PrintBox3d. 3d printer in Russian

Recently, I was lucky not only to test the Russian PrintBox3d printer, but also to look into the production workshop.

What I want to share with habrachiteleley.

Chips:

- 2 motors per Z axis

- Meteorite-resistant frame

- Own stepper motor controllers based on developments for industrial CNC

- Many spare parts

')

Caution! A lot of aluminum!

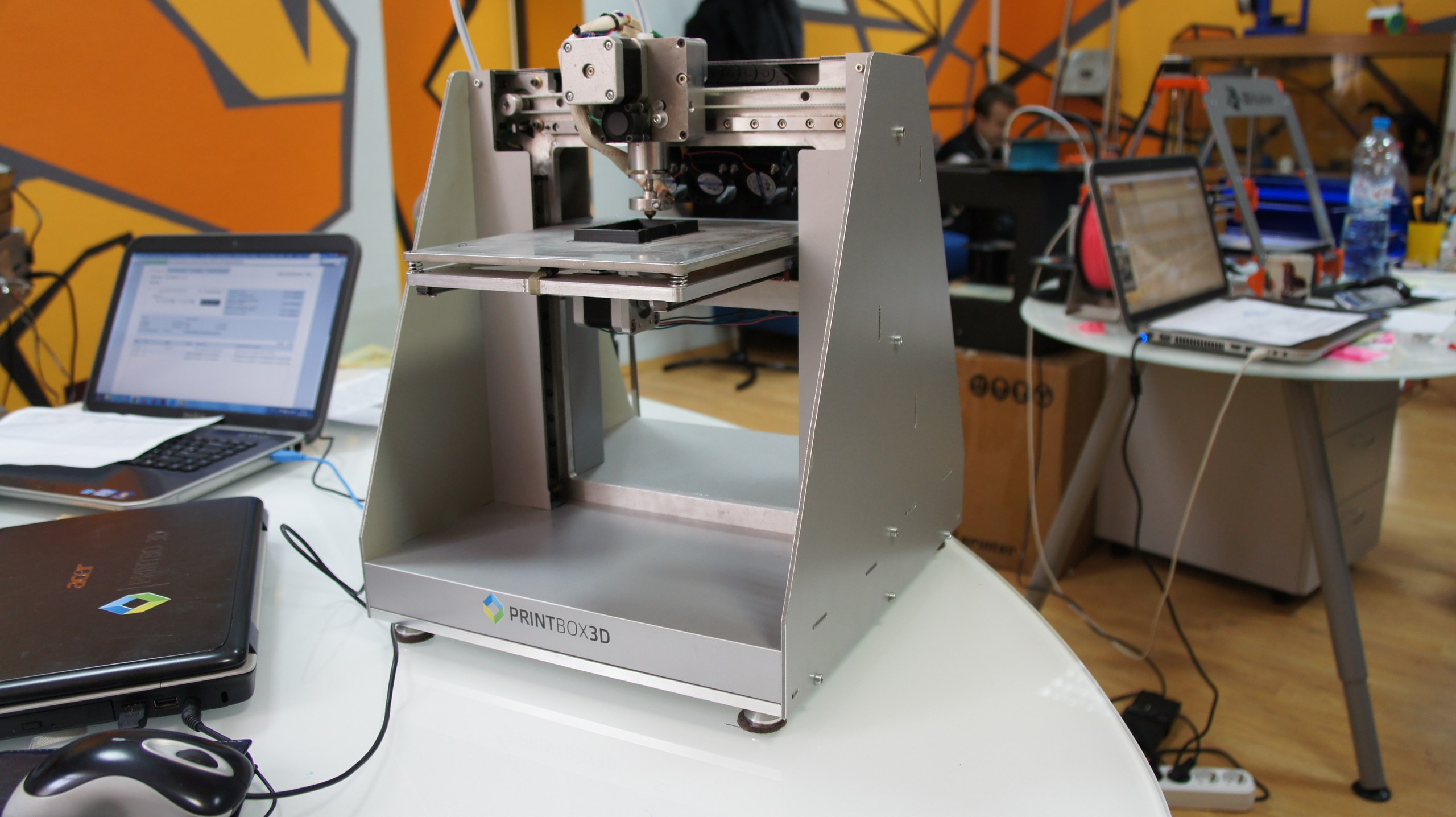

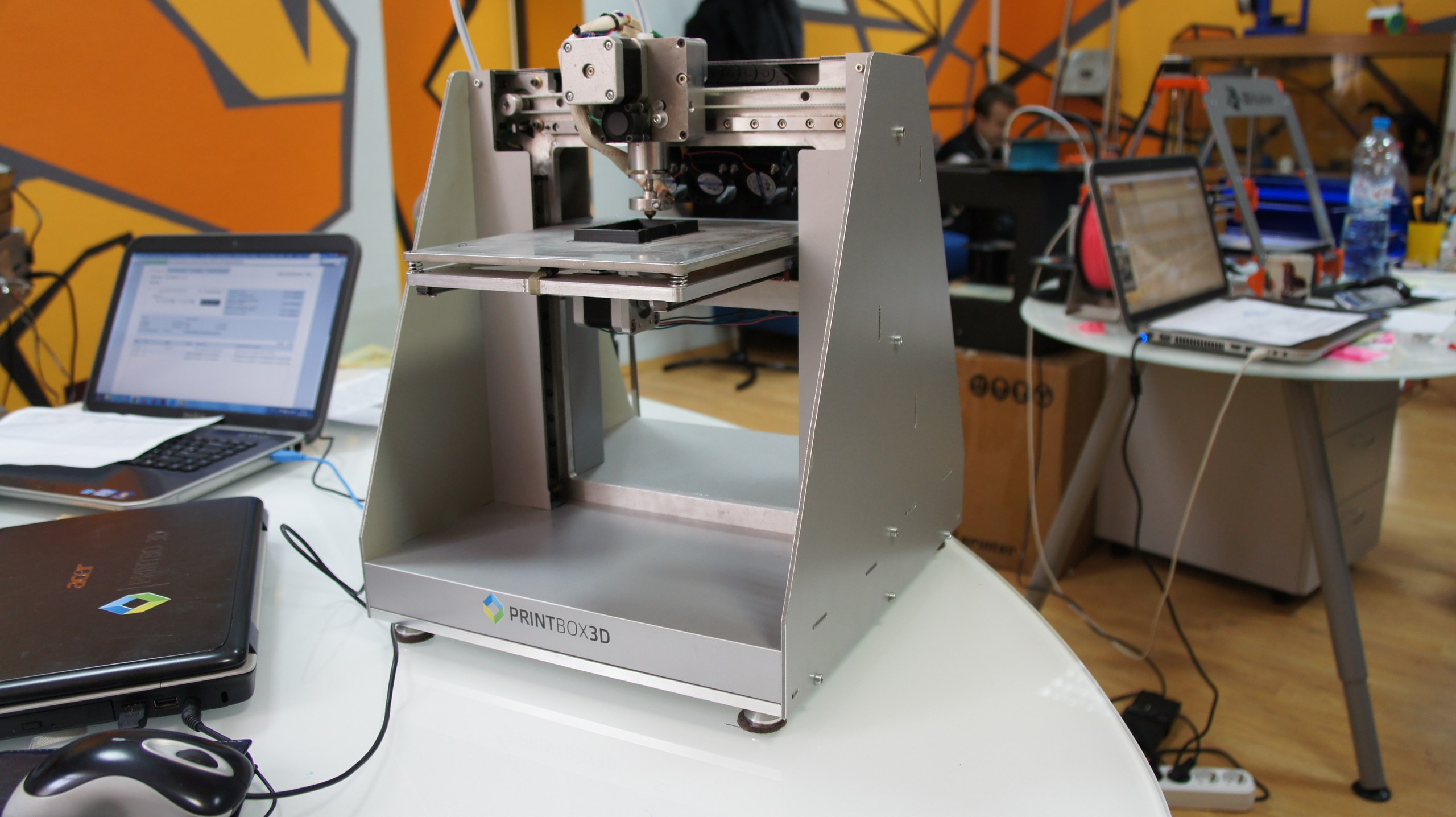

( in the photo the very first printer prototype )

TTX

CONSTRUCTION AREA SIZE 185 × 160 × 150 MM

PRINT MATERIAL ABS, PLA, PVA, OTHER

PRESS RESOLUTION (MICRON) 50 (0.05 mm)

PRINT SPEED UP TO 30 CM ^ 3 / HOUR

LAYER THICKNESS 50 MKM, WALL THICKNESS 190 MKM

OPERATING SYSTEMS WINDOWS XP, WINDOWS 7, MAC OSX, WINDOWS 8, VISTA, LINUX

WEIGHT (WITHOUT PACKING) 10.5 KG

OVERALL DIMENSIONS (WITHOUT PACKING) 320 × 360 × 390 MM

The printer runs on open source software (Cura, Slic3R and Repetier-Host).

For the convenience of users, printer developers have translated the Cura program into Russian. (for which they respect)

