Do you love them so much to see what's inside them?

As children, we “dissect” our toys to see how they work. When we grow up, many of us have a habit of digging deeper into a steadfast “viewing” of ourselves and our own kind, and we become psychologists, surgeons or, at worst, Samoyeds. We are also ready to peer endlessly at the objects of our love and interest ...

Today we invite you to combine our passion for scanners and your research activity. Hope you enjoy.

So, this is a high-speed document scanner ELAR SCAMAX .

Used to stream digitized documents. The key definition of this type of equipment is usually the word “speed”. This scanner, for example, digitizes from 90 to 340 pages per minute. And how many pages does he digitize per month? In Week? In order to understand this, there is another indicator of work, namely, productivity. Performance can be judged, in particular, by how the system of loading and unloading documents is arranged, cleaning, replacing consumables, how the scanner reacts to random interference - paper clips, for example. In other words, performance is more important than speed, because speed is measured in ideal conditions, and life always brings its own changes to perfect circumstances.

')

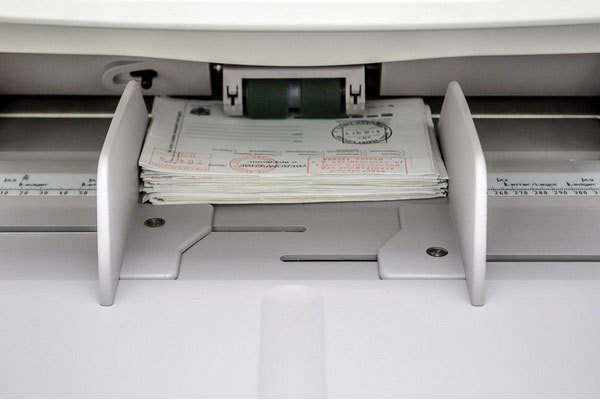

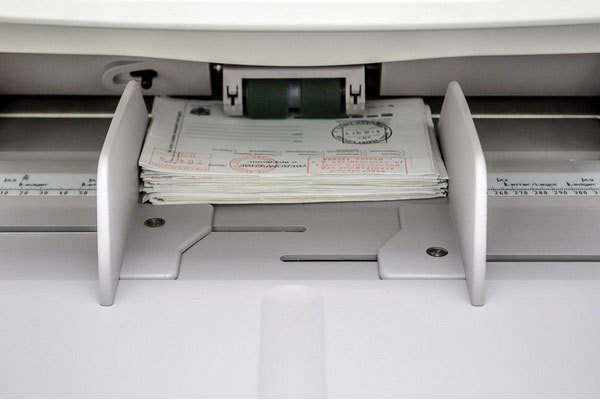

Let's start with the feed tray. One document fits into a tray or a pack of 500 sheets - this is not important, because the tray is able to “adjust” to the thickness of the paper and its quantity. The actual availability of documents is determined by the photo sensor located in the tray.

You can put standard A4 sheets in the tray, or you can place documents from 2x6 cm or long logging tape. Moving one stop automatically moves the other in the opposite direction (so that the documents are located in the center of the tray).

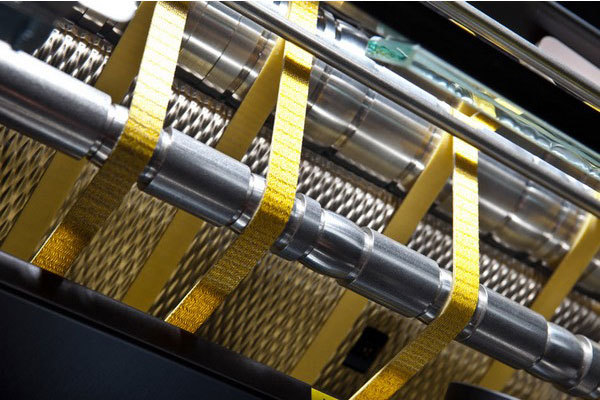

These are feed rollers. The block of feed rollers is able to process paper of the most different thickness, even if documents of different density are contained in one pack. It is designed so that the operator does not have to change the adjustment settings. Resistant to dust: due to the composition of the rubber used, cleaning the surface of the roller linings is necessary only in exceptional cases.

