Imperceptible difficulties of rocket technology: Part 4. More about engines and tanks

The tribute to the imperfections of our world to the developers of rocket technology is varied and unpleasant. Today we will talk about what you have to pay for increasing the parameters of liquid jet engines and about the unnoticeable problems that await tank designers.

LRE work patterns

The existence of different schemes allows developers to choose the right one, with the desired advantages (ease of use, ease of production, high traction or high specific impulse) and acceptable drawbacks.

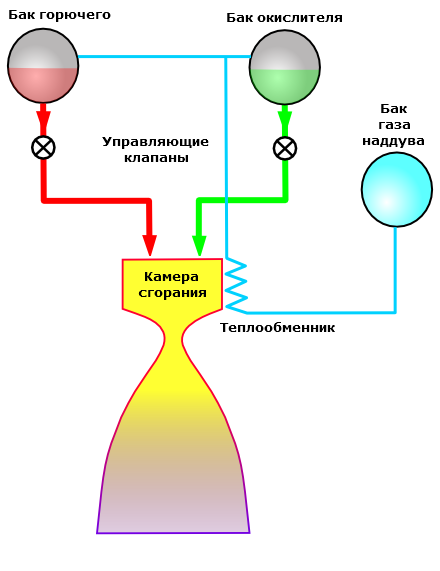

Displacing feed

The easiest option. The gas pressure boost (first was nitrogen, now massively switched to helium) provides the necessary pressure parameters at the inlet to the engine. At the pressure feed, the first rocket experiments of GIRD and Goddard were carried out, but she did not leave the stage with time. This scheme is used in propulsion satellites and spacecraft. "Unions", "Shuttles", "Apollos" used it. Particularly well displacing flow combined with a UDMH / AT fuel pair due to its self-ignition. It turns out a simple, reliable engine with the possibility of multiple inclusion.

Advantages:

- Simplicity.

- Reliability.

- Cheapness

- No weight loss per turbopump.

- High efficiency for low thrust engines

Disadvantages:

- Low specific impulse.

- Bad for high thrust engines.

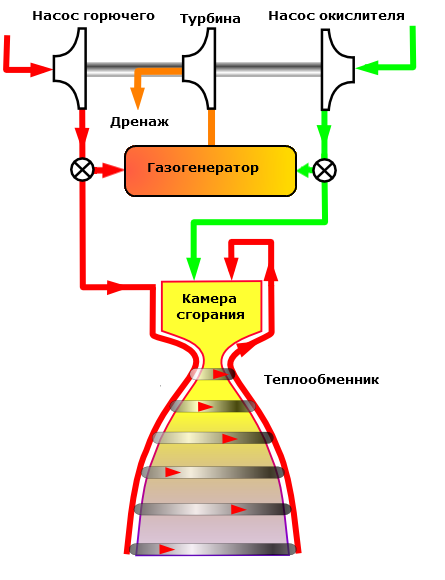

Open circuit

To increase thrust, specific impulse and engine power, a pump was already needed. The required parameters could provide only the turbine. In the first "real" rockets - "V-2", "R-7", a separate working substance was used to drive the turbine - concentrated hydrogen peroxide, but then switched to burning a small fraction of the fuel components. At first, the exhaust of the gas generator was simply dumped to the side, a very effective torch was obtained:

The Atlas launch vehicle is launched. Pay attention to the size, power and color of the torch. It can be clearly seen that the tha operates on an excess of fuel that burns in the atmospheric air.

Drainage of generator gas directly overboard looked wasteful, so they began to send it to the supercritical part of the nozzle - and add a little bit of UI, and how the curtain will work:

Classic picture - F-1 engine

However, the drainage of the gas generator of an open circuit has another interesting use case - as a roll control engine:

Second stage PH Falcon-9. Rotation of the exhaust pipe leads to a twisting force that controls the tilt of the stage.

