Maketon Nova Base - a marathon for assembling a 3D printer

Like many residents of Tatarstan, the guys from the ENNOVA project (developers of desktop 3D printers) decided to cheat. Without suspending work on a new 3D printer, they decided to get rid of the materials for the first Nova Base model, and arranged a sale of unassembled printers. It sounds strange, but looking ahead, I will say that everyone was happy.

Maker + Marathon = Makerthon

I'll start with a little observation. Almost every one of us in life has had a chance to compare the cost of goods in a store and its cost, or more precisely the cost of components. Here I stand in a small shop, choose some kind of

')

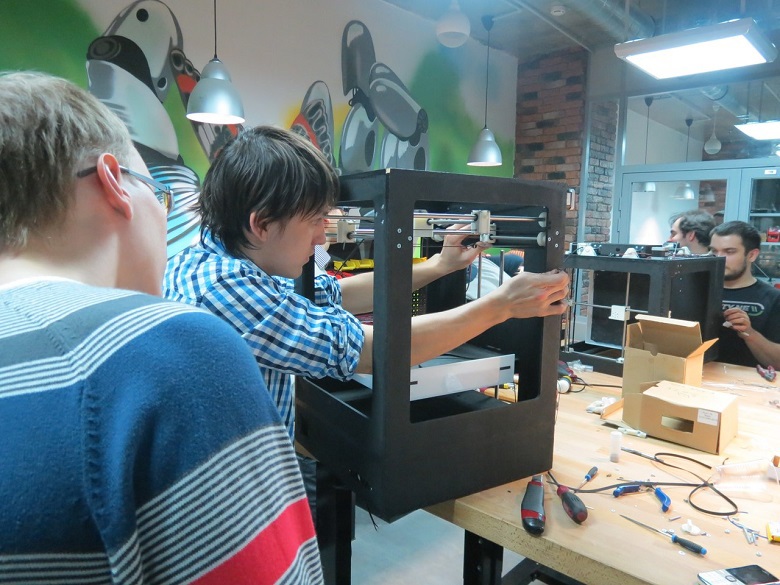

Ultimaker Original build is in full swing (6 AM time)

For the “handy” and not so much, we at Navigator Campus tried a new format — the makerton (like a hackathon, only with a maker root, that is, “do something with our hands”). The idea is funny - we forget about everything in life for 48 hours and fully devote this time to the work of the hands and brain. The first two times we collected Ultimaker Original 3D printer. The result pleased me - 40 people without sleep and rest created a car from raw materials, which they read about on the Internet every day. Despite the hard work and not quite the expected result, the guys were delighted with what can actually be done with their own hands.

We still have a lot of ideas for the makerton in our head. For example, collect quadcopters , plastic machines for the same printers, CanSat's , paper robots, and others. While we were thinking about them, guys from ENNOVs came running to us and offered to assemble their printer. They had a problem: the whole team is busy developing a new version, and there is a lot of material in the warehouse for the current Ennova Base model. The proposal was simple and straightforward - you buy an unassembled printer for 35 tons of rubles and finish the assembly during the makerton under the strict guidance of the developers. At the end - you take away the working printer home. As a bonus, all early adopters are personal support from developers and unique skills. What, the decision in the spirit of Lean Startup, you will not think up better.

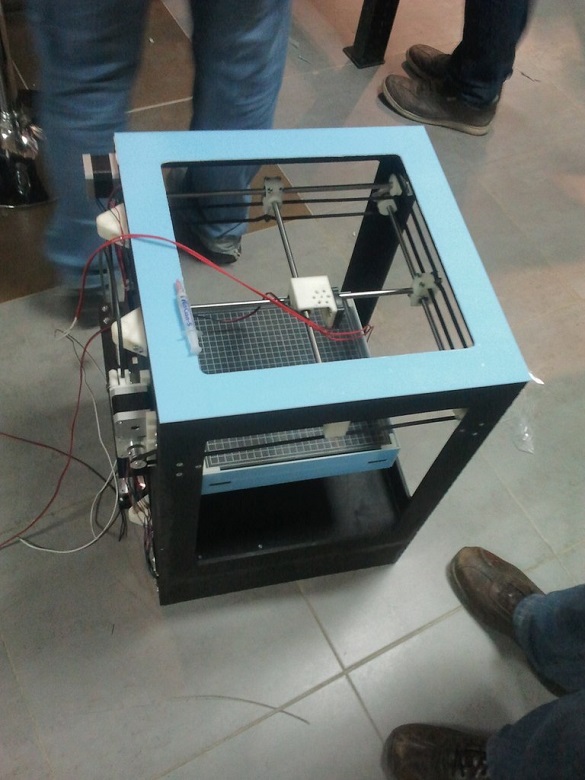

Ready copy of the Nova Base printer - a sample for assembly

The first makerton Nova Base took place on April 11-12. The Ennova team was well prepared and all the printers were assembled in 17 hours - they started at 19.00 Fridays and finished at 12.00 Saturday. As a result, 4 printers were taken away, someone was collecting it alone, some of them were three. Why did they decide to start a printer? From the conversation with the participants - one will print to order, the other team will use it as a tool in their developments, and the other two teams will just “for themselves”. And the Ennova team still wants to spend a couple of days off in this mode.

And this is almost the assembled printer of one of the participants.

Test print immediately after assembly and calibration

In general, creating with your hands is what is in each of us. In the pilot launch of the makerton, we had a schoolboy from the 10th grade, he single-handedly assembled the Ultimaker Original. Despite the fact that he had very little experience with tools, he succeeded. The main thing is to have the right tool at hand and at least one person who will tell you how to use it.

Source: https://habr.com/ru/post/220115/

All Articles