By the way, rubber pads on rollers are the only consumables in the scanner: they are very rare, but still have to be changed, unlike all other parts and mechanisms of the equipment.

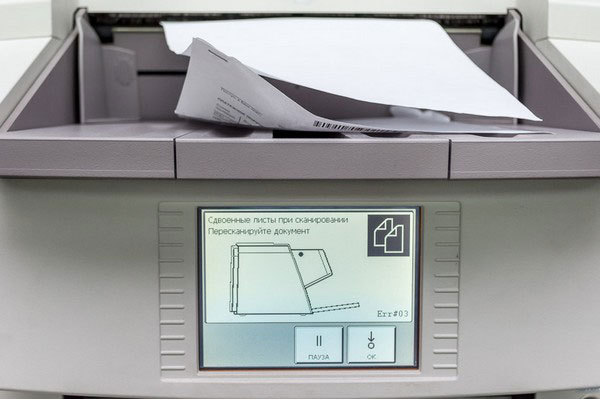

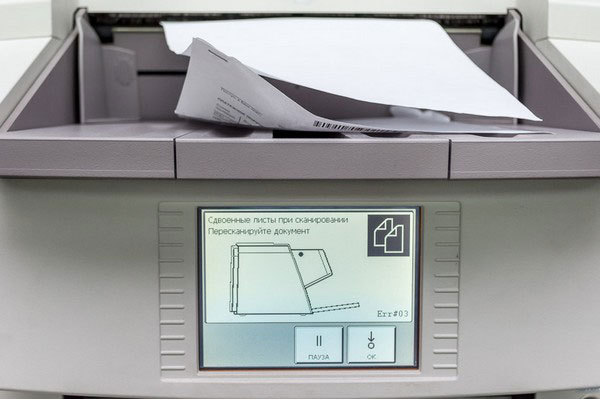

Three ultrasonic sensors determine the double sheets by the number of pages. If the user missed the attached documents, the scanner will digitize them, return them to the receiving tray (nothing will ever get stuck in the scanner), and will offer the user a choice: save an electronic copy or rescan the document again.

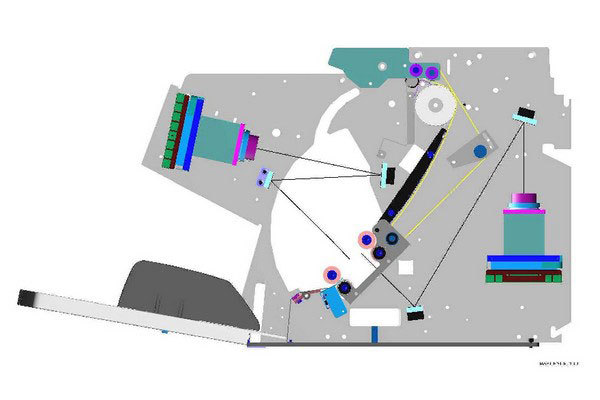

Inside the scan area, the document is illuminated by two LED blocks that are slightly offset from each other. Lamps are safe for originals of documents, provide the correct color rendition on graphic images. They "turn on" immediately, without requiring time to warm up. Conform to modern standards of energy saving and, at the same time, are themselves durable and unpretentious to maintain.

