Why in Russia there are almost no civil / commercial high-tech production?

I finished the article reviewing the situation with microelectronics in Russia by stating that Russia now has the technical capabilities to create any military microcircuits (if you disregard the price). However, both in the comments to that article, and in many others, everyone was more concerned about the lack (at the level of measurement error) of the production of purely commercial (civilian) high-tech products. This question worried me too, because I was constantly tormented by the questions of everyone who is somehow connected with high technology and business in Russia.

I finished the article reviewing the situation with microelectronics in Russia by stating that Russia now has the technical capabilities to create any military microcircuits (if you disregard the price). However, both in the comments to that article, and in many others, everyone was more concerned about the lack (at the level of measurement error) of the production of purely commercial (civilian) high-tech products. This question worried me too, because I was constantly tormented by the questions of everyone who is somehow connected with high technology and business in Russia.The answer to this is important if you yourself want to create a competitive high-tech product - so as not to spend the best years of life in initially unequal conditions.

Under the cut, we’ll try to figure out how “high-tech” companies differ from “low-tech” ones, what is needed is for high-tech companies to be born and survive, why we have a better software than a hard, which started a silicon valley in the US and can we copy it? "Why China is tearing up everyone, and also let us take a look at everything that happens in Skolkovo, Rosnano, the fund for promising research and whether they will lead to the flourishing of Russian innovations. Of course, I could be wrong somewhere - I will be happy to add to the comments.

')

Immediately it should be noted that due to the many-sided nature of the problem, the volume of the article turned out to be rather large, so you can start reading from the summary at the end, and then read only those sections that will cause interest. I just want to warn you - the story is “non-linear”, neighboring headers can describe different aspects of the problem and be practically unrelated to each other.

The situation with high-tech production from a height

- Economy Under capitalism, business tries to make the most money using a minimum of capital and with minimal risk. A high-tech business - despite its external attractiveness - is a crappy business: it takes a lot of capital, payback times are big, big risks, you have to hire capricious engineers for more and more money. In theory, this should be offset by super-profits, but this does not always happen. As a result, high-tech businesses are engaged when there is no place in a simple business or when the state makes such a business attractive (subsidies, double use of the results of government contracts execution - in both civil and military).

In the case of Russia, for a number of reasons, a low-tech business (construction, trade, natural resources) may have too high a profit - and this makes a high-tech business completely pointless from an economic point of view. On the other hand, the scheme of work on government contracts excludes the receipt of large profits (usually it is necessary to show a net profit of about 5%), it requires maintenance, dual use can be difficult because of the secrecy and state ownership of the intellectual property - i.e. again, it is absolutely not attractive for a commercial artist. - Cost and availability of capital . High-tech business requires a lot of money, and from the very beginning. Despite the fact that there is enough money in Russia, for natural reasons they are concentrated among people engaged in simple business and it may not be interesting for them to understand the intricacies of high-tech business. Also, in view of the above-mentioned higher profitability of a simple business - it delays much of the investment capital, and accordingly makes it more expensive for everyone.

- People The idea of high-tech business is born and implemented by people who have a good technical education and (optionally) work experience. In recent decades, the quality of technical education has been falling, as has the number of graduates in technical specialties. Further, the problem is aggravated by the “export of raw brain”: emigration and outsourcing .

It is believed that fundamental and applied science should generate innovations - but in practice this does not occur - again, because of bureaucracy, the inability to quickly raise money to test ideas, “brainwashing” (people’s leaving for “low-tech” but highly paid work). - Bureaucracy and logistics : Since the goods need to be produced in reality, the speed and cost of the delivery services work becomes extremely important - both at the reception (many components from around the world) and shipment (including Russian mail), speed and cost of customs, other bureaucratic restrictions (such as restrictions of the state drug control on the circulation of industrial chemicals and the FSB with cryptography, certification of goods). Naturally, even now all obstacles can be overcome - but it takes time and money, and competitors in other countries gain an advantage.

- State policies of other countries and patents : It is difficult to expect from foreign states that have achieved success in high technologies (for example, in microelectronics) a voluntary rejection of leadership positions - for this there are export licenses and patents. Russia naturally acts in the same way and does not sell, for example, the production technology of the most modern aircraft engines to China, preferring to sell the engines themselves. “Closing” patents will not allow you to do what has already been done - and you may not be able to sell a license to use a patent, and if you sell it, you will not be able to sell a competitive product. This all makes it extremely difficult to enter already occupied markets with a similar product - you definitely need to invent something new.

