Ultimaker 2

Make magazine called the Ultimaker Original printer “the most accurate and fastest 3D printer” in November 2012.

And I waited, waited for the opportunity to touch at least the first model, and here - immediately the second!

I hasten to share with the community about what I saw.

What is Ultimaker 2 ?

Very beautiful video:

')

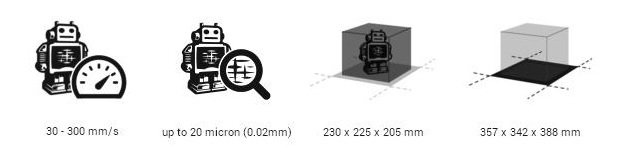

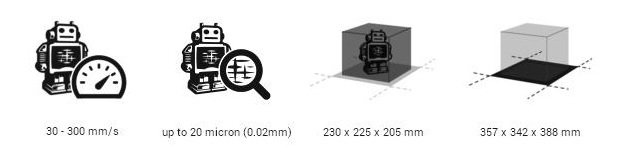

Layer thickness: up to 20 microns

Printing area 23 x 22.5 x 20.5 cm

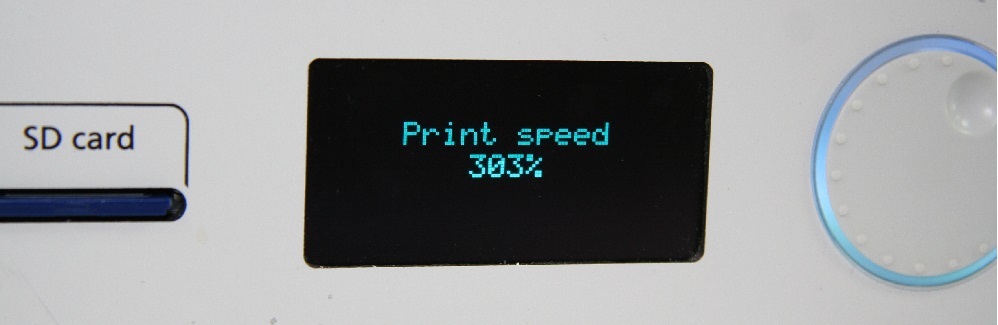

Print speed: 30mm / s-300mm / s

Movement speed: 30mm / s-300mm / s

Recommended plastic: 2.85 mm

Price of use: ~ € 0.05 / cm ^ 3 (plastic and electricity)

Fully assembled and ready to use printer

Speed is what distinguished Ultimaker from the very start of the project.

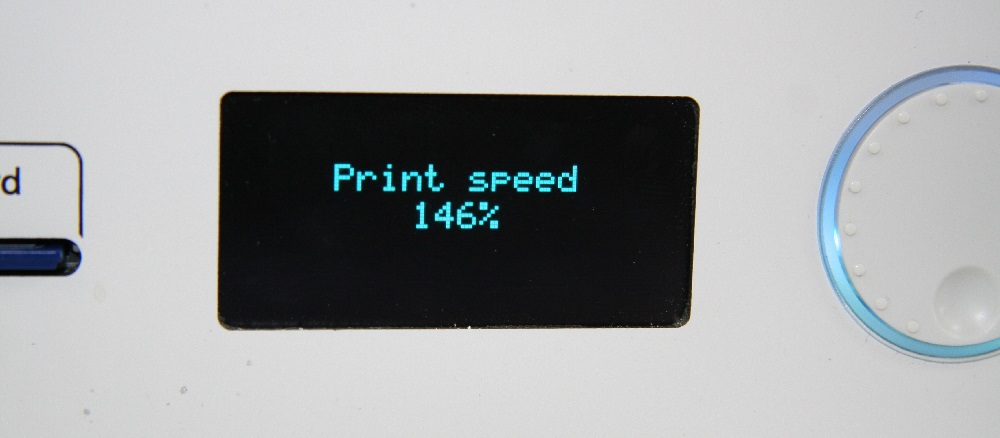

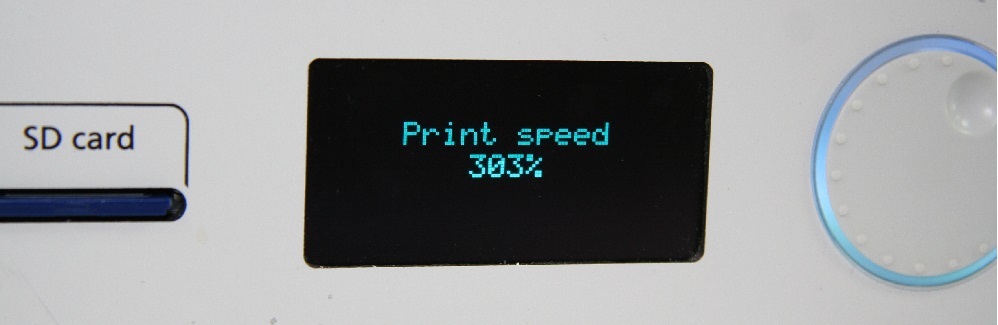

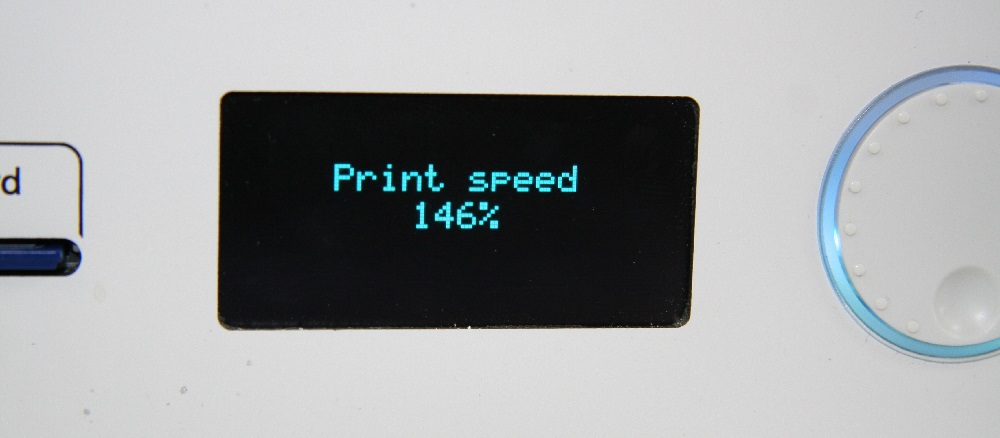

The printer allows you to wind thevoice speed on the go, while printing using the wheel on the right:

And this printer is the quietest of all I've seen.