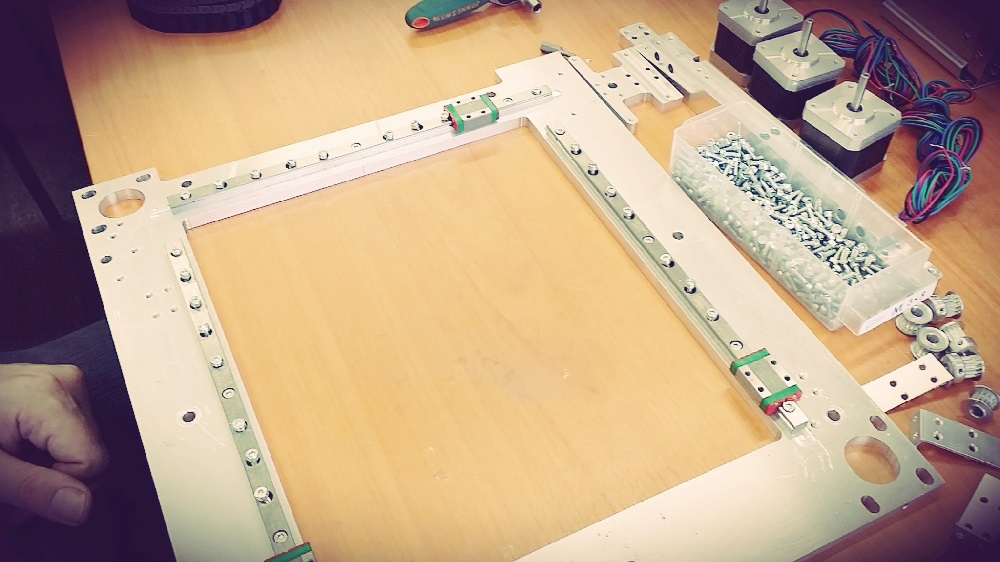

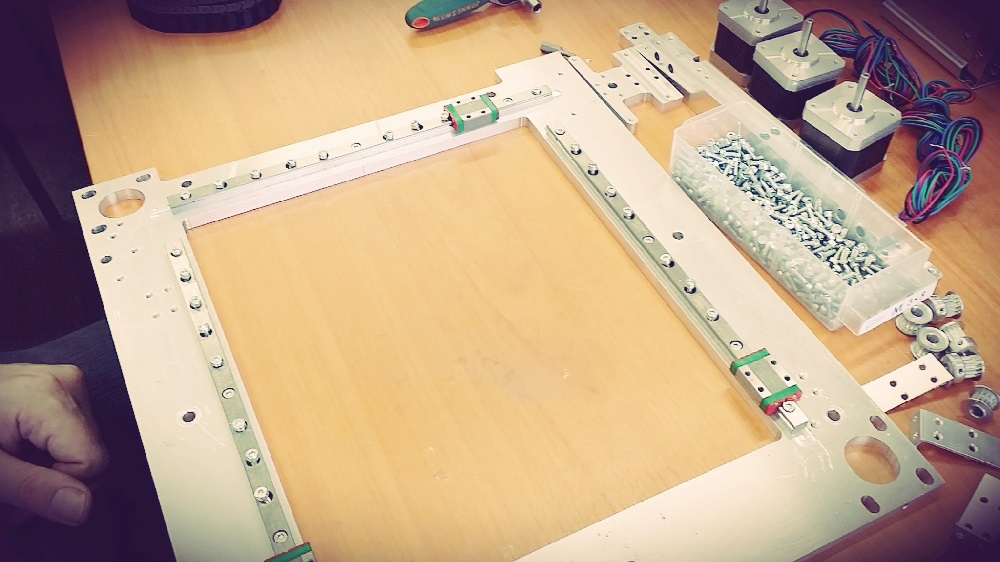

“A good printer in our understanding begins with the frame”

the accuracy of the printer (positioning of the print head) begins with the frame. The reliability of the design allows to withstand even "extreme transportation" (Russian Post).

(According to the prevalence in the Earth’s crust, aluminum is 1st among metals and 3rd among elements, second only to oxygen and silicon. According to various researchers, the mass concentration of aluminum in the crust is from 7.45 to 8.14%).

(In the body of an adult there is up to 140 mg of aluminum. The daily adult need for aluminum is estimated at 2.45 mg.).

(The most ancient product, containing 85% of aluminum, dates from the 3rd century AD)

"Our difference from world leaders is based on a powerful frame . "

(Aluminum compounds are found not only on Earth, but also on the Moon and Mars. Aluminum is even found in apples - up to 150 mg / kg.)

8mm pure aluminum.

(The first product made of aluminum was a rattle made for the French Emperor Napoleon III in the 50s of the 19th century).

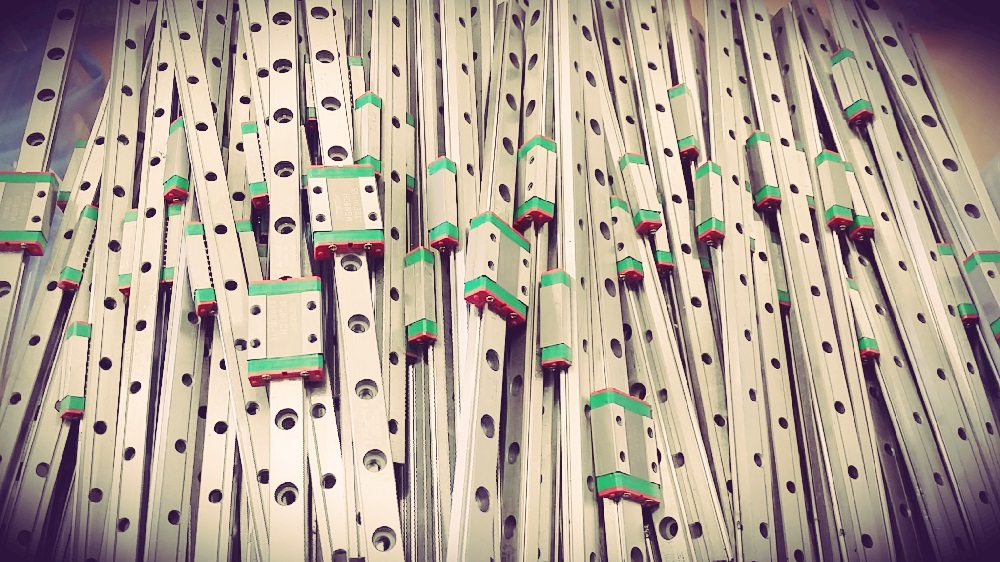

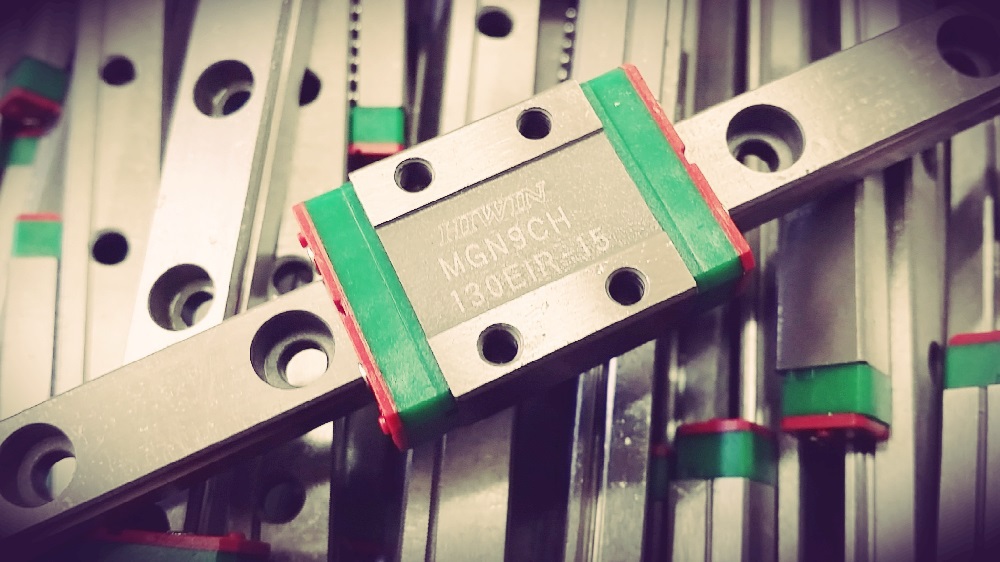

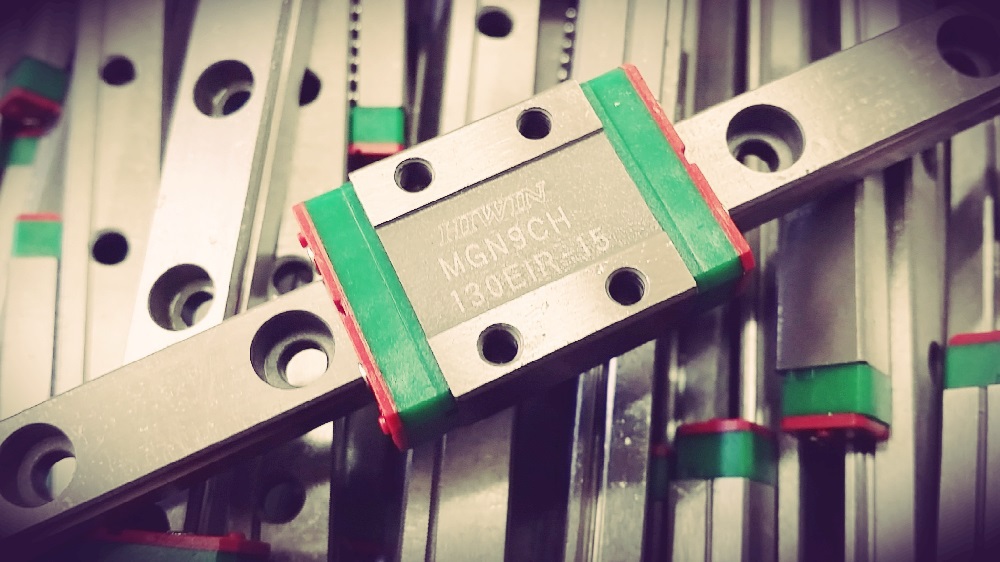

The fact that provides the position / movement of the printhead / platform (guides) are 3 types - screw, cylinder or rail.

Screw guides are slow and are mainly used for Z axis positioning.

The main load on the speed and accurate movement falls either on the cylinders or on the rails.

PrintBox3d developers have opted for the rail, because “Cylinders have only 2 points of support and there have been cases that the cylinders bend, at the rail, the same points of support are every 2 cm and the life span of the rails is longer than that of the cylinder.”

Resource rail is higher than that of cylinders.

Support points every 2 cm.

Precise milling on CNC machine = precise and rigid construction.

Aluminum is stronger than plastic, glass, textolite. Yes, and heat conduction properties are better.

