JoysMaker R2 Black - 3D printer for the inexperienced

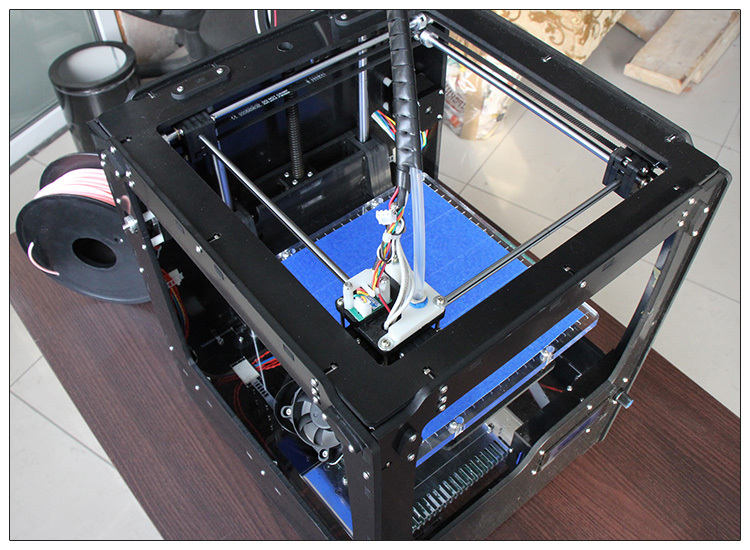

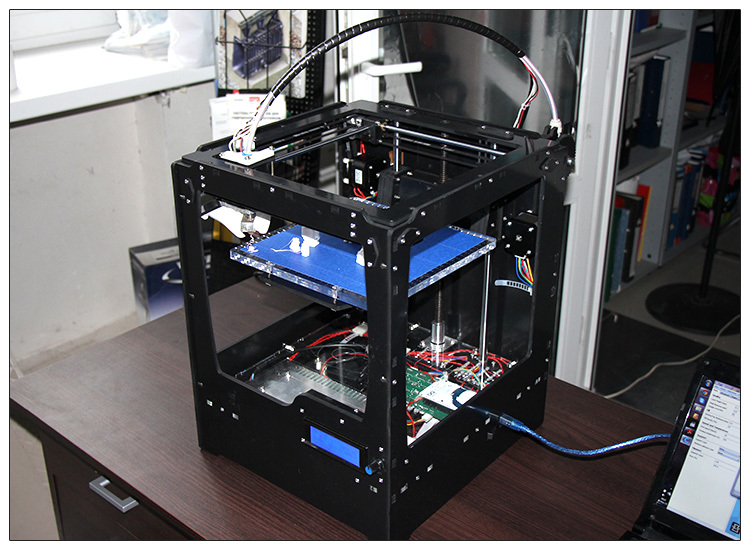

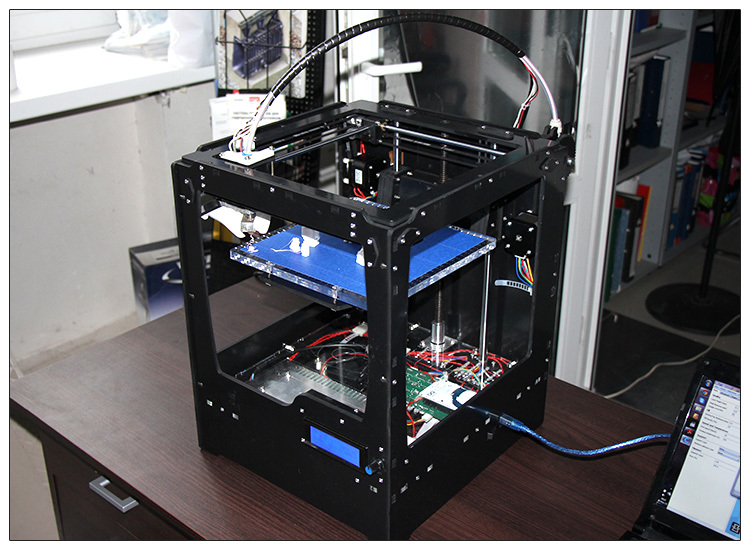

Recently, no one is surprised by another 3D printer. I got an FDM Joysmaker R2 Black printer in an acrylic case, I liked it first of all with characteristics comparable to more expensive competitors. Just want to note that Joysmaker printers are manufactured and shipped from China, this is a replica of the well-known Ultimaker.