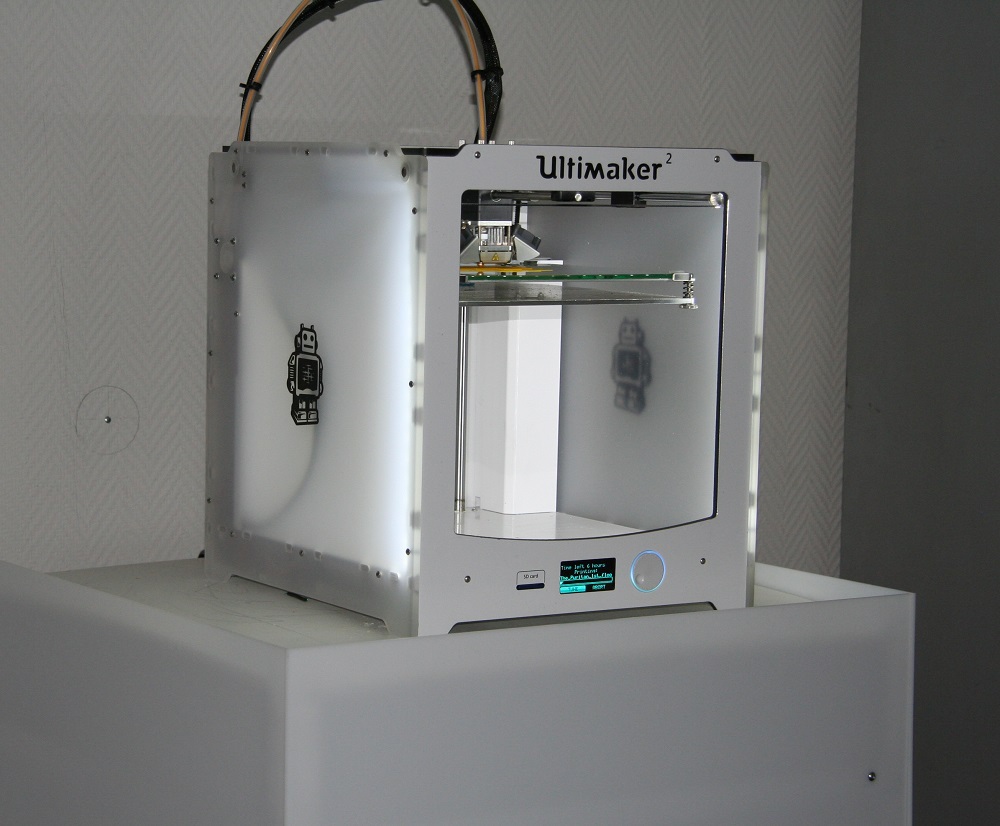

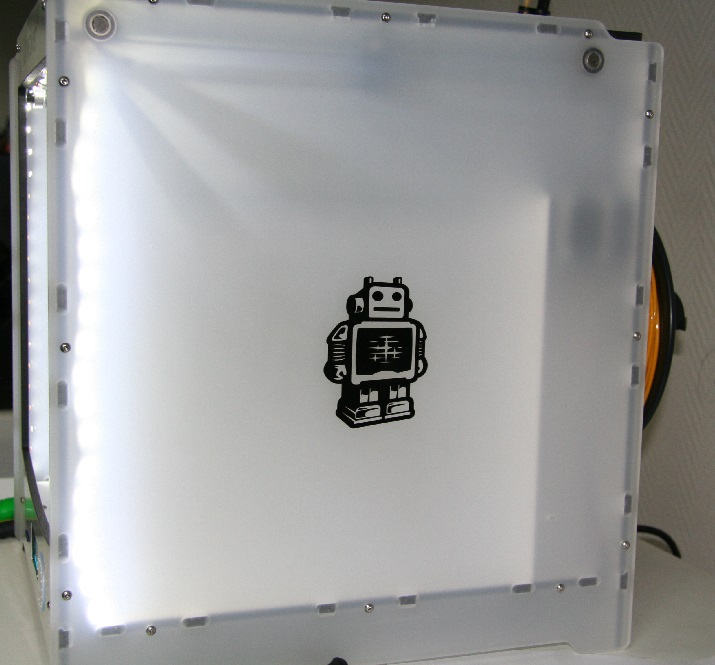

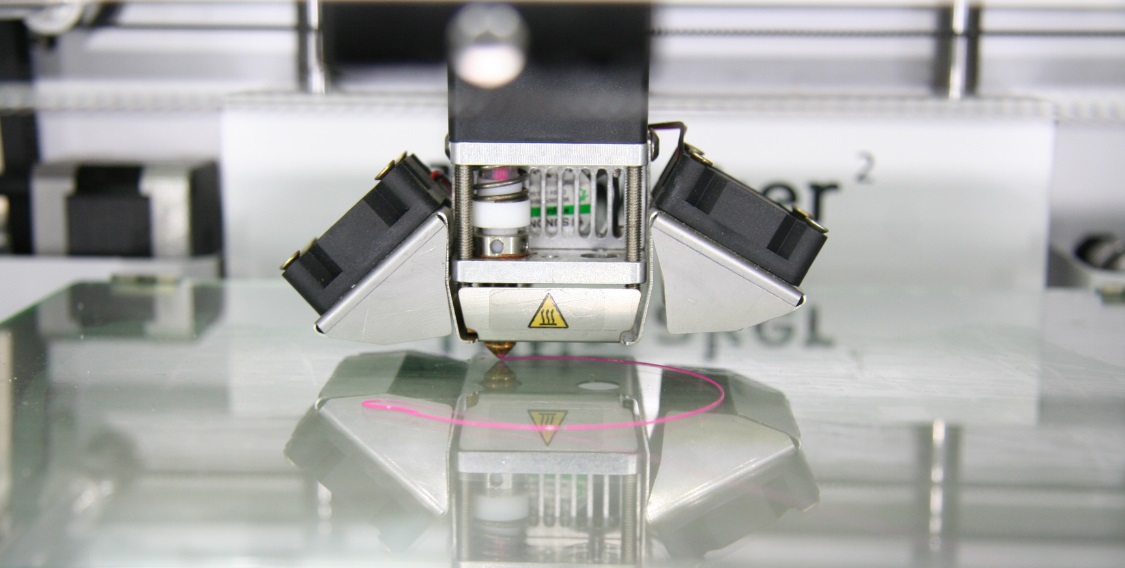

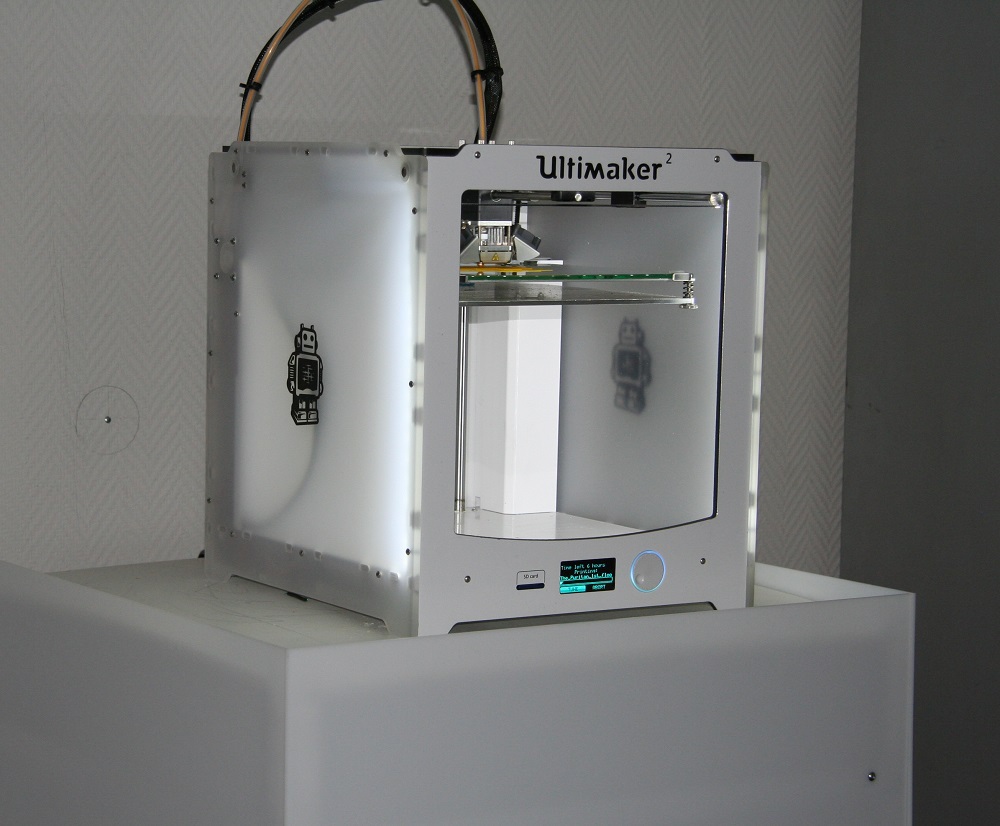

Front view

Side panel of matte plastic that very stylishly scatters light.

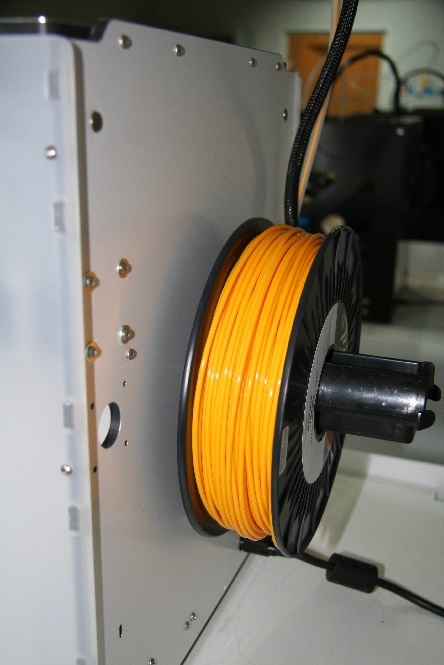

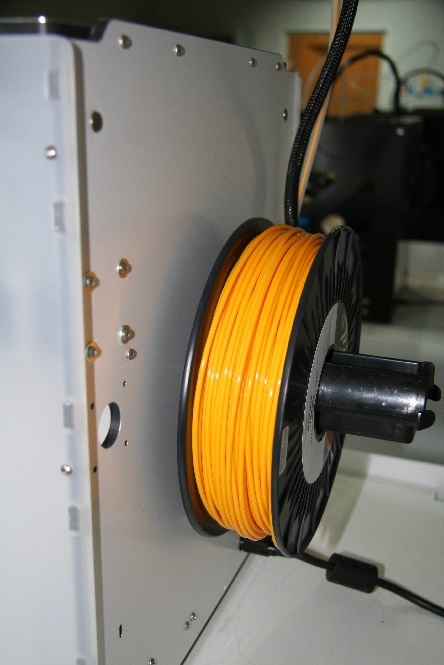

The coil is mounted at the back.