View in dynamics (from the third minute)

The open scheme is used now, and is unlikely to disappear in the near future. Due to the relatively small loss of MD, it allows you to make a more powerful engine ( F-1 ) or a cheaper engine ( RS-68 ) or make development possible for a team with limited resources ( Merlin ).

')

Advantages:

- Easier and cheaper closed circuit.

Disadvantages:

- Less specific impulse than a closed circuit.

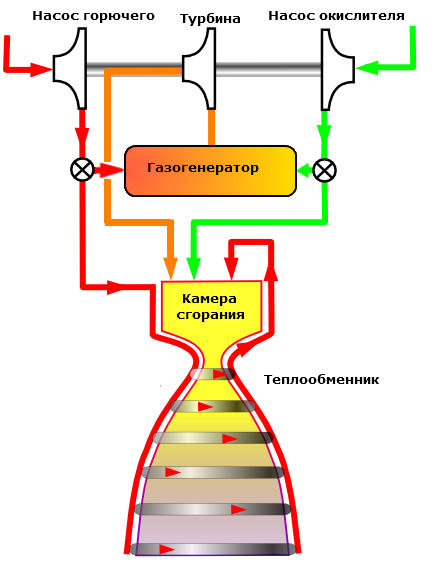

Closed scheme

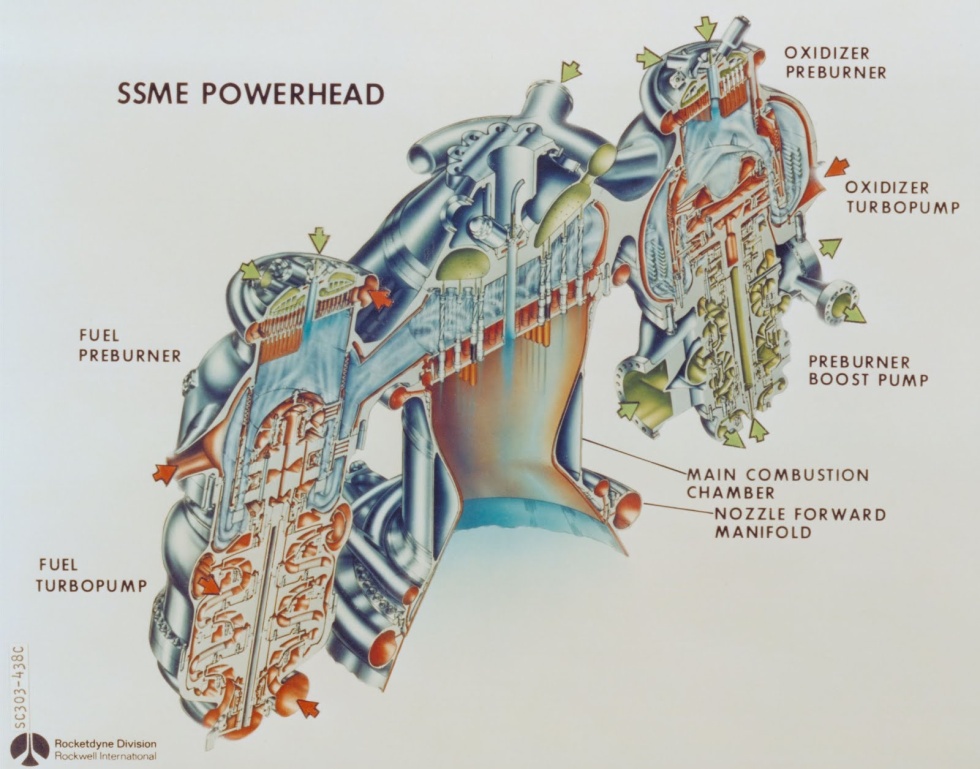

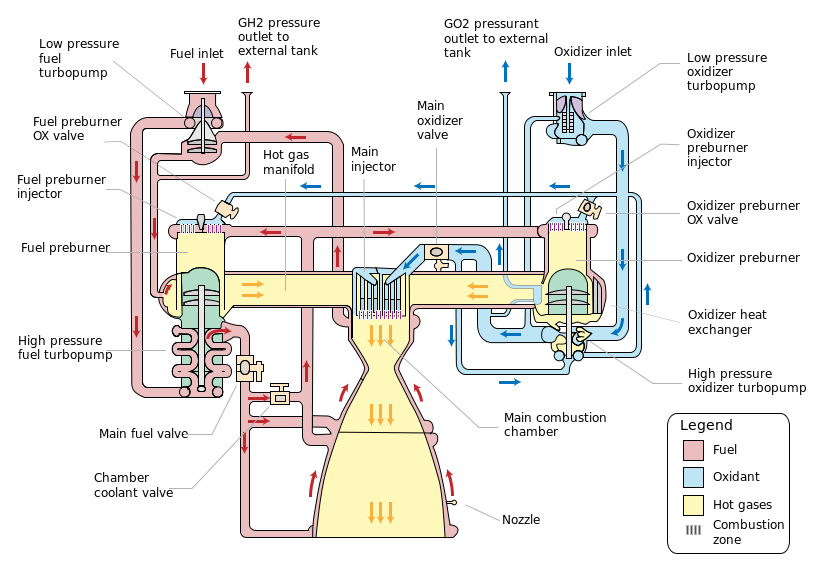

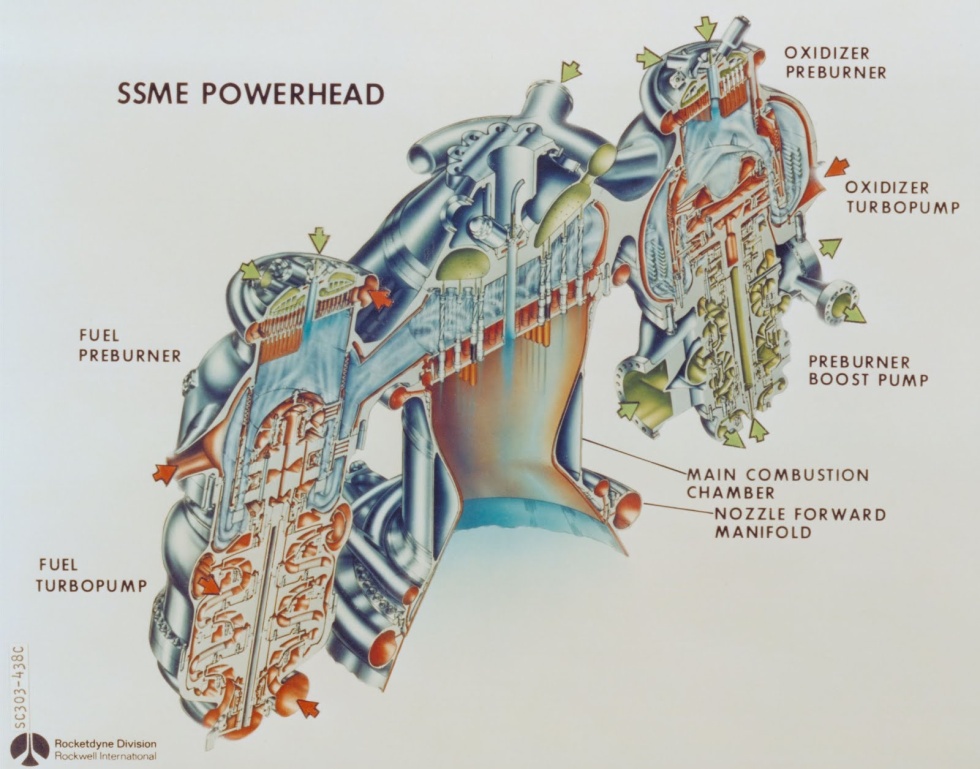

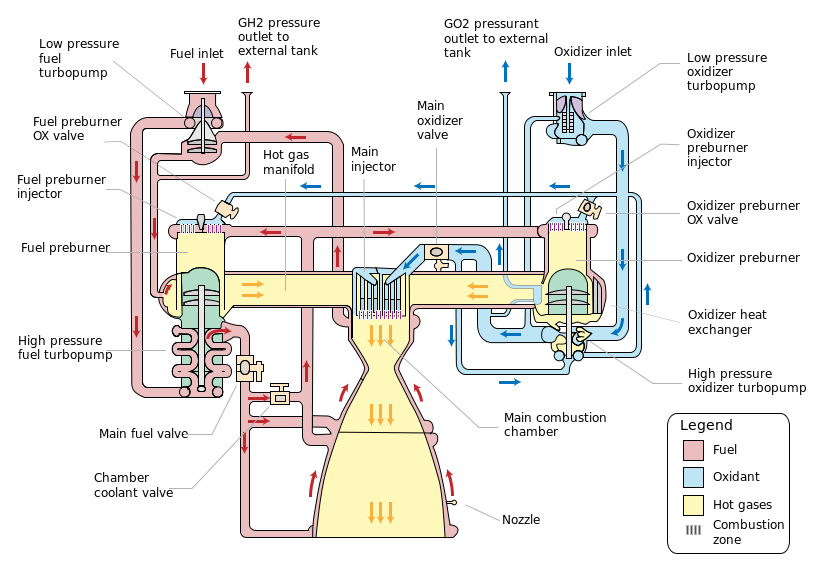

The logical solution for increasing the UI of the engine was an attempt to direct the exhaust of the gas generator to the combustion chamber so that it burned out in the best conditions to create thrust. This task turned out to be quite difficult - there is a very high pressure in the combustion chamber, additional questions arise about the stability of the engine, because one more feedback, “TNA-combustion chamber”, is added. The engines of