Considering the cost of shipping from China and remembering my adventures with customs a couple of years ago, I decided to order it in Moscow in the online store, and besides, it was available there. I did not order a kit for assembly, and immediately took the assembled version, it remained only to charge the plastic coil and calibrate.

The first thing I naturally rushed to closely examine this device, I should note that the quality of performance exceeded my expectations. The case of black acrylic looks no longer as handicraft as plywood. There was a booklet with brief instructions that prompted the lucky owner to take the first steps in communicating with a 3D printer.

')

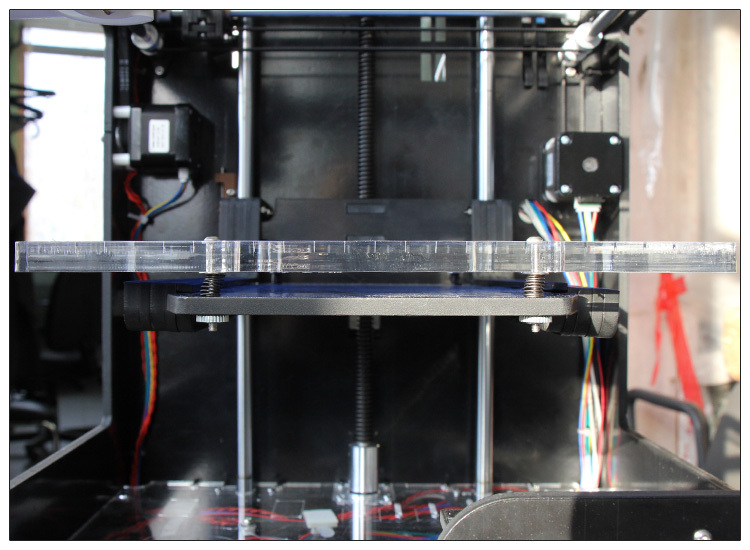

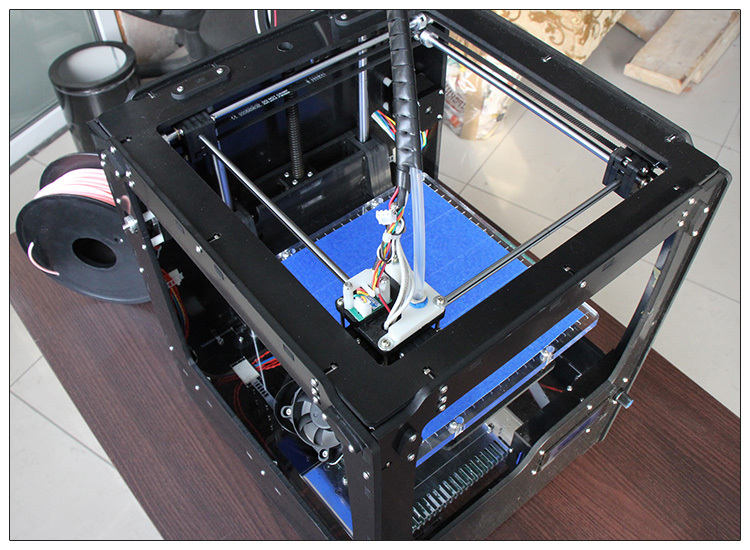

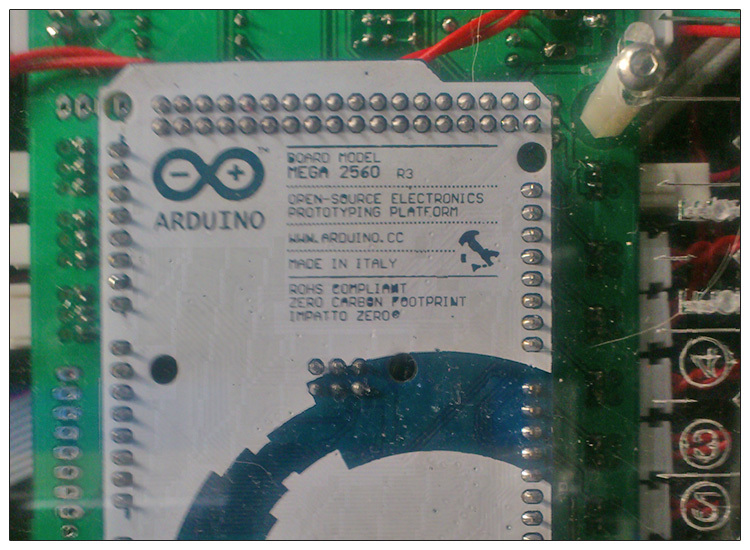

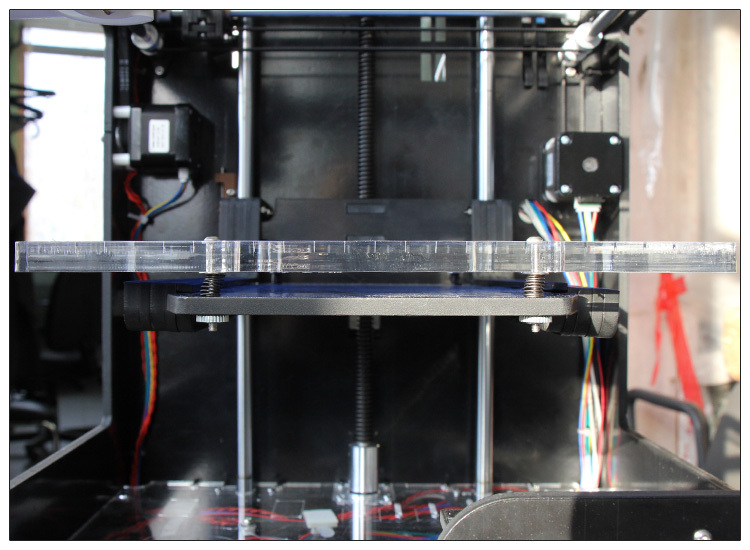

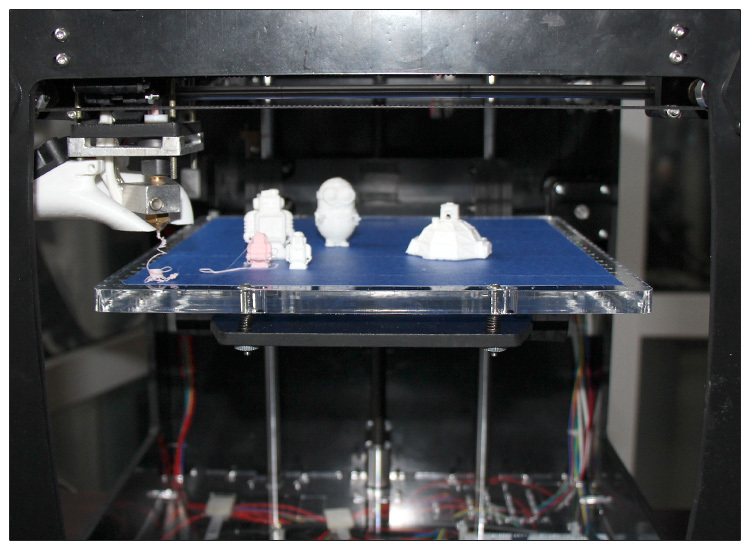

I can not say that the printer is heavy, but not easy. In total, its weight is about 13 kg. A couple of photos of the filling itself will help you see the details below:

Size of the printer working area: 21x22x22 cm.