Plastic feed system.

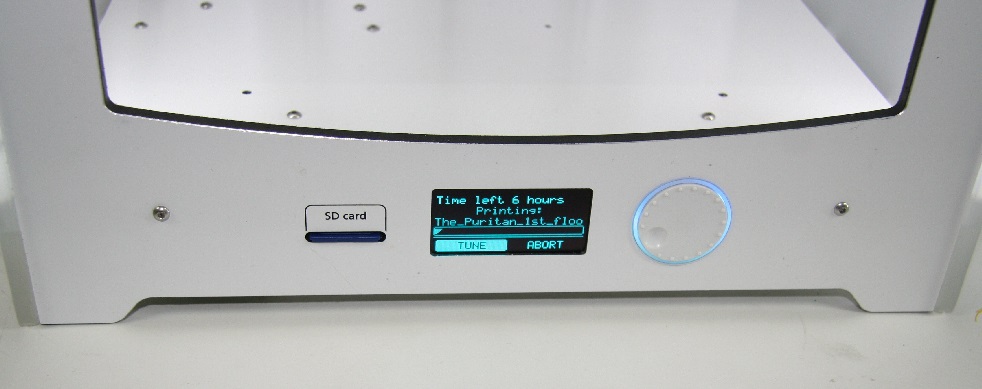

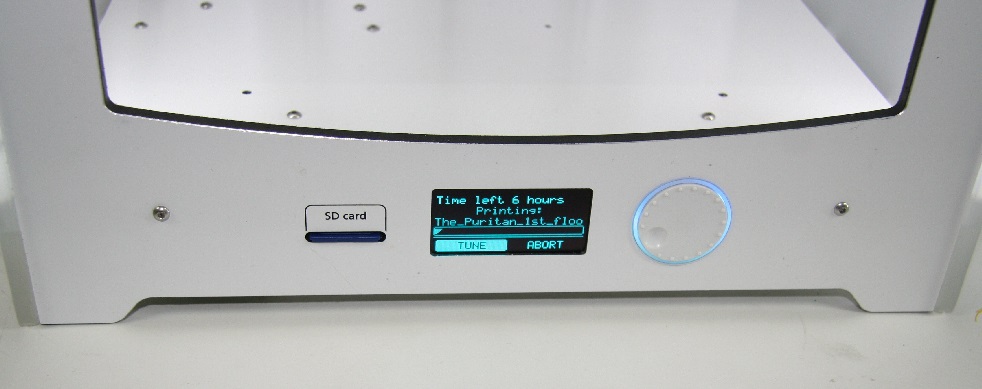

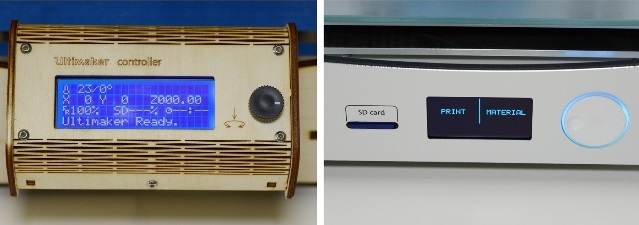

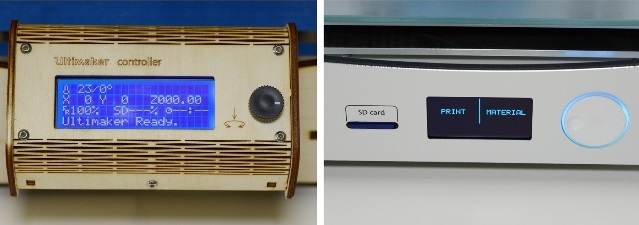

Minimalistic front panel.

Body materials - composite (aluminum-plastic-aluminum) and translucent matte plastic.

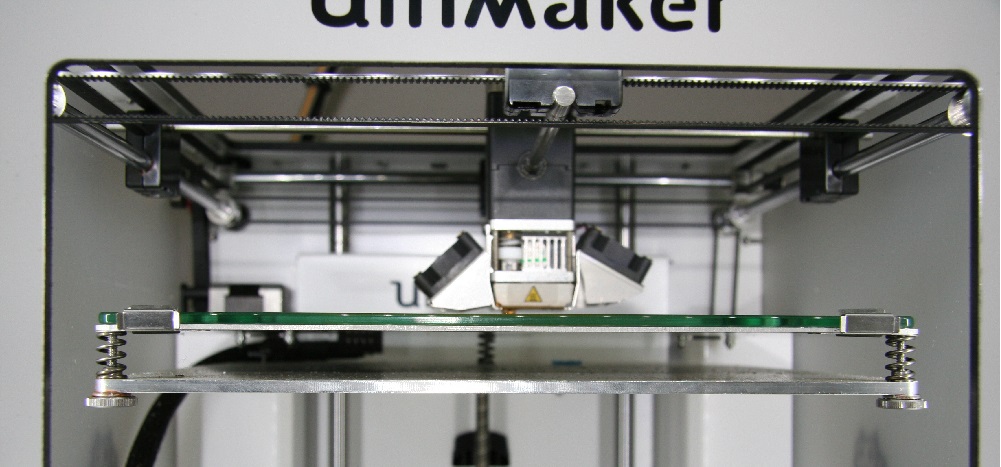

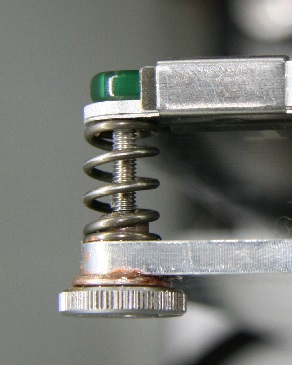

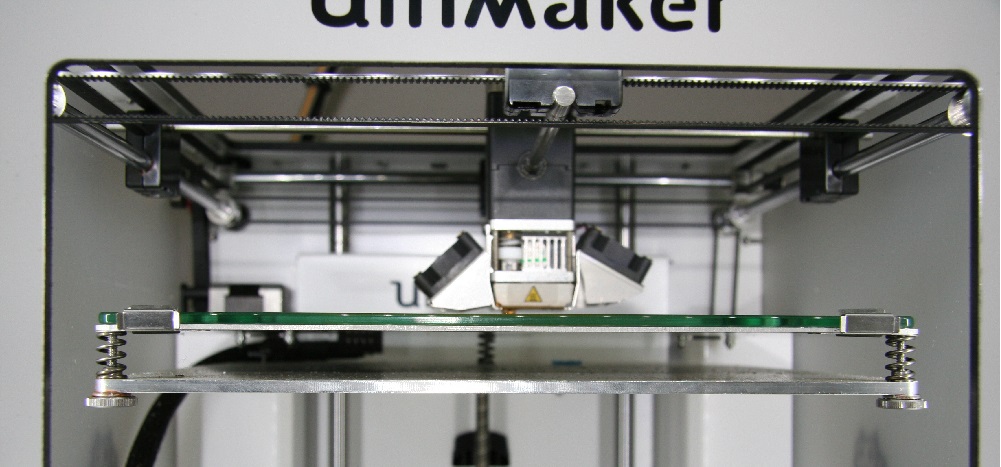

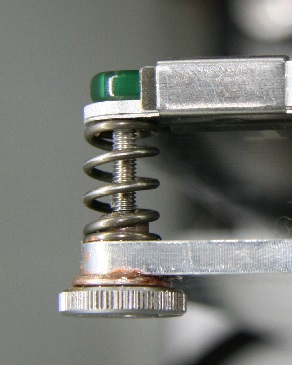

Glass, aluminum, heating element over the entire area of the platform, springs, aluminum.

The platform is heated, the top layer is glass, and a Kapton is glued to it.

Bottom view. Calibration screws - 3 pcs.