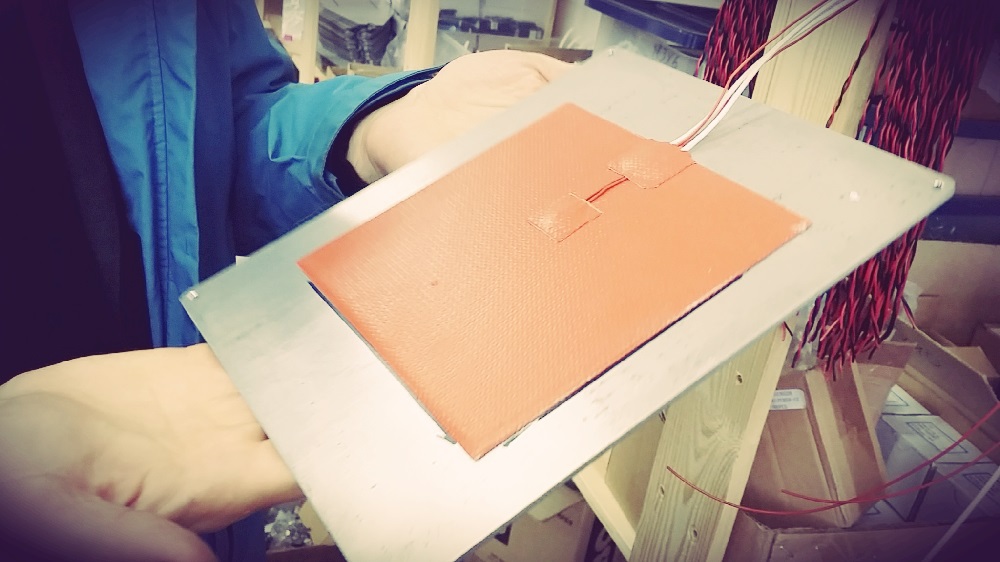

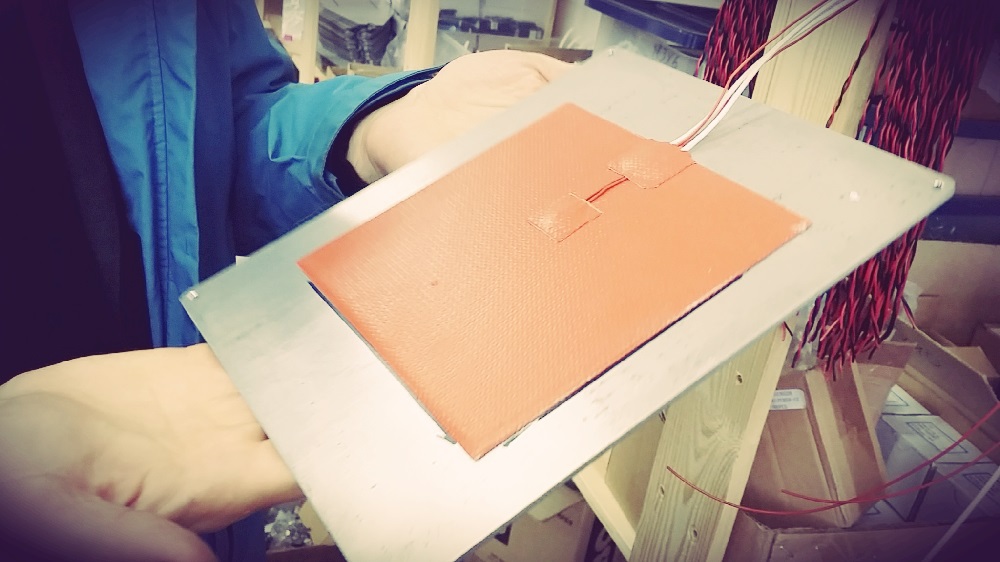

Platform made of aluminum with a flexible bottom heater. The size of the heater is smaller than the size of the platform - 15x15 cm.

But, due to the good thermal conductivity of aluminum, the heating of the platform is uniform.

Adjustment of the horizon (calibration of the platform) is done manually with screws, done once in production (mounting rigidity and design features allow you to adjust once and for a long time.)