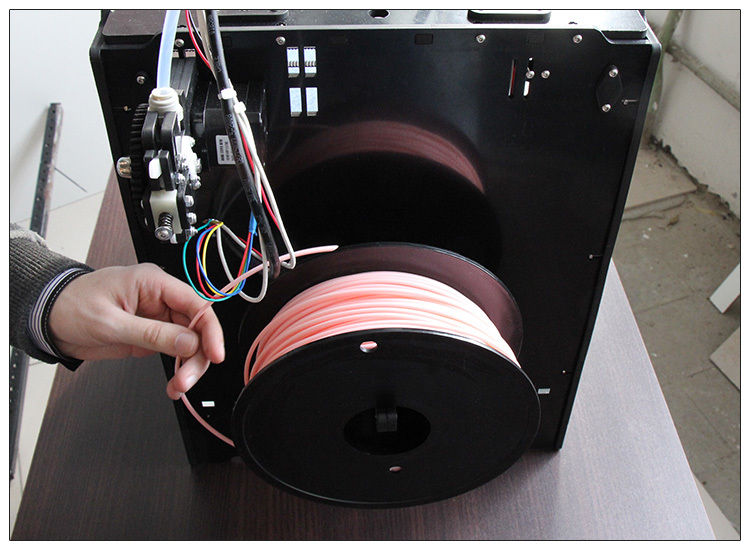

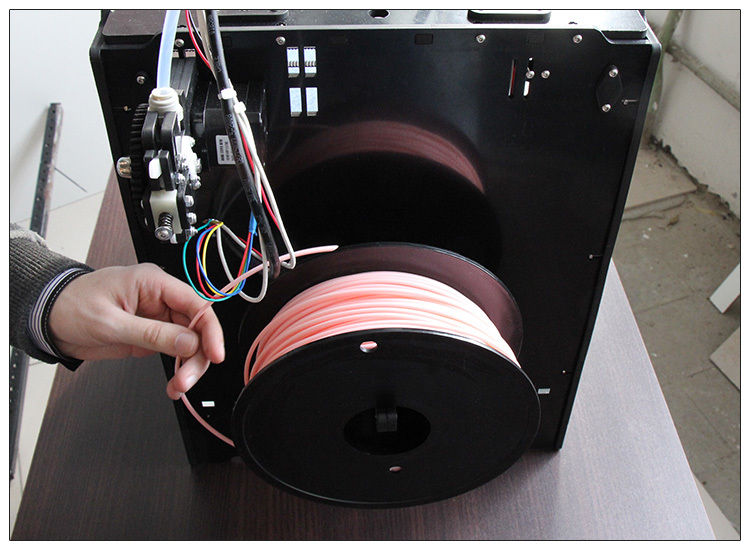

I brought the coil pink, do not ask why. It should be noted that the model Joysmaker R2 Black itself has the ability to use both PLA-plastic and ABS-plastic.

An important indicator when ordering this model is the number of extruders. In my model there was one extruder, but if you wish, you can add a complete set with two extruders. The thing turned out to be tricky and without thehelp of the hall of the call to a friend I could not push the plastic thread into it and get to the base of the print head, which in turn would heat this very thread.

I will briefly describe the process of this operation below.

1. Pull up the lever, which allows you to lower the lower structure of the extruder completely down.

2. Push the plastic thread all the way. You should see it at the other end of the transparent tube and feel the base of the nozzle.

3. Pull up the lower structure of the extruder, returning the white lever to the initial position, eventually fixing with the transverse lever.

A short video of how we did it is attached below.