The biggest misconception

It is worth emphasizing again - the biggest widespread misconception about high-tech production is that there are very high profits, the work is not dusty, but dirty and labor-intensive industries (energy, mining and processing of minerals, food industry) are not very important. physical production of developed high-tech devices is better left to third world countries, and the only thing that supposedly prevents the high-tech from flourishing in Russia is theft / corruption / do not sell the necessary equipment / lack of wie their Jobs.In reality, everything turns out to be wrong: a high-tech business has high capital requirements, there are long payback periods, there are always risks, profits are dripping slowly and do not impress the imagination (only sometimes there are outstanding results - when we received a “closing” patent for a very tasty technology, and there are resources to defend him in court - however, such technologies and developing cheap will not work). In the West, high-tech went only because in the ordinary, simple business there was nothing to do + paying for work under military contracts + the state allowed intellectual property to be left with the contractor and used for commercial purposes.

In addition, those who listen to American political programs for “domestic use” have probably heard the phrase “Bringing the Jobs Back Home”: this is actually a recognition that the post-industrial economy (“we are developing, and monkeys overseas are collecting”) has not justified itself and leads to the extinction of entire sectors of the economy. Therefore, blindly copying the American "post-industrial" path is clearly not worth it.

Here is a quote from vasiaa , skipped on the forum on microelectronics, successfully emphasizing the current situation:

Angstrom is very poor, the export is 132 million rubles, and sells products for 700-800 million rubles, or 25-30 million dollars in full ... I have a friend who in Zelenograd has a company for construction, repair about the same amount per year.Link on the topic with numbers.

Read more about the difference between a “high-tech” business and a “low-tech” one.

Low-tech business - creates surplus value by moving goods created by others, and creating goods for the production of which need one technological operation without a large amount of intellectual property. Often geographically tied to the source of resources (hydro, coal mine, oil field, field engineers for outsourcing).Examples:

- Bought the goods in bulk - sold at retail.

- Bought goods abroad, dragged through customs, sold in bulk / retail.

- Bought an apartment - they sold an apartment a year later.

- Built a building - sold out apartments / rented as offices.

- They bought alumina, in Soviet factories by electrolysis they received aluminum pigs, sold in bulk.

- Drilled holes in the ground, laid the pipeline, pump oil and sell in bulk.

- They bought oil, divided it into fractions (+ catalytically processed), and sold petroleum products in bulk.

- We hired engineers, we fulfill development orders with hourly rates (= offshore programming)

High-tech business - creates products with a high proportion of development costs, requiring a large number of operations. Accordingly, for commercial success, a lot of cheap capital is required, the minimum additional expenses for logistics and bureaucracy, the maximum sales volumes around the world in order to “spread” the development costs to the maximum number of copies of the final product.

Examples:

- Developed an iPhone and software for it - organized production - sold products

- Developed a processor - implemented support in operating systems and third-party software - ordered production - sold products

- Developed a chip manufacturing technology using 10nm technology - developed libraries - licensed to manufacturers

- Developed a general-purpose microcircuit - ordered production - advertised - sold through distributors

- Developed a nuclear reactor - built by the customer - helped with the operation.

Consider an example - CD / DVD-RW

Low-tech business:

High-tech business:

It would seem that making an apparatus for reading / writing such concentric “grooves” should not be difficult:

Naturally, all this work can be done by different companies within their areas of expertise, something can already be done - and it is cheaper to simply buy, and something will be patented - and you will have to buy licenses (if the patent owner is good enough).

At the time of receipt of the pre-production prototype, we have already spent about $ 5-15 million. Further, although the cost of large-scale production of the finished device may be quite low (10-50% of the sale price), in order to “beat off” the $ 15 million spent on development, return interest on loans, and compensate for the risks that investors took on produce product in a series of 1-10 million copies and above.

Those. risks are quite high, there are many customs and logistics passages in general, capital requirements are high, you need to find and hire a large number of developers in different areas, and the expected profit is quite modest and completely inadequate by Russian standards, the required titanic efforts (compared to commonplace trade or construction). And most importantly - the success of the entire event depends on the volume of the series. No force on earth will allow you to make 1000 DVDs with a near-market price from scratch - you need to look for someone to sell exactly 10 million. On the other hand, competitors have already repulsed their development costs for a long time, and have the opportunity to sell the product close to the cost price.

Accordingly, if you enter the already busy market with the same product (“catch up and overtake”) - commercial success is almost impossible to achieve, something essential to improve consumer properties is absolutely necessary (the notorious “innovations”).

Consider an example - CD / DVD-RW

There is a task - you need to put a batch of CD / DVD writers.Low-tech business:

- Phoned wholesalers, found that cheaper

- Purchased a batch (often with the possibility of payment later)

- Passed customs 1 time.

- Have sold.

- Put your 5-10-50% in your pocket.

High-tech business:

It would seem that making an apparatus for reading / writing such concentric “grooves” should not be difficult:

- Bought access to the specifications on CD and DVD.

- We hired engineers, developed electronics (controller, power part of motor control, control of laser diodes and photodiodes).

- Developed a microcircuit controller (for maximum cost reduction in the series)

- We ordered the manufacture of masks for mass production of the controller chip (we are cool and do it right away without errors)

- We ordered the manufacture of a batch of plates, their cutting, packaging and testing.