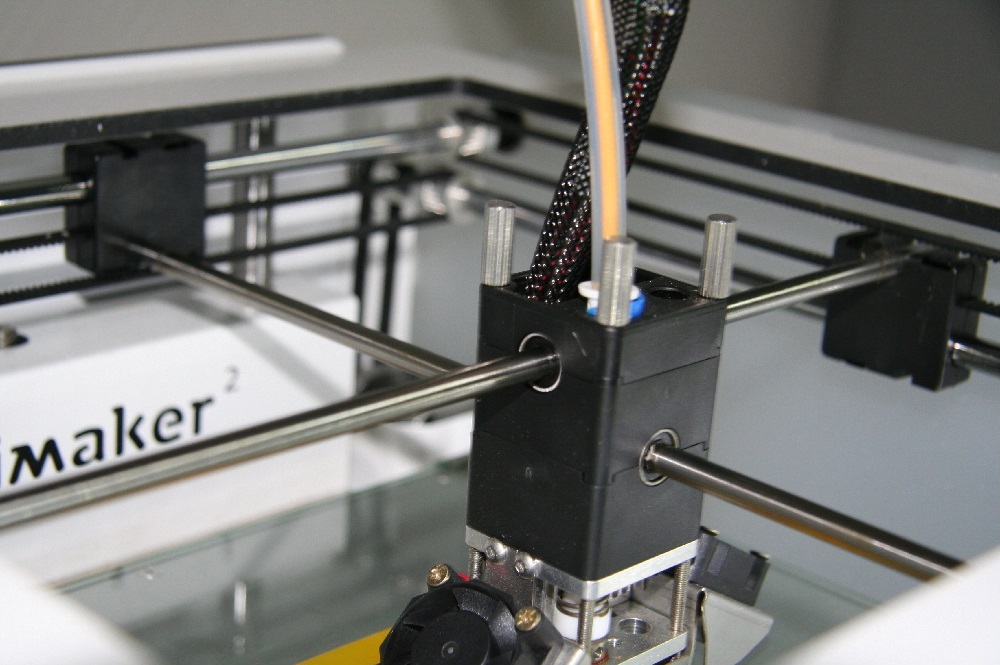

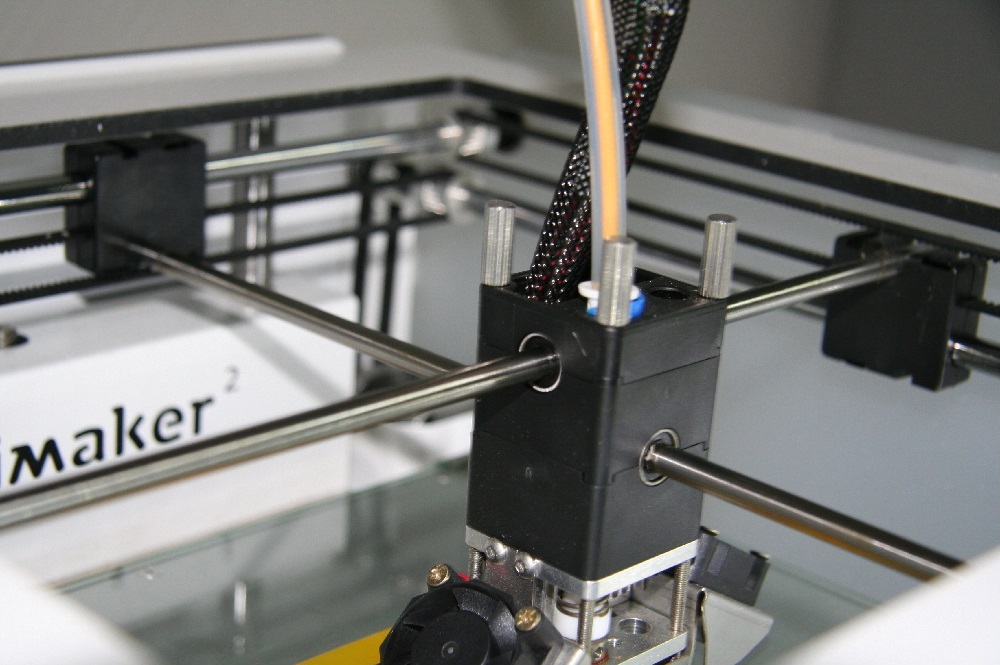

The original cross-shaped design guides (cylinders) along the axes X and Y.

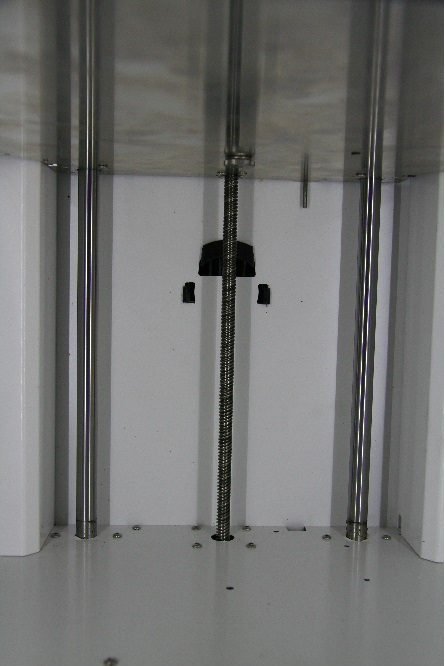

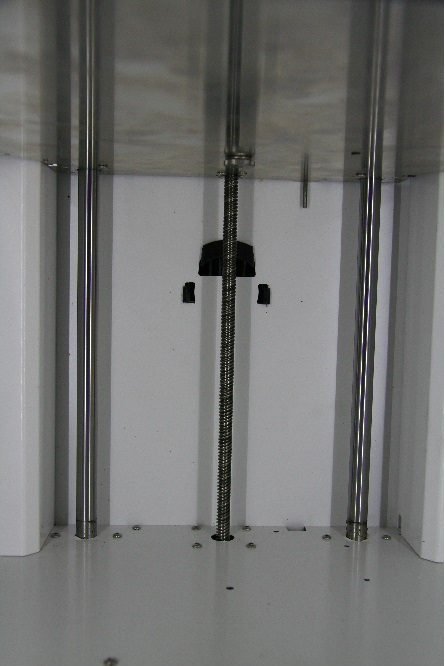

Reinforced guides along the Z axis.

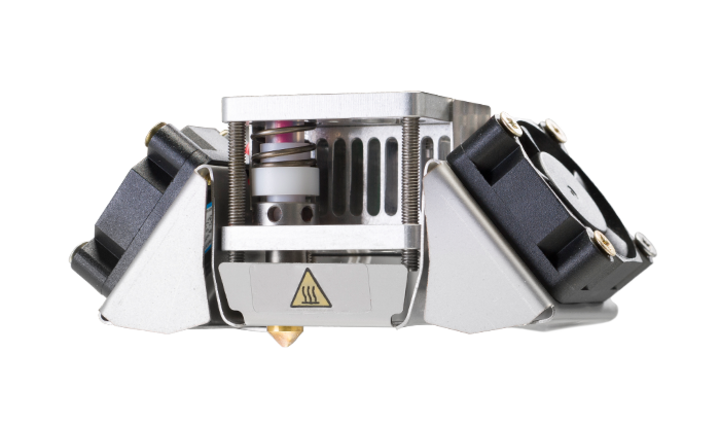

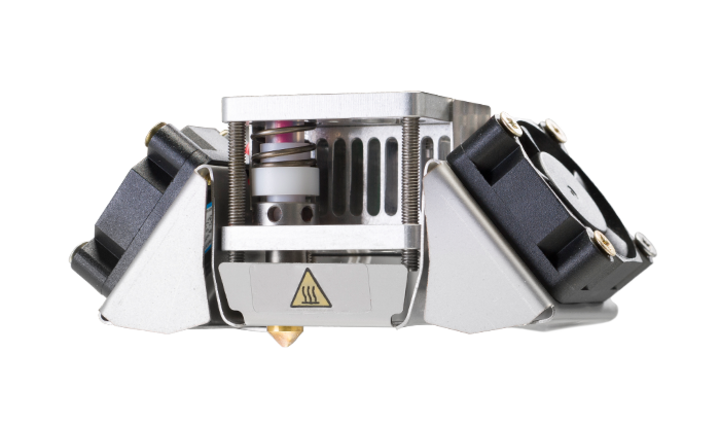

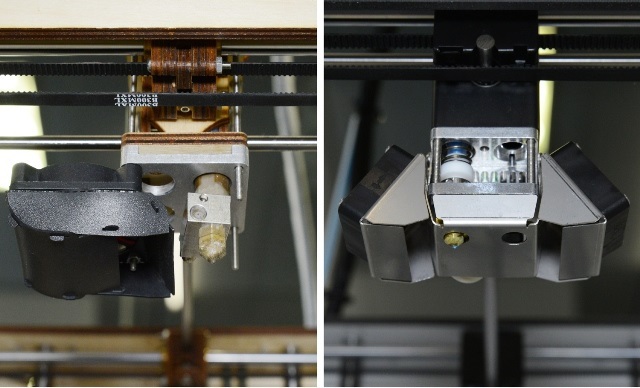

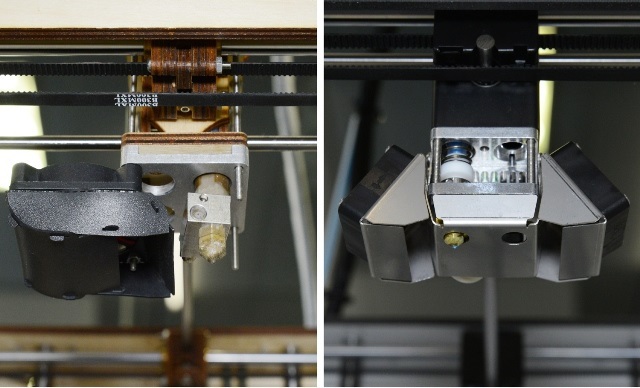

The printing head is made of metal with a Teflon insulator; it heats up quickly (220 ° C in 1 minute) and is equipped with a more accurate PT-100 temperature sensor instead of a thermocouple.