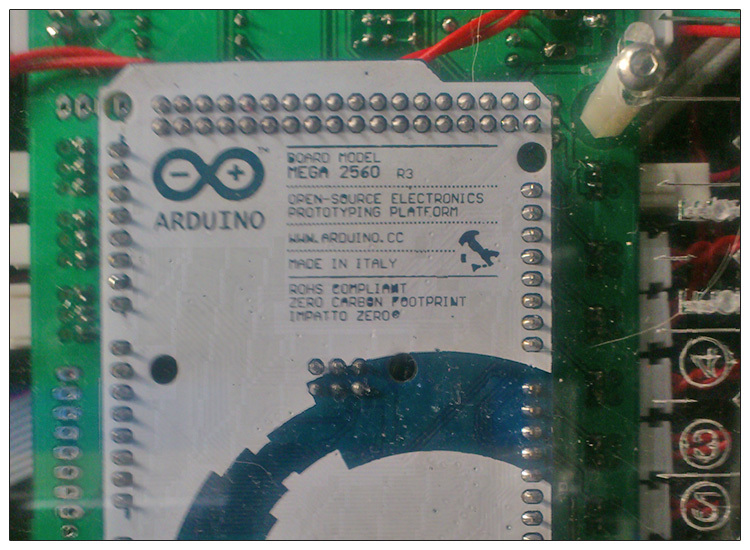

After preparing the printer it remains only to install the software. Joysmaker uses the same software as Ultimaker, namely the Cura program. What can I say, China produces counterparts that are not inferior to the original, while maintaining compatibility with software.

Finally, after calibrating the printer, we were ready to go to print. Many ready-made models can be downloaded in the open spaces of the network, but it is much more interesting to create a model yourself. For simple models, the Trimble SketchUp Pro (Pro, because there is an export in obj) is quite suitable. The printer itself “eats” files with the .stl extension and works much faster with them when they are copied to the memory card itself.