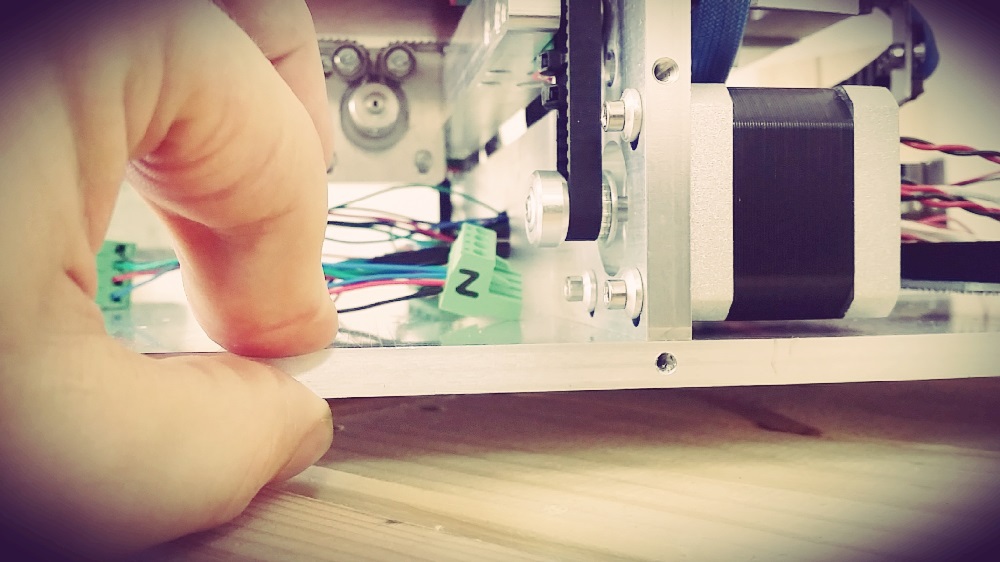

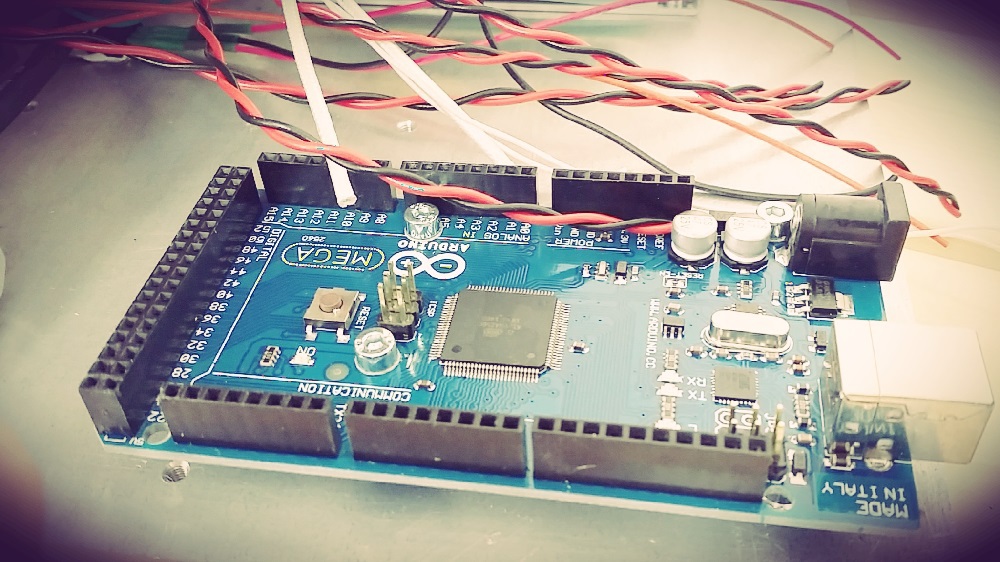

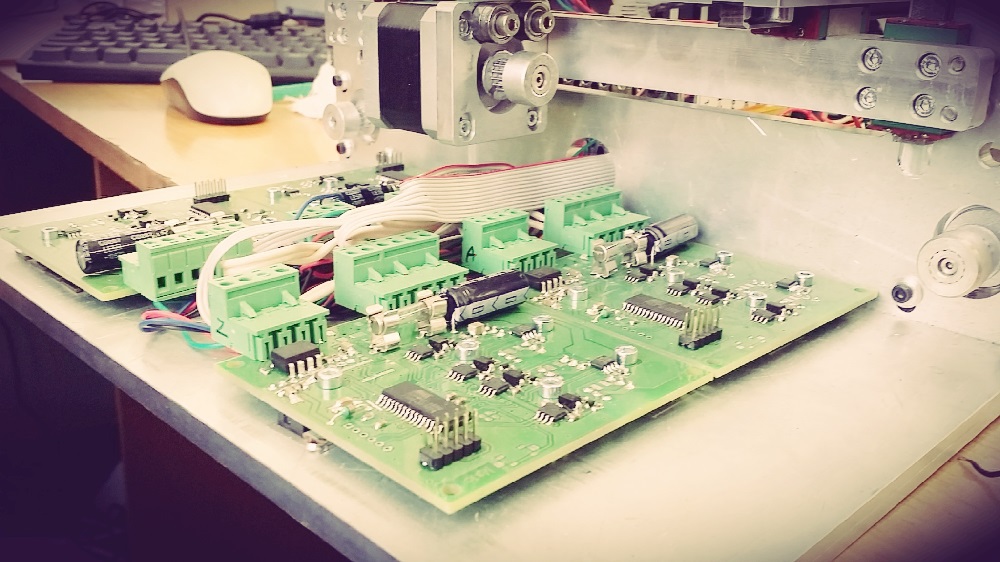

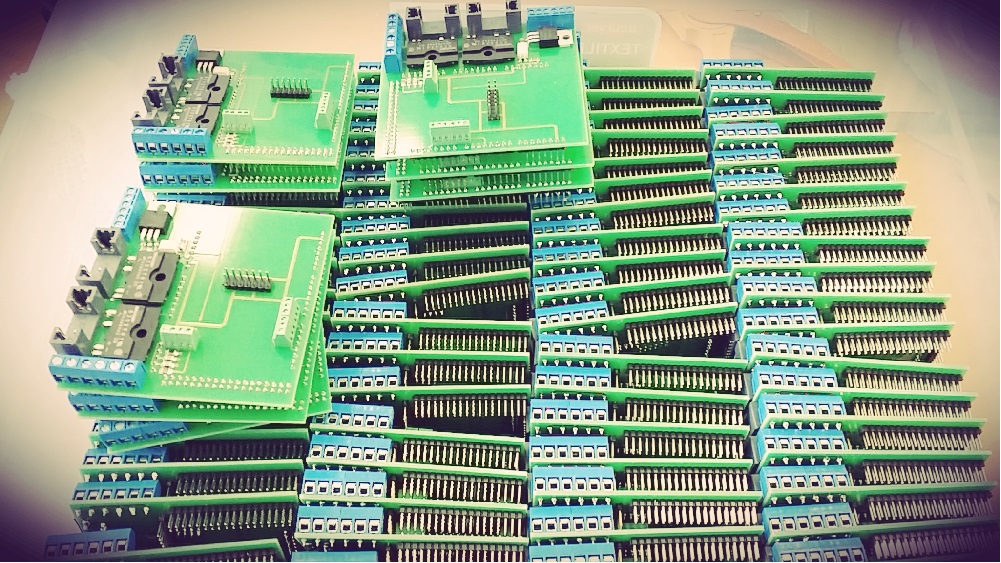

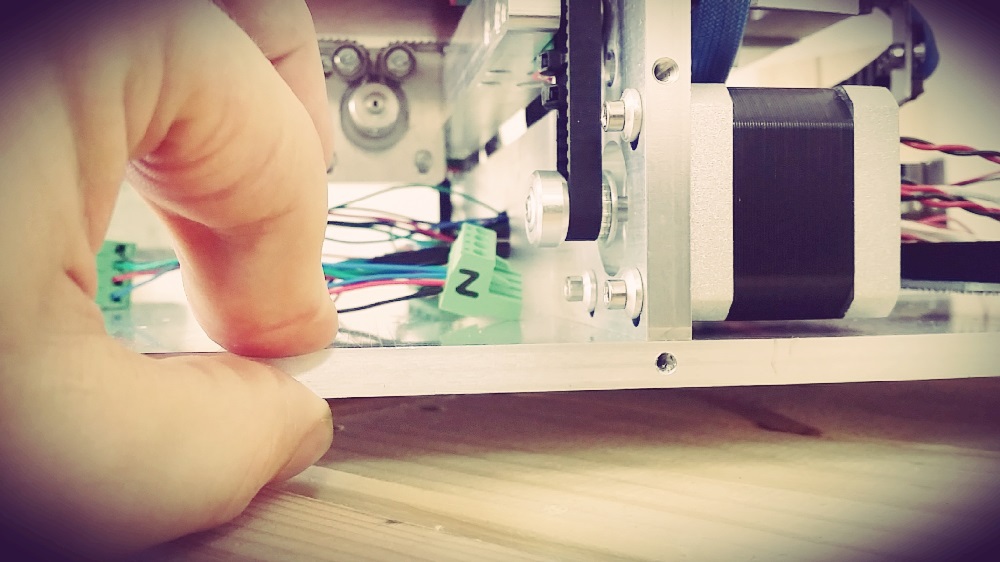

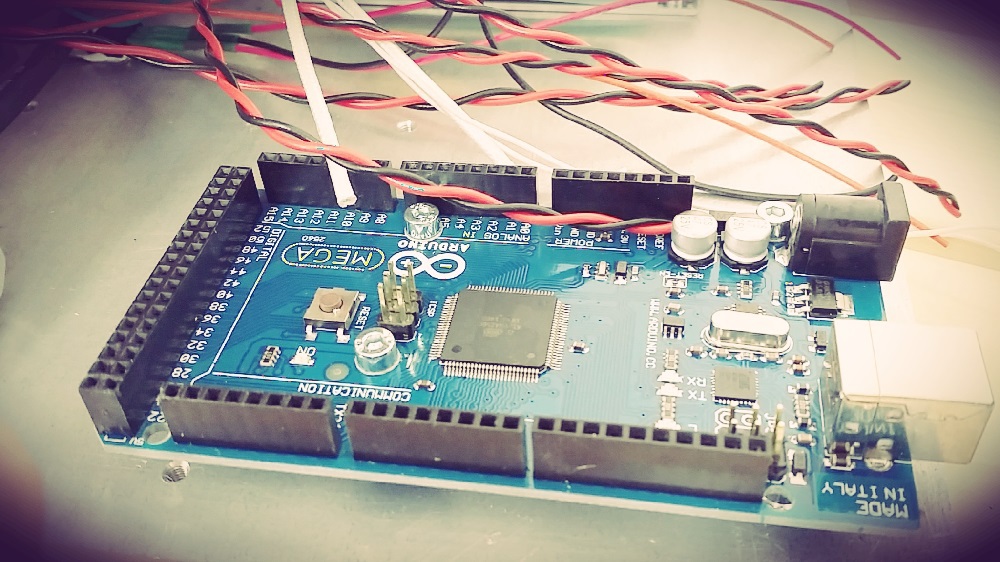

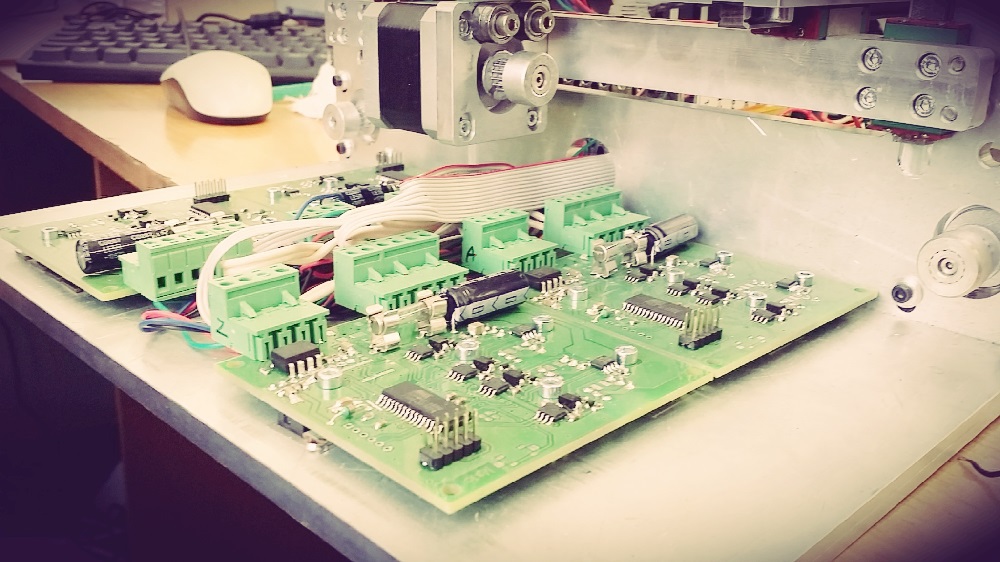

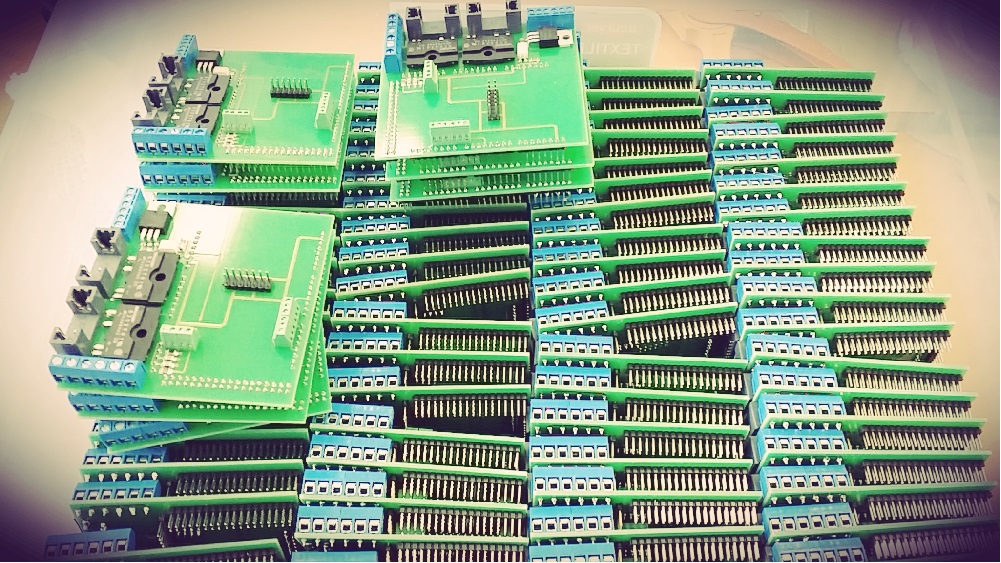

There is an arduino as a control board - but for each motor it has its own controller of stepper motors (this allows for better inertia damping, working at higher powers.)

each engine has its own controller (total 4 controllers, remember that we have 2 motors on the Z axis.)

Fuse. Saves. (This is Russian sockets)