You can see a place under the second extruder, so 2x color printing will be soon.

Active coolers of the working part (controlled through software settings).

Omnivorous Printer: ABS, PLA, Laywood, Nylon, Laybrick, Bendlay

2.85 mm plastic, 750 gr, recommended - Innofil3D PLA.

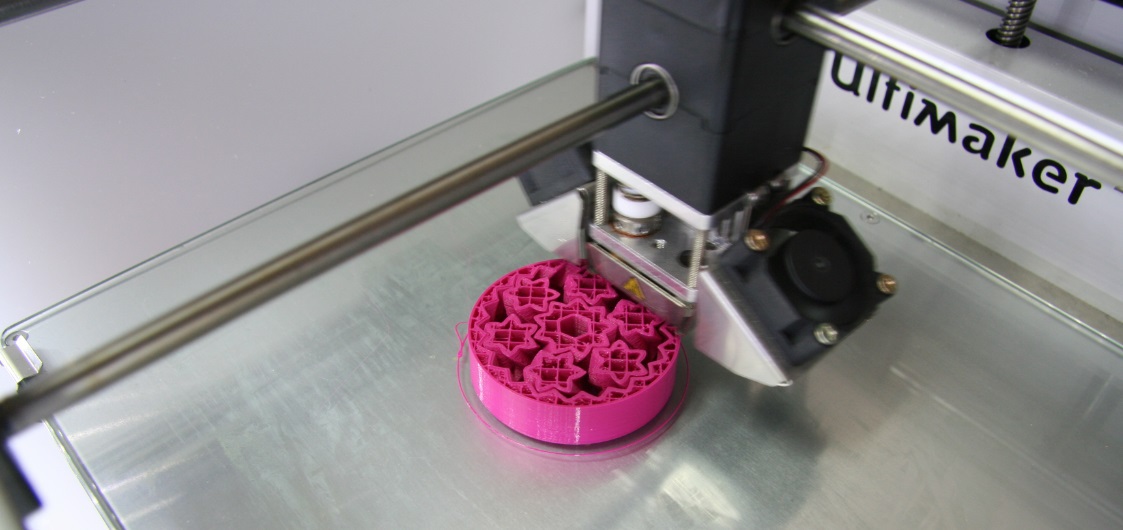

Juicy colors, but in reality - even juicier.

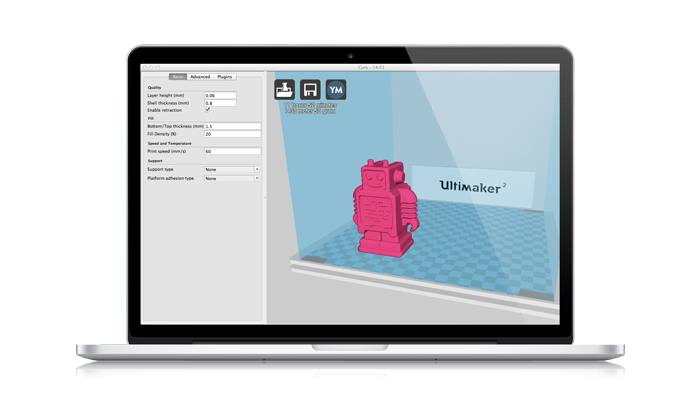

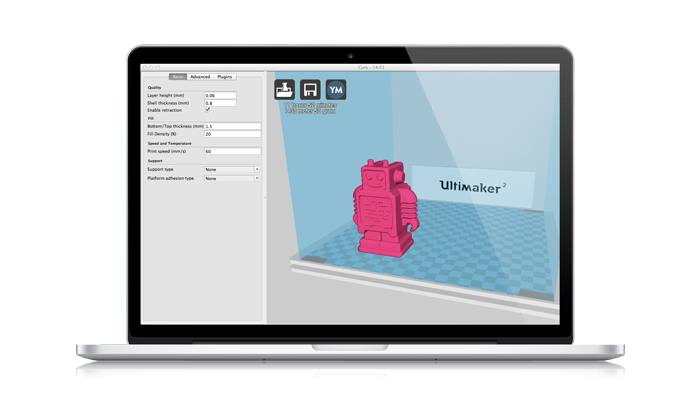

Cura is an open-source product, this software can be modified and enhanced by user efforts.

The software is specially "sharpened" for the parameters of Ultimaker 2 (for example, at a thickness of 20 microns).

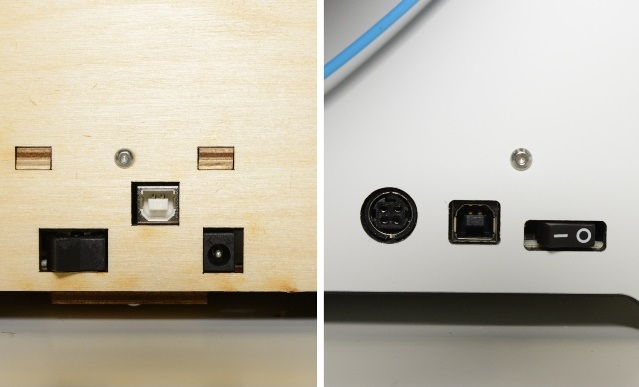

The downloaded / drawn 3D model after “cutting” into Cura is saved on the SD card, which is then inserted into the front panel and printing begins. Work through the SD card allows you to eliminate failures that can be caused due to continuous connection with the computer (voltage spikes, computer crashes, etc.).

An upgrade for Wi-Fi connection is planned for the near future.

Now Cura "cuts" the model much faster. In addition, Ultimaker developed UltiGCode, a variant of G-code that allows you to change the settings for materials and the draw process in the printer settings (and not the slicer) without having to re-cut.