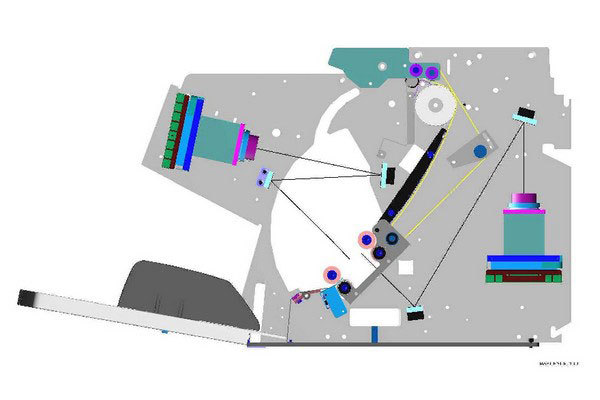

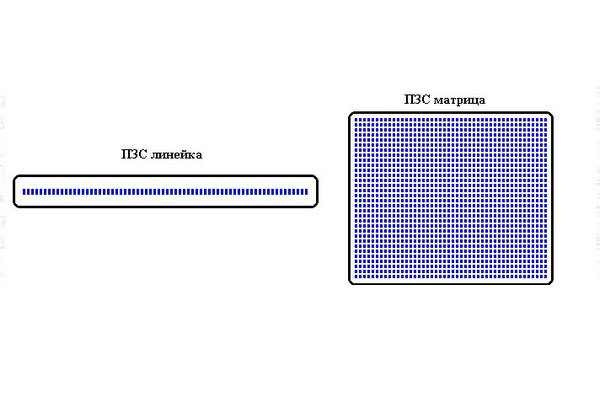

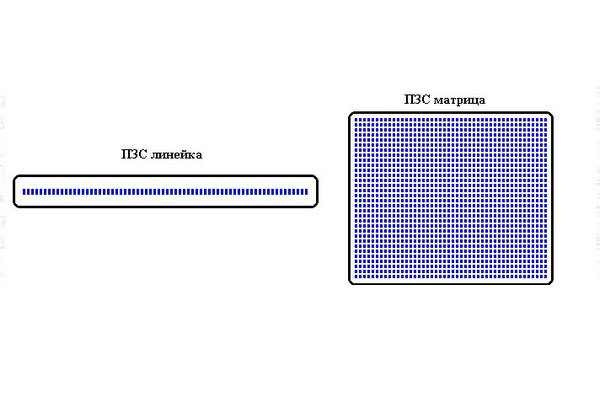

The reflected light, which transmits the information contained in the image, falls on the mirror, which reflects it on the second mirror. The second mirror projects the image through the lens onto the CCD.

Since the sheet is constantly in motion, the entire page is scanned line by line. The CCD transforms the information contained in the image into an analog electrical signal. The camera electronics digitizes it and transfers it to the PC interface. Embedded microprocessors ( FPGA Xilinx Virtex and Spartan ) process images formed by a CCD image sensor in real time and improve image quality — eliminate page tilting, cut to size, orient images by text, remove blank pages and clear images from “noise”. If there are bar-code marks on the document, the scanner sorts the electronic images according to the specified parameters of the documents. Moreover, the image can be converted to any necessary graphic format - TIFF, PDF, JPEG. To scan the two sides of the document, an additional camera is installed. The scanner allows you to simultaneously save several versions of one image (black and white, gray and full color), processing up to 1020 images per minute.

It is this combination of high-speed scanning and simultaneous image processing that allows, without loss of performance, to obtain already processed graphic images that do not require additional labor for additional post-processing.

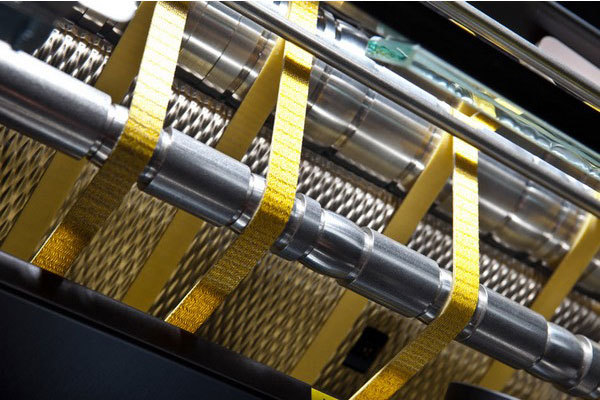

Yellow belts are a paper pulling mechanism. There are no rollers, a minimum of motors, bearings and mechanical elements. The pulling path is not sensitive to the entry of documents with paper clips, since there are no glass and plastic surfaces in it. No random clip will ruin the device.

The industrial design provides easy access to the main components and elements of the scanner. It can be quickly disassembled into its component parts for routine inspection, cleaning and replacement of consumables, and so on.