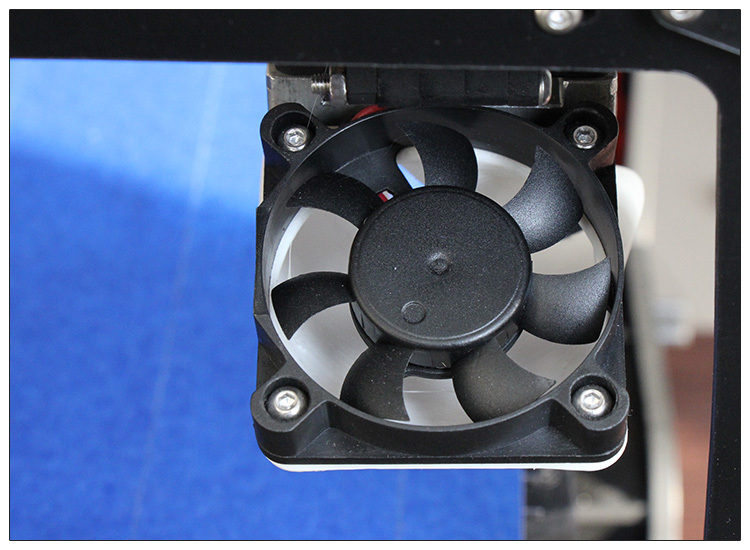

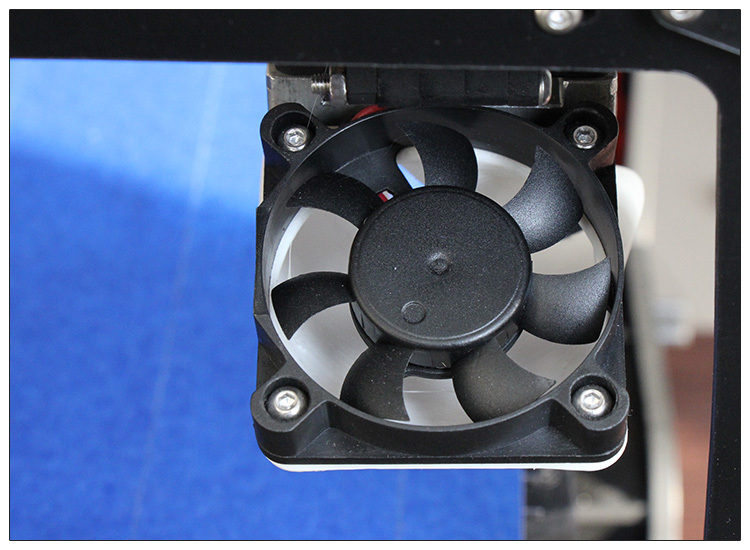

Well, we could only wait 30 seconds after which the nozzle of the 3D printer warmed to 220 degrees and started the process. A narrowly directed mini-fan is also mounted to the printhead of the printer, which prevents the parts from melting in the hot air interlayer between the heated platform and the extruder. The cooler works very quietly and unnoticed. All processes were also quite convenient to track through the built-in display, optionally appeared in models R2, which allows you to track many parameters. Of the languages available only English.

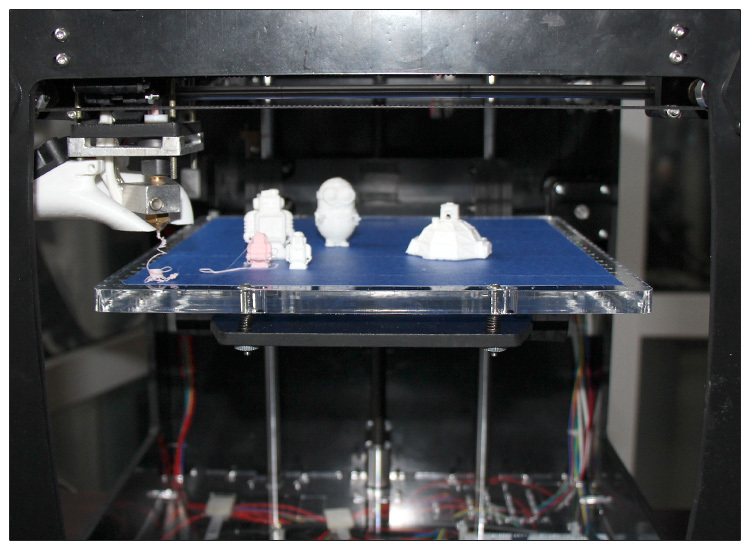

The accuracy of the positioning and the final product that JoysMaker R2 manufactures is often lame, however, a lot is decided by properly calibrating the printer. For small pieces of time, it takes quite a bit; the smallest robot printed 11 minutes at a layer thickness of 0.5 mm.

The main characteristics, according to the manufacturer, for JoysMaker R2 Black are:

Printing technology: FDM

Materials used: ABS, PLA

Number of extruders: 1 (can be installed 1 more)

Heated platform: yes

Working area: 210x210x220 mm

Print speed: 50-300 mm / s

Layer thickness claimed: ≥0.05 mm

Declared accuracy: 0.0125 mm

Cooling details: yes

Nozzle diameter: 0.4 mm

Print from SD card: yes

LCD display: yes

OS: Win / Mac / Linux

Power supply: 220V 50Hz

JoysMaker R2 Black prints by fusing (FDM - Fused Deposition Modeling) and must admit that with incorrect calibration and overheating of the platform and the printing nozzle, the layers of the part began to crawl, turning the detailed model into an unknown design. As it turned out later, an error was made on my part, which was expressed in the primary under-calibration and incorrect software setup. Cura allows you to customize print settings for a future model individually, thereby making quite delicate items in terms of accuracy, subtlety and complexity.

For those wishing to print more complex designs using two coils, there is at the same time a similar model with an extension, which marks itself as JoysMaker R2 Double Black.

I would also like to express special thanks to Cyril and Vyacheslav for their support and encouragement to conduct the review. We were pleased with the purchase and the new toy, which has found application not only in work, but also in household items.