- Hired developers of firmware (support for all formats, error correction codes, etc.)

- We hired opticians who will develop a read / write system from 2 different laser diodes (red for DVD and IR for CD) without loss of power using clever dichroic filters.

- We ordered the manufacture of a prototype of dichroic filters, mirrors, 4 lenses (probably at least 1 of them is aspherical), molds for casting plastic lenses for mass production.

- Since the screw drive of the carriage motor has a pitch of about 5mm and the stepping motor has, at best, 200 steps per revolution, we get the minimum carriage motion pitch of the order of 25 microns, and the interval of tracks on a DVD is 0.74 microns. We develop an electromagnetic lens shift system with 4 coils both in the horizontal plane and in the vertical (focus + support for multilayer disks)

- They hired the developers of mechanics, developed and ordered the manufacture of molds for plastic parts and molds for carriage molding.

- We collected all the details for the first prototype - it all worked almost the first time.

Naturally, all this work can be done by different companies within their areas of expertise, something can already be done - and it is cheaper to simply buy, and something will be patented - and you will have to buy licenses (if the patent owner is good enough).

At the time of receipt of the pre-production prototype, we have already spent about $ 5-15 million. Further, although the cost of large-scale production of the finished device may be quite low (10-50% of the sale price), in order to “beat off” the $ 15 million spent on development, return interest on loans, and compensate for the risks that investors took on produce product in a series of 1-10 million copies and above.

Those. risks are quite high, there are many customs and logistics passages in general, capital requirements are high, you need to find and hire a large number of developers in different areas, and the expected profit is quite modest and completely inadequate by Russian standards, the required titanic efforts (compared to commonplace trade or construction). And most importantly - the success of the entire event depends on the volume of the series. No force on earth will allow you to make 1000 DVDs with a near-market price from scratch - you need to look for someone to sell exactly 10 million. On the other hand, competitors have already repulsed their development costs for a long time, and have the opportunity to sell the product close to the cost price.

Accordingly, if you enter the already busy market with the same product (“catch up and overtake”) - commercial success is almost impossible to achieve, something essential to improve consumer properties is absolutely necessary (the notorious “innovations”).

Why is business in Russia so reluctant to go into high technology?

This is the most important question, it was even repeatedly raised, but left unanswered the main one on nanotechnology in Russia .The answer is simple - a serious business always goes where there is more profit and less risk.

In the conditions of idealized competition, the rate of profit of “simple” business tends to zero, and in countries where capitalism is already hundreds of years old - it forces you to constantly invent something for the sake of an extra percentage of profit and, in extreme cases, go to an “unpleasant” high-tech business to capital, long payback periods and high risks. You cannot open another store - in all the “tasty” places everything is already open, you cannot drill a well for “easy” oil - all convenient deposits have already run out, you can of course go to construction - but because of the wildest competition you have to be content units of interest per annum.

In Russia, in the beginning of the 90s, it was just a simple business that survived and was privatized, and the first generation of liberal businessmen lobbied for such changes in legislation that allowed them to maintain high incomes without going to high technologies. Since there was practically no civilian high-tech business, there was no one to protect his interests.

If there was an iron curtain - the existence of high-tech production in such conditions would still be possible, just those who deal with it would sell manufactured goods with worse performance at significantly higher prices (in high technology - less series = higher price). However, with open borders, the domestic producer in such conditions will inevitably lose the competition with imports, and no reasonable level of duties will change anything here.

The current situation, even without manual intervention in the long term, is unstable and as capitalism matures over 2-4 generations (50-100 years), the profit rate of a simple business will naturally decrease (due to the natural change of generations of owners of large businesses).

Where did hi-tech production in the west historically come from?

Radio tubes owe their aggressive development not to a warm tube sound, but to radiolocation and military communications. The first computers were invented not for playing tic-tac-toe, but for ballistic calculations: those who calculated the angle of elevation of the instrument faster and more precisely — that one won. Then - the lighter and smaller the computers in ballistic missiles were - the more plutonium with lithium-6 deuteride and false targets could be placed in the ballistic missile warhead and the higher the accuracy of the hit. Thermal imagers were invented not to assess heat leaks on civilian objects, but so that tanks and infantry could conduct aimed fire on a moonless night without a de-scaling infrared illuminator.Only after the basic technology in the West was brought to serial military production and all development costs were paid, the executors received “closing” patents — commercial companies came, and found applications in the civilian sphere — with an increase in production by orders of magnitude. .

And when serial civilian products began to satisfy all the requirements of the military — they began to be used directly in military technology — taking advantage of its monstrously low cost. This is a bourgeoisie called COTS - Commercial Off-The-Shelf, cheap and cheerful.