Of course, we have described not everything that he has inside, but only that which has the greatest effect on performance. Next time, we will talk about how it “interacts” with external systems when implementing its main functionality - streaming the input of documents and the creation of digitization centers.

Today we invite you to combine our passion for scanners and your research activity. Hope you enjoy.

So, this is a high-speed document scanner ELAR SCAMAX .

Used to stream digitized documents. The key definition of this type of equipment is usually the word “speed”. This scanner, for example, digitizes from 90 to 340 pages per minute. And how many pages does he digitize per month? In Week? In order to understand this, there is another indicator of work, namely, productivity. Performance can be judged, in particular, by how the system of loading and unloading documents is arranged, cleaning, replacing consumables, how the scanner reacts to random interference - paper clips, for example. In other words, performance is more important than speed, because speed is measured in ideal conditions, and life always brings its own changes to perfect circumstances.

')

Let's start with the feed tray. One document fits into a tray or a pack of 500 sheets - this is not important, because the tray is able to “adjust” to the thickness of the paper and its quantity. The actual availability of documents is determined by the photo sensor located in the tray.

You can put standard A4 sheets in the tray, or you can place documents from 2x6 cm or long logging tape. Moving one stop automatically moves the other in the opposite direction (so that the documents are located in the center of the tray).

These are feed rollers. The block of feed rollers is able to process paper of the most different thickness, even if documents of different density are contained in one pack. It is designed so that the operator does not have to change the adjustment settings. Resistant to dust: due to the composition of the rubber used, cleaning the surface of the roller linings is necessary only in exceptional cases.

By the way, rubber pads on rollers are the only consumables in the scanner: they are very rare, but still have to be changed, unlike all other parts and mechanisms of the equipment.

Three ultrasonic sensors determine the double sheets by the number of pages. If the user missed the attached documents, the scanner will digitize them, return them to the receiving tray (nothing will ever get stuck in the scanner), and will offer the user a choice: save an electronic copy or rescan the document again.

Inside the scan area, the document is illuminated by two LED blocks that are slightly offset from each other. Lamps are safe for originals of documents, provide the correct color rendition on graphic images. They "turn on" immediately, without requiring time to warm up. Conform to modern standards of energy saving and, at the same time, are themselves durable and unpretentious to maintain.

The reflected light, which transmits the information contained in the image, falls on the mirror, which reflects it on the second mirror. The second mirror projects the image through the lens onto the CCD.

Since the sheet is constantly in motion, the entire page is scanned line by line. The CCD transforms the information contained in the image into an analog electrical signal. The camera electronics digitizes it and transfers it to the PC interface. Embedded microprocessors ( FPGA Xilinx Virtex and Spartan ) process images formed by a CCD image sensor in real time and improve image quality — eliminate page tilting, cut to size, orient images by text, remove blank pages and clear images from “noise”. If there are bar-code marks on the document, the scanner sorts the electronic images according to the specified parameters of the documents. Moreover, the image can be converted to any necessary graphic format - TIFF, PDF, JPEG. To scan the two sides of the document, an additional camera is installed. The scanner allows you to simultaneously save several versions of one image (black and white, gray and full color), processing up to 1020 images per minute.

It is this combination of high-speed scanning and simultaneous image processing that allows, without loss of performance, to obtain already processed graphic images that do not require additional labor for additional post-processing.

Yellow belts are a paper pulling mechanism. There are no rollers, a minimum of motors, bearings and mechanical elements. The pulling path is not sensitive to the entry of documents with paper clips, since there are no glass and plastic surfaces in it. No random clip will ruin the device.

The industrial design provides easy access to the main components and elements of the scanner. It can be quickly disassembled into its component parts for routine inspection, cleaning and replacement of consumables, and so on.

Of course, we have described not everything that he has inside, but only that which has the greatest effect on performance. Next time, we will talk about how it “interacts” with external systems when implementing its main functionality - streaming the input of documents and the creation of digitization centers.

Source: https://habr.com/ru/post/219273/

All Articles