the closed circuit were the first to start making the USSR - the NK-15 and the NK-33 were placed on a heavy H-1 rocket, the RD-253 working on the Proton. The USA took up this scheme rather late - the first propulsion engine of the closed US circuit was the SSME space shuttle engine, which, on the other hand, became the first closed cycle engine on an oxygen / hydrogen pair.

Admire the complexity of the engine

Advantages:

- The greatest UI.

Disadvantages:

- The most difficult and expensive scheme.

Phase transition scheme

An elegant “hack” of rocket engine physics - the need to cool the engine nozzle is used as an energy source for the operation of a turbopump unit. The scheme was invented for the engine RL-10 , which is already fifty years used in the upper stage "Centaurus".

Advantages:

- No weight loss on tha.

- The simplicity of the design.

- Reliability.

Disadvantages:

- Suitable only for a pair of oxygen-hydrogen.

- The pressure is lower than in the scheme with THA, therefore, the MD is lower.

Insides of tanks

Inside the tanks of the launch vehicle is also a lot of interesting things. The tanks are standing one above the other, so we need supply pipelines for the “upper” component, pressurization pipelines, and it may also be necessary to solve the problem of finding a number of fuel components with different temperatures. And then there is the problem of fuel fluctuations, which also need to be addressed.

Piping components

This is the fuel tank (lower) of the first stage of the Soyuz-2.1v launch vehicle. Pay attention to the large pipe with a corrugated shell. This is the oxidizer pipeline. Since the oxidizer is liquid oxygen, it is necessary to put thermal insulation so that the pipe does not intend to contain kerosene. Alas, all this requires additional weight.

And this is the Angara RN. Highlighted in yellow - a pipeline that performs the same function. Judging by the proportions, it is also an oxidizer pipeline (oxygen tanks are more kerosene for oxygen-kerosene pairs), but derived from the side to simplify and reduce the cost of production. On the one hand, it is not aesthetic, but the digital control system with the asymmetry of the rocket will cope.