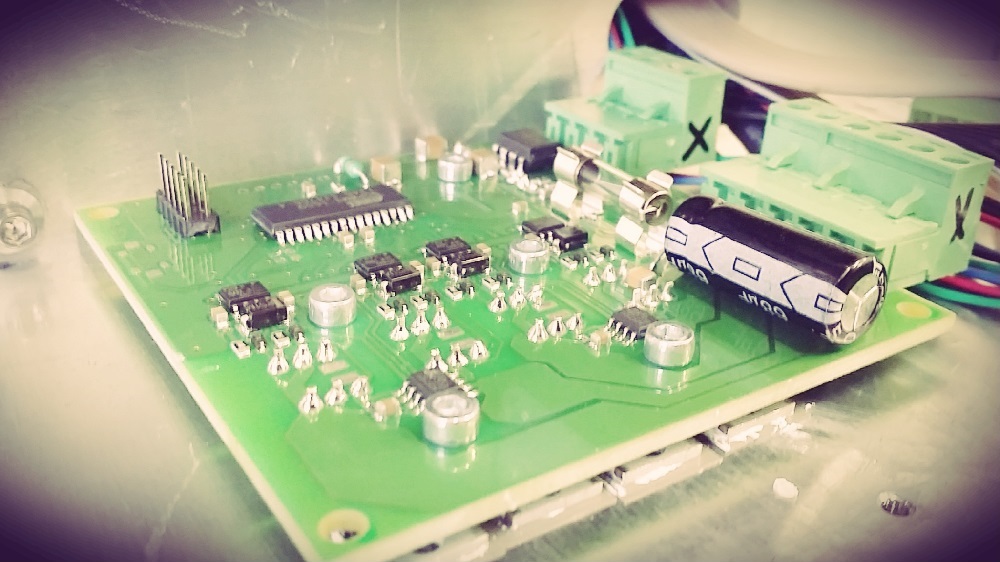

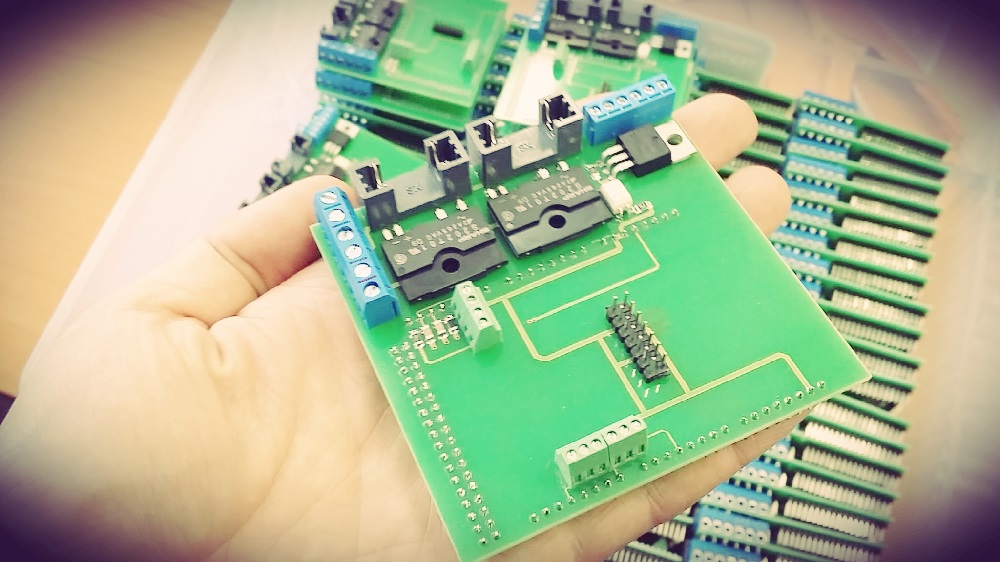

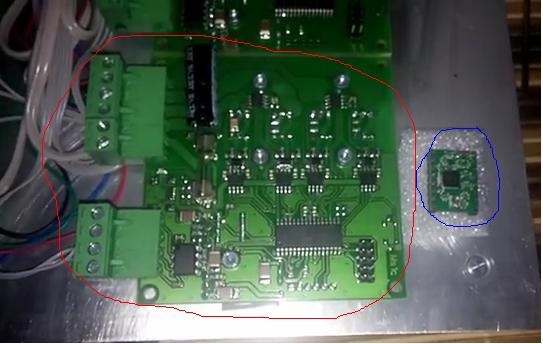

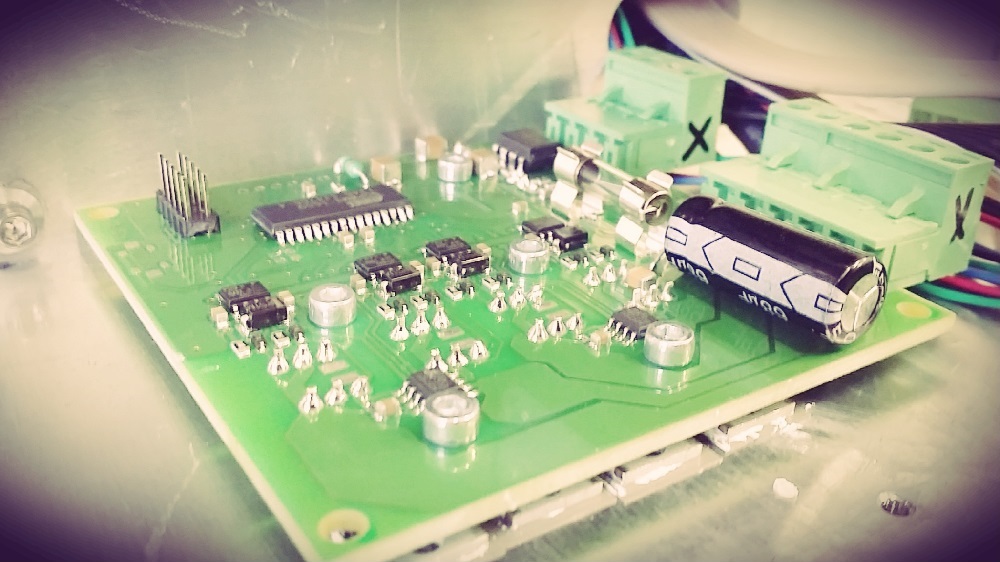

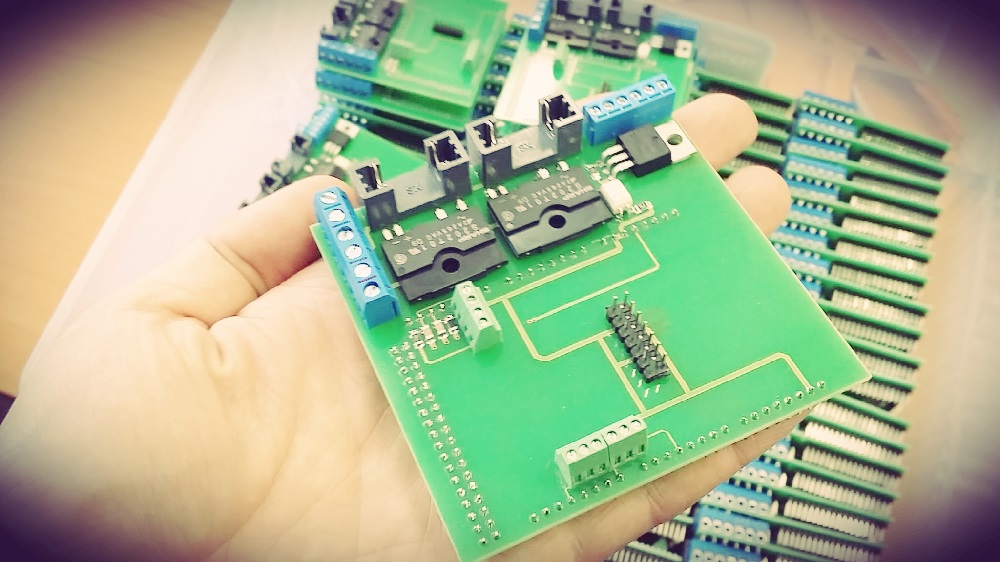

Controllers - own development and own production.

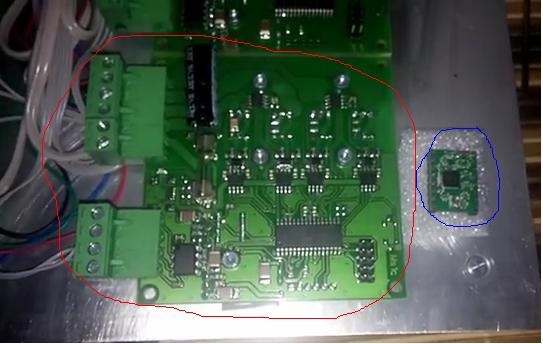

Comparison red - Russian controller, blue - Chinese controller.

There are spare.

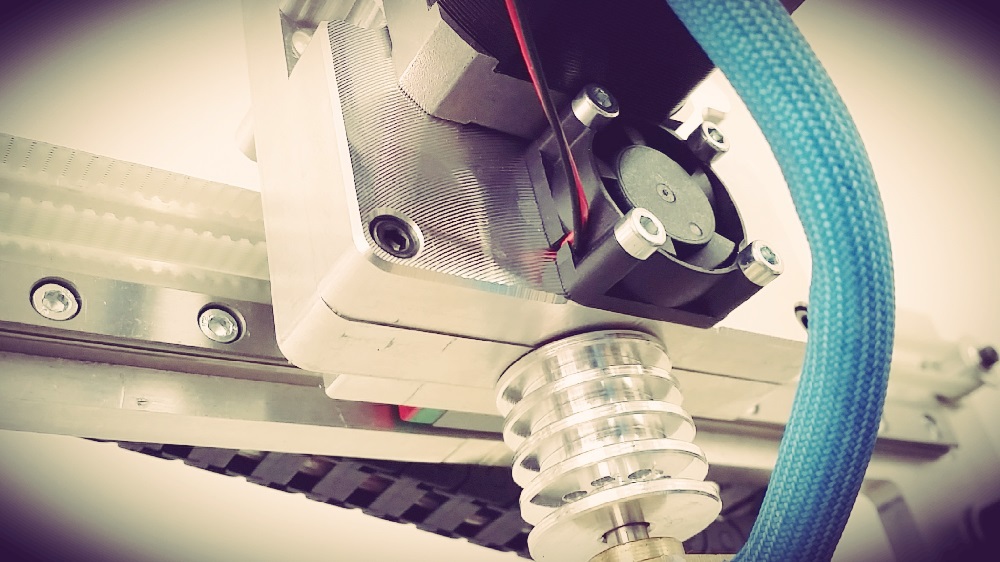

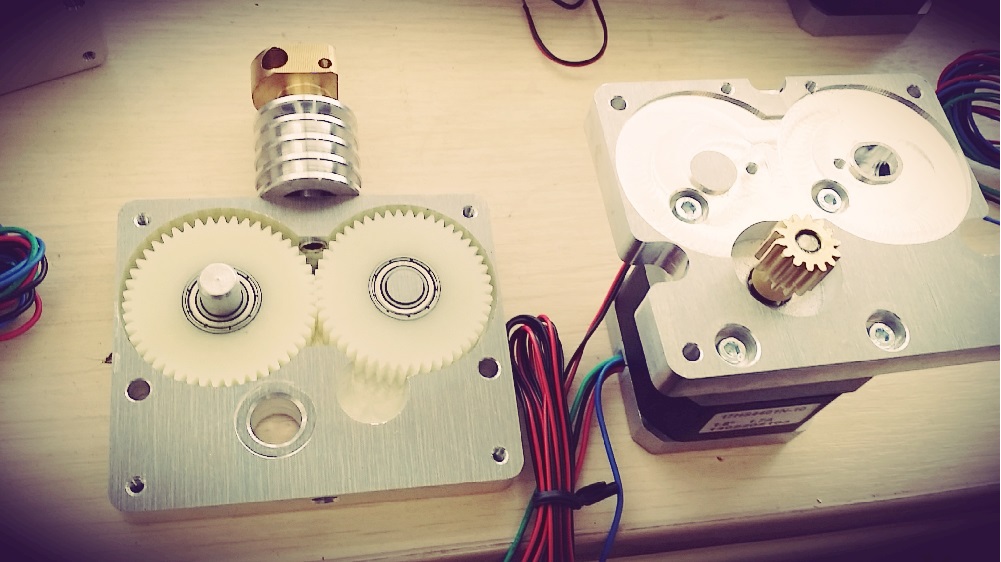

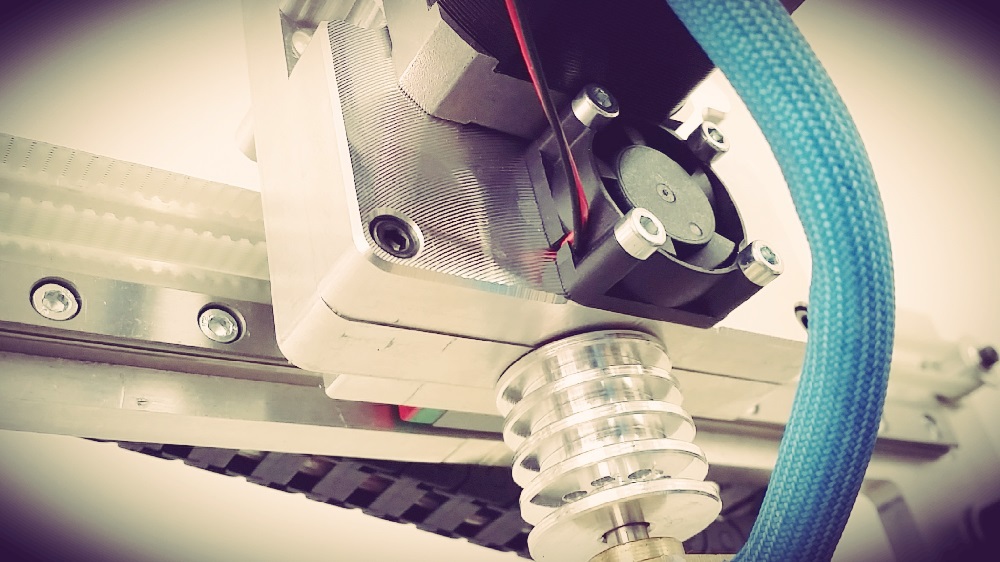

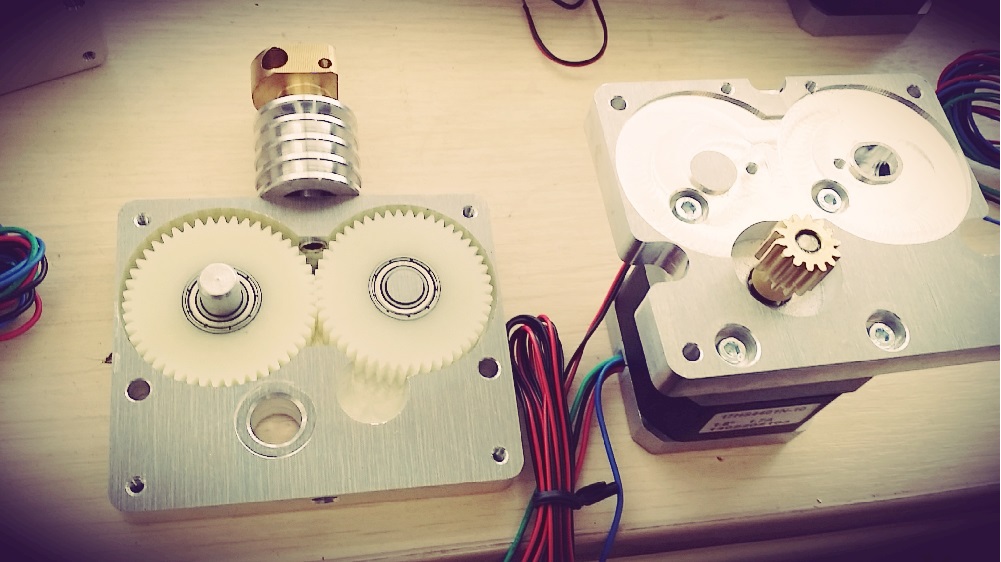

Big = powerful motor on the extruder. (The rigidity of the frame and its own drivers allow you to accurately control the heavy part at high speeds with a sharp change in direction.)