Russian community

Model library

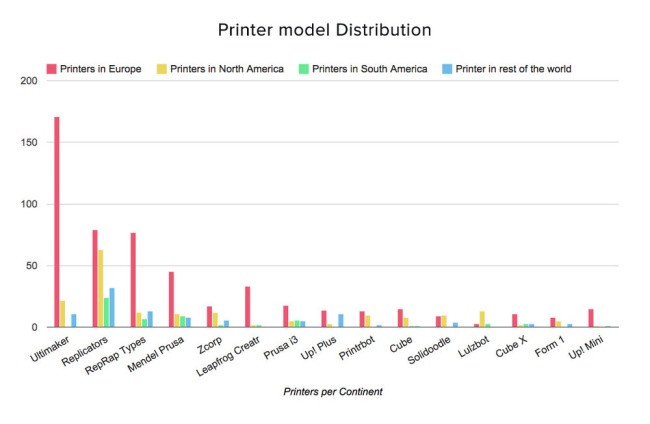

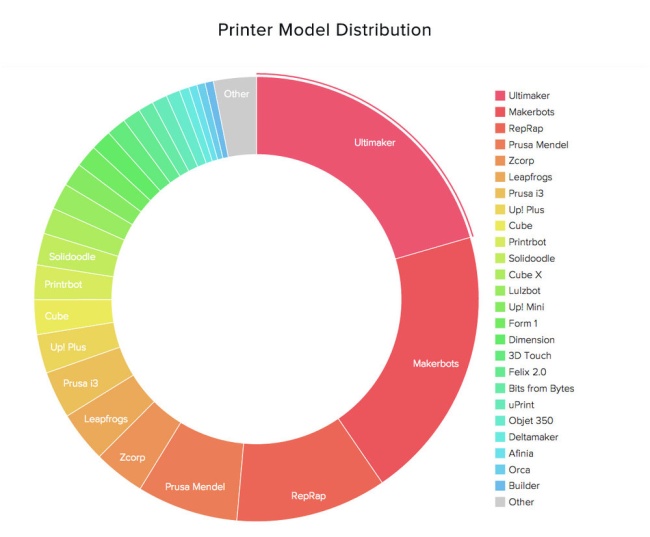

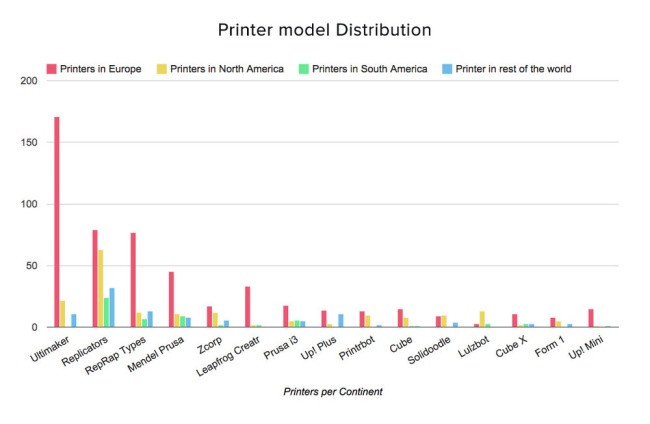

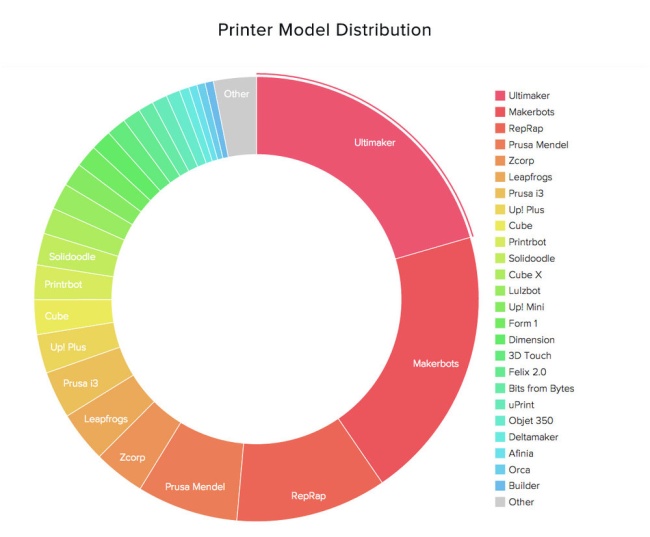

According to the materials (end of April 2014) www.3dhubs.com/trends

Growth rate:

Sales by continent:

Market Shares:

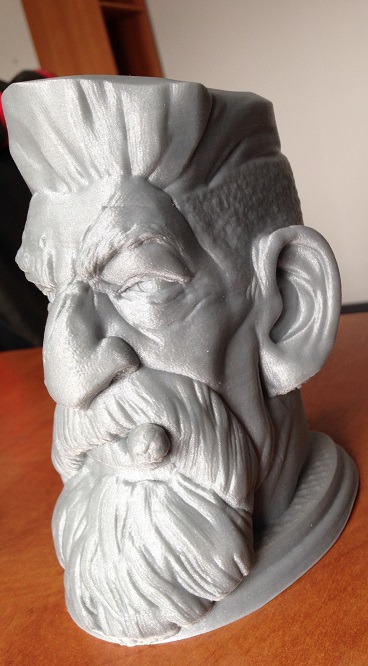

Even closer.

Emerald / malachite.

Silver.

Video with unpacking (10 min)

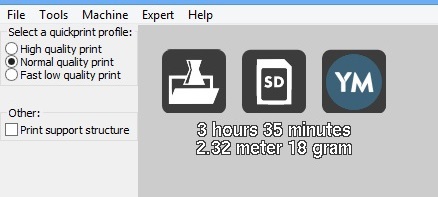

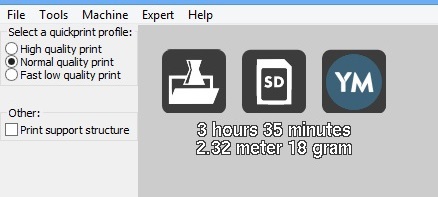

Having downloaded a detail from the Internet - I open it in Cura.

The program reads how many meters of plastic it will take and how long printing will take place:

The mode “for beginners” is chosen - no need to bother - choose from 3 items.

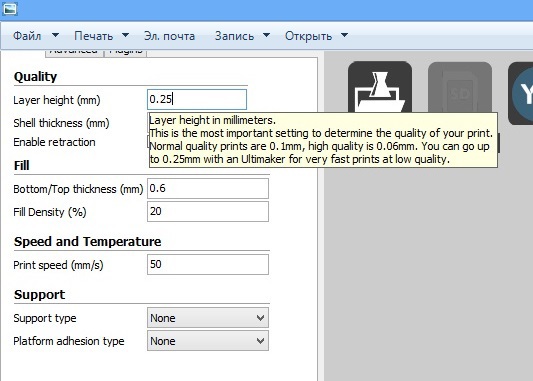

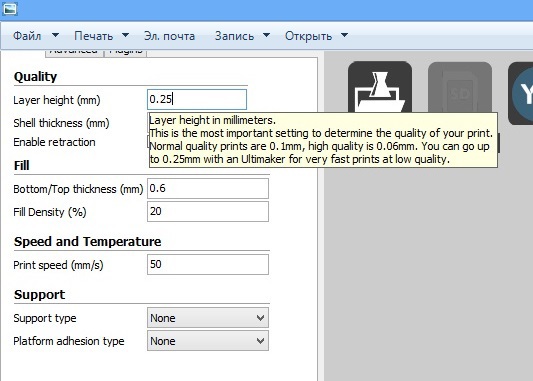

You can switch to the "expert" mode:

The program politely gives hints for each item:

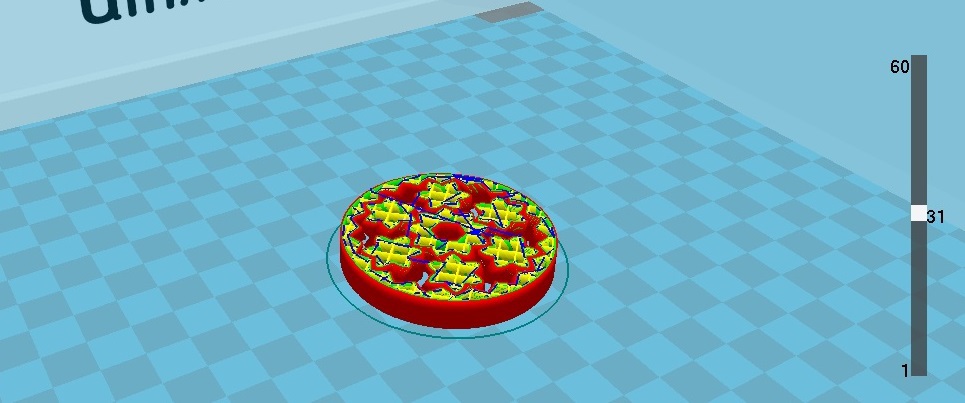

There are different types of preview:

Transparent:

X-rays:

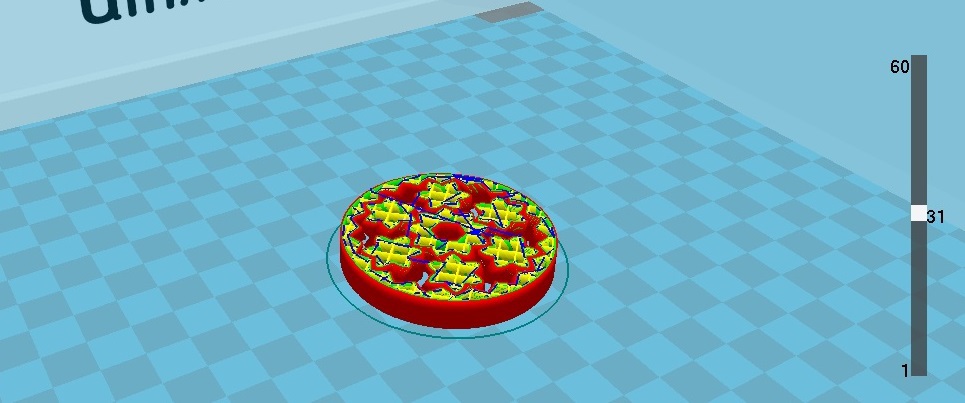

Layers:

The slider on the right is on the 60th layer.

The slider on the right is on the 31st layer.