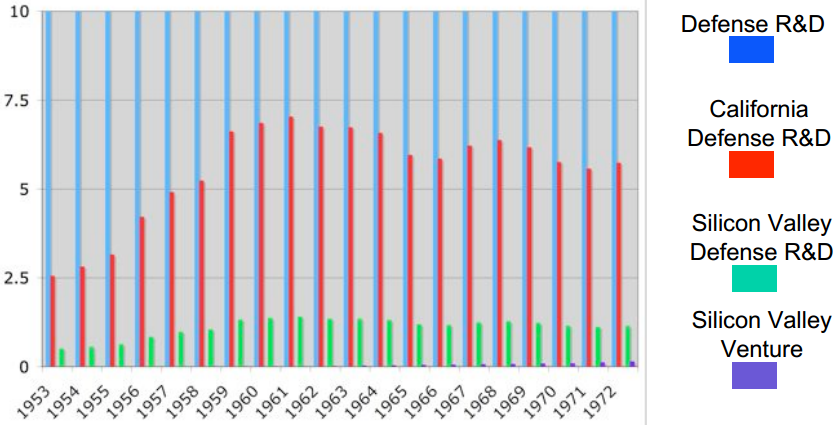

How was silicon valley born in the USA?

In the Silicon Valley - in the 50s, the company carried out military orders for the development of various electronics (radar, apollo, onboard computers for ballistic missiles, etc.), and the state was the largest buyer during the 60s. The state left intellectual property behind the performers, but demanded to grant licenses to other domestic companies.You can estimate the ratio of private investment and government orders: it took 20 years to pour money through government contracts to make the column of private investment at least visible. The graph from the report at link # 3 below.

Having accumulated experience, having earned money for private investment in 20 years of fat, new companies were able to make complex microcircuits of commercial value, and due to lack of competition they could have fantastic profits: so, the i8080 processor cost $ 360 (and this is civil version), with a plate of 76mm, they were about 50 fit (my estimate of the area at the yield of ~ 50%), the cost of building the plant paid off in just a week of work - by today's standards an incredible profit. For comparison, now the microelectronic plant has a payback period of about 5 years or more with ~ 500 times higher capital requirements (~ $ 10 billion) for new technological standards (10-14nm), and it is generally difficult to pay for old standards.

Hence the conclusion: Silicon Valley is not a beautiful office complex (it’s not there at all), not an “innovation atmosphere” - these are huge profits based on technologies developed for the money of the military in the first 20 years. Then - the business just continued to concentrate there by inertia. Blind repetition of this is now impossible nowhere - simply because those conditions are no longer (opening a new industry with a huge commercial potential) and once again nobody wants to pour so much money for 20 years.

References:

1. Institutions and growth

2. How the West Was Won

3. Hidden in Plain Sight: The Secret History of Silicon Valley as well as a report on YouTube .

Problems of high-tech "import substitution" strategy "catch up and overtake"

“Overtake and overtake” and “import substitution” - 2 very popular topics for public speeches by government officials at all times. It would seem that Intel makes the processors (owns both the production technology for the finest technical processes and the development of the processors themselves), that we should cut corners, independently develop the production technology, the circuit and make our processors with blackjack and courtesans (in the idealized case) ?

As we remember, Intel spends on research and development (R & D) $ 10.6 billion per year. Naturally, we put 10 billion in the open field and after a year get the result of Intel will not work. For at least the first 5 years, a new catch-up company will grow from $ 0.1 billion in R & D expenses per year to $ 10 billion per year - staff will grow, equipment will be bought, and so on. After 5 years, it will be able to spend money as quickly as efficiently as Intel. Now we need another 5 years to complete the development cycle of 1 product. It has been 10 years since the start of the project - we have already spent ~ $ 70 billion and were able to get a product comparable in performance with an Intel processor and produced in a domestic factory. However, we can sell it with reservations only in the local market - because Intel holds closing patents on key technologies that they will not sell under any circumstances. In the local market, we earn mere pennies, after all, these are only ~ 150 million buyers against 7 billion world markets. Since most of the cost of a high-tech product is the total cost of development - it is little dependent on the volume of production. Therefore, the processor for the local market is doomed to be 7000/150 = 45 times more expensive. But if we do not set a goal to return investments in the local market, this is not the end.

We continue to work for another 20 years at $ 10.6 billion a year - 30 years after the project began, when all the old patents have expired, and we have about as many new patents as our competitors - we were finally able to compete with Intel. The difference, however, is that Intel paid for its R & D costs from profits, and we had to pay for everything from the money of a public investor. Well, capital expenditures are also needed - $ 7 billion every 3 years for the construction of factories at the leading edge of technology, + $ 70 billion. Overtaking and overtaking Intel cost us ... $ 352 billion and 30 years of work.