Powerful motor allows you to push viscous plastic through a narrow nozzle at high speeds and with high quality / precision

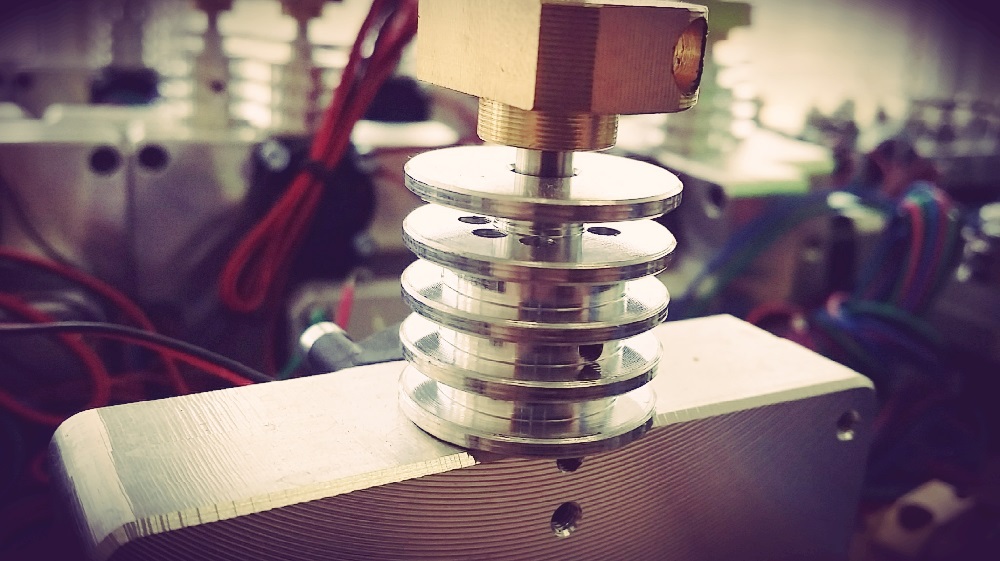

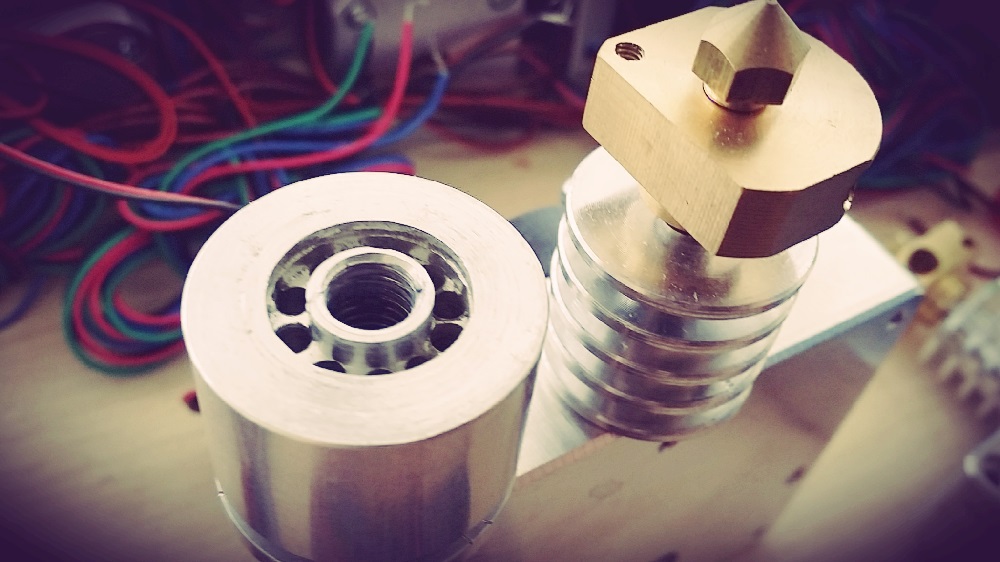

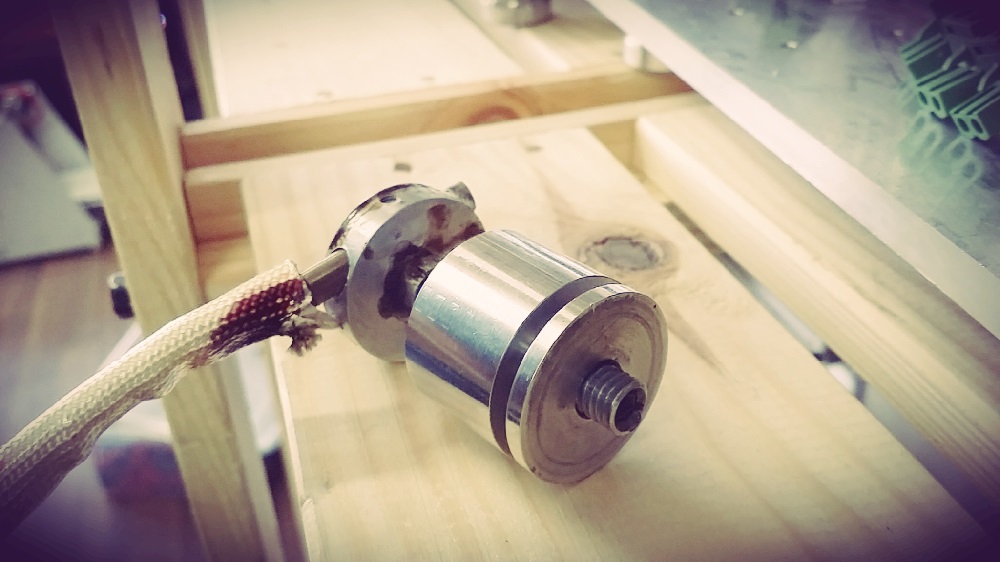

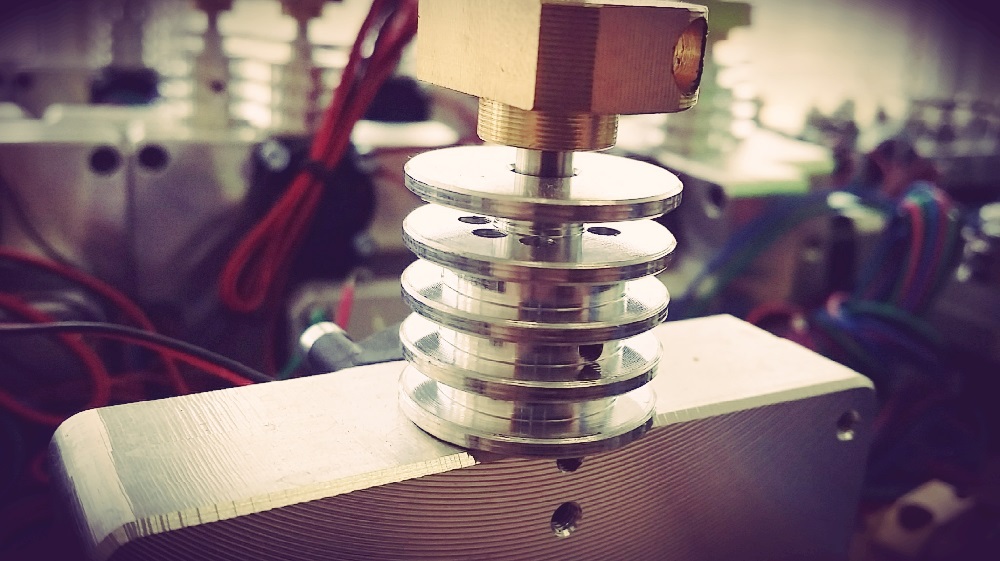

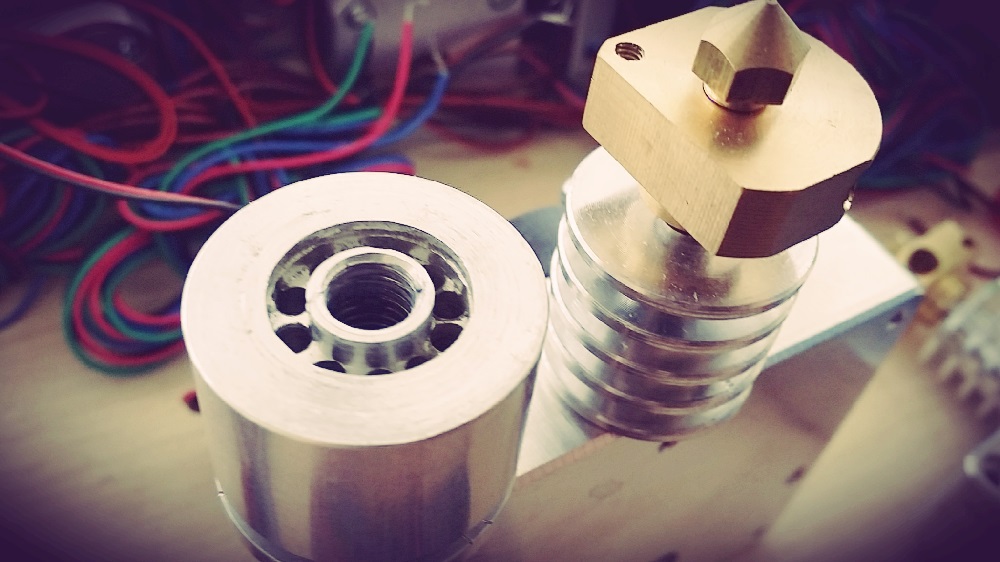

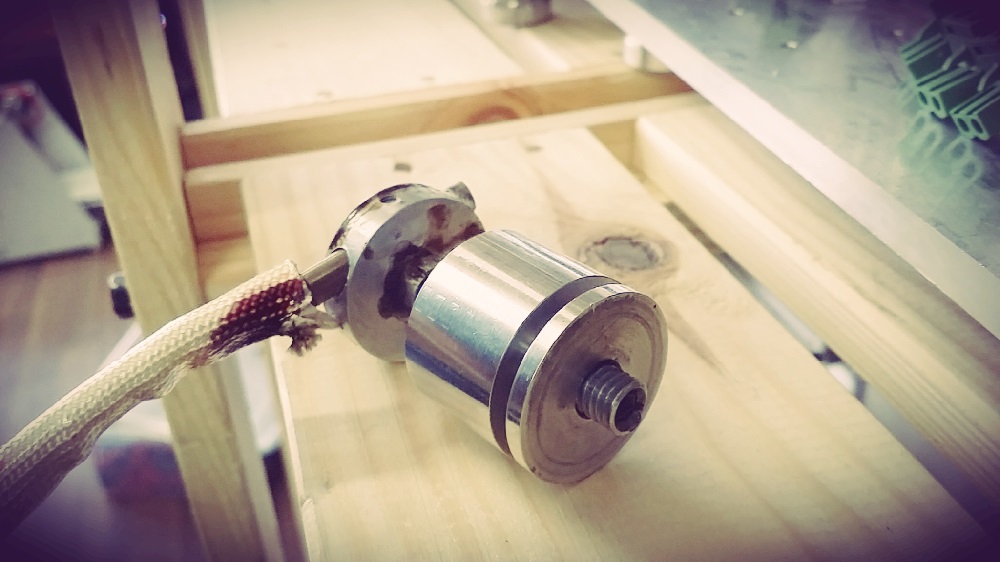

The original design - the air passes inside the radiator (round holes in the center).

Working prototype (left) and the final industrial version of the radiator (right).

One of the first versions of the radiator and heater - passed numerous tests.

I have seen a lot ...

Extruder with cover removed.

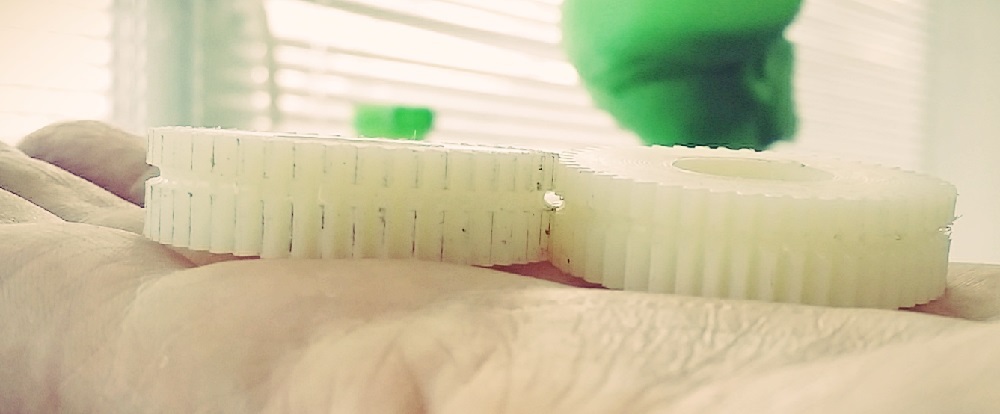

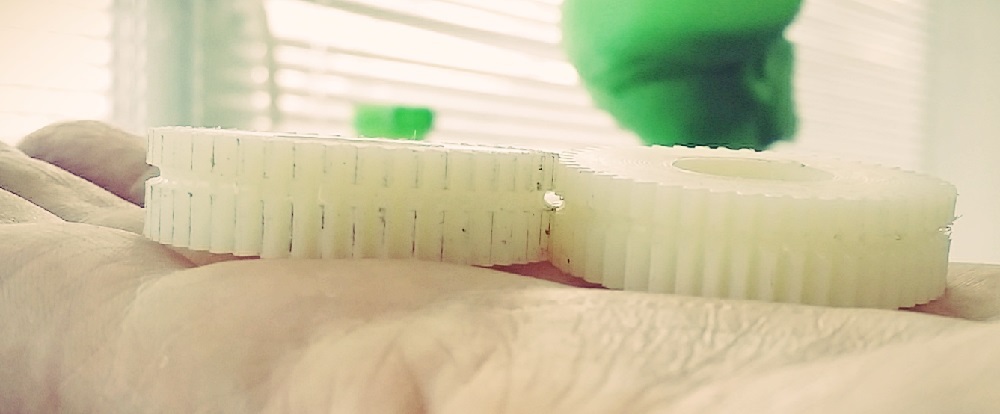

The gears are made of high quality European fluoroplastic.

It slides pretty well, it is very poorly washable and holds high temperatures.

Non-scratching (crimp) plastic feed format that allows you to print very thin nozzles at high speed

The plastic is clamped and pulled into the hole between the gears.

In conventional printers, plastic is pushed by teeth and because of this it is scratched and deformed, which distorts print speed / accuracy, but plastic is not pushed by teeth, but crimped from all sides. As a consequence - the absence of "artifacts" and "gaps".

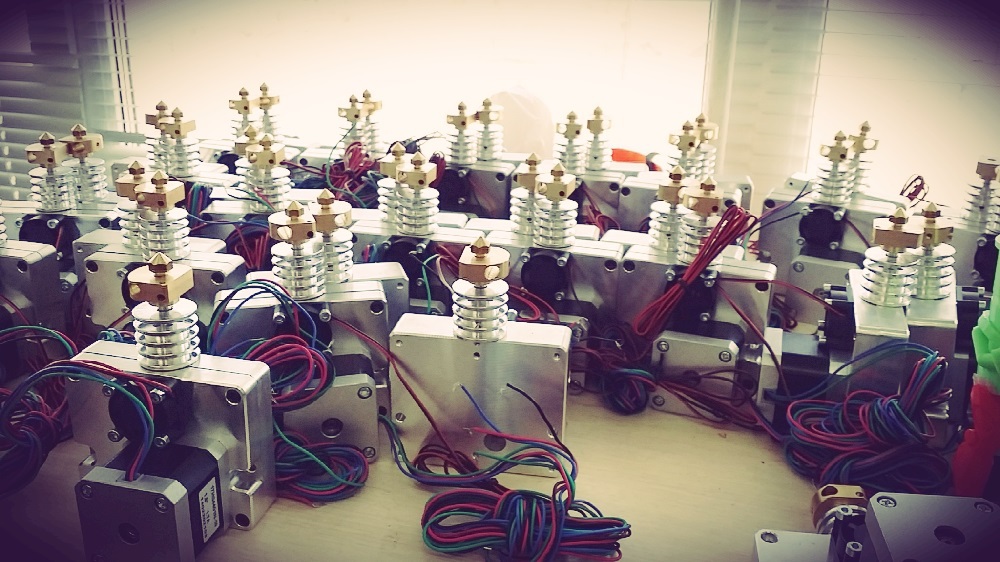

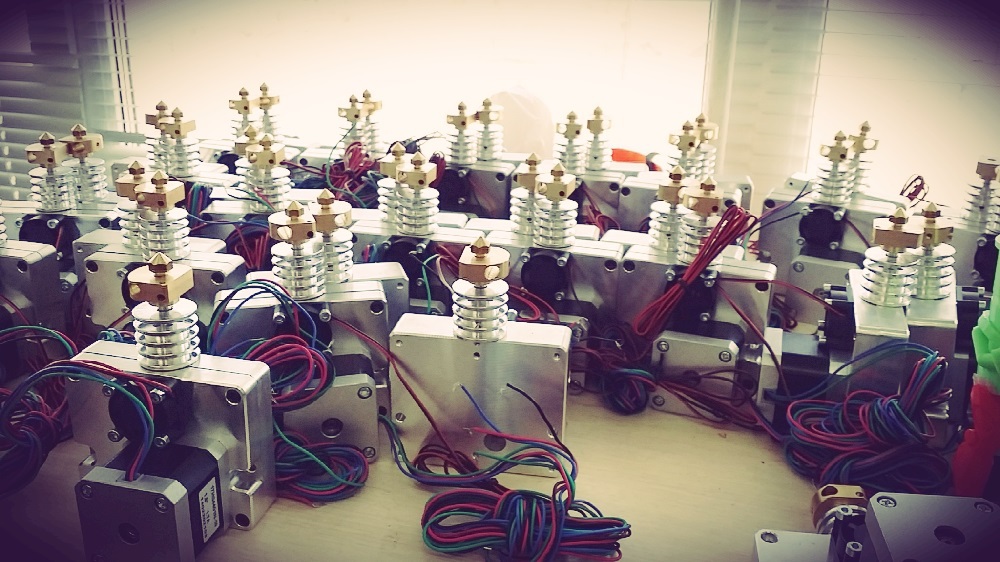

Since Production is in Russia, and there are a lot of challenges this side of the border. (Has anyone tried to get a spare extruder / component for a Replicator or Solidoodl from the USA / Germany / Netherlands / China?)

Humming?

The largest number of fans.