We save it all on the SD card and insert it into the printer - it shows the time and meters:

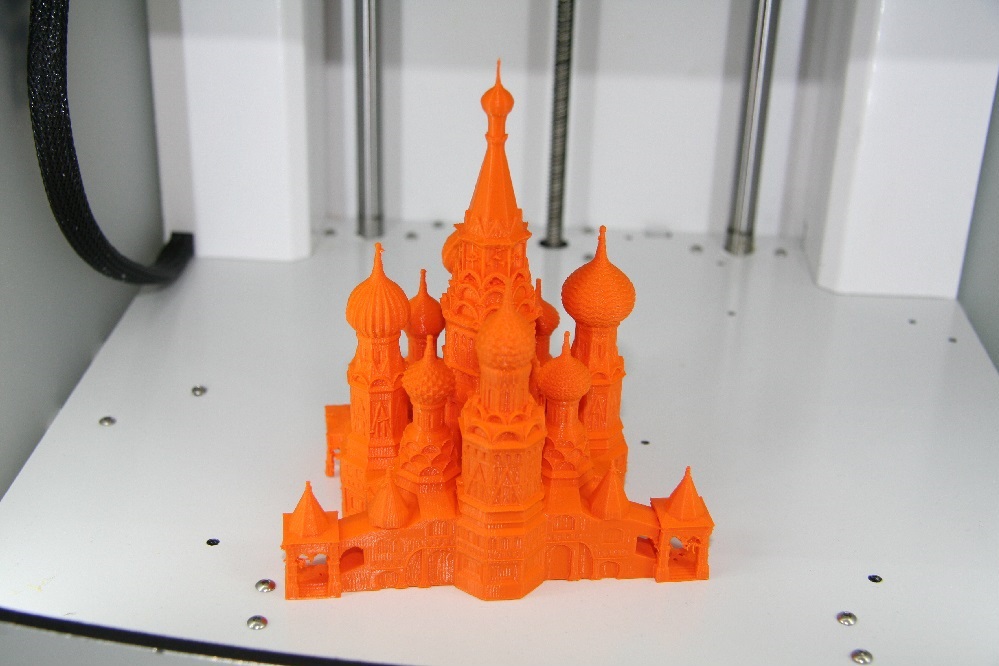

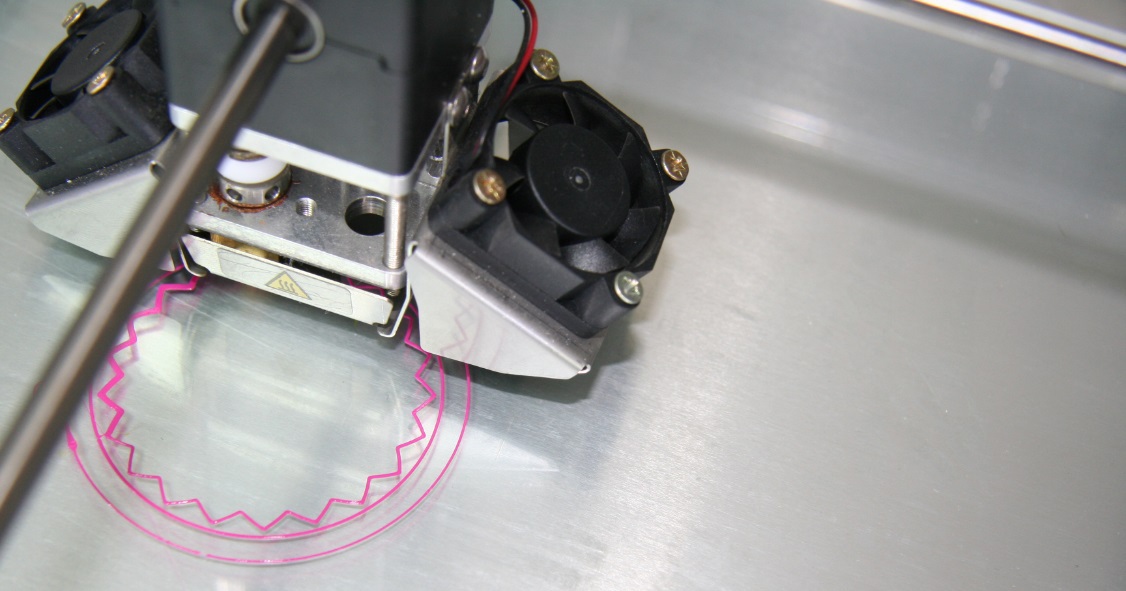

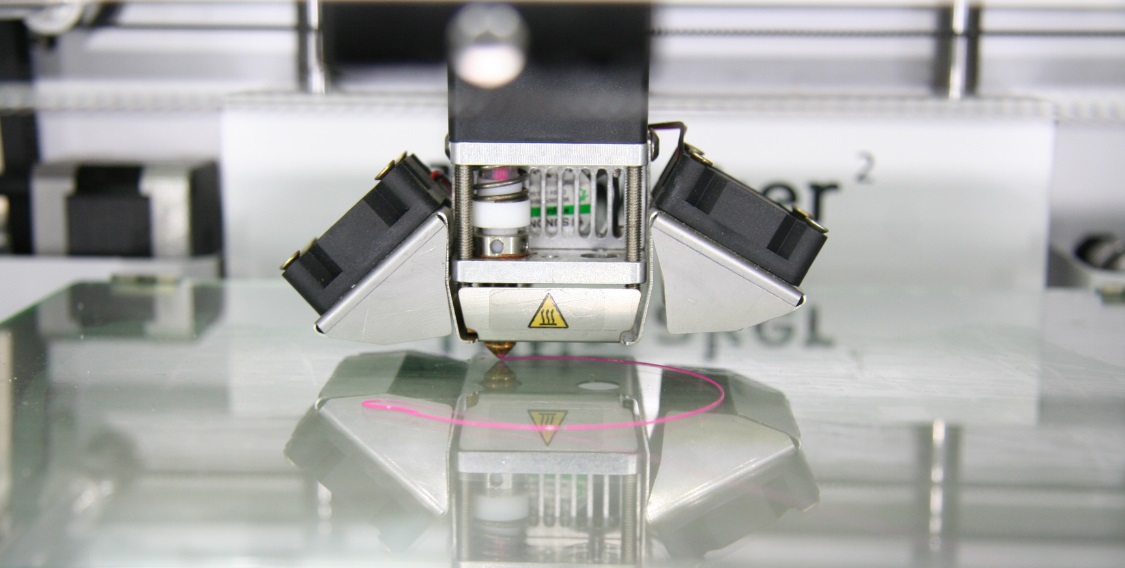

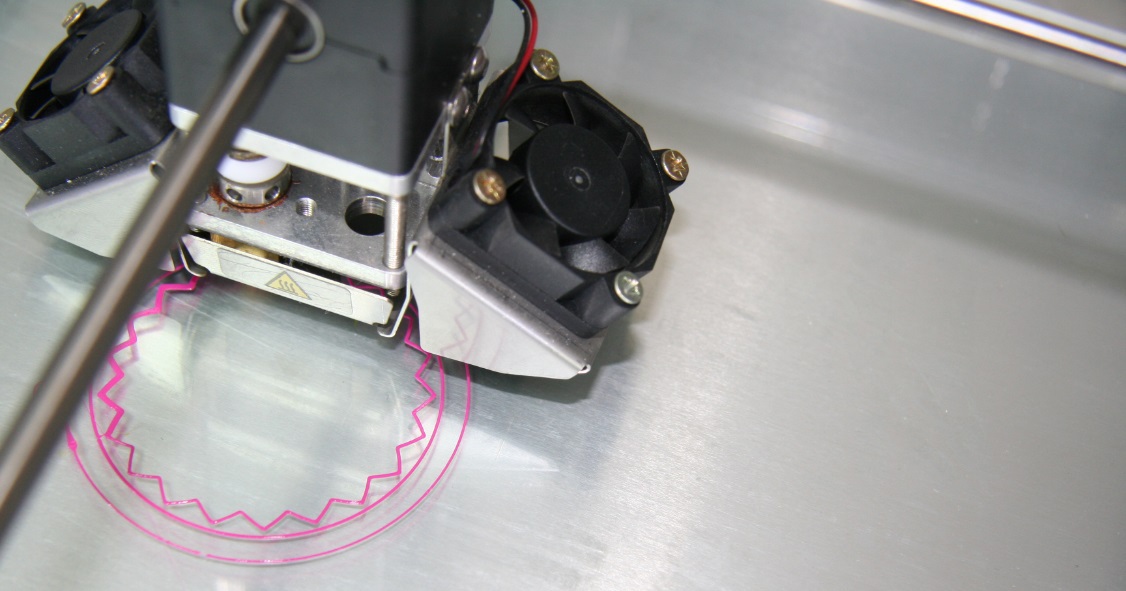

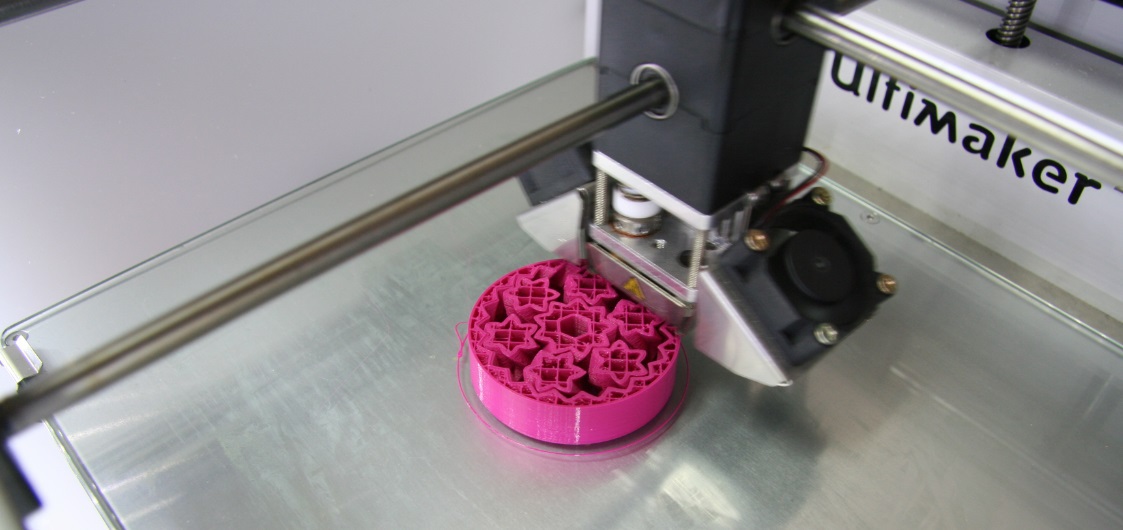

Printing went:

You can change various settings during printing.