If we lived in the world of the elf market economy, one could simply buy Intel. The current market capitalization is only $ 127 billion, it would have been possible to redeem it with a premium of 50% - a total of $ 190 billion is needed, which looks better than $ 352 billion and 30 years of hard labor. However, strategic technology companies no one in their right mind is selling for any money. For money without limits, you can only buy luxury items - yachts and diamond watches.

Finally, the last problem - the volume of the world market of processors from the appearance of another player twice will no longer be. Those. if all - only to reach the level of Intel in 30 years - then the profit in the first approximation will be half that of one Intel can get - the market will be divided in half. In fact, it turns out that "who first got up - that and sneakers": if you entered the processor race in the 80s it was possible with millions of costs - now there are not enough hundreds of billions to outrun Intel with their business model, and without any guarantees return on investment. Naturally, you can catch up with the "fabless" company (ARM or AMD) - it will cost 5-10 times cheaper, but the result is worse because the company will not independently own all the necessary technologies (guaranteed backlog by technical process + “political” risks associated with the use of a third-party factory).

Proceeding from all this, it is completely senseless to expect the results of Intel from the Elbrus of the MCST: the MCST has an annual development budget of ~ 0.05% of Intel’s. When Babayan (with all the ambiguity of his personality) asked for a miserable (by industry standards) $ 100 million for the development and production of a processor in silicon, they just twisted their fingers to their heads , although in reality, as we see, tens and hundreds of billions are needed now. Due to the “power of intellect” and hard labor, you can “pull out” a 2-fold budget difference, a 5-fold difference - but no force on earth would allow the MCST to achieve Intel results at a 2,000-fold difference budget.

The situation with cars is quite similar: Avtovaz spent 1.7 billion rubles on development in 2012, and Volkswagen - $ 12.8 billion, 263 times more. If Avtovaz could start effectively spending $ 12.8 billion a year on development, then in 10-30 years one would expect results at the Volkswagen level. Naturally, in the early 90s the costs would have been several times smaller - but then new private owners needed short-term profit, and not investment with a return in 10 or more years. And just like with Intel, buying a car maker to immediately get access to its technology will not work, as history has shown in an attempt to buy Opel.

If, however, to start breakthrough projects with “hats and caps”, you will get an E-mobility. The project budget estimate was 150 million euros - a mere penny in comparison with competitors. How can you try to create a competitive product, hoping for all the many years of development and production to spend 2% of what competitors spend on development for 1 year?

About buying technology

And what if you buy ready-made technology, build a candle factory on imported equipment (on credit) for the production of processors and cut coupons?High-tech companies can earn income through:

1) Intellectual property - when they come up with something that others do not have

2) Capital

3) Efficient operating activities (0-5% per year, depending on luck)

If our intellectual property is not there, and we all bought / licensed, then the profit will be received by the one who licensed this technology to us. Yes, if you bargain for a discount - then some kind of profit can be recaptured over the course of 5-10 years of hard labor. Again, if all equipment is purchased, then we pay for the intellectual property used in the development and creation of this equipment in the first place.

If there is no capital, then the bank naturally gets the return on capital.

Only profit for “efficient operations” remains - but by the Russian standards, these miserable percentages are mere pennies.

It should now become clear why the future of the Angstrom-T project, about which I wrote earlier, is covered with darkness. There they also paid a little for the equipment, and the equipment lay in the warehouse without bringing a profit for 5 years - in general, this is a canonical example of how you can arrange an epic failure on level ground.

With perfect implementation, if the negotiations on equipment prices and licenses reached a fight (figuratively speaking), the loan was received at the rate of market leaders (~ 4-5% and not double-digit), everything would be built and put into operation as soon as possible. in 2008, then Angstrom-T would be able to work at 0. Now, it remains to be seen who will take off 50-66% of the debt.

Why is IT business in Russia alive, and high-tech production is not?

Due to the fact that the product of labor of clean IT companies “magically” passes through customs borders and bureaucratic barriers, most of the negative factors do not work here: only the cost of money (= competition for capital with a simple, profitable business) and a shortage of engineers. Even these 2 remaining problems can be circumvented by implementing the project to the prototype / beta test stage by the forces of friends on long winter evenings (that is, without investment and without the painful hiring of developers)You also need to remember that we have a lot of IT business, which cannot be called high-tech: selling employees time paying them part of the funds received is not high technology, it is the commonplace exploitation of the local field engineers - exporting their raw brains.

Skolkovo, Rosnano and others from a height

Skolkovo decided that if the business itself does not want to invest in high technologies, the pill needs to be sweetened: they did tax privileges for residents, and for small rounds of investments (if approved by the grant committee) - some of the money can be obtained free of charge (or rather, they require bureaucracy returns).Understanding that something is wrong with the Customs, they also (in theory) compensate for customs payments on imported goods for the construction of Skolkovo itself and used by residents for research. In practice, it is difficult to use this benefit.