cable channel for fastening wires to the extruder.

Its production gears for extruder.

One of the distinguishing features - printing at an extreme angle without support.

This figure is printed without supports - the chin and the back of the head are printed almost overhang.

If a “foreign” 3D printer breaks down (although 3D printers break very rarely), then it will have to be sent for warranty repair to Germany / USA, and then wait for it to return. Read about the speed of delivery from abroad here .

For a Russian printer, this period is shortened (not half a year, but weeks).

cable channel for fastening wires to the extruder.

All printers are checked before sending to the client - they are printed with several details. On the picture

detail to check the flatness of the table and the accuracy of laying layers.

P.S. A great TED video that motivates creating instead of consuming.

I also want to thank the creators of 3D printers for contributing to the "creators" business and for the opportunity to "spy" a little on this process.

What I want to share with habrachiteleley.

This is not a gadget, it is a workhorse that will work for years.

Unlike consumers of "home" models, our customer is a professional or amateur, but with high demands on print quality, ready to deal with software and for which accuracy and performance are more important than convenience and design.

Chips:

- 2 motors per Z axis

- Meteorite-resistant frame

- Own stepper motor controllers based on developments for industrial CNC

- Many spare parts

')

Caution! A lot of aluminum!

When designing the printer, we laid the foundation for a good machine.

