parameters determining the engine power are the pressure it is able to withstand, which, in turn, depends on the elastic modulus of the membrane material, the gas permeability of the membrane and its adhesion to the substrate.

In graphene treated with liquid ClF 3 , ionic bonds are formed between fluorine and carbon, as a result of which a positive charge is formed, which is 1/6 of a hole for each fluorine atom. Such ionic bonds can be easily destroyed because they have a very low energy of ~ 54 kJ / mol. This is about ten times less, the energy of the CF covalent bond. When the quasistable ClF 3 molecule loses its ionic bond, this leads to a transition of ClF 3 into the gas phase and a rapid increase in pressure. According to the researchers, the internal pressure is ~ 23 MPa. This pressure is sufficient for local separation of graphene from the substrate. Due to the high strength of graphene, whose Young's modulus can reach 1 TPa, and low gas permeability, all gas remains inside the bubble. Structural analysis of graphene showed that even after 10 thousand cycles, no structural abnormalities occur. The authors believe that the characteristics of such an engine can be significantly improved by optimizing the parameters of the laser pulse, the beam diameter, as well as the selection of the most effective "working fluid".

Unfortunately, access to the full text of the article is paid, but additional materials are freely available on the journal’s website.

______________________

The engine consists of graphene particles with ClF 3 inclusions. Between carbon atoms and ClF 3 molecules, CF chemical bonds arise, which can easily dissociate. In particular, these bonds are destroyed when irradiated with a laser with a wavelength of 532 nm. Destruction of bonds leads to the fact that the molecules are trying to "move away" from carbon atoms. As a result, the pressure under the graphene layer increases, graphene separates from the substrate, and a blister (bubble) is formed. When the laser is turned off, graphene quickly returns to its original flat state, because the reactivity of ClF 3 is very high, and it forms bonds with carbon atoms again. The rapid increase in volume under a layer of graphene is equivalent to the expansion of the working fluid and the movement of the piston in an internal combustion engine. The key parameters determining the engine power are the pressure it is able to withstand, which, in turn, depends on the elastic modulus of the membrane material, the gas permeability of the membrane and its adhesion to the substrate.

In graphene treated with liquid ClF 3 , ionic bonds are formed between fluorine and carbon, as a result of which a positive charge is formed, which is 1/6 of a hole for each fluorine atom. Such ionic bonds can be easily destroyed because they have a very low energy of ~ 54 kJ / mol. This is about ten times less, the energy of the CF covalent bond. When the quasistable ClF 3 molecule loses its ionic bond, this leads to a transition of ClF 3 into the gas phase and a rapid increase in pressure. According to the researchers, the internal pressure is ~ 23 MPa. This pressure is sufficient for local separation of graphene from the substrate. Due to the high strength of graphene, whose Young's modulus can reach 1 TPa, and low gas permeability, all gas remains inside the bubble. Structural analysis of graphene showed that even after 10 thousand cycles, no structural abnormalities occur. The authors believe that the characteristics of such an engine can be significantly improved by optimizing the parameters of the laser pulse, the beam diameter, as well as the selection of the most effective "working fluid".

Unfortunately, access to the full text of the article is paid, but additional materials are freely available on the journal’s website.

______________________

The text was prepared in the Blog Editor from © SoftCoder.ru

')

Source: https://habr.com/ru/post/221601/

All Articles