Inter-tank compartment

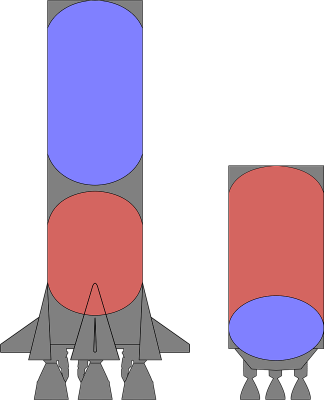

At the second and third stages of the Saturn-V rocket, a very beautiful solution was used - the oxygen and hydrogen tanks had a common wall:

On the left - the first step with inter-storage compartment, on the right - the second step with a common wall. Red - fuel, blue - oxidizer.

The difficulty was that liquid hydrogen and oxygen had a temperature difference of 70 degrees Celsius. Therefore, the wall consisted of two layers of aluminum with thermal insulation between them. This design has saved as much as 3.6 tons in the second stage. Curiously, the Space Shuttle fuel tank was in a sense a step backwards, it had a classic inter-tank compartment.

Supercharging pipelines

If you deployed the SSME scheme above, then you saw outlets of gasified hydrogen and oxygen there. They were used to boost the corresponding tanks. On the one hand, they saved weight on separate gas tanks of pressurization, on the other hand, they received an additional pipeline:

The same picture is large.

Damping walls

If you carefully looked at the pictures of the tank cuts, then you saw rings of different widths and crosses at the bottom of the shuttle tanks. These are special elements for damping fuel oscillations.

Crosses on the bottom of the fuel tank of the shuttle serve to prevent the formation of a funnel when emptying the tank. The fact is that the funnel can lead to the suction of the gaseous component of the fuel, which can cause problems in pipelines and engines.

Ring-shaped elements serve to dampen the oscillation of the fuel. Since it is liquid, overflowing the fuel to one wall during a maneuver can cause problems for the stabilization system. Partitions can be very large, as in the first stage of Saturn-I:

Or virtually absent, as in the third step of the Saturn-V:

The video is long, but I recommend to watch it - it is very interesting to see the behavior of liquid hydrogen during acceleration of the rocket and in zero gravity.

The general rule is as follows: the more maneuvers are expected from a step, the larger the size of the partitions will be. Here, for example, the Soviet bloc “E” is the third step of the LV “Vostok”. Here, the partitions are almost the full height of the tank, because the unit can maneuver very actively and cannot allow the fuel to splash:

And all this, alas, additional costs of the masses.

Tank emptying and synchronization system

Another problem to be solved. Firstly, the burning of each engine is something unique. There will definitely be a small variation of thrust and fuel consumption components. Even for one engine, it is necessary to install a special system so that the fuel and oxidizer end at the same time. And if we have several tanks or side steps, then we have to install a special system that will ensure the simultaneous termination of components in several steps. Now this system is also called a fuel consumption control system and consists of a set of level sensors and a digital computer, which, in addition to controlling a rocket, also solves this problem:

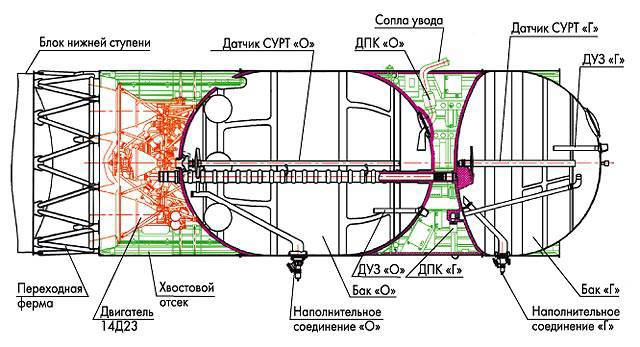

The third stage of the Soyuz launch vehicle. On the axis of the tanks are level sensors for SURT.

However, even despite the efforts of SURT, she herself has a limitation of accuracy, so some small proportion of the fuel is still lost. It is taken into account when refueling, adding to the so-called. "Guaranteed fuel supply".

Epilogue

I recommend to watch the series "Moon Machines" ( Russian version , English version ). Very well and visually shows the difficulties that have to be solved when designing space technology.

To navigate:

Source: https://habr.com/ru/post/215959/

All Articles