General form

( in the photo the very first printer prototype )

TTX

CONSTRUCTION AREA SIZE 185 × 160 × 150 MM

PRINT MATERIAL ABS, PLA, PVA, OTHER

PRESS RESOLUTION (MICRON) 50 (0.05 mm)

PRINT SPEED UP TO 30 CM ^ 3 / HOUR

LAYER THICKNESS 50 MKM, WALL THICKNESS 190 MKM

OPERATING SYSTEMS WINDOWS XP, WINDOWS 7, MAC OSX, WINDOWS 8, VISTA, LINUX

WEIGHT (WITHOUT PACKING) 10.5 KG

OVERALL DIMENSIONS (WITHOUT PACKING) 320 × 360 × 390 MM

Soft

The printer runs on open source software (Cura, Slic3R and Repetier-Host).

For the convenience of users, printer developers have translated the Cura program into Russian. (for which they respect)

Frame

“A good printer in our understanding begins with the frame”

the accuracy of the printer (positioning of the print head) begins with the frame. The reliability of the design allows to withstand even "extreme transportation" (Russian Post).

(According to the prevalence in the Earth’s crust, aluminum is 1st among metals and 3rd among elements, second only to oxygen and silicon. According to various researchers, the mass concentration of aluminum in the crust is from 7.45 to 8.14%).

(In the body of an adult there is up to 140 mg of aluminum. The daily adult need for aluminum is estimated at 2.45 mg.).

(The most ancient product, containing 85% of aluminum, dates from the 3rd century AD)

"Our difference from world leaders is based on a powerful frame . "

(Aluminum compounds are found not only on Earth, but also on the Moon and Mars. Aluminum is even found in apples - up to 150 mg / kg.)

8mm pure aluminum.

(The first product made of aluminum was a rattle made for the French Emperor Napoleon III in the 50s of the 19th century).

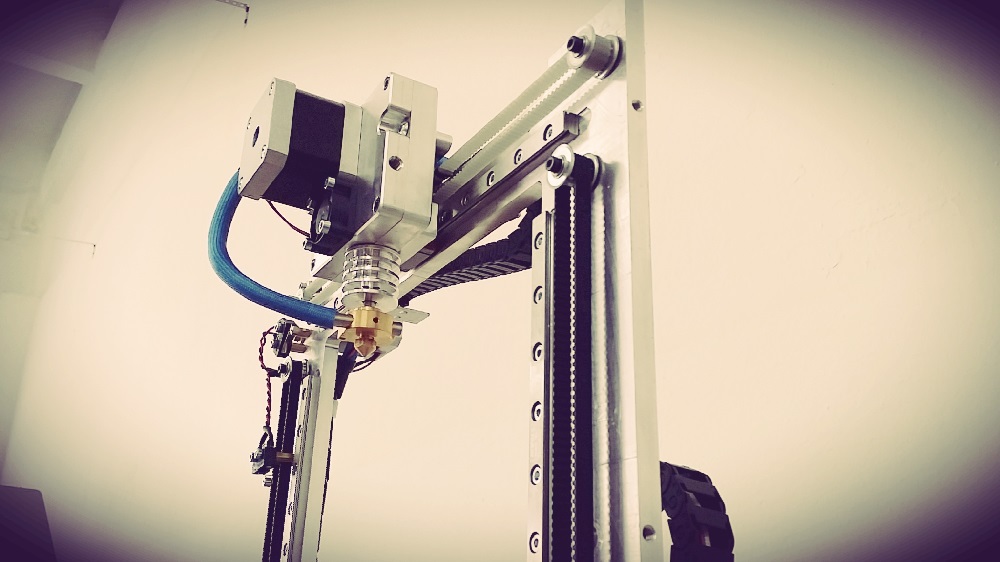

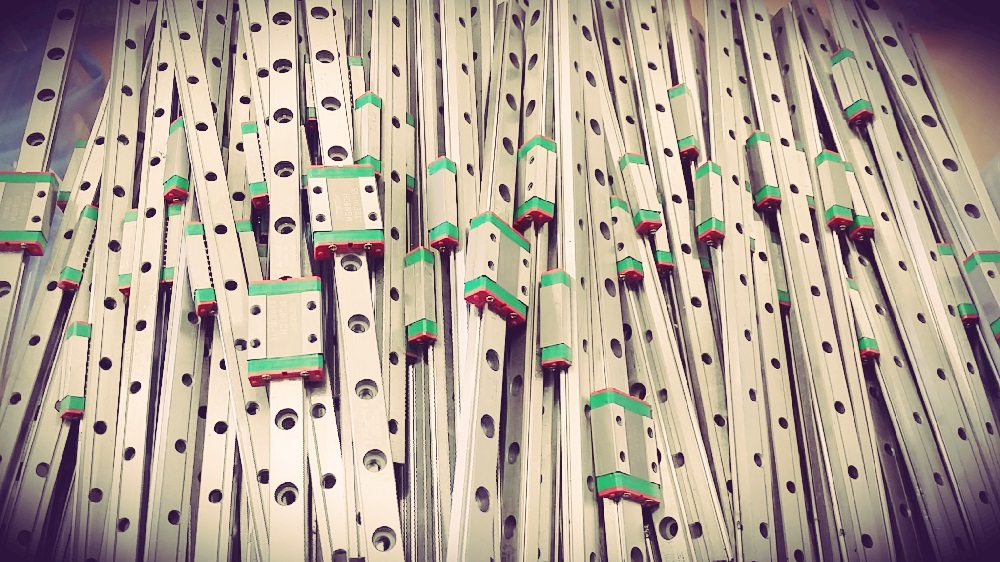

Guides

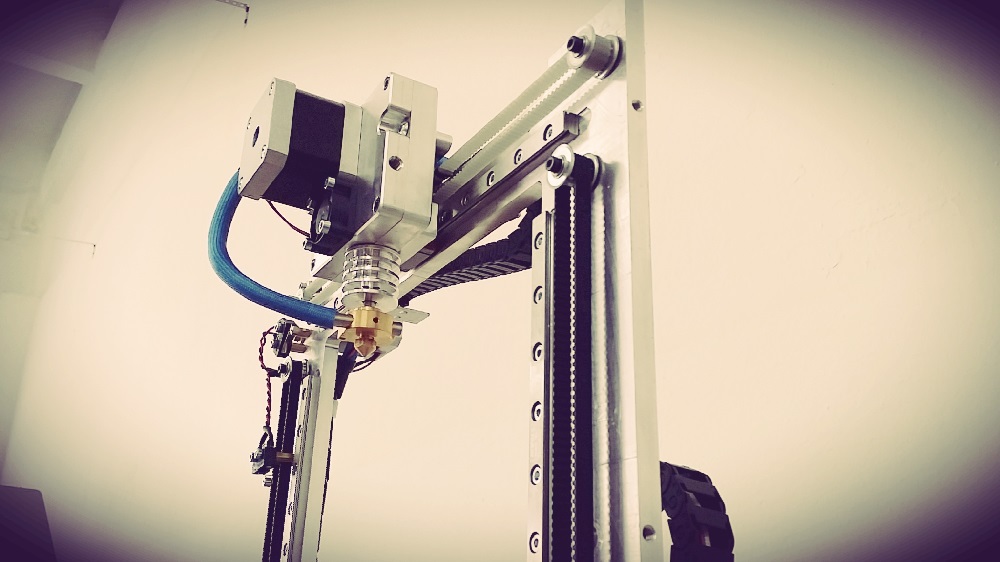

The fact that provides the position / movement of the printhead / platform (guides) are 3 types - screw, cylinder or rail.

Screw guides are slow and are mainly used for Z axis positioning.

The main load on the speed and accurate movement falls either on the cylinders or on the rails.

PrintBox3d developers have opted for the rail, because “Cylinders have only 2 points of support and there have been cases that the cylinders bend, at the rail, the same points of support are every 2 cm and the life span of the rails is longer than that of the cylinder.”

Resource rail is higher than that of cylinders.

Support points every 2 cm.

Precise milling on CNC machine = precise and rigid construction.

Platform

Aluminum is stronger than plastic, glass, textolite. Yes, and heat conduction properties are better.

Platform made of aluminum with a flexible bottom heater. The size of the heater is smaller than the size of the platform - 15x15 cm.

But, due to the good thermal conductivity of aluminum, the heating of the platform is uniform.

Adjustment of the horizon (calibration of the platform) is done manually with screws, done once in production (mounting rigidity and design features allow you to adjust once and for a long time.)

Electronics

There is an arduino as a control board - but for each motor it has its own controller of stepper motors (this allows for better inertia damping, working at higher powers.)

each engine has its own controller (total 4 controllers, remember that we have 2 motors on the Z axis.)

Fuse. Saves. (This is Russian sockets)

Controllers - own development and own production.

Comparison red - Russian controller, blue - Chinese controller.

There are spare.

Extruder

Big = powerful motor on the extruder. (The rigidity of the frame and its own drivers allow you to accurately control the heavy part at high speeds with a sharp change in direction.)

Powerful motor allows you to push viscous plastic through a narrow nozzle at high speeds and with high quality / precision

The original design - the air passes inside the radiator (round holes in the center).

Working prototype (left) and the final industrial version of the radiator (right).

One of the first versions of the radiator and heater - passed numerous tests.

I have seen a lot ...

Extruder with cover removed.

The gears are made of high quality European fluoroplastic.

It slides pretty well, it is very poorly washable and holds high temperatures.

Non-scratching (crimp) plastic feed format that allows you to print very thin nozzles at high speed

The plastic is clamped and pulled into the hole between the gears.

In conventional printers, plastic is pushed by teeth and because of this it is scratched and deformed, which distorts print speed / accuracy, but plastic is not pushed by teeth, but crimped from all sides. As a consequence - the absence of "artifacts" and "gaps".

A lot of little things

Since Production is in Russia, and there are a lot of challenges this side of the border. (Has anyone tried to get a spare extruder / component for a Replicator or Solidoodl from the USA / Germany / Netherlands / China?)

Humming?

The largest number of fans.

cable channel for fastening wires to the extruder.

Its production gears for extruder.

Extreme angles

One of the distinguishing features - printing at an extreme angle without support.

This figure is printed without supports - the chin and the back of the head are printed almost overhang.

If a “foreign” 3D printer breaks down (although 3D printers break very rarely), then it will have to be sent for warranty repair to Germany / USA, and then wait for it to return. Read about the speed of delivery from abroad here .

For a Russian printer, this period is shortened (not half a year, but weeks).

cable channel for fastening wires to the extruder.

All printers are checked before sending to the client - they are printed with several details. On the picture

detail to check the flatness of the table and the accuracy of laying layers.

We look at the 3D printer as a working tool.

Print example

P.S. A great TED video that motivates creating instead of consuming.

I also want to thank the creators of 3D printers for contributing to the "creators" business and for the opportunity to "spy" a little on this process.

Source: https://habr.com/ru/post/220445/

All Articles