After reading the list of residents and visiting websites, I got the impression that most of the resident companies become participants in the hope of finding money to implement their ideas, do not receive money (~ 85% of residents) and die without being born, leaving only " one "in the statistics of the number of residents.

Also in Skolkovo there are several collective use centers (CCP) of various really useful scientific equipment - they are separate commercial companies, they buy equipment for their money + Skolkovo co-investment, obviously using customs privileges (it was not possible to find out the distribution of Skolkovo-CCP co-investment shares). Services for the use of CCPs are substantial money, and accordingly for 85% of residents are not available.

The most living residents of Skolkovo are subsidiaries of existing domestic and foreign companies that simply save taxes in Skolkovo. For example, Sberbank in its development center writes a banal Internet bank, Mobixchip - outsourcing the development of chips for an Israeli company, Intel Software - outsourcing for Intel, and so on. As we remember, outsourcing is a low-tech business, the exploitation of a local field of engineers - in Russia there is no intellectual property left, only salary and payroll taxes.

In general, Skolkovo is certainly 1 step in the right direction (~ 0.5% of the way), 1 step in the opposite direction (support from development centers - hi Bangalore, they themselves live normally), but the number of PRs does not correspond to the microscopic volume of grants and invested means (by world standards). In Skolkovo, they solve the problems that are easy to solve: build beautiful offices, distribute grants to a small number of companies, shine in the press, and not those that need solutions: the availability of cheap capital for tens of thousands (and not 136 in 4 years) of small startups at various stages, speed and cost of logistics, customs, an unusually high yield of a simple large business, which makes a high-tech business a meaningless occupation without permanent subsidies.

Also, the idea that high-tech companies need to be dragged to one place - tracing from the silicon valley of the sample of the 60s of the last century, when there was no Internet. Now, on the contrary, it is necessary to encourage maximum filling by high-tech companies throughout the country, so that it is easier for them to find engineers (who do not always want / can go to Moscow).

Rosnano- at first glance, it acts on the basis of the hypotheses “Business simply does not want to invest in high technologies”, “Business has too little money” and “Nanotechnology is a breakthrough direction, invest a little in market conditions and become the leader”. Unlike Skolkovo, it is required to create something physically in Russia, financing on market terms (people say that interest rates on loans are double-digit), there are no tax breaks. It is not at all surprising that in such market conditions competitive high-tech projects did not line up for money.

Projects that are in the investment stage are difficult to estimate - until real sales start, you can always make a good face on a bad game. It is simple to produce high-tech products, and to produce products that are competitive in the world market - these are tasks that differ in complexity by orders of magnitude.

From what I had heard about:

SITRONICS-Nano - the purchase of equipment and a license for 90nm technology for Micron. Small-scale production, for the civilian commercial market is doomed to be too expensive.

Mapper Lithography about which I wrote earlier. In Russia, production of an insignificant and uncritical part of the equipment is localized (part of electronic optics, actually a “plate with holes”: lithography with micron norms and ion etching), however, the share of Rosnano's investment in the project is small - it would be difficult to demand more.

Optogan - production of LEDs and finished devices based on crystals produced abroad. As Tiberius unearthed at the time, the crystals of Optogan and Sveletjed were extremely similar.

Nitol- built a plant for the production of polycrystalline silicon, but it turned out that during construction the cost of polysilicon fell several times, due to the shock growth of production in China. I had to close. It remains to be understood why it is impossible to manufacture products with a “Chinese” price.

Plastic Logic - money from Rosnano with the condition of building a plant in Zelenograd received, but then they decided to build a plant. Now they plan to sell technology. Production and research remained in the UK / Germany.

Havel- Were going to do thin-film solar cells increased efficiency. Judging by open information, the efficiency is 8%, while the cheapest Chinese polycrystalline batteries now have an efficiency of 16-17% (at about the same price per watt, about $ 0.5 per watt or less). Accordingly, on the open market, commercial prospects are limited. The technology supplier company (Oerlikon) - the solar business managed to sell Tokyo Electron Ltd., and it is physically liquidating it right now - it lost the competition to China.

Unikom - crushed automobile tires as a filler for asphalt. The founder of the project is a noble swindler . The company filed for bankruptcy last year, but something is still moving there.

Liotech - production of LiFePO 4 batteries. It was not possible to elicit from them a sample of the battery, what prices of products there are unknown.

ELVIS-NeoTek - fabless chip design for video surveillance and video surveillance systems based on them.

Crocus Nanoelectronics - production of MRAM-memory on 300mm plates. On the finished plates with CMOS-logic put several additional layers for MRAM-memory in the Moscow production . I hope from such logistics (to carry the plates through the whole world at least 2 times during the production cycle) the cost price suffers slightly.

As we see, competitive high-tech production somehow does not want to go completely to Russia on market conditions - it is in every way possible that the critical components remain abroad. However, it is also possible and necessary to integrate into the world division of labor for civilian purposes - it is not necessary to drag the entire chain to one country, but at least somewhere critical components should be here.