You can wind the speed while printing.

14 minutes to complete printing:

The final touches.

Detail is ready.

- Very fast

- very stylish

- very silent

-Very expensive Cheaper by 17 thousand than Replicator 5th generation.

And I waited, waited for the opportunity to touch at least the first model, and here - immediately the second!

I hasten to share with the community about what I saw.

What is Ultimaker 2 ?

Very beautiful video:

')

Features

Layer thickness: up to 20 microns

Printing area 23 x 22.5 x 20.5 cm

Print speed: 30mm / s-300mm / s

Movement speed: 30mm / s-300mm / s

Recommended plastic: 2.85 mm

Price of use: ~ € 0.05 / cm ^ 3 (plastic and electricity)

Fully assembled and ready to use printer

Speed

Speed is what distinguished Ultimaker from the very start of the project.

The printer allows you to wind the

And this printer is the quietest of all I've seen.

Appearance

Front view

Side panel of matte plastic that very stylishly scatters light.

The coil is mounted at the back.

Plastic feed system.

Minimalistic front panel.

Body materials - composite (aluminum-plastic-aluminum) and translucent matte plastic.

Platform

Glass, aluminum, heating element over the entire area of the platform, springs, aluminum.

The platform is heated, the top layer is glass, and a Kapton is glued to it.

Bottom view. Calibration screws - 3 pcs.

Guides

The original cross-shaped design guides (cylinders) along the axes X and Y.

Reinforced guides along the Z axis.

Printhead

The printing head is made of metal with a Teflon insulator; it heats up quickly (220 ° C in 1 minute) and is equipped with a more accurate PT-100 temperature sensor instead of a thermocouple.

You can see a place under the second extruder, so 2x color printing will be soon.

Active coolers of the working part (controlled through software settings).

Plastic

Omnivorous Printer: ABS, PLA, Laywood, Nylon, Laybrick, Bendlay

2.85 mm plastic, 750 gr, recommended - Innofil3D PLA.

Juicy colors, but in reality - even juicier.

Soft

Cura is an open-source product, this software can be modified and enhanced by user efforts.

The software is specially "sharpened" for the parameters of Ultimaker 2 (for example, at a thickness of 20 microns).

The downloaded / drawn 3D model after “cutting” into Cura is saved on the SD card, which is then inserted into the front panel and printing begins. Work through the SD card allows you to eliminate failures that can be caused due to continuous connection with the computer (voltage spikes, computer crashes, etc.).

An upgrade for Wi-Fi connection is planned for the near future.

Now Cura "cuts" the model much faster. In addition, Ultimaker developed UltiGCode, a variant of G-code that allows you to change the settings for materials and the draw process in the printer settings (and not the slicer) without having to re-cut.

Russian community

Model library

Market share and statistics

According to the materials (end of April 2014) www.3dhubs.com/trends

Growth rate:

Sales by continent:

Market Shares:

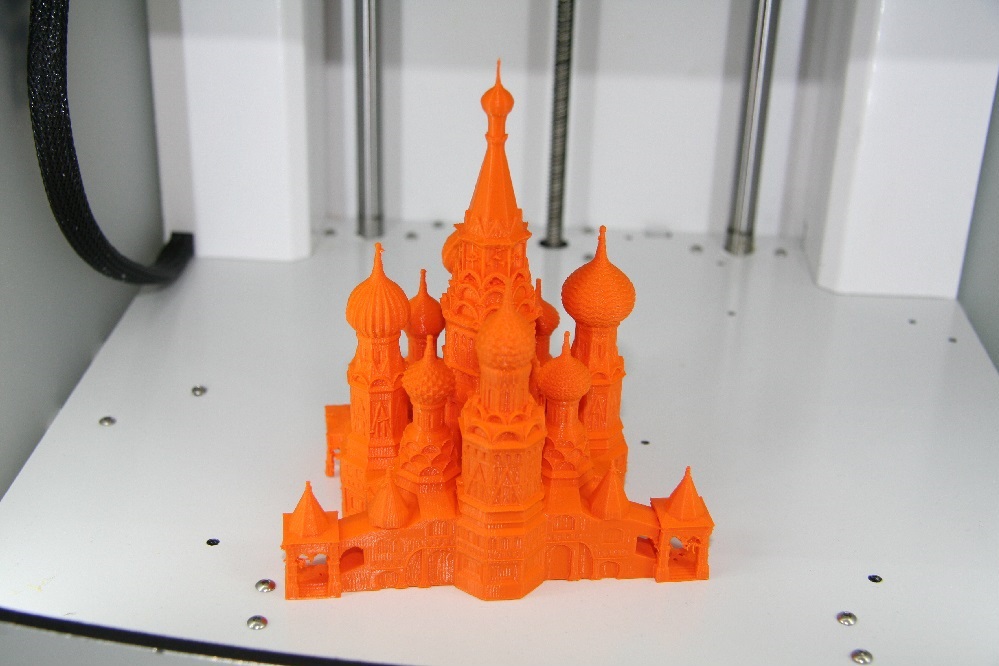

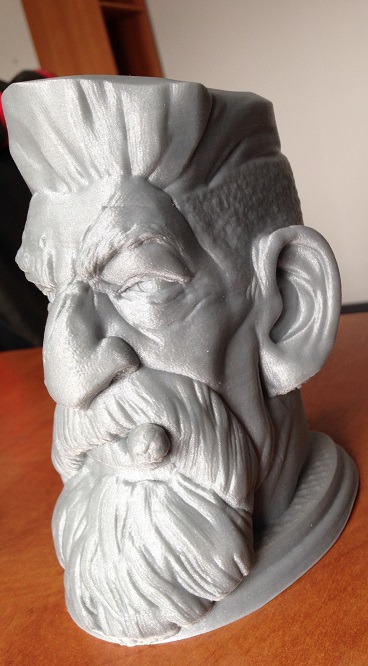

Printed Objects

Even closer.

Emerald / malachite.

Silver.

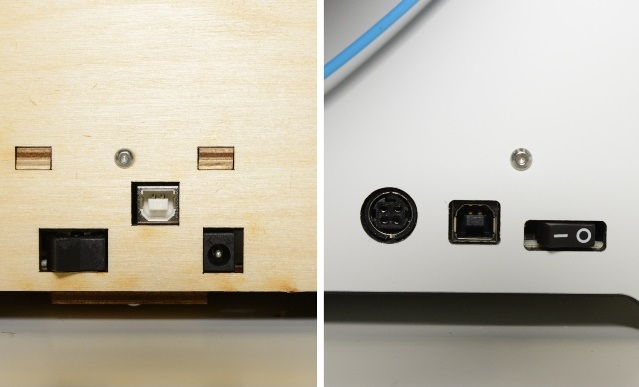

Comparing Ultimaker Original and Ultimaker 2 Designs

expand

Video with unpacking (10 min)

Personal printing experience on Ultimaker 2

Having downloaded a detail from the Internet - I open it in Cura.

The program reads how many meters of plastic it will take and how long printing will take place:

The mode “for beginners” is chosen - no need to bother - choose from 3 items.

You can switch to the "expert" mode:

The program politely gives hints for each item:

There are different types of preview:

Transparent:

X-rays:

Layers:

The slider on the right is on the 60th layer.

The slider on the right is on the 31st layer.

We save it all on the SD card and insert it into the printer - it shows the time and meters:

Printing went:

You can change various settings during printing.

You can wind the speed while printing.

14 minutes to complete printing:

The final touches.

Detail is ready.

findings

- Very fast

- very stylish

- very silent

-

PS Teaser for the next review

expand

Source: https://habr.com/ru/post/220931/

All Articles