Considering the cost of shipping from China and remembering my adventures with customs a couple of years ago, I decided to order it in Moscow in the online store, and besides, it was available there. I did not order a kit for assembly, and immediately took the assembled version, it remained only to charge the plastic coil and calibrate.

The first thing I naturally rushed to closely examine this device, I should note that the quality of performance exceeded my expectations. The case of black acrylic looks no longer as handicraft as plywood. There was a booklet with brief instructions that prompted the lucky owner to take the first steps in communicating with a 3D printer.

')

I can not say that the printer is heavy, but not easy. In total, its weight is about 13 kg. A couple of photos of the filling itself will help you see the details below:

Size of the printer working area: 21x22x22 cm.

I brought the coil pink, do not ask why. It should be noted that the model Joysmaker R2 Black itself has the ability to use both PLA-plastic and ABS-plastic.

An important indicator when ordering this model is the number of extruders. In my model there was one extruder, but if you wish, you can add a complete set with two extruders. The thing turned out to be tricky and without the

I will briefly describe the process of this operation below.

1. Pull up the lever, which allows you to lower the lower structure of the extruder completely down.

2. Push the plastic thread all the way. You should see it at the other end of the transparent tube and feel the base of the nozzle.

3. Pull up the lower structure of the extruder, returning the white lever to the initial position, eventually fixing with the transverse lever.

A short video of how we did it is attached below.

After preparing the printer it remains only to install the software. Joysmaker uses the same software as Ultimaker, namely the Cura program. What can I say, China produces counterparts that are not inferior to the original, while maintaining compatibility with software.

Finally, after calibrating the printer, we were ready to go to print. Many ready-made models can be downloaded in the open spaces of the network, but it is much more interesting to create a model yourself. For simple models, the Trimble SketchUp Pro (Pro, because there is an export in obj) is quite suitable. The printer itself “eats” files with the .stl extension and works much faster with them when they are copied to the memory card itself.

Well, we could only wait 30 seconds after which the nozzle of the 3D printer warmed to 220 degrees and started the process. A narrowly directed mini-fan is also mounted to the printhead of the printer, which prevents the parts from melting in the hot air interlayer between the heated platform and the extruder. The cooler works very quietly and unnoticed. All processes were also quite convenient to track through the built-in display, optionally appeared in models R2, which allows you to track many parameters. Of the languages available only English.

The accuracy of the positioning and the final product that JoysMaker R2 manufactures is often lame, however, a lot is decided by properly calibrating the printer. For small pieces of time, it takes quite a bit; the smallest robot printed 11 minutes at a layer thickness of 0.5 mm.

The main characteristics, according to the manufacturer, for JoysMaker R2 Black are:

Printing technology: FDM

Materials used: ABS, PLA

Number of extruders: 1 (can be installed 1 more)

Heated platform: yes

Working area: 210x210x220 mm

Print speed: 50-300 mm / s

Layer thickness claimed: ≥0.05 mm

Declared accuracy: 0.0125 mm

Cooling details: yes

Nozzle diameter: 0.4 mm

Print from SD card: yes

LCD display: yes

OS: Win / Mac / Linux

Power supply: 220V 50Hz

JoysMaker R2 Black prints by fusing (FDM - Fused Deposition Modeling) and must admit that with incorrect calibration and overheating of the platform and the printing nozzle, the layers of the part began to crawl, turning the detailed model into an unknown design. As it turned out later, an error was made on my part, which was expressed in the primary under-calibration and incorrect software setup. Cura allows you to customize print settings for a future model individually, thereby making quite delicate items in terms of accuracy, subtlety and complexity.

For those wishing to print more complex designs using two coils, there is at the same time a similar model with an extension, which marks itself as JoysMaker R2 Double Black.

I would also like to express special thanks to Cyril and Vyacheslav for their support and encouragement to conduct the review. We were pleased with the purchase and the new toy, which has found application not only in work, but also in household items.

Source: https://habr.com/ru/post/218749/

All Articles