Then Rosnano began to finance “development centers” (again, “Hi Bangalore”) - outsourcing, which leaves nothing but salary taxes in Russia: Aquantia, Quantenna, SiTime.

If you look at the investment figures of Rosnano, you may get the impression that Rosnano is in many cases a majority investor. However, Rosnano seems to publish figures for a specific investment project, and not general ones for the company: the project budget for SiTime is 541 million rubles, despite the fact that back in 2007, SiTime received a total of 40+ million investment.

By the way, the SiTime SiT8008 chip was able to pick it up: it's a generator based on MEMS, not quartz. The micromechanical resonator is sealed in a vacuum of _internal_ crystal. This is really high-tech - it is a pity that both production and intellectual property remain abroad.

Ultimately, Rosnano is doing what it can, forcing state-owned companies to use their products (where possible), go 0.5% of the way forward, 1 step back (supporting “development centers” as in India) - fundamental difficulties with the emergence and survival of commercial high-tech companies in Russia are not solved. Investing in companies on commercial terms is only the last and most pleasant step in high technology.

FPI (Advanced Research Foundation)- created as a domestic analogue of DARPA, which can solve problems with the availability of capital and bureaucracy (to be optimistic). However, there is a significant difference: in DARPA, the state is left with only a non-exclusive license to use the acquired intellectual property, while with us, the executor of property rights on IP does not remain. In the US, a performer can commercialize development without any restrictions, including in the civilian market, while our state can remain with this intellectual property like a dog in the manger + the performer is motivated only by salary and short-term modest profit for "surrendering the topic".

Those. , - F14A — Intel, .

. ..

?

A popular explanation is “low wages.” But low wages and in Africa - and the heyday of high-tech production there is not observed.To begin with - in China there was no privatization modeled on Russia - and large companies engaged in simple high-profit business (mining and primary processing of natural resources, energy, etc.) remained state-owned. Privatized on the contrary, the company is smaller, where after buying it is necessary to pry, and not to cut coupons. As a result, entrepreneurs were forced to engage in the development of a real, complex business, rather than the division and operation of a “simple” one. The confirmation is easy to see by looking at the list of Chinese billionaires . Although we can already see the rising problem of the bubble in the construction market in China.

Where it all takes money for the creation of a business is not personally clear to me. The existing business is actively credited in state banks, and the debt load there is monstrous. Thanks to the huge public investment (“reverse build-operate-transfer” - the state finances, the private company manages, the debts are minimal), China managed to jump onto the step of the outgoing train of microelectronics. If in the early 1990s, China was still trying to import microelectronic technologies from us, now it is far ahead (the blue chart is the lag in the input of microelectronic technologies from the US, the red is from China).

SMIC, the largest Chinese microelectronic factory, plays “white”, fulfilling all the requirements of the US export control, for which it received the status of “Validated end user”, removing many restrictions on this particular company at the price of strict exclusion of military orders.

Next - a huge number of engineers. Logistics costs are minimal - production is compactly located along the coast by specialization. The most striking example is Shenzhen, where, without leaving the city limits, one can go through all the steps of electronic production from the development to loading onto the ship in the shortest time on earth.

It is the availability of skilled labor and capital, the speed and costs of logistics, the minimum of import / export bureaucracy - are the necessary prerequisites for successful high-tech production, and not low wages. And in China, with these factors, everything is more or less excellent. Naturally, this does not mean that in China there are no other problems.

About the impossibility of spending the revenues from the sale of oil

Often we hear that revenues from the extraction and refining of oil (and other resources) cannot be spent, because they will inevitably cause inflation (" Dutch disease ").In fact, of course, they can be spent without inflation inside the country - for this they need to be spent abroad immediately, buying imported production equipment (if sold), paying for the work of foreign engineers, whom we lack (insourcing), buying foreign high-tech companies (if sold). Naturally, the state itself doesn’t need equipment and engineering engineers, and therefore there should be a mechanism by which private companies could receive a part of the state’s foreign exchange earnings directly in the form of currency for expenses strictly _ outside the country_. However, if to be realistic, it is not necessary to expect the appearance of such a mechanism in the foreseeable future.

Naturally, inflation in this case will not go anywhere - it will just be abroad, and accordingly will be a headache for other countries with a deficit in the balance of foreign trade.

Returning to the list of popular and incorrect reasons:

1) There are no smart people. - There are a lot. But they prefer to work where their work is assessed as highly as possible - outsourcing, abroad, in a simple but highly profitable business.2) Many smart people and innovative ideas, but they do not know how to commercialize them. “Innovative ideas” trivially lose out to the simple business in economics — so no one is after them. In order for one idea to fire, a test of 99 ideas must be paid for and failed.

3) No money. There is money, but it is earned mainly in the “simple” business by people who are of little interest in high technology (both because of the economy and because of complexity).

4) Too much oil money / only oil can be pumped. This is a good business. Under capitalism without limitation, business is exactly what this is obliged to do.

5) VAT (including customs). VAT is in many countries with developed high-tech production. If the work is done legally, then with competition in the foreign market, VAT is returned (including customs VAT for imported equipment), but this certainly increases the capital requirements somewhat.

6) Corruption. Corruption is certainly part of the problem - because allows simple business to have unreasonably high profits. And since corruption is everywhere - kickbacks are not invented in Russia, and it is not from a good life in China that officials have to be shot down - in Asia, corruption without control is especially fierce.

7) The climate is bad (Scab). In high-tech production, controlled temperature and humidity are usually required - and taking into account the energy consumption for air dehumidification (when it is first cooled and then heated) with the Russian continental climate, the energy costs are actually less.

8) Too little built office space for innovative startups. I suppose everything is obvious here - as practice has shown, world-class companies are normally born in garages / apartments without glamor.

Summary

In order for commercial high-tech production to be born and survive - it must be profitable, there must be a lot of people who have money to check and patent protection for a heap of ideas (shoot 1 out of 100), cheap capital must be available for sale, there will be many engineers available who will implement the idea in practice; the implementation process should not be aggravated by logistic (speed and cost of delivery services, prices of local executing companies) and bureaucratic difficulties (certification, tography and the Federal Security Service, Customs, Federal Drug Control Service, even with its limitations on commercial chemicals) that may give an advantage to competitors in other countries.How we came to life like this : There is almost no civilian / commercial high-tech production in Russia, because in the process of privatization, private business received “simple”, high-yielding assets. In the future, this business lobbied for laws that preserve revenues “above market” for a simple, low-tech business. The heyday of bureaucracy and all sorts of artificial restrictions (customs, numerous certificates, permits ...) again make it possible to have an easy profit on overcoming the difficulties in special ways.

Business did not do so because it is somehow bad or stupid: it was the most profitable strategy, and therefore there was no choice .

In such conditions, a high-tech business (which is obliged to compete in the global market to maximize the series and, accordingly, reduce costs) is completely unprofitable: it requires a lot of money, qualified engineers, has great risks, long payback periods.

As a result, now a simple business (construction, retail and wholesale, mining and processing of resources, outsourcing) wins the struggle for investment capital. Naturally, it is possible to attract investments abroad - but then the investor wants the parent company that owns the main assets in foreign jurisdiction (i.e., everything degenerates into the classic “Russian development center” scheme + everything else abroad).

The state, for its part, closes the possibility of “initial capital accumulation” for companies performing government contracts (as happened in a silicon valley in the USA) - retaining intellectual property and demanding to show a modest net profit when carrying out government contracts, which is not gives you even a prospect to earn enough money to launch your risky high-tech projects.

Want to break Intel? : If you want to create your own high-tech business related to real production, a really new idea is needed first (with old ideas you usually need too much money for a commercial result in a busy market), you need to immediately think how to maximize the existing Russian problems: abandon the extra-large-budget projects (like your processor, plugging into the Intel belt), make a working prototype on your own, first of all find engineers - in the wildest deficit skilled labor is a fatal problem, use a minimum of too expensive capital (and not as a Displair), minimize the number of physical things crossing our customs border (possibly up to 0). If you focus on the local market or a narrow niche - you need to immediately realistically assess the market volume in pieces - so that it is clear how little money can be spent on development, and how much angles will have to be cut to reduce the cost of development.

Want to break Facebook? : Well, everything is much simpler. Bureaucracy, customs and logistics problems practically does not create. It remains only to find a new idea, the availability of capital and qualified engineers - and many more detailed articles are devoted to solving these last 2 problems.

When to wait for competitive domestic processors and video cards? : x86 processors in the United States are not developing because there are some other people there - after all, our compatriots work at both Intel and nVidia and many other high-tech companies. Here the principle of "who first got up - that and sneakers". In the Silicon Valley in the 50-70s, they poured a huge pile of American taxpayers' money (about $ 50 billion, including inflation) through military research contracts - and they are rightly using the result so far.

In addition, for more than 40 years, Intel has been reinvesting the income from the sale of processors into technology complication, owning a bunch of patents - and in order to reach their level under equal conditions (taxes, bureaucracy, availability of capital), I would roughly need about $ 352 billion and 30 years of work - of course no one can go. Everyone needs their own Intel for 0.1, and better $ 0.01 billion :-)

However, for the same reasons, it is also difficult for the United States to create its own technology for separating uranium by centrifuges and to build fast-neutron nuclear power reactors. So somewhere they are winning, somewhere we are, somewhere China - you need to develop something where there is an advantage and not to overstrain where in order to achieve parity you would have to spend all the resources of the country on 1 company.

Source: https://habr.com/ru/post/